Abstract

This chapter develops a mathematical programming model to optimize the operation of a hybrid energy system consisting of a hydrokinetic, photovoltaic, wind system, a battery bank, and diesel generator. The optimization approach is aimed at minimizing the cost function subject to the availability of renewable resources, total load energy requirements, as well as the diesel generator and the battery operational constraints. Furthermore, the mathematical models of all other components of hybrid, the proposed system, and the optimization control algorithm is also developed. The main purpose of the control algorithm proposed here is to minimize the use of the diesel generator in the electricity generation process, while maximizing the use of the hydrokinetic system and other available renewable energy sources. For simulation purpose, hourly water velocity, solar irradiation, wind data, and load demand data have been collected and used as an input data. The economic analysis has resulted in the calculation of optimized daily operation cost of the proposed hybrid system in summer and winter conditions. The obtained results represent also a helpful tool for energy planners and justify the consideration of hydrokinetic-based hybrid energy systems more seriously.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

For a sustainable and clean electricity production in isolated rural areas, renewable energies appear to be the most suitable and usable supply options [1]. Apart from all being renewable and sustainable, each of the renewable energy sources has its specific characteristics and advantages that make it well suited for specific applications and locations [2].

The solar photovoltaic (PV) and wind turbines are well established and are currently the mostly used renewable energy sources for electricity generation in small-scale rural applications. However, for areas where adequate water resource is available, micro-hydro is the best supply option compared to other renewable resources in terms of cost of energy produced [3]. Different from traditional hydropower technology, hydrokinetic (HKT) systems generate electricity by extracting kinetic energy of flowing water instead of potential energy of falling water. This makes HKT far less site specific and more competitive compared to traditional micro-hydropower [4].

It has to be noted that apart from being capital-cost intensive, the other main disadvantages of the HKT system as well as of other renewable energy technologies are their resource-dependent output powers and their strong reliance on weather and climatic conditions [5]. Therefore, they cannot continuously match the fluctuating load energy requirements each and every time. Standalone diesel generators (DG), on the other hand, have very low initial capital costs and can generate electricity on demand, but their operation and maintenance costs are very high, especially when they run at partial loads [6]. In order for the renewable sources to reliably respond to the load energy requirements, they can be combined in a hybrid energy system with backup DG and energy storage systems [7]. The most important feature of such hybrid system is to generate energy at any time by optimally using each available energy sources [6]. The fact that the renewable resources available at a given site are a function of the season of the year implies that the fraction of the energy provided to the load is not constant. This means that for hybrid systems comprising HKT, DG, and other renewable sources in their architecture , the renewable energy fraction and the energy storage capacity are projected to have a significant impact on the DG fuel consumption, depending on the interaction between the daily variation of renewable resources and the ones of load demand. A high renewable output power will be able to respond to the load requirements and/or charge the battery; this will result in less fuel consumption by the DG.

Several research works have been conducted on the subject of optimal operation control of hybrid renewable energy systems with DG [8–10]. Currently, few publications are available on standalone HKT systems; however, it is very rare to find research dealing with HKT systems combined with other renewable sources and DG. In [11], the author investigated the potential use of hydrokinetic-based hybrid systems for low cost and sustainable electrical energy supply. Different hybrid system configurations with PV, wind, and diesel generator are modeled and simulated using the Hybrid Optimization Model for Electric Renewable (HOMER) software. The simulation results from two different case studies show that hybrid systems with HKT modules incorporated in their architectures have lower net present costs as well as lower costs of energy compared to all other supply options where the HKT modules are not included.

The hybrid system considered in this study is composed of micro-HKT, PV, wind modules with backup DG, as well as a battery storage system. Unlike the abovementioned chapters, this chapter focuses on minimizing the operation cost of micro-HKT-based hybrid system during a 24-h period. The aim of this study is also to highlight the daily fluctuation of load demand and energy supply, as well as real operational challenges in standalone electricity generation. Considering a short time horizon, the operation costs of the battery and the renewable systems are negligible, therefore only the fuel cost of the DG is considered. The micro-HKT/PV/wind/DG/battery hybrid system operation costs are nonlinear, as they depend on the component size and type, the nonlinear load variations, the nonlinear resources fluctuations, and the dispatch strategy [12] .

The various optimization techniques available in literature such as probabilistic, iterative, and other classical approaches do not take into account the short-term or seasonal variation of the resources as well as the one of the load energy demand. The optimization model developed in this study takes into account the nonlinearity of the operation costs linked with the considered micro-HKT/PV/wind/DG/battery hybrid system, and this necessitates the use of nonlinear programming. Heuristic approaches such as the one used in this work are fast and more efficient than classical approaches in terms of their ability to solve complex nonlinear problems [13]. To get the best of this modern optimization approach, a detailed and accurate model describing the nonlinear hybrid system performance has been derived. Most of research works published previously have assumed a fixed load demand as well as same daily operational cost, which can be extrapolated to get any cost in the selected time horizon. Therefore, in this model, the power flow is considered taking into account more practical and realistic daily and seasonal fluctuation in the load energy demand in order to evaluate more accurately the corresponding fuel costs of the micro-HKT/PV/wind/DG/battery hybrid system.

The subsequent sections focus on the proposed hybrid system and the component models . The optimization model, which comprises the objective function, constraints, and other parameters, is presented, followed by the analysis of the simulation results, discussion, and conclusion.

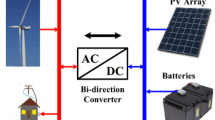

2 Hybrid Energy System Components

The power flow of the proposed hybrid system is shown in Fig. 27.1. The load demand (P L) is primarily met by the sum of the output power from renewable components , and the battery starts discharging within its operating limits as soon as the renewable powers do not meet the demand. If the sum of the renewable output power is above the load energy demand, the battery is charged. The DG is used only when the power from the renewable output and the battery cannot respond to the load energy requirements. The mathematical models of the system’s different components are presented in the following subsection:

2.1 Hydrokinetic System

HKT systems extract kinetic energy from moving water without the need for a dam, barrage, or penstock. The operation principle and the advantages of this power generation technology compared to other renewable options have been discussed in detail in reference [11].

The power output (P HKT) of the HKT system within a sampling time can be expressed as follows:

where ρ W is the density of water (1000 kg/m3), C p,H is the coefficient of the HKT turbine performance, η HKT is the combined efficiency of the HKT turbine and the generator, A HKT is the turbine area (m2), v W is the water current velocity (m/s), and f(t) is the water probability density function.

2.2 Wind Energy System

Wind energy systems convert the kinetic energy of moving air into mechanical and then electrical energy [14]. As for the HKT system, the power output (P WT) of the wind system within a sampling time can be expressed as follows:

Where ρ a is the air of water (1225 kg/m3), C p,W is the coefficient of the wind turbine performance, η WT is the combined efficiency of the wind turbine and the generator, A WT is the wind turbine area (m2), v a is the wind velocity (m/s), and f(t) is the wind probability density function.

2.3 Photovoltaic System

When light strikes a silicon, gallium arsenide, or cadmium sulphide cell, an electric current is generated through the PV effect [15] . The power rating of a PV panel is expressed in peak Watts (Wp) indicated at “standard test conditions” conducted at a temperature of 25 °C and irradiance of 1000 W/m2. The output power (P PV) of the solar PV system can be expressed as follows [16]:

where A PV is the total area of the PV generator (m2), η PV is the module efficiency, I is the hourly irradiance (kWh/m2), and f(t) is the radiance density function.

2.4 Diesel Generator

A DG is normally diesel engine coupled to generator. The DG is usually designed in such a way that it always operates between 80 and –100 % of its power rating (P GD) to achieve high efficiency [17]; this condition can be used later as an operation constraint. With this operation strategy as well as operation constraint, the DG is expected to run at high load factors, which will result in a decrease of the fuel consumption and increase of the DG life span [10].

2.5 Battery Storage System

The output power from the renewable components, and the load demand at given time t, determine whether the battery is charging or discharging. At any time, the battery state is associated to the previous state of charge and to the energy produced and consumed situation of the system during the time t 0–t. The battery dynamic equation can be expressed as follows [18]:

where SOC is the state of charge of the battery, η Bat is the battery charging or discharging efficiency, E nom is the battery system nominal energy, and P Bat is the power flowing from the battery system .

3 Optimization Model and Proposed Algorithm

3.1 Model Development

In the model developed in this work, the battery is charged by the renewable components only; this means that the DG is switched on only to supply the load. This configuration guarantees the optimum use of HKT, PV, and WT outputs, while no energy is wasted when the DG runs, since the total power produced matches the load demand. Therefore, the economical operation problem is to find the optimal scheduling of energy production at any given time that minimizes the DG fuel expenses, while totally responding to the load energy requirements within the system’s operating limits and constraints.

3.1.1 Objective Function

The objective is to minimize the fuel consumption cost from the DG during the operation time. This can be expressed as:

where N is the number of sampling intervals within the operation range or period of the system; a ,b, and c are the fuel cost coefficients; j is the jth sampling interval; P DG(j) is the output power from the DG at jth sampling interval, and Δt is the sampling time.

3.1.2 Constraints

The different constraints on the operation are as follows:

-

Power balance:

-

Variable limits:

-

Battery state of charge:

3.2 Proposed Algorithm

The objective function to minimize has been modeled as a nonlinear function of the DG output power. The nonlinear optimization problem can be solved using the “fmincon” function in Matrix Laboratory (MATLAB) [19]. This function solves problems in the form:

Where x, b, b eq, l b , and u b are vectors, A and A eq are matrices, c(x) and c eq (x) are functions that return vectors, and f(x) is a function that returns a scalar, f(x), c(x), and c eq (x) can be nonlinear functions.

4 Case Study

4.1 Resources and Load Data

A rural household is selected as case studies to analyze the behavior of the hybrid system. This system has to be optimally sized such that demand is always met at any given time. The hourly renewable resources as well as load demand for a 24-h period are shown in Table 27.1. These data are used as input to the energy optimization model developed in Sect. 27.3 above.

It has to be noted that these data have been collected for a day in September where the water resource is the lowest in the year. Therefore, the considered turbine is sized in such a way to give a rated power of 1 kW at 1.4 m/s water velocity. Thus, it is assumed that the produced HKT power remains constant for water velocities above 1.5 m/s.

4.2 Components Size and Model Parameters

The focus of the current study is principally on the optimal energy management of the hybrid system; therefore, the optimal sizing of the system components has been done using the HOMER. As a result, the combination of HKT (3 kW)/PV (1 kW)/WT (1 kW)/DG (1 kW)/13 batteries has been considered for simulation purposes of the developed optimal operation control algorithm. The battery as well as the DG parameters used in the simulation is shown in Table 27.2. The case where the DG alone is supplying the load is also considered for comparison purposes.

5 Simulation Results and Discussion

The objective function expressed in Eq. (27.6) means that the operation time (resulting in fuel consumption) of the DG needs to be minimized. Keeping that in mind, from the first constraint (27.7), the load has to be met first by the renewable resources as well as by the battery if the SOC is within the operating ranges; otherwise, the DG switches on to compensate the deficit in demand.

Figure 27.2 shows how the load demand as well as the maximum and optimum output power flow from the HKT, PV during the 24-h interval (winter case). Figure 27.3 shows the power balance between the load and the renewable resources; the DG output power, the battery power flow as well as the battery SOC during a 24-h period are also displayed. The following observation can be made after analyzing these two figures:

Daily DG, battery power flow, and battery SOC (winter case). SOC state of charge of the battery, P DG power rating of the diesel generator, P BAL (on Fig. 27.3) is the difference between the sums of the optimum renewable output power minus the load demand P L

-

From Fig. 27.2, it can be noticed that during the night and early morning the load demand is low; therefore, it is successfully met mainly by the HKT system; the wind and PV systems are not able to generate during these periods because of the lack of wind and solar resources. P BAL (on Fig. 27.3) is the difference between the sums of the optimum renewable output power minus the load demand P L. If P L is positive, the surplus of generated power can be used to charge the battery; if P L is negative, the shortage of energy can be brought in by using the battery (P B) first then the DG (P DG) within their operating limits. During the day, when the solar and wind resources are available, the load is met by the HKT, PV, WT, and battery bank.

-

The morning peak load demand occurs between 7 a.m. and 9 p.m.; therefore, the HKT, PV, and the battery are used at their maximum output to supply the load; the DG also switches on only to balance the energy needed and then switches off as soon as there is enough power from the other power sources. The DG operating time and output power depend on the load demand, battery SOC, and the amount of power from the renewable resources. It can be seen that the DG is not used to charge the battery but only to supply the load.

-

After the morning peak, the SOC of the battery is at its minimum operation limit (40 %); therefore, the renewable outputs produce more power than the load requirement. This surplus is used to charge the battery bank to an SOC of 95 % which is reached at the end of the afternoon as shown in Fig. 27.3, where the negative part of the battery power flow (P B) represents the charging process.

-

In the evening, gradually from 5 p.m., reaches the peak between 7 p.m. and 8 p.m., and then finally decreases at 9 p.m. Therefore, from 5 to 6 p.m., the HKT and PV are used at their maximum outputs in conjunction with a small contribution of the DG and the battery. After 6 p.m., the PV system can no more provide energy and the load demand is increasing; therefore, the contribution of the battery is maximal and the DG output power also increases to balance the energy needed by the load.

-

A poor WT output is noticeable in the afternoon and in the evening; this power is also used to supply the load and contributes to the battery charging power requirement.

The developed model can also be used to analyze the difference in power flow during summer and winter due to different climatic conditions and load requirements which have significant effects on the diesel dispatch strategy and fuel consumption. Using the date from Sect. 27.4 above, the simulation results reveal that the DG supplies more power in winter than in summer; this is due to lower PV and WT outputs, lower SOC of the battery, as well as higher load demand in winter than in summer.

The actual daily fuel expense for the selected DG can be found by multiplying the diesel price ($/L) by the amount of fuel used (L/day). It has to be highlighted that this daily fuel expense is highly dependent on the size and type of DG (fuel cost curve and fitting parameters from the manufacturer) used in the simulation.

Table 27.3 shows how much operation fuel can be saved by using the hybrid system instead of the selected DG in a winter or a summer day. These results demonstrate that it is very important to take into account the variations of the load and renewable energy resources with seasons when calculating the system’s daily operation cost.

6 Conclusion

A mathematical model to optimize the operation of a hybrid energy system consisting of a HKT, PV , wind system, a battery bank, and DG has been developed. This model aims to minimize the use of the diesel generator while maximizing the use of the available renewable energy sources. As already mentioned, this work considers the nonlinearity of the renewable resources, load demand, as well as diesel fuel consumption resulting in uniform daily operational costs. The hourly water velocity, solar irradiation, wind speed , load demand, as well as the diesel generator fuel consumption curve parameters data have been used as input data for simulation purposes. The simulation results show that by using the proposed hybrid system and taking into account the nonlinearity in daily and seasonal variations of the load demand, more accurate operation costs (fuel consumption) can be obtained.

The discrepancies in daily operations cost achieved highlight the potential of the proposed optimization model to reduce fuel consumptions for the hydrokinetic-based hybrid system compared to the diesel-only scenario. These results also demonstrate that it is very important to take into account the variations of the load and renewable energy resources with seasons when calculating the system’s daily operation cost.

References

Kusakana K, Vermaak HJ (2013) Hybrid renewable power systems for mobile telephony base station in developing countries. Renew Energy 51:419–425

Hepbasli A (2008) A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renew Sust Energy Rev 12(3):593–661

Paish O (2002) Small hydropower: technology and current status. Renew Sustain Energy Rev 6(6):537–556

Vermaak HJ, Kusakana K, Koko SP (2014) Status of micro-hydrokinetic river technology in rural applications: a review of literature. Renew Sustain Energy Rev 29:625–633

Chen F, Duic N, Alves LM, Carvalho MG (2007) Renewislands—renewable energy solutions for islands. Renew Sustain Energy Rev 11(8):1888–1902

Kusakana K, Vermaak HJ (2013) Hybrid diesel generator—battery systems for off-grid rural applications. IEEE international conference on industrial technology (ICIT 2013), 25–28 Feb 2013, Cape Town, pp 839–844

Gupta A (2010) Modeling of hybrid energy system. Ph. D. Thesis, alternate hydro energy centre Indian institute of technology Roorkee. Roorkee—247 667 (India) July, 2010

Bernal-Agustın JL, Dufo-Lopez R (2009) Simulation and optimization of stand-alone hybrid renewable energy systems. Renew Sustain Energy Rev 13:2111–2118

Bajpai P, Dash V (2012) Hybrid renewable energy systems for power generation in stand-alone applications: a review. Renew Sustain Energy Rev 16:2926–2939

Hu Y, Solana P (2013) Optimization of a hybrid diesel-wind generation plant with operational options. Renew Energy 51:364–372

Kusakana K, Vermaak HJ (2013) Hydrokinetic power generation for rural electricity supply: case of South Africa. Renew Energy 55:467–473

Kusakana K, Vermaak HJ (2013) Hybrid diesel generator/renewable energy system performance modeling. Renewable Energy 67:97–102

Koutroulis E, Kolokotsa D, Potirakis A, Kalaitzakis K (2006) Methodology for optimal sizing of stand-alone photovoltaic/wind generator systems using genetic algorithms. Solar Energy 80:1072–1088

Ghedamsi K, Aouzellag D (2010) Improvement of the performances for wind energy conversions systems. Int J Electric Power Energy Syst 32:936–945

Skoplaki E, Palyvos JA (2009) On the temperature dependence of photovoltaic module electrical performance. A review of efficiency/power correlations. Solar Energy 83:614–624

Singh GK (2013) Solar power generation by PV (photovoltaic) technology: a review. Energy 53:1–13

Dufo-Lopez R, Bernal-Agustın JL (2008) Influence of mathematical models in design of PV-Diesel systems. Energ Convers Manage 49:820–831

Sechilariu M, Wang BC, Locment F (2014) Supervision control for optimal energy cost management in DC microgrid: design and simulation. Electric Power Energy Syst 58:140–149

Kumar AS, Munda JL (2014) Optimisation of voltage and frequency regulation in an isolated wind-driven six-phase self-excited induction generator. J Energy Inst. http://dx.doi.org/10.1016/j.joei.2014.03.007 Accessed 9 July 2015

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Kusakana, K., Vermaak, H., Numbi, B. (2015). Optimal Operation Control of Hydrokineticbased Hybrid Systems. In: Sayigh, A. (eds) Renewable Energy in the Service of Mankind Vol I. Springer, Cham. https://doi.org/10.1007/978-3-319-17777-9_27

Download citation

DOI: https://doi.org/10.1007/978-3-319-17777-9_27

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-17776-2

Online ISBN: 978-3-319-17777-9

eBook Packages: EnergyEnergy (R0)