Abstract

The enablers are recommended to improve the performance of Lean New Product Development (NPD) processes. This chapter presents an alternative to select enablers for improving the implementation of Lean NPD according to the difficulties of the company’s NPD process. Based on this literature review, a questionnaire was developed to identify the level of implementation for the Lean NPD enablers and the frequency of occurrence of each problem in the portfolio of NPD projects. The likelihood of the implementation of the Lean NPD enabler to decrease the frequency of NPD problems is represented by the correlation level between Lean NPD enablers and problems. The comprehension around this subject allows project managers to drive the NPD process improvement to lean culture, saving resources and maximizing the benefits of this effort.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Product Development

- NPDNew Product Development

- Multiple Alternative

- NPDNew Product Development Process

- Lean Implementation

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

3.1 Introduction

Lean product development (LPD) is the application of lean thinking, originally conceived for manufacturing processes, in New Product Development (NPD) processes. LPD departs from the customer’s perception of value to create new and profitable values streams within the organization, exploring synergies between processes, people, tools, and technology (Kennedy 2003; Slack 1999). Browning and Worth (2000) emphasize that the concept of LPD goes beyond the goal of waste elimination: it aims at maximizing the value added to customer, shareholders, employees, society, and suppliers. The concept of LPD has been given increasing practical significance by companies that have succeeded in improving their manufacturing processes, and find that product design is the new operations bottleneck (Reinertsen 2009). Besides the widely known lean principles, this implementation comprises the application of numerous interrelated enablers, such as the existence of chief engineer, employee empowerment, customer focus, early problem solving, minimal constraint and value stream mapping.

There are several ways to identify these enablers for NPD in the literature, such as practices (Khan et al. 2013), principles (Cooper and Edgett 2008) and critical success factors (Nepal et al. 2011). These enablers are recommended to improve the performance of Lean NPD processes. It might be complex for a practitioner to define a comprehensive approach to improve the NPD process for a specific organization. Moreover, the companies still have limited resources for implementing several Lean NPD enablers simultaneously in their NPD process. Therefore, this paper presents an alternative to select enablers for improving the implementation of Lean NPD according to the difficulties of the company’s NPD process.

This paper investigates which LPD enablers impact or influence the improvement of usual problems in companies’ NPD process. Based on the comprehension of such influence, it is possible to identify and select a set of LPD enablers that will allow the mitigation of NPD problems occurrence. The aforementioned association was determined and validated through a survey carried out with 64 Brazilian companies. First, we assessed the frequency of occurrence of product development problems in our sample of companies using an adapted version of the questionnaire proposed by Paula et al. (2012). Next, we assessed the implementation level of LPD enablers most frequent cited in literature. Correlations between LPD enablers and NPD problems from the two questionnaires were calculated and analyzed.

3.2 LPD Enablers

Several methods have been proposed to improve the traditional product development process (Clark and Wheelwright 2010; Eppinger 2002). Such methods, although providing some benefits to companies, do not seem sufficient to achieve the breakthrough improvements that characterize LPD (Letens et al. 2011; Liker and Morgan 2011; Morgan and Liker 2008). Khan (2012) states that research is still required in order to distinguish between the most critical enablers and those which can be substituted with other equivalents. Field research may also be required to determine whether or not these enablers have presence in industry.

Ballé and Ballé (2005) comment that any of the enablers, worthwhile as they may be, taken out of the system will not yield significant efficiency gains in the development process. Moreover, no integrated framework of the identified LPD enablers has been put forward in the surveyed literature, nor has a methodological guide been formulated to support the application of lean thinking on an engineering project (Dekkers et al. 2013; Reis et al. 2013; León and Farris 2011; Jayanth et al. 2010). Table 3.1 consolidates the frequency of appearance of LPD enablers in literature.

3.3 NPD Problems

The problems addressed by NPD literature form two groups. The first of these are concerned with development process effectiveness; the subsequent market success of the newly developed product (Hines et al. 2006). Specific problems within this group include lack of alignment of the product development strategy with the wider business strategic plan, unnecessary development activity, lack of understanding of customer requirements, and ultimately high new products failure rates (Graebsch 2005; Haque and Moore 2004; Bauch 2004).

The second group of problems is concerned with the efficiency of the development process itself. These include the lack of a formal or standardized process, ineffective control of high volume development environments, poor internal communications and lack of common focus (Reinertsen 2009; Oppenheim 2004). They also include an inability to improve or learn from mistakes, and ultimately poor project deadline achievement and fiscal control. As a consequence of this problem-solution focus, the LPD literature adopts as its major theme of study the identification of the best practices associated with alleviating these problems (Hoppmann et al. 2011; Kato 2005). Table 3.2 shows the appearance frequency of the main problems cited in NPD literature.

3.4 Method

The research method was divided into two stages: (i) questionnaire development and data collection; and (ii) correlating LPD enablers and NPD problems. All analyses were performed using SPSS® v.18 software.

Some criteria were used to select the companies and the respondents. First, the studied companies needed to be undergoing a lean implementation at both the shop floor and administrative areas. Second, the geographic location was restricted for companies placed in the South of Brazil, in order to reduce any effect of external environment (e.g. availability of skilled labor). The non-random selection of companies for surveys is a common approach in other studies (e.g. Saurin et al. 2010; Boyle et al. 2011).

Furthermore, a minimum 5-year experience in lean implementation and product or process development was required for all survey respondents. Such sample characteristics were similar to previous studies about lean, namely: (i) to limit the sample to a specific geographical location (Sanchez et al. 2011; Bhasin 2012) and; (ii) to emphasize experienced companies in lean implementation (Shah and Ward 2007). The questionnaires were sent and received by email during the first quarter of 2014.

Table 3.1 was used to develop questionnaire about LPD enablers. Enablers that appeared to be overlapping were merged, while others that combined multiple practices were divided (Table 3.3). A scale from 0 to 9 was used to assess the intensity of the adoption of the LPD enablers, in which 9 denotes full adoption and 0 the lack of adoption of each enabler.

A list of frequent product development problems proposed by Paula et al. (2012) was used to develop the questions about the NPD problems. The initial 52 typical product development problems were classified into categories of NPD problems that appeared in the NPD literature (Table 3.2). Six of those problems were merged with others as they overlap similar meanings. Table 3.4 presents the 44 NPD problems and 13 categories. The questionnaire asked the frequency at which each problem occurred at the company using a 6-point scale, from 1 (very rare) to 6 (very frequent). The procedure used to validate the questionnaire was the Cronbach’s alpha. Cronbach alpha was assessed to assure the internal consistency of the questionnaire. Values above 0.7 were considered enough to validate questionnaire’s internal consistency (Hair et al. 2006). The following step was to investigate the relationship between the LPD enablers and NPD problems. A Pearson’s correlation analysis was used, as it measures the relationship between two quantitative variables (Rencher 2002).

3.5 Results

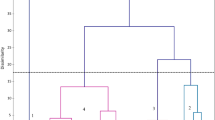

The internal consistency of the entire group of variables was very high, with a Cronbach’s alpha of 0.977 and 0.968, for the LPD enablers and problems, respectively. The correlation analysis between the 30 LPD enablers and the 44 NPD problems resulted in a matrix with i-enablers (i = 1, …, 30) and j-problems (j = 1, …, 44). Table 3.5 shows all correlations that are significant at 0.05 and 0.01 levels. From the 1320 possible correlations, 694 were considered significant and presented a negative correlation. The fact that there were no significant positive correlations is logical, as LPD enablers are expected to reduce the presence of problems. However, a few problems presented significant correlation with more than one enabler, which indicates that the problem occurrence would be significantly reduced if simultaneously applied such enablers. This finding provides companies an orientation with regards to the application of a proper set of enablers in order to mitigate NPD problem’s frequency. Moreover, the strongest correlations are also highlighted in Table 3.5.

Out of the thirty studied LPD enablers, two of them did not present a significant correlation with any of the listed NPD problems: LPD enablers 1 (Multiple alternatives) and 4 (Extensive simulation/prototyping). Although the literature suggests that the enabler “Multiple alternatives” is an important enabler in the LPD implementation, results show that it does not present a significant correlation with most cited NPD problems. Many authors from LPD literature (David and Goransson 2012; Khan 2012) proposed a strong relationship between NPD problems and the process of set-based concurrent engineering, which, among its main enablers, include the practice of exploring multiple alternatives. However, Kato (2005) and Gautam and Singh (2008) argue that stressing a wide variety of alternatives in a NPD process may lead to dubious consequences; i.e., if, on the one hand the discussion of multiple alternatives can bring innovative solutions, on the other, it may result in loss of focus on the customer and what he perceives as value. Thus, based on this study sample, this enabler is not significantly influential for problems frequency reduction.

Contrary to popular belief, the results show that enabler 4 “Extensive simulation/prototyping” does not have a significant impact on any of the NPD problems. This result is somewhat surprising in light of conventional wisdom about the difficulty of developing any new product without a minimum level of simulation or prototyping within the organization. However, this result is consistent with the findings of Oliver et al. (2004) and Matsui et al. (2007), who infer that the manufacture and testing of prototypes along a product development is extremely expensive and difficult. Moreover, few companies have an exclusive area for prototyping, which makes its manufacture occur in current production lines, affecting the productive capacity and even the condition of their machinery. Moreover, since one of the main objectives of LPD implementation is NPD lead time reduction, Schuh et al. (2008) and Oliver et al. (2004) state that, especially in technology business, longer times for simulation and prototyping may cause loss in the product time to market, which impacts its innovative aspect for consumers.

Overall, the sum of correlations for each LPD enabler and all NPD problems indicate that enablers 18 (Knowledge/information flow/cadence/pull), 28 (Lessons learnt reflection process), 30 (Separating research from development), 27 (Employee empowerment/individual responsibility) and 23 (Rapid learning/comprehension) are the ones that present the strongest impact for mitigating NPD problems and, therefore, the most indicated for companies that are struggling with their NPD processes. These results are aligned with the findings of Dal Forno et al. (2013) and Oppenheim (2011), who emphasize the importance of employee involvement practices and the process of reflection and learning from past activities. However, such result neglects the company’s context, whose maturity level for NPD process must be taken into account. Further, the occurrence of NPD problems must be properly considered, since they are the main input for decision on LPD enablers adoption.

3.6 Conclusion

This chapter showed an alternative to select enablers for improving the implementation of LPD according to the most cited NPD problems in literature. Among the 30 LPD enablers and the 44 NPD problems it was identified 694 significant negative correlations at 0.05 and 0.01 level. This finding provides the companies an orientation with regards to the application of the proper enablers in order to mitigate NPD problems’ frequency. The correlations indicated that some LPD enablers are associated to the frequency of many NPD problems. Therefore, the comprehension around this subject allows project managers to drive the NPD process improvement to lean culture, saving resources and maximizing the benefits of this effort.

Furthermore, the results of this study are intended to complement the usual recommendation and categorization of LPD enablers based on benchmarking of previous researches. Our findings indicate that the implementation of LPD enablers matters with regards to occurrence frequency of LDP problems, although not all enablers matter to same extent. Moreover, some results demonstrate that, although literature indicates a certain level of impact, the correlation between enablers and problems may present different impacts than the expected ones.

Each of the LPD enablers under study is associated with a significant lore about their impact on the occurrence frequency of LPD problems of companies undergoing a lean implementation. Overall, the evidence presented here suggests that the studied LPD enablers, presented in the literature as fundamental for a lean implementation, significantly affect the likelihood of LPD problems occurrence. In particular, the impact of four out of five enablers’ constructs appears to be the most substantial across the frequency of occurrence of LPD problems. The influence of the enabler construct “Set-based concurrent engineering for concept generation”, however, does not appear to be as significant for mitigating LPD problems occurrence as expected.

The results also indicate that there is not a fixed recipe for success since every organization starts with a different set of problems and constraints, which is supported by the findings of Singh et al. (2010) and Bhasin (2012). In general, the success of implementation of any particular management practice depends upon organizational characteristics, and not all organizations can or should implement the same set of enablers. The understanding of the company’s current context, specifically its NPD problems occurrence frequency, is fundamental for the appropriate adoption of LPD enablers. According to contingency arguments, organizations should use LPD enablers that are effective to their NPD problems. Therefore, the contingency approach assumes that it is the company’s context that, in the long run, determine the organizational responses in the lean implementation, whether it is on the shop floor or NPD process.

There are some limitations due to the nature of the sample used in the survey that must be highlighted. First, the respondents were mostly from companies located in the South of Brazil, their answers might be linked to regional issues, where the spread of lean may have come under local influences. Thus, as this limitation restricts the results to this geographic condition it also increases the certainty that the results apply to those companies. It is worth noting that companies of other countries may experience the same contextual conditions. Second, the sample size effectively confirmed only some relationships between the LPD enablers and NPD problems and it was not possible to reject all null hypotheses proposed. Those hypotheses that were not rejected may exist in a lower level. If that is the case, larger sample sizes can highlight those effects. Nevertheless, the exploratory nature of this research provided important evidences for developing more structured models that should be empirically tested.

Due to poor evidence in literature about the likelihood of any interdependent influence, further investigation would add more data and help to establish a holistic perspective about the problem and identify interactions among the LPD enablers and their influence over NPD problems. Such research opportunity would raise a more extensive and coherent analysis in order to really comprehend and specify the contexts in which problems are expected to occur.

References

Baines T, Lightfoot H, Williams GM, Greenough R (2006) State-of-the-art in lean design engineering: a literature review on white collar lean. Proc Inst Mech Eng Part B: J Eng Manuf 220(9):1539–1547

Ballé F, Ballé M (2005) Lean development. Bus Strategy Rev Autumn 16(3):17–22

Bauch C (2004) Lean product development: making waste transparent. Diploma Thesis at Technical University of Munich

Bhasin S (2012) Prominent obstacles to lean. Int J Prod Perform Manage 61(4):403–425

Boyle TA, Scherrer-Rathje M, Stuart I (2011) Learning to be lean: the influence of external information sources in lean improvements. J Manuf Technol Manage 22(5):587–603

Browning T, Worth F (2000) Value-based product development: refocusing lean. Eng Manage J 168–172

Clark K, Wheelwright S (2010) Managing new product and process development: text cases. Harvard Business School, New York

Cooper R, Edgett S (2008) Maximizing productivity in product innovation. Res Technol Manage 51(2):47–58

Cusumano M, Nobeoka K (1998) Thinking beyond lean: how multi-project management is transforming product development at Toyota and other companies. Free Press, New York

Dal Forno A, Forcellini F, Bornia A (2013) Desenvolvimento lean de produtos: uma análise da literatura. In: Proceedings of Workshop em Sistemas e Processos Industriais Santa Cruz do Sul

David A, Goransson M (2012) Lean product development: the bank of tomorrow? Master of Science Degree Project in Business and Economics at Lund University

Dekkers R, Chang C, Kreutzfeldt J (2013) The interface between “product design and engineering” and manufacturing: a review of the literature and empirical evidence. Int J Prod Econ 144:316–333

Eppinger S (2002) Patterns of product development interactions. In: Proceedings of the international conference on engineering design, pp 283–290

Gautam N, Singh N (2008) Lean product development: maximizing the customer perceived value through design change (redesign). Int J Prod Econ 114:313–332

Graebsch M (2005) Information and communication in lean product development. Diploma Thesis at Technical University of Munich

Hair JF, Tatham RL, Anderson RE, Black W (2006) Multivariate data analysis. Pearson Prentice Hall, Upper Saddle River

Haque B, Moore M (2004) Applying lean thinking to new product introduction. J Eng Des 15(1):1–31

Hines P, Francis M, Found P (2006) Towards lean product lifecycle management: a framework for new product development. J Manuf Technol Manage 17(7):866–887

Hoppmann J, Rebentisch E, Dombrowski U, Thimo Z (2011) A framework for organizing lean product development. Eng Manage J 23(1):3

Jayanth J, Das A, Nicolae M (2010) Looking beyond the obvious: unravelling the Toyota production system. Int J Prod Econ 128:280–291

Karlsson C, Ahlstrom P (1996) The difficult path to lean product development. J Prod Innov Manage 13:283–295

Kato J (2005) Development of a process for continuous creation of lean value in product development organizations. MIT, Cambridge

Kennedy M (2003) Product development for the lean enterprise: why Toyota’s system is four times more productive and how you can implement it. Oaklea Press, Richmond

Kennedy M, Harmon K, Minnock E (2008) Ready. set. dominate: implement Toyota’s set-based learning for developing products and nobody can catch you. Oaklea Press, Richmond

Khan M (2012) The construction of a model for lean product development. PhD Thesis at School of Applied Sciences Cranfield University

Khan M, Al-Ashaab A, Shehab E, Haque B, Ewers P, Sorli M, Sopelana A (2013) Towards lean product and process development. Int J Comput Integr Manuf 26(12):1105

León HCM, Farris JA (2011) Lean product development research: current state and future directions. Eng Manage J 23(1):29–51

Letens G, Farris JA, Van Aken EM (2011) A multilevel framework for lean product development system design. Eng Manage J 23(1):69–85

Liker JK, Morgan J (2011) Lean product development as a system: a case study of body and stamping development at Ford. Eng Manage J 23(1):16–28

Matsui Y, Filippini R, Kitanaka H, Sato O (2007) A comparative analysis of new product development by Italian and Japanese manufacturing companies: a case study. Int J Prod Econ 110:16–24

Meybodi M (2013) The links between lean manufacturing practices and concurrent engineering method of new product development: an empirical study. Benchmarking: An Int J 20(3):362–376

MIT (2001) Lean enterprise self-assessment tool: version 1.0. Lean Aerospace Initiative, Cambridge

Morgan J, Liker J (2008) The Toyota product development system. Productivity Press, New York

Nepal B, Yadav O, Solanki R (2011) Improving the NPD process by applying lean principles: a case study. Eng Manage J 23(1):52–68

Oehmen J, Rebentich E (2010) Waste in lean product development. Massachusetts Institute of Technology’s Lean Advancement Initiative July

Oliver N, Dostaler I, Dewberry E (2004) New product development benchmarks: the Japanese. North American an UK consumer electronics industries. The J High Technol Manage Res 15:249–265

Oppenheim BW (2004) Lean product development flow. Syst Eng 7(4):352–376

Oppenheim B (2011) Lean for systems engineering with lean enablers for systems engineering. Wiley, New Jersey

Paula I, Fogliatto F, Cristofari C (2012) Method for assessing the maturity of product development management: a proposal. Afr J Bus Manage 5(38):10285–10302

Pessoa M (2008) Weaving the waste net: a model to the product development system low performance drivers and its causes. LAI White Paper, Cambridge

Reinertsen D (2009) The Principles of product development flow: second generation lean product development. Celeritas Publishing, California

Reis Z, Costa C, Milan G, Eberle L (2013) Revisão da literatura sobre a implementação da filosofia lean no PDP. Revista Global Manager 1(1)

Rencher AC (2002) Methods of multivariate analysis, 2nd edn. Wiley Interscience, Canada

Sanchez J, Vijande M, Gutierrez J (2011) The effects of manufacturer’s organizational learning on distributor satisfaction loyalty in industrial markets. Ind Mark Manage 40(4):624–635

Saurin TA, Ribeiro JL, Marodin G (2010) Identification of research opportunities based on a survey on lean production implementation conducted in Brazilian and foreign companies. Gestão and Produção 17(4):829–841

Schuh G, Lenders M, Hieber S (2008) Lean Innovation: introducing value systems to product development. In: Proceedings of PICMET, Cape Town

Shah R, Ward P (2007) Defining and developing measures of lean production. J Oper Manage 25:785–805

Singh B, Garg S, Sharma S (2010) Development of index for measuring leanness. Measur Bus Excellence 14:46–59

Slack R (1999) The lean value principle in military aerospace product development. Lean Aerospace Initiative Massachusetts Institute of Technology

Sobek D, Liker J, Ward A (1998) Another look at how Toyota integrates product development. Harvard Bus Rev 76(4):36

Sobek D, Ward A, Liker J (1999) Toyota’s principles of set-based concurrent engineering. Sloan Manage Rev 40:67–84

Tsinnpoulos C, MacCarthy I (2002) New product development as a complex system of decision. In: Proceedings of the IEEE international engineering management conference

Wang L, Ming X, Kong F, Li D, Wang P (2012) Focus on implementation: a framework for lean product development. J Manuf Technol Manage 23(1):4–24

Ward A (2007) Lean product and process development. Lean Institute, USA

Ward A, Liker J, Cristiano J, Sobek D (1995) The second Toyota paradox: how delaying decisions can make better cars faster. MIT Sloan Management Review 15

Womack J, Jones D, Roos D (1991) The machine that changed the world: the story of lean production. Harper Perennial, New York

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Tortorella, G.L., de Castro Fettermann, D., Marodin, G.A., Fogliatto, F.S. (2015). Lean Product Development (LPD) Enablers for Product Development Process Improvement. In: Davim, J. (eds) Research Advances in Industrial Engineering. Management and Industrial Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-17825-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-319-17825-7_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-17824-0

Online ISBN: 978-3-319-17825-7

eBook Packages: EngineeringEngineering (R0)