Abstract

Traditional artistic stone processing techniques offer vast possibilities for finishing stone products. However, stone processing is physically highly demanding work requiring stamina as well as skill. This makes products expensive to produce and the detailed design only accessible for skilled masons as an efficient communication between designers and masons is difficult. We introduce a robot-based approach to produce “artistic” surfaces for individualized stone products. First, distinctive traditional, manual processing techniques will be introduced and analyzed towards enabling us to specify the necessary requirements of an adaption to an industrial robot. These requirements are then implemented in an automated tool and an automated path planning algorithm. Building upon a visual programming environment we will present an accessible interface that allows the user to apply customizable stone structuring patterns to an individual stone product.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Stonemasonry is an old craft, which developed over centuries. It is characterised by a high number of different techniques, which make use of both tool geometry, as well as the tool’s handling. There are also a vast number of different stones with different heterogeneous behaviour: Not every technique is applicable for every stone. While some techniques are easy to produce, other techniques are demanding and require high manual skills and long training.

Thus the production of artistic stone surfaces with such techniques requires knowledge and talent. This restricts the accessibility of techniques for designers and architects—the sole possibility is the communication with a skilled mason. However, the number of techniques and their variability combined with the many different kinds of stones make it impossible to communicate the vision of one’s design idea in detail. This results in the re-application of traditional old patterns whereas new design strategies do not often find their way into architectural applications. As such, the main field of application for stone-structuring techniques is still the restoration of old buildings.

Another drawback is that most techniques are physically demanding, so that even a skilled mason needs a long time to produce large surfaces—making the application of stone structuring to building fronts very expensive.

While there exist some large specialised machines for stone structuring, they either rely on very simple, fixed chisel-strategies or simply aim to imitate traditional techniques with grinding tools. As such, they do not allow the user to go beyond traditional structuring strategies or to work with three-dimensional, curved, surfaces. Generic methods that can also be applied to stone structuring such as milling (Hayes et al. 2014), sawing (Garrido et al. 2009) and waterjet-cutting (Bortolussi et al. 2009; Ciccu and Bortolussi 2010) are being used in industry but are either very time consuming or do not closely emulate the finish of traditional stone structuring techniques. Current research in the field of architecture and design focuses mostly on cutting, rather than surface processing (Rippmann et al. 2013; Kaczynski et al. 2011). All these problems are addressed in a new robot based approach, where a robot-mounted tool performs the traditional techniques and then goes beyond the scope of manual processes (Fig. 1). The freedom of the robot allows variation in the technique parameters and results in huge design possibilities. Furthermore, a design interface is implemented which allows designers to model their ideas and carve them into stone as the special masonry knowledge is embedded within the code and thus not required of the user.

First we will describe the techniques, which have been analyzed. We will then describe the adaption of these techniques to the robot. The path planning which connects the design interface with real robot cell will be shown. In conclusion, we will give an overview to the design interface and show first examples of the design possibilities.

2 Defining a Stone Structuring Process

Robotic arms are highly multifunctional machines with a power and precision that—at least in combination—by far exceed the capabilities of human arms. However, in order to be able to program a particular robotic task, we have to be able to clearly define it.

This task definition is one of the main challenges towards applying robotic labour to stone surface structuring: The most common robotic applications are well defined and structured (e.g. pick-and-placing or spot-welding in the automotive industry), while some more complex processes such as milling can at least be quantified, measured, and evaluated based on static criteria such as the minimization of difference between the digital data and resulting physical output.

Stone surfacing is much less defined: Two stone masons utilizing the same technique and an identical tool can produce very different surfaces that are the result of small variations in force, angle, speed, and other parameters. These variations are then not defects, but rather make up the aesthetic appeal of traditionally structured stone surfaces. Previous research and literature reviews show that a direct translation of human movements to robotic movements is highly challenging even for tasks that are considered easy for humans. The precise timing and force control needed to exactly emulate a human mason was therefore considered to be beyond the scope of the research project. As such, the idea was that rather than trying to emulate human processes directly, we would attempt to create optimized robotic processes that incorporate traditional masonry strategies but augment them in the areas where a robot exceeds a stonemason, namely, in speed and accuracy. The first step towards implementing new movement strategies is to analyse existing, manual techniques and to evaluate them in regards to “compatibility” with robotic processes.

3 Analysis of Traditional Techniques

Due to the high number of different techniques, a first selection of popular strategies was made with the help of the masons of Bamberger Natursteinwerke, who later also supported the analysis of the different techniques. The selection was based on the dissemination of techniques and an estimation of their potential for automation. Tooling, aligned tooling, punching and bush hammering were selected as first experiments. When not considering the complete imitation of the mason’s movement, the most important aspects of the techniques are the chisel movement and the kinetic energy, which is applied to the chisel with the hammer. Both are analysed with the high speed camera system GOM Pontos HS (Fig. 2, left) capturing the manually-performed techniques with 20,000 fps. The videos can afterwards be analysed with the help of markers placed on the chisel and the hammer. Thus we can analyse the relevant movements in X and Y direction as well as the angle around the Z axis (Fig. 2, right). The energy was estimated by the speed of the hammer before impact and its weight. In the process of analysis we also analysed further aspects of automation such as predictability of results and necessary positioning precision (for detailed information on analysis, see Steinhagen et al. 2015). Similar methods have so far only been applied in the field of anthropology and archaeology to understand prehistoric tooling processes (Williams et al. 2010).

-

1.

Tooling This technique is very common for finishing traditional stone surfaces, creating highly characteristic rounded grooves. An example of a processed surface can be seen in Fig. 4. It is performed with a drove chisel and a mallet. An example of the movement can be seen in Fig. 3. While moving through the stone the chisel is rotating slightly. At the end of the movement it leaves the stone. This movement results in the characteristic appearance. The Energy was estimated to be 19.46 J. This energy can be applied with a robot mounted actor. Based on these first measurements we can say with a high confidence that the movement of the chisel is challenging but reproducible. Positioning accuracy and predictability of the results are manageable as well.

-

2.

Aligned Tooling Aligned tooling is a variation of tooling which main application can be found at the edges and corners of complex stone products where there is no space for performing the original tooling. The chisel does not leave the stone and moves linear into the stone, resulting in triangular, rather than rounded grooves (Fig. 5). The movement analysis exhibits only a small rotation of the chisel. Since smaller drove chisels are commonly used, the energy level is smaller than what we observed with normal tooling, while other values are mostly within the same range. Resulting from all this aspects we conclude that the automation of this technique should be even easier than normal tooling.

-

3.

Punching This technique is performed with a punch and a hammer. There are different variations of this technique: Either single punches are performed in point punching or concluding punches are performed to produce a linear pattern through in line punching (Fig. 4, center). However, especially the second one is difficult to automate since the predictability of the punches is low. For point-punching, the movement is relatively simple since it linearly punches into the stone with an estimated energy of 23.99 J.

-

4.

Bush Hammering This technique uses a hammer head with a number of tips and can be either performed with a special bush hammer or pneumatic tools. The hammer hits the surface but does not move deep into the stone, producing a shallow pattern on the surface (Fig. 4, right). This results in a movement that is relatively easy to perform and requires just 1.14 J, but only offers a limited degree of variability.

4 Design Parameters for Stone Structuring

Building upon the analysis of human stone masons using high-speed cameras a custom, a modular tool was developed that emulates the stone masons micro-movements and decouples its chisel from the robot itself, preventing backlash to the robot’s gear system. Therefore, the robot acts in the macro-scale as a high-speed, accurate spatial positioner while the modular tool interacts with the stone. This modular approach allowed us to pursue the time-constrained process development in two parallel tracks, while also facilitating future maintenance and trouble-shooting.

Based on the custom-developed stone-structuring tool (Fig. 6), we have identified a number of design parameters that can be adjusted to greatly influence the surface finish and process time. These have been grouped into three different layers, with the first one defining the general layout of the design and the second and third one fine-tuning the structure and depth of the processing.

-

Layer 1. Tool position and rotation in the material’s surface. The general tool position has got the most significant impact on the surface as it defines its overlaying structure, e.g. by following the isocurves of a surface, tracing lines, or being aligned according to the raster information of an image (see below). This positioning happens exclusively in the XY plane of flat material, or alternatively on the UV/mesh parametrization of curved surfaces.

-

Layer 2. Relative tool inclination. The tool’s inclination in relation to the stone-surface is performed around the chisel edge by the internal tool mechanism. Due to the optimized movement of the tool, following the predefined path rather than a straight line, the tool inclination has got a distinctive effect on the surface finish, allowing us to accurately fine-tune the width of each stroke. Figure 7 shows a range of possibilities the designer can use.

-

Layer 3. Hardware: Width and Force. The third strategy to influence the surface finish is through adjusting the hardware parameters, most notably the tool dimensions and the force with which the tooltip is applied to the stone. In particular, the tool-width has a significant impact on process time—however, while larger tools allow for quicker processing of structures, they are also more geometrically limited when not following the rulings of a surface.

For the initial experiments we have created a number of different strategies that utilize the three parameters previously described, depending on the design intent. These first structures are based on patterns, curves, raster images, or a combination of the above.

-

1.

Patterns. Manual stone structuring is based on regular patterns that are applied to a surface. As such, we have created a set of adjustable, regular patterns that can then also be perturbed through attractor points or other parameters. In Fig. 8, a sine curve adjusts the rotation both within the stone surface plane, as well as around the tool’s X axis, resulting in a 3D form which would not be possible with a manual process.

-

2.

Curves. Here the toolpath is provided as a list of curves that have to be chiseled into the stone. A significant challenge is the division of a curve into a number of linear segments with a fixed length (according to the used tooltip). To divide the curve according to different chisel sizes we assessed the chord, which connects the starting point on the surface with points on the curve. The length has to correspond to the chosen chisel length. This approach works in cases where the curvature is not too high, and there are no complex forms, small grooves or waveforms. Based on the chord middle the chisel position is then derived. If a long curve is divided in different chisel segments, the overlap of two chisel positions is a parameter, which can vary. Thus a curve can be build up from a number of chisel positions with a fixed chisel size. The inclination of the chisel is derived from the normal surface vector of this chisel position and the design inclination defined by the user.

-

3.

Raster Images. In previous research we have already explored the possibilities of using raster images for surface structuring. In the case of stone structuring, the brightness values of an image are sampled and then turned into toolpaths. Depending on the (processed) surface of each stone, the stone becomes then either brighter or darker where it is hit. In addition to locally adjusting the brightness, the orientation of the tool geometry can also be informed by the process, e.g. based on vectorized geometry.

5 Geometry and Representation

The representation of the developed strategies is a very important topic as it is crucial for allowing a new user to estimate the result of the programmed process. An ideal way to accurately represent the effect of the tool would be to perform Boolean operations for each hit. However, such a process would be extremely computationally expensive, and would thus interrupt the fluid design process. As an alternative, the most basic representation of the tool would be a line, representing its chisel edge. While this visualizes the effect of the first fabrication layer (see above) it would not show the effect of the tool’s inclination. We therefore implemented a geometric model that calculates the approximate shape of each chiseling movement based on the tool size, inclination, force and stone without having to “physically” intersect two geometries. Therefore, the geometric footprint and memory requirements are kept low, even for complex structures (Fig. 9).

However, significant challenges arise once doubly-curved surfaces are processed (or when the tool’s y-axis moves away from the straight rulings of the surface), both in regards to the physical process and the initial preview: The contact surface between the tool and the stone then covers only a part of the length of the tool, which can possibly chip either tool or stone. Depending on the stone that is being used, the user has to evaluate the effect based on the visual feedback provided by our software, and either takes the risk with soft stone, or use an automated process to optimize the tool’s orientation with the goal of lessening the irregular effect.

6 Programming Stone Structuring Design Patterns

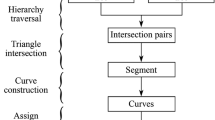

We expect that by solving the kinematic complexity and timing of a stone structuring process with an intelligent, modular tool, the robot can be used much more freely as a design tool with a comparably low stone-specific overhead. This macro-path planning is however still highly challenging, as no commercial solutions for the dynamic structuring of stone are available on the market. Initial virtual simulations of early stone-structuring approaches showed that the large-size of the structuring tool, along with the geometric constraints of traditional chiselling tools, can very quickly lead to unreachable positions, and singularities—thus requiring a capable, dynamic robot simulation environment where such processes can be reliably defined, simulated, and optimized. As such we decided to build upon the flexible KUKA|prc framework (Brell-Cokcan and Braumann 2010) and expanded it at the source code level with new simulation capabilities, improved interpolation algorithms, and multi-core optimizations to more efficiently optimize stone structuring processes. KUKA|prc itself builds upon the visual programming environment Grasshopper and expands the standard modules with a range of robot simulation and control components. As such it is ideal for the usage as a path planning tool for complex technical systems with an easy to use interface.

The path planning is divided in different steps. First, the user designs an idea as described above and receives feedback regarding the applicability of different chisel sizes to the curvature by color-coding each preview position. With this information the designer can decide when to apply a distinct chisel size to a surface point.

For non-planar surfaces, the whole path planning is performed on a scanned mesh representation of the stone. This is necessary because of high production deviations in the machining of stone products, where the tool is continuously ground down by the abrasive stone. These initial offline steps can be performed without a robot.

The first step where the robot is needed is the measuring of the initial stone position. We implemented a measurement system, which was developed in a previous research project (Müller et al. 2014). It is based on a laser triangulation sensor, which captures a number of points on the stone. The points are than matched with a point cloud of the stone and thus the stone is virtually placed in the robot’s simulated workspace.

The robot’s poses are then updated and checked for singularities and other conflicts such as reachability. Due to the geometries of stone processing, the only probable singularities in the process are poses where the fourth axis and sixth axis are aligned. These positions can be resolved if the inclination of the chisel is slightly changed for the corresponding movement instruction. This approach builds upon the new monitoring function of KUKA|prc which exposes much of the simulated robot data for analysis and optimization. For an iterative update of the chisel positions we then coupled the robot simulation with the plugin Hoopsnake. Thus the angle is automatically altered only as much as is absolutely necessary.

As a further step, we plan to implement a module that optimizes the sequence of the single chisel poses in regard to the process time, so that even complex stone products with a high number of chisel positions can be produced efficiently.

7 Conclusion

In this chapter, we have presented our work on the analysis of traditional stone processing techniques and their adaption to an industrial robot. By implementing this knowhow and strategies into the custom soft- and hardware, our research allows designers to be directly involved in the structuring of stone. Changeable parameters such as tool inclination and different design patterns can be adjusted or new stone products can be defined from scratch.

The automated path planning also enables the designer to focus on the design rather than on the intricacies of robotic path planning such as singularities.

Thus we have developed a competitive approach that will enable a broader user group to apply traditional stone processing techniques. Our further work will focus on the optimisation of the shown technique, the adaption of other techniques, and new robot control interfaces for dynamic processes (Braumann and Brell-Cokcan 2015). Furthermore, we will optimize the process speed by analysing and optimising the dynamic behaviour of the robot and tool.

References

Bortolussi, A, Foldyna, J, Ciccu, R, Scucka, J, Martinec, P and Sitek, L 2009, ‘Ornamental stone surface treatment by pulsating water jets’, Proceedings of the 9th Pacific Rim International Conference on Water Jetting technology, Koriyama-city.

Braumann, J and Brell-Cokcan, S 2015, ‘Adaptive Robot Control’, Proceedings of the 33rd eCAADe Conference, Vienna.

Brell-Cokcan, S and Braumann, J 2010, ‘A New Parametric Design Tool for Robot Milling’, in Life In:Formation—Proceedings of the 30th Annual Conference of the Association for Computer Aided Design in Architecture, New York, pp. 357–363.

Ciccu, R and Bortolussi, A 2010, ‘Stone Surface Finishing by Pulsed Waterjets’, Proceedings of the Global Stone Congress 2010, Alicanta.

Garrido, J, Martin, RM, Armesto, JI and Lopez, JS 2009, ‘Stone cutting automation technology based on features’, Proceedings of the 2009 IEEE International Conference on Mechatronics, Malaga.

Hayes, J, Fai, S, and While, P 2014, ‘Digitally-Assisted Stone Carving on Canada's Parliament Hill’, Proceedings of the 32nd eCAADe Conference, Newcastle upon Tyne, pp. 643–651.

Kaczynski, M, McGee, W and Pigram, D 2011, ‘Robotically Fabricated Thin-shell Vaulting: A method for the integration of multi-axis fabrication processes with algorithmic form-finding techniques’, ACADIA 11: Integration through Computation: Proceedings of the 31st Annual Conference of the Association for Computer Aided Design in Architecture, Banff, pp. 114–121.

Müller, M, Brüninghaus, J and Kuhlenkötter, B 2014, ‘Konzept zur vollautomatischen Bauteillagebestimmung von Freiformbauteilen zur Korrektur für die Roboterbearbeitung’ in Konferenzband Automation 2014, Baden-Baden.

Rippmann, M, Curry, J, Escobedo, D and Block, P 2013, ‘Optimising Stone- Cutting Strategies for Freeform Masonry Vaults’, Proceedings of the International Shell and Spatial Structures Symposium IASS, Wroclaw.

Steinhagen, G, Brüninghaus, J and Kuhlenkötter, B 2015, ‘Robotergestützte künstlerische Steinbearbeitung’, in Tagungsband Mechatronik 2015, Dortmund.

Williams, EM, Gordon, AD and Richmond, BG 2010, ‘Upper Limb Kinematics and the Role of the Wrist During Stone Tool Production’, American Journal of Physical Anthropology, 2010 Sep, vol. 143, no. 1, pp. 134–45.

Acknowledgments

The research leading to these results has received funding from the European Union Seventh Framework Programme (FP7/2007-2013) under grant agreement n°606453. SME consortium partner: Klero GmbH, Bamberger Natursteinwerk, G. Gibson & Co Ltd, II Architects. Research consortium partners: TU Dortmund University, Association for Robots in Architecture, Labor. Associate consortium partner: KUKA. Web: www.arosu.eu.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Steinhagen, G., Braumann, J., Brüninghaus, J., Neuhaus, M., Brell-Cokcan, S., Kuhlenkötter, B. (2016). Path Planning for Robotic Artistic Stone Surface Production. In: Reinhardt, D., Saunders, R., Burry, J. (eds) Robotic Fabrication in Architecture, Art and Design 2016. Springer, Cham. https://doi.org/10.1007/978-3-319-26378-6_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-26378-6_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-26376-2

Online ISBN: 978-3-319-26378-6

eBook Packages: EngineeringEngineering (R0)