Abstract

In this chapter, selected low (T < 200 °C)-temperature wet-chemistry routes for the synthesis of crystalline inorganic compounds are described and reviewed, outlining their main features and application fields. In particular, the chosen approaches are hydro/solvothermal synthesis, template-assisted approaches, nucleation and growth in solution/suspension, microemulsion and miniemulsion. The described synthetic strategies have been selected since all of them, once optimized the experimental set-up and conditions, comply with the paradigms of green chemistry, being based on low (or even room) temperature of processing, on low chemical consumption (they are all bottom-up approach), in many cases having water as solvent or dispersing medium. In this regard, environmentally friendly methodologies for the controlled synthesis of inorganic nanostructures represent a stimulating research playground, since the use of environmentally friendly, green, cost-effective and technically sound approaches to inorganic crystalline nanostructures does not necessarily imply to sacrifice the sample crystallinity, purity, and monodispersity.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1.1 Introduction

The concepts of green chemistry are currently entailing all the fields of chemistry and particularly inorganic chemistry represents an exciting playground for the design and optimisation of green chemistry-inspired routes. Green chemistry, defined as “the utilization of a set of principles that reduces or eliminates the use or generation of hazardous substances in the design, manufacture, and application of chemical products” [ 1] is an already established and widened concept in the field of preparative chemistry, its extension to inorganic chemistry being one of the most bewitching developments. Environmentally friendly methodologies for the controlled synthesis of inorganic nanostructures are a noticeably stimulating research field since this encompasses not only the control of the final composition but also, and more importantly, a fine-tuning of the obtained materials in terms of crystallinity (crystalline phase, crystallite size), shape, morphology.

The control over size, shape, and morphology, combined with mild conditions of processing parameters (mainly in terms of temperature and pressure), are important conditions to be fulfilled for sustainable and cost-efficient production of functional inorganic materials. Further requirements to be met in order to chemically design and implement from the environmental, technical, and economical points of view sustainable synthesis routes are (1) reproducibility, (2) ease of processing, (3) use of safe, cost-effective, earth-abundant and common chemicals and solvents, (4) easy purification steps, and (5) high yields.

As pointed out by Wong, Mao et al. [2] in one excellent review on the topic, the use of environmentally friendly, green, cost-effective and technically sound approaches to inorganic crystalline nanostructures does not necessarily imply to sacrifice the sample crystallinity, purity, and monodispersity. Furthermore, the huge application potential of functional inorganic nanomaterials in many fields can be realized only provided that large quantities of materials can be prepared with high reproducibility in terms of composition, size, shape, morphology by applying sustainable and green procedures, involving (1) the lowest amount of toxic chemical and/or solvents, (2) low temperature and, last but not least, (3) easy-to-be-implemented and to-be-scaled-up safe procedures.

Several synthetic approaches to crystalline inorganic nanostructures, either metallic or binary (oxides, chalcogenides, halides) compounds, have been extensively described in some books and excellent reviews [3–7]. In particular, the books of Caruso [8] and Schmid [9] provide a comprehensive collection of the main synthetic approaches to colloids, colloids assemblies, and nanostructures, together with a thorough overview on their properties and applications. One of the mentioned reviews, the one by Dahl et al. [4] is particularly focused on “green approaches” to engineered nanomaterials, outlining the possibility to produce, in an environmentally friendly approach, ligand-functionalized inorganic nanoparticles. In this regard, the use of novel dispersing phases such as ionic liquid and supercritical fluids has also been reported.

In a further comprehensive review by Cushing et al. [3], the main advances in the liquid-based processing of inorganic materials, ranging from coprecipitation, to sol–gel process and Pechini method, to microemulsion to hydrothermal/solvothermal and from template synthesis to biomimetic-based routes have been extensively reviewed. Some of the above-mentioned approaches such as sol–gel or the Pechini method will, however, not be further discussed in this review, since they involve a final annealing step at high temperatures.

The present review chapter is instead devoted to provide a general overview, with no aim to be extensive and comprehensive, on the most important, technically relevant, and sustainable wet-chemistry routes to inorganic materials.

Wet-chemical routes are preferred to solid-state ones for preparing inorganic crystalline materials since the liquid phase is more versatile with respect to the variation of structural, compositional, and morphological features of the resulting compound materials. Furthermore, the molecular homogeneity of the starting solution or the microscopic homogeneity of the suspensions typically used in colloidal-based methods is generally retained in the final materials. At variance to that, an inherent limit of solid-state reactions is that there is no medium in which the reactants are dissolved, therefore severely limiting the interaction between components. The reaction can only take place either at the interface between the two solid precursors, or through migration of the reactants through a third phase; such processes are therefore usually relatively slow, can lead to nonhomogeneous final products and/or require high energies and/or intermediate milling steps. Also from the environmental point of view, solid-state syntheses present several drawbacks, such as long processing times and high energy consumption, determined by the high processing temperatures. The main advantage of these techniques is that they are relatively simple to implement and, once the protocol has been optimized, they proceed without significant intervention on part of the operator. Also, scaling-up of the protocols is generally quite straightforward [10].

In conclusion, within the framework of nanostructures synthesis, liquid-phase synthetic routes are instead generally considered a more promising alternative to the ceramic method and ball milling [11–13] (mechanosynthesis) method, as these latter are rather crude and energy-consuming approaches, whereas liquid-phase synthesis allow a finer and more direct control over the reaction pathways on a molecular level during the synthetic process itself. In this context, a first distinction among wet-chemistry approaches can be performed between surfactant-assisted and surfactant-free approaches, the latter being characterized in some cases by the presence of coordinating organic solvents [14], which may play also the role of stabilizing agents.

In this chapter, the underlying idea is to focus on low temperature-based routes, being in this particular context “low” intended as lower than 200 °C, since this further constraint not only fulfills one of the paradigms of green chemistry but also enables unusual crystallization pathways to be explored. The other focal point of this chapter is the obtainment of “crystalline” inorganic nanomaterials since, as already outlined in a previous work by Muñoz-Espí et al. [15], crystallinity is in many case conditio sine qua non for the achievement of particular functional properties. It is worth to mention, inter alia, luminescence as well as catalytic, electronic, and magnetic properties. Also Liz-Marzan with coauthors has extensively pointed out the role played by nanostructures shape, morphology, and possible anisotropy in dictating some relevant functional properties, typically optical ones [16–19].

To accomplish an ordered growth of the targeted nanostructures, which is a mandatory requirement to control also their structure and morphology at the upper (up to micrometers) length scales, is a fascinating and even challenging playground for the preparative inorganic chemist. In fact, the mastery of nanocrystal nucleation and growth represents a primary challenge in inorganic materials chemistry and the formation of an ordered array of atoms or molecules (i.e., the obtainment of a crystalline structure) is, as already outlined, in many cases a necessary requirement to afford enhanced functional properties [17]. Although the temperature can be set by the operator, to dictate the structural evolution of an inorganic systems toward the 3D long-range periodical order characterizing crystalline materials is not straightforward. To better understand the pathways leading to crystallization in order to properly orientate the structurally controlled formation of the materials, in situ as well as temperature- and time resolved studies are always required [20–22].

In this regard, the basic concept of achieving a fine control on the evolution of the resulting material over several length scales, up to final crystalline phase, is the file rouge of many recently implemented low-temperature routes to inorganic colloids. Several authors have thorough investigated the effect of the different experimental parameters in directing and ruling the growth of the obtained nanostructures [23].

This review chapter is aimed at providing a broad overview on the main features as well as on the pros and cons of the some selected routes for the low or even room temperature obtainment of targeted crystalline inorganic materials.

The chapter begins with the description of more classical wet-chemistry approaches to crystalline inorganic nanostructures, such as the hydrothermal one, and then review some of the most relevant colloidal-based approaches, with a special focus on those affording crystallization of the desired nanostructures in confined space, such as miniemulsion and microemulsion. The template-assisted synthesis of nanostructures is also concisely reviewed, as well as the classical colloidal methods based on the nucleation and growth of nanostructures from solutions/suspensions, typically in presence of stabilizing ligands [3]. Although some examples are provided, the detailed discussion of the application of the described routes to the synthesis of different types of inorganic materials is out of the scope of the present contributions, aimed instead at providing a comprehensive, though general, perspective. Nevertheless several bibliographic references are provided for interested readers.

As mentioned at the very beginning, being the topic of the chapter the low-temperature synthesis of inorganic nanosized materials, only those examples and routes involving the low-temperature solution- or suspension-based processing of materials will be reviewed and discussed. Moreover, due to the broadness of the topic, several references to tutorial textbooks are also provided thorough. Due to space constraints, some methods will only be shortly mentioned, and interested readers are referred to pertinent references. In particular, some less common, though very elegant, routes such as biomimetic approaches [24–28], sonochemical synthesis [4, 29–31] and the use of supercritical fluids [10, 32–34], though low temperature, are not discussed further.

1.2 Wet-Chemistry Approaches to Crystalline Inorganic Nanostructures

1.2.1 Hydrothermal and Solvothermal Synthesis

The term hydrothermal synthesis typically refers to synthesis based on an aqueous medium which are carried out at relatively high pressures and temperatures [2, 10, 21, 33–50], either above or under critical conditions. The analogous term “solvothermal” refers instead to the same typology of reactions carried out in solvents other than water. Being, however, the focus of this chapter on sustainable wet-chemistry routes, the former will be discussed in more detail.

Whereas the first hydrothermal synthesis protocols were developed to mimic the conditions in which crystals grow within the Earth crust [38, 44], more recently, this method has been applied to the synthesis of more complex systems, such as binary or ternary metal compounds, in nanosized crystalline form. As it can be appreciated by the figures below (Fig. 1.1), the interest towards hydrothermal synthesis for the production of inorganic nanostructures has exponentially and steadily increased in the last 20 years.

This general and versatile strategy has been widely implemented to the preparation of different classes of inorganic compounds, encompassing binary and ternary oxides, sulfides, nitrides, etc., as extensively reported elsewhere [21, 51]. In their review, Mao, Park et al. [2] describe the application of these methods to the synthesis of titania and titanate nanostructures.

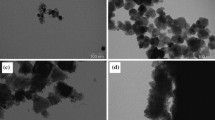

Several works have been published on many different compounds such as zinc oxide [52, 53], titania [54, 55], ceria [56], metal sulfides [57–60] as well as several more complex ternary oxide compounds [21] such as titanates [2], phosphates [61] and ferrites [11, 34, 43, 62–67]. As far as interesting class of ternary oxides, e.g., ferrites, are concerned, the literature reports several examples of hydro/solvothermal approaches to these functional inorganic materials. Most commonly synthesized ferrites are perovskite ferrites, with general formula MFeO3, and spinel ferrites with general formula MFe2O4. When the hydrothermal method is taken into consideration, the bismuth ferrite BiFeO3 is the most commonly synthesized perovskite. Low temperature hydrothermal routes (60–250 °C) have also been used for the synthesis of spinel ferrites (e.g., CoFe2O4, NiFe2O4, and ZnFe2O4) [65, 68–70]. Recently we have applied hydrothermal synthesis to the preparation of nanostructured crystalline spinel ferrites and manganites [67]. The synthesis is based on the successful combination of coprecipitation of metal oxalates from an aqueous solution with hydrothermal treatment of the resulting suspension at mild temperatures (i.e., < 180 °C). In this protocol, hydrothermal conditions, though sub-critical, were achieved through autogenous pressure (by heating the reaction mixture in a closed vessel); additionally the possible decomposition of oxalate species to carbon dioxide could also determine a further increase in pressure. This approach has been proven to be very attractive due to several factors: (1) excellent reproducibility, (2) ease of procedure and implementation (possibly scale-up), (3) nontoxic precursors, (4) mild temperatures, (5) the use of water as greenest solvent, (6) easy and quick purification of products (without the need for other solvents), (7) high yields, (8) high product purity, (9) and high versatility (numerous different compounds were synthesized through this method, since oxalates of many metals can be easily prepared). Hydrothermal synthesis of transition metal oxides such as W, Mo, V, Mn, Ti, Fe oxides under milder conditions (i.e., temperature < 200 °C) has been the topic of a contribution by Whittingham [40, 41], whereas more recently a paper focused on hydrothermal synthesis strategies for inorganic semiconductor nanostructures has appeared [51] In this latter review, the authors describe the most representative hydrothermal synthetic strategies of inorganic semiconducting nanostructures in particular evidencing four types of approaches: (1) organic additive- and template-free hydrothermal synthesis, (2) organic additive-assisted hydrothermal synthesis, (3) template-assisted hydrothermal synthesis, and (4) substrate-assisted hydrothermal synthesis. In addition, the two strategies based on exterior reaction environment adjustments, including microwave-assisted and magnetic field-assisted hydrothermal synthesis, are also reviewed.

All these hydrothermal-related synthetic protocols take advantage of the particular physical conditions involved whenever the starting solution or suspension is subjected to an increase of pressure and temperature, both parameters being either separately changed or interdependent. In fact, hydrothermal (and solvothermal) synthesis can be actually carried out by using special devices such as autoclaves, ensuring a separate control of temperature and pressure, or rather by using hermetically closed reactors in which the increase in the pressure (autogeneous pressure) is determined by the fact that the reaction suspension/solution is heated in a closed vessel. The temperature can be either under or at the critical point of the chosen solvents, both conditions, however, affording remarkable variations in the main physicochemical properties of the solvent. In fact, in general, ionic product of the solvent tends to increase with rising temperature and pressure, whereas viscosity decreases. In the case of water, the dielectric constant depends on both pressure and temperature as it is directly proportional with the former, but inversely proportional with the latter [10, 44]. All these variations strongly affect the kinetics of dissolution of the inorganic precursors and also of the nucleation and growth phenomena of the resulting materials, also disclosing unusual pathways for the crystallization of the targeted compounds.

In this regard, being the present chapter focussed on crystalline inorganic compounds, it is worth to devote some attention to the pathways leading to crystallization under (even subcritical) hydrothermal conditions. In this context, whenever nanocrystals form from an aqueous supersaturated solution, the precipitation process should occur slowly [71], in order to avoid the uncontrolled formation of amorphous solids. The nonstandard conditions in which hydrothermal synthesis takes place [2, 34–39, 43–45, 72–76], enables the solubilization of generally less soluble compounds which can, in these particular solvent-dependent conditions, be solvated more efficiently and therefore react more fastly and easily [37, 44]. Many different process mechanisms can be hypothesized, also depending on the specific synthetic protocol adopted. As outlined in one of our recent publication on the topic [67], in the most widely accepted theory [36, 37, 54, 66], the process involves two steps: (1) in situ transformation followed by (2) precipitation and growth. During the former phase the inorganic precursors are dissolved: therefore tiny amounts of the target oxide form as solvated species (owing to the conditions in which the process occurs); during the second phase, the low solubility of the aforementioned products causes them to nucleate and form crystals. Depending on the conditions involved (temperature, pressure, precursors, etc.) different products and/or crystalline polymorphs can nucleate and grow.

In general, hydrothermal synthesis is attractive, compared to more traditional synthesis protocols, due to the fact that crystalline products with high purity and compositional uniformity, as well as appreciable crystallinity, may be obtained under relatively mild conditions. Furthermore, since, as mentioned, changing the temperature and pressure of the reaction mixture induces relevant variations in the properties of the solvent [10, 36, 79], nonclassical crystallization pathways may be explored [80]. The environmental significant aspect of this class of synthesis is that hydrothermal and solvothermal routes allow inorganic materials to be prepared at substantially lower temperatures than those typically employed in solid-state reactions or also in many wet-chemistry routes such as the Pechini method or the sol–gel process, both involving a final annealing step at high temperature.

As reported in the cited as well as in further books and reviews [2, 10, 33–37, 39, 42–45, 47, 48, 50, 79–84] on the topic, solvo- and hydrothermal routes have been extensively applied to prepare a wide array of different inorganic compounds, many with also technological relevance such as ternary oxides. Recently, Walton [21] reviewed the mild solvothermal synthesis of metal perovskites and pyrochlores, by wisely outlining as solvothermal route is not a “processing step,” but rather a “genuine synthesis method,” allowing in most cases a one-pot and one-step formation of a highly crystalline form of the desired inorganic compounds. Furthermore, this approach enables, by using easy set-ups and recovery/purification steps, the synthesis of a wide plethora of inorganic materials in high yield and with reasonably short processing times.

Nevertheless, a challenging aspect of solvo/hydrothermal syntheses is that they occur in closed vessel, thus in many cases hindering the evolution of the system to be followed by spectroscopic, diffraction, or microscopy-related methods. Also the monitoring of the complex relationships among temperature, pressure, and the solvent chemicophysical properties (e.g., viscosity, dielectric constant), which have been extensively studied only for water [48, 85, 86] and which are relevant for the solubilization and recrystallization of the precursors, is in many cases prevented, or at least dramatically limited, by the reaction occurring in the “black-box” represented by the autoclave or by the reactor. In this context many efforts have been devoted to time- and temperature-resolved studies, always carried out at synchrotron facilities, thus exploiting the high spectral resolution and the shorter acquisition times (critical to follow the different steps of the reaction) enabled by the use of synchrotron light.

Recent and future developments in this field are to be mainly envisioned in the application of continuous flow reactors [87–92] as well as in the combination of hydrothermal synthesis with microwave heating [4, 43, 46, 62, 87, 93–96], affording formation of the targeted structures at relatively low temperatures.

1.2.2 Template-Assisted Synthesis Approaches

In the wide realm of low-temperature green synthesis approaches towards inorganic nanostructures, the use of structure directing agents such as templating agents and membranes, scaffolds, surfactants micelles, and ligands represents a powerful tool to direct the structural evolution of the targeted nanostructures [2, 27, 28, 97–116]. The resulting nanostructures display typically, depending on the morphology of the template, either 3D, 1D, or hollow morphologies. As outlined by Cushing et al. in their comprehensive review on the topic [3], a sharp distinction and classification can be hardly performed, since the general definition “template synthesis” encompasses a wide range of synthetic routes and methods which can be better described as hybrid approaches among further already discussed strategies (e.g., seeded growth in the presence of a ligand and colloidal-related methods).

The template-assisted synthesis is conceptually simple: the nucleation/growth of the targeted materials is let to occur either on or inside/within a suitable chosen or designed templating scaffold (typically displaying a completely different chemical nature and composition) dictating both the shape as well as the size of the forming material. In other words, the replication of one structure into another is accomplished under structural inversion. The scaffold can be either an assembly of monodispersed and shape-controlled nanostructures, a porous materials (the porosity being tuneable from the micro- (pore diameter d < 2 nm) to the mesoporous (2 < d < 50) scale, according to IUPAC definition [117]), or a membrane (for instance in the case nanotubes or nanorods are the targeted morphology).

The most acknowledged definition of a template is as “a structure-directing agent.” As reported by Thomas [100], in case of direct or “true” templating, the templated material is a 1:1 (but inverse) copy of the template structure, and no changes in order or length scale of the template structure occur. Templating can therefore be seen as an effective approach to the formation of nanostructured or porous materials, as size and shape of the resulting pore structures can be easily tuned by choosing the appropriate template structures.

A further rough distinction can be performed between soft templating and hard templating [100]. The former are typically soft materials, such as micelles, gels, nature-derived scaffolds (e.g., chitin), affording the formation of globular or spherical systems which serve as templates, which then yield 3D, typically spherical. On the contrary, in the case of hard templating, hard inorganic materials such as silica and alumina are employed as negative replica of the targeted materials. In both cases, the removal of the templating agent (in the former case by typically using thermal treatment to trigger the oxidative degradation of the organic material or by an extraction with suitable solvents, in the latter one by selectively dissolving the inorganic template with etching agents such as HF) affords the formation of a material displaying a morphology which is the replica of the templating scaffold. The material can be either grown on the template or within the template. The use of reactive templates, acting both as structure directing agents as well as precursors have been also reviewed in the literature [104].

As far as the use of hard templates for the shaping of soft materials is concerned, a relevant contribution in this field is the paper by Thomas, Goettmann, and Antonietti [100], reviewing the use of hard templates for soft materials, also outlining the related critical issues. This review describes the possibilities of using hard templates to create nanostructured “soft” materials, for example, polymer networks, or carbonaceous materials. The authors give first of all a classification based on the distinction between endo- (e.g., silica and colloidal crystals) and exotemplating (e.g., zeolites, periodic mesoporous silica, and alumina membranes) inorganic materials (see Scheme 1.1), and for each class of approaches they provide extensive examples concerning the whole range of hard templates described in the literature, such as silica nanoparticles, zeolites, periodic mesoporous silicas, aluminum oxide membranes, and colloidal crystals. These approaches are, however, mostly devoted to the synthesis of soft materials, though the review of Thomas reports also the use of porous materials and membrane as scaffold for the synthesis of inorganic materials.

Schematic presentation of templating approaches toward nanostructured soft materials using endo and exotemplates. Reprinted with permission from ref. [100]. Copyright 2008 American Chemical Society

In the last years, an increasing interest has been devoted to the use of well defined and shape-controlled, ideally monodisperse polymer particles (latex) to be used as soft templates for the synthesis of metal or metal oxide nanoparticles. The template can be either sacrificial, being removed (through calcination or etching agents) in the final step of the synthesis (and yielding in this case hollow spheres), or rather be the core of a core-shell nanostructure. Alternatively, also inorganic hard templates can be used for the controlled formation of inorganic hollow spheres, although these latter approaches typically require the etching of valuable inorganic cores such as Au or Ag. Very spread is also the use of porous structures [3] to afford the spatially controlled growth on nanostructures. Zeolites [72, 73, 118–123], mesoporous materials [120, 124–135] as well as metalorganic framework [136–144] can be conveniently used as 3D scaffolds and/or nanoreactors for the formation of metal, metal oxides, and further inorganic binary or even ternary compounds. The main application for this kind of inorganic nanocomposites (typically metal or metal oxide nanoparticles inside metal oxides templating matrices) is as supported catalysts [145, 146] in the field of heterogeneous catalysis, although some authors have envisioned also further fascinating potential uses of these nanocomposites, for instance as luminescent materials [147–150]. A further implementation is represented by inorganic scaffolds serving as templates for the growth of further inorganic hard materials. As it can be appreciated from the figure below (Fig. 1.2), the degree of control on the final structures and morphology is very high.

SEM images of a macro-/mesoporous silica template, its carbon nitride replica, and a titanium nitride replica derived therefrom. Reprinted with permission from ref. [100]. Copyright 2008 American Chemical Society

In this case, which could be also envisioned as a particular case of growth in confined spaces, the wall of the porous material acts as “seed” for the formation of the targeted structure. For instance, mesoporous alumina has proven to display suitable surface chemistry to promote the adsorption of ions from aqueous solution [151], whereas a further and related approach is the impregnation of these porous materials in solution of a salt of the targeted compound and subsequent chemical reduction to the metal species. By this route, several examples on M-SiO2 (M = Pt, Pd, Au) have been reported in the literature. As outlined in the review of Cushing et al., the aqueous nature of the reactions in which these processes occur somehow limits the number of metals (i.e., metals with negative standard electron potential are excluded) which can be produced by this approach [3].

As far as 1D nanostructures are concerned [100, 104], their ordered growth typically requires the presence of a tubular channel-based template. In this regard, a very widely used approach is based on the resort to inorganic membranes to template and direct the growth of anisotropic inorganic nanostructures. As reported in the review by Wong et al. [2], by using the cylindrical channels of membranes, different inorganic nanorods, nanowires, nanofibers, also displaying impressively ordered vertical assembly, have been prepared. From the sustainability point of view, as outlined by Wong, these template-assisted approaches are typically high-throughput, relatively simple, cost-effective, and requiring a low amount of reagents, the reactions typically occurring in aqueous media, and at low temperatures. The final step, implying the transformation of the precursors into the targeted compound is typically chemically triggered (i.e. a chemical reduction). Therefore, they can be generally considered environmentally friendly approaches. The use of the template method for the controlled synthesis of ordered array of inorganic functional materials, among which several ternary oxides (BiFeO3, Bi2Ti2O7, BaCrO4, BaWO4) as well as of metal fluorides such as CaF2, SrF2, BaF2 have been reviewed by several authors [2, 104]. In particular, an exhaustive overview of different kinds of inorganic 1D nanostructures, also chiral ones, grown inside the channels of inorganic oxides is reported by Qi [104], discussing also the complex topological and structural relationships existing among the templating matrix and the resulting materials, as well as the obtainment of complex architectures and superstructures.

Hollow particles [8, 98, 102, 152–158] have gained an increasing attention, also in the field of drug delivery and biomedicine, for their unique ability to serve as confined reaction cavities as well as delivery systems able to release encapsulated substances upon certain stimuli. As far as hollow structures are instead concerned, their formation is typically based on the oriented growth of the final material on a sacrificial templating scaffold. In this framework, different authors have reported the successful synthesis of hollow spheres by typically using soft templates, which are then eventually removed.

1.3 Colloidal and Colloid Assemblies for the Synthesis of Inorganic Nanostructures

By exploiting the bewitching and fascinating potentials of the colloidal state [160–173], it can be realized how colloidal methods are among the most appealing routes for the low temperature preparation of inorganic colloids, since the complex interplay among the different experimental parameters involved (chemical nature and chemico-physical properties of the surfactants, cosurfactants, dispersing media, and of dispersed phase) represents a versatile playground for the tailored growth of nanocrystals, enabling, in the above-mentioned mild conditions, a fine control on the very early stages of nanostructure formation (i.e., nucleation and growth).

As a matter of fact, the interplay among the different parameters involved (nature of dispersing and dispersed phase, chemical nature and structure of the surfactant(s), temperature, pH, power and time of sonication concentration of the reactants, the possible presence of electrolytes, water content, etc.) strongly affects the stability of the resulting colloidal dispersion, as well as size and polydispersity of the obtained nanostructures, and their role has been the topic of different reports and investigations [8, 15, 159–173]. The use of colloidal systems for crystallization processes in liquid phase has been recently reviewed by Rafael Muñoz-Espí et al. [15], but in the following section, we focus on the approaches involving a controlled nucleation and growth of crystalline colloidal nanostructures from solution/suspension and on the synthesis in confined space by exploiting the confinement dictated by the boundaries of droplets in suspension. Also, the crystallization of colloidal systems have been the focus of several investigations [15, 161, 166, 174–191].

1.3.1 Nucleation and Growth of Crystalline Colloidal Nanostructures from Solution/Suspension

This very wide class of approaches encompasses not only the experimentally optimized (1) nucleation and growth of inorganic nanocrystals in suspension (typically in the presence of stabilizing ligands) [192, 193], (2) the chemical reduction of metal salts to give different kinds of metal featuring very different morphologies (nanoparticles, nanoprisms, nanostars, etc.), and combination thereof, but also (3) the seeded growth in which small (<5 nm) nanoparticles act as seed for the epitaxial attachment of metal ions to give bigger nanostructures, thus turning a suspension of small nanoparticles into larger colloids.

Several further low temperature synthetic approaches are reported in the literature, which are based on colloids, colloid assemblies. A comprehensive overview is reported in some dedicated books [8, 9].

The nucleation of crystals from solution has been the topic of extensive investigations, from both the experimental and theoretical point of view. In this regard, classical and two-step models have been recently reviewed [80, 194]. In this paper by Erdemir it is pointed out as, in solution crystallization, the first event of nucleation plays a decisive role in determining the crystal structure and size distribution. The account further discusses the shortcomings and limitations of classical nucleation theory and review studies contributing to the development of the modern two-step model. This latter is based on the assumption that a sufficient-sized cluster of solute molecules forms first, followed by reorganization of that cluster into an ordered structure (Fig. 1.3).

Alternative pathways leading from solution to solid crystal: (a) supersaturated solution; (b) ordered subcritical cluster of solute molecules, proposed by classical nucleation theory; (c) liquid like cluster of solute molecules, dense precursor proposed by two-step nucleation theory; (d) ordered crystalline nuclei; (e) solid crystal. Reprinted with permission from Ref. [194]. Copyright 2008 American Chemical Society

The molecular mechanism of nucleation, the evolution from nuclei to seeds, and from seeds to nanocrystals, and the influence on it of thermodynamic and kinetic control, have been described also by Xia and other authors in a recent review [195] devoted to shape-controlled synthesis of metal nanocrystals, highlighting also the pivotal role played by structure, shape, and exposed facets of an inorganic nanocrystal in catalysis and optics. In a comprehensive and excellent paper, Polarz [196] discusses the morphology energy landscape leading to anisotropy of inorganic colloidal particles and points out the strong effects that shape and morphology have not only on the catalytic properties but also on the optical, electronic, mechanical, and self-assembly properties. Therefore, the tailoring of particle shape, size, morphology, and crystallinity becomes a condition to get the desired functionality and properties [104, 187, 189, 197–201].

As far as the nucleation and growth of metal colloidal nanostructures is concerned, some comprehensive reviews have been published dealing with the synthesis of nanosized metal and alloys nanoparticles from solution. Starting from the pioneering work of Faraday, dated back to 1857, the chemical reduction of transition metal salts in the presence of stabilizing agents to generate zerovalent metal colloids in aqueous or organic media is one of the most applied approach to the wet-chemistry low-temperature synthesis of these materials (S. Bradley, in: [202]). The first reproducible standard protocols for the preparation of metal colloids (e.g., gold by reduction of HAuCl4 with sodium citrate) were established by Turkevich [174, 203], but afterwards several further paramount contributions were reported [204]. Solution synthesis of metal nanoparticles and their applications have been reviewed by several authors [4, 8, 16, 49, 182, 205–213].

As far as this approach is concerned, reducing metal salts to the zerovalent metallic form is a widely used, effective, one-step and one-pot strategy to produce a wide plethora of metal nanostructure. This real bottom-up approach ensures limited use of reactants and thus complies with the atom economy paradigm of green chemistry. Typically used ligands are, according to the nature of the metal to be stabilized, thiol, amines, phosphines. For instance, gold nanoparticles are effectively stabilized by thiol ligands. Different thiol-stabilized noble metal nanoparticles (e.g., Au, Ag, Pt, Pd) have been extensively reviewed elsewhere [4, 17, 23, 207, 214–217]. The synthesis of metals through reduction from both aqueous and not aqueous solutions has been extensively reviewed by Cushing et al., also reporting a survey of metals (Fe, Co, Ni, Ru, Ag, Au) and metal alloys (CoxNiy, FexNi1−x) reduced from both typologies of solutions. The review by Cushing also reports a very detailed (though not updated, dating the review 2004) survey of several coordinating polymers and capping ligands for the stabilization of nucleated colloids, based on O-, C-, N-, P-, S- donor atoms [3].

In regard to the synthesis of inorganic oxidic nanostructures, the surfactants-free nucleation/growth of transparent suspensions of colloidal nanocrystals from a precursors solution is typically relying on the sol–gel reaction of suitable precursors (e.g., metal acetates and acetylacetonates) in the presence of a base. Among metal oxides, one of the most investigated ones is zinc oxide. ZnO is a very intensively studied material: and its properties, applications [218–220] and synthesis route have been extensively reviewed by several authors [52, 53, 182, 218–237], to which interested readers are referred. The classical route to ZnO nanocrystals explored by Bahnemann is based on the reaction of zinc acetate with NaOH in 2-propanol [192]. In this paper, Bahnemann and coworkers observed as the changes in the solvent nature could affect also the spectral features of the obtained colloids. In an analogous fashion, we have recently performed a thorough study and pointed out also the role that the chemicophysical properties of the dispersing medium, mainly its viscosity and dielectric constant, have on the structural and morphological evolution of the forming inorganic colloids, in our case nanosized zinc oxide [238]. In our case, by modifying and optimizing the well-known procedure reported by Spanhel et al. and Bahmemann et al. [192, 193, 221, 229, 239], we developed an easy and highly reproducible route to nanostructured colloidal ZnO nanoparticles based on the controlled hydrolysis and condensation of zinc acetylacetonate (acac) in alkaline conditions. It turned out that the four different tested dispersing media (water, glycol, 2-propanol, ethanol) proven to exert a strong influence not on the crystalline phase (in all cases wurtzite) but on the growth direction of the nanostructures and on their final shape and morphology (spherical or needle-like). In the case of metal oxides, effective moieties to strong bind the ligand to the hydroxylated surface of the oxides are carboxylates, cathecolates, phosphates [240–247].

Many further example of the application of these straightforward syntheses to other inorganic crystalline materials are reported in the literature. The same approach, based on a controlled precipitation, can be implemented to the synthesis of metal sulfides and further oxide colloids. A further approach relies on the reaction of suitably tailored molecular precursors, which spontaneously or under application of stimuli (e.g., heat) decomposes to give the targeted MxSy compounds.

As far as the seeded growth is instead concerned, it turns out that the use of structurally well defined seeds is critical to afford nanostructures with controlled morphologies and narrow size distribution. The co-presence, in the precursor suspension, of further structure directing agents such as surfactants can further contribute to achieve, for instance, anisotropic structures. By suitably optimizing the experimental conditions, the controlled, low or even room temperature crystallization of inorganic nanomaterials can be accomplished. In this regard, the review of Dahl also discusses in detail the role that seeds, reducing agent, additives and ligands (if present) have on the final morphology, structure, size, and size distribution of the resulting inorganic materials. The use of etching agents and methods enable in this context to access also exotic anisotropic nanostructures (such as nanoprisms), whose achievement is justified by enhanced functional properties, typically optical ones, anisotropic nanostructures are endowed with [248]. In fact, just to cite the most relevant ones, the optical properties of nanostructures are shown to be mainly influenced by the surface plasmon resonance of conduction electrons, the frequency of which is determined not only by the nature of the metal but also by a number of other parameters, such as particle size and shape, the presence of a capping shell on the particle surface, or the dielectric properties of the surrounding medium [16]. In this framework, Mulvaney, Alivisatos, Marzan, Pileni [16, 23, 179, 183, 201, 249–256] and further authors have also investigated the role that surfactants as well as ligands can play in orienting the anisotropic growth by, for instance, directing the epitaxial growth of one crystallographic phase at the same time hindering the growth of others. As far as the use of etching agents is concerned, their use allows modifying the growth mechanism within typical reduction-based approaches, affording the crystallization of colloids featuring unusual and exotic geometries. A very simple example in this regard is the adaptation of the classical reduction synthesis method for silver nanoparticles, typically obtained by reduction of silver nitrate in the presence of either citrate or sodium borohydride. If hydrogen peroxide and potassium bromide are added in tiny amounts to the starting solution, before the reducing agent is added, instead of the classical spherical shaped nanoparticles, the formation of silver nanoprims [210, 249] can be observed. In this case, the careful choice of suitable shape modifying agents affords the growth of the nanostructures in the desired morphology. Analogously, Murphy et al. successfully prepared silver nanowires by etching the metallic nanostructures with sodium hydroxide [257].

As far as other binary metal compounds are concerned, metal sulfides [5, 182, 258–262] are surely those attracting most interest, due to their exciting functional properties. One example of interesting colloidal approach to metal sulfides by exploiting the different experimental parameters of colloidal suspensions is the one we developed some years ago, addressing the synthesis of colloidal CuS nanostructures by taking advantage of the peculiar features, i.e. inherent viscosity and low dielectric constant, of the dispersing media, in this case carboxylic acids [263]. The crystalline hexagonal phase (covellite) of CuS is often described as a p-type semiconductor (energy gap 1.2–2.0 eV) [264–268] which shows superconductivity at 1.6 K. In our case, we design an original synthesis route base on promoting the controlled nucleation and growth on the CuS nanoparticles in a carboxylic acid. In detail, the optimized methodology was based on the fast nucleation of the sulfide triggered by the reaction of thioacetic acid (acting as a slowly releasing sulfide source) with water and copper carboxylates (acetate, propionate) in the corresponding carboxylic acid (acetic, propionic) as a solvent.

1.3.2 Miniemulsion and Microemulsion: Chemistry in Nanoreactors

This section is not intended to be comprehensive and cover the whole array of available colloidal emulsion-based methods, but rather to focus on selected methods allowing the spatially controlled formation and growth of colloidal nanostructures. Among these colloidal methods, those of microemulsion and the related miniemulsion approaches represent a very appealing option. Although the reviewed methods have been initially developed for polymer and hybrid systems, our attention will be exclusively focused on their implementation in the field of inorganic preparative chemistry. At the beginning the definition of microemulsion was quite contested [269], but presently a general accepted definition describes microemulsion as a dispersion made of water, oil, and surfactant(s), which is an isotropic and thermodynamically stable system with dispersed structure having a diameter typically ranging in the 1–100 nm range [167, 168, 270–272]. In this context, the role of the surfactant is to reduce the interfacial tension and stabilize the whole dispersion: its chemical nature, in particular in terms of hydrophilic-lipophilic balance (HLB) is one of the most important parameters in ruling the dispersion stability. HLB is an empirical value which numerically depends on the amount and nature of the hydrophilic/lipophilic chemical moieties present in the given surfactant chemical structure [273].

Though the many similarities and common features, at variance to that, miniemulsions are kinetically stabilized heterophase system with an average droplet size is in the range of 30–500 nm [15, 152, 169, 274–282]. This metastable state is represented by a critically stabilized system for which droplets collision and diffusional degradation processes are hindered. This means that, whereas upon mixing two microemulsions there is an immediate reagents exchange, when mixing two miniemulsions the droplets do not spontaneously exchange reactants, but rather require an external stimulus (i.e., ultrasound).

Both systems can be classified according to the nature of the prevailing phase as direct or inverse micro- or miniemulsion, the former being characterized by oil droplets dispersed in water as dispersing medium (oil-in-water (O/W) micro- or miniemulsions) the latter being instead characterized by water droplets in dispersed in the continuous organic phase (water-in-oil, W/O).

In miniemulsion, the diffusional degradation processes, leading to the Ostwald ripening phenomenon (larger droplets growing at the expense of smaller ones), is counteracted by adding a “co-stabilizer” or “osmotic pressure agent.” This additive is insoluble in the continuous phase and therefore generates an osmotic pressure between the droplets, which counterbalances the Laplace pressure (due to the curved interfaces and causing the diffusional degradation) and restricts the mass transfer. This co-stabilizer is usually a long-chain hydrocarbon (most commonly hexadecane) in the case of direct miniemulsions, whereas in the case of inverse miniemulsion is either a salt or a sugar.

Whereas microemulsions are typically spontaneously formed by mechanical stirring, miniemulsion does instead require high shear forces produced by high energy ultrasounds (on a lab scale) or high-pressure devices (for upscaled applications). These high shear forces induce constant fission and fusion processes between the droplets, leading to a strong decrease in droplets size and polydispersity, until a “steady state” is eventually reached (see Fig. 1.4) [152, 169, 275–278, 283].

Scheme for the formation of miniemulsion by ultrasounds. Reprinted with permission from ref. [276]. Copyright 2002 Elsevier

Although, as previously mentioned, they have been mostly used for the preparation of polymer or hybrid systems [274–276, 284–289], the fascinating concept underlying the extension of these two approaches to the inorganic synthesis is the use of the formed droplets to let the desired reaction to occur within the confined space dictated by the droplets boundaries. This “chemistry in a nanoreactor” has been successfully applied by several authors to accomplish the formation of crystalline inorganic nanostructures at low or even room temperatures [15, 152, 169, 173, 277, 278, 281, 282, 290]. In particular, if the inorganic nanoparticles and nanostructures are targeted, inverse W/O microemulsions are the most convenient systems to be used, since the involved reactions are typically occurring in aqueous medium and also because the solubility of inorganic precursors in water is typically higher than in organic solvents.

For both methods, the nanoreactor approach is a two steps one: two different micro- or miniemulsion are prepared: one containing a metal salt aqueous solution, the other one an aqueous solution containing a precipitating (e.g., a base and a sulfide source) or a reducing agent (e.g., sodium borohydride and a citrate). Upon miniemulsification, the shear forces imparted on the individual droplets of both precursors force them to undergo fission and fusion processes, leading to an immediate reaction between the precursors, typically a precipitation or a chemical reduction.

The described two-microemulsions/miniemulsions-based approach can be conveniently used to prepare binary metal compounds such as metal halogenides, sulfide and oxide. These latter represents the main class of compounds prepared through microemulsion systems, being the reaction of choice typically a precipitation of the targeted oxide by adding to the micro- or miniemulsion containing the metal oxide

Mini- and microemulsion can be also conveniently used for the preparation of hollow structures [154, 291], as well as of core-shell nanostructures [173, 292], either fully inorganic or hybrid organic–inorganic. The most common strategy to prepare hollow particles relies on the use of a sacrificial template, removed afterwards by thermolysis or dissolution [98, 153, 293]. An even more elegant approach to these inorganic nanocapsules is to promote the sol–gel processes at the liquid–liquid interface. This is possible through the so-called “soft-template” routes, involving the presence of surface-active agents [15].

Whereas for silica several examples are reported [291], for metal compounds such as metal oxides and chalcogenides, reports on the formation of hollow particles by soft-template methods are much more limited. Recently, Muñoz-Espí et al. successfully addressed the synthesis of transition metal oxides and hydroxides of group 4 (i.e., TiO2, ZrO2, and HfO2) by exploiting the sol–gel precipitation of zirconium and hafnium hydroxides (ZrO(OH)2 · H2O and HfO(OH)2 · H2O) at the droplet interface by creating interfacial species through the addition of triethylamine to water in- oil miniemulsions containing the inorganic precursor (zirconium or hafnium oxychloride). In this case, a mild thermal treatment of the samples was required to yield the corresponding metal oxide, ZrO2 or HfO2, being the method suitable also to prepare mixed metal oxides of defined composition, HfxZr1−xO2 [294]

The careful optimization of the surfactant self-assembly and concentration enables also a fine control over particle shape, which can be also tailored through the addition of different salts to the emulsion [295]. As outlined in Sect. 1.3.1, the most straightforward approach to metallic nanoparticles is the chemical reduction of corresponding metal salts. Such method can be easily implemented to micro- and miniemulsion systems, letting the reduction reaction to occur in the confined space of the droplets. As far as microemulsions are concerned, Pileni and coworkers have pioneered an interesting approach in which an anionic surfactant (typically Aerosol OT (AOT)), is used, whose counter ion is the metal of interest [296, 297]. They reported the successful synthesis of metallic copper [298, 299] and silver [300–302].

An alternative route relies on the incorporation and subsequent decomposition of single-source precursors such as metal complexes with 2-ethylhexanoates, acetylacetonates, or 1,5-cyclooctadienes into o/w microemulsion to promote the synthesis of metallic nanoparticles [303]. Microemulsions were also exploited for the preparation of substitutional alloys, such as FexPty alloys [304].

As far as the resort to inverse miniemulsion for the synthesis of metal or metal alloys is concerned, Landfester et al. [274, 290] used, as polar phase, low melting point metals (gallium, mp = 29 °C or sodium, mp = 98 °C) or alloys (Wood’s metal, mp = 70 °C or Rose’s metal, mp = 110 °C), which were heated above their melting temperature and miniemulsified in hydrophobic continuous phase by using amphiphilic block copolymers. By lowering again the temperature, solidification of the metal and formation of stable nanoparticles were accomplished.

For oxidic nanostructures, the sol–gel process is particularly convenient for the preparation of oxide materials, especially when aiming at porous materials, due to the high flexibility and tunability they allow (good control on stoichiometry of the final products). At the same time, micro- and miniemulsion ensure a finer and more controllable grain size [305, 306].

By the two miniemulsions-based route, different inorganic crystalline compounds were produced by precipitation in confined space, such as pure and doped ZnO [307, 308], M(OH)2 (M = Ca, Mg) [309], lanthanide-based phosphors [310], ZrO2/HfO2, CeO2 [311], TiO2 [312, 313]. The nanoreactor concept can be also conveniently exploited to afford the controlled decomposition of tailored single–source to yield crystalline nanocomposites, for instance through decomposition processes triggered by light. An example in this framework is reported by our group [314]. The gold-containing titanium peroxo-complex AuCl4(NH4)7[Ti2(O2)2(Hcit)(cit)]2 · 12H2O is a crystalline molecular single-source precursor of the composite Au/TiO2 [315]. Upon thermal treatment at 700 °C it decomposes to generate the crystalline composite; the decomposition can also be induced by UV irradiation. In the mentioned work, the single-source precursor was suspended in an inverse miniemulsion and subjected to photodecomposition. As expected by this pathway, a fine dispersion of crystalline gold nanoparticles dispersed on amorphous titania was obtained. The products were used as catalyst in the gaseous phase oxidation of 2-propanol, also comparing them with similar products obtained in bulk suspension. Interestingly, samples prepared in miniemulsion showed a strong increase in both conversion and selectivity.

All these examples have shown as, in the confined space produced inside the droplets, unconventional crystallization pathways can occur, leading to the crystallization already at room temperature. For instance, in the case of miniemulsion, Landfester and coworkers [15, 152, 169, 275, 277, 278, 283] have already pointed out interesting effects of the confined space on the fate and structural evolution of the contained inorganic systems. It was pointed out as physical properties of liquids in nanodroplets can be substantially different from those of the bulk phase and therefore the morphosynthetical control of the crystalline habitus of the formed structures was highlighted.

Also, the confined space can alter the fate of the chemical systems. As a working example, in the case of ZnO synthesis in inverse miniemulsion [307], the confinement of the precursor formulation in a the droplet was proven to be a key issue in determining the formation of wurtzite instead of the expected (in the adopted pH range) zinc hydroxide. In fact, in basic media (in our case the pH of the final miniemulsion was determined to be 13.4), ZnII ions form the amphoteric hydroxide species, ZnOx(OH)g(H2O)z in a colloidal state, which forms as amorphous or crystalline species. This species spontaneously evolves to crystalline wurtzite ZnO not only under the action of heating or irradiation, through a dehydration process, but also upon prolonged storing and aging in its mother liquor, which in this case was pursued by their confinement.

1.4 Conclusions

In this chapter, four of the most employed wet-chemistry and colloid-based routes affording the controlled crystallization of different inorganic nanostructures at low or even room temperature, have been reviewed and discussed. In particular, the focus of the contribution was on synthetic approaches based on mild conditions and/or low temperatures. In most of the presented examples, the crystallization of the inorganic nanostructures was pursued at low (T < 200 °C) or room temperature. Though not comprehensive, the chapter aimed at providing a broad overview on the potential and advantages of these low temperature approaches to controlled shaped inorganic nanostructures.

References

Anastas PT, Warner JC (2000) Green chemistry theory and practice. Oxford University Press, New York

Mao Y, Park T-J et al (2007) Environmentally friendly methodologies of nanostructure synthesis. Small 3(7):1122–1139

Cushing BL, Kolesnichenko VL et al (2004) Recent advances in the liquid-phase syntheses of inorganic nanoparticles. Chem Rev 104(9):3893–3946

Dahl JA, Maddux BLS et al (2007) Toward greener nanosynthesis. Chem Rev 107:2228–2269

Mitzi DB (2004) Solution-processed inorganic semiconductors. J Mater Chem 14(15):2355–2365

Mitzi DB (2009) Solution processing of inorganic materials. Wiley, Hoboken

Schubert U, Hüsing N et al (2008) Materials syntheses. Springer, Vienna

Caruso F (ed) (2004) Colloids and colloid assemblies—synthesis, modification, organization and utilization of colloid particles, 1st edn. Wiley-VCH, Weinheim

Schmid G (ed) (2004) Nanoparticles: from theory to application. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Schubert U, Hüsing N (2005) Synthesis of inorganic materials, 2nd edn. Wiley-VCH, Weinheim

Glaister RM, Allen NA et al (1965) Comparison of methods for preparing fine ferrite powders. Proc Brit Ceram Soc No 3:67–80

Sritharan T, Boey FYC et al (2007) Synthesis of complex ceramics by mechanochemical activation. J Mater Process Technol 192–193:255–258

Lazarevic ZZ, Jovalekic C et al (2012) Preparation and characterization of nano ferrites. Acta Phys Pol 121:682–686

Niederberger M, Pinna N (2009) Metal oxide nanoparticles in organic solvents—synthesis, formation assembly and applications. Springer, New York

Muñoz-Espí R, Mastai Y et al (2013) Colloidal systems for crystallization processes from liquid phase (invited highlight). CrystEngComm 15(12):2175–2191

Liz-Marzan LM (2006) Tailoring surface plasmons through the morphology and assembly of metal nanoparticles. Langmuir 22(1):32–41

Grzelczak M, Perez-Juste J et al (2008) Shape control in gold nanoparticle synthesis. Chem Soc Rev 37(9):1783–1791

Abalde-Cela S, Aldeanueva-Potel P et al (2010) Surface-enhanced Raman scattering biomedical applications of plasmonic colloidal particles. J R Soc Interface 7:S435–S450

Alvarez-Puebla RA, Liz-Marzan LM (2010) Environmental applications of plasmon assisted Raman scattering. Energy Environ Sci 3(8):1011–1017

Wang YX, Yun WB et al (2003) Achromatic Fresnel optics for wideband extreme-ultraviolet and X-ray imaging. Nature 424(6944):50–53

Modeshia DR, Walton RI (2010) Solvothermal synthesis of perovskites and pyrochlores: crystallisation of functional oxides under mild conditions. Chem Soc Rev 39(11):4303–4325

Sakdinawat A, Attwood D (2010) Nanoscale X-ray imaging. Nat Photon 4(12):840–848

Romo-Herrera JM, Alvarez-Puebla RA et al (2011) Controlled assembly of plasmonic colloidal nanoparticle clusters. Nanoscale 3(4):1304–1315

Calvert P, Rieke P (1996) Biomimetic mineralization in and on polymers. Chem Mater 8(8):1715–1727

Livage J, Sanchez C (2005) Towards a soft and biomimetic nanochemistry. Actual Chim 290–291:72–76

Sanchez C, Arribart H et al (2005) Biomimetism and bioinspiration as tools for the design of innovative materials and systems. Nat Mater 4:277–288

Andre R, Tahir MN et al (2012) Bioinspired synthesis of multifunctional inorganic and bio-organic hybrid materials. FEBS J 279:1737–1749

Ma T-Y, Yuan Z-Y (2012) Bioinspired approach to synthesizing hierarchical porous materials. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Lepoint T, Lepoint-Mullie F et al (1999) Single bubble sonochemistry. In: Crum LA, Mason TJ, Reisse JL, Suslick KS (eds) Sonochemistry and sonoluminescence. Kluwer, Dordrecht, Netherlands, pp 285–290

Kumar RV, Palchik O et al (2002) Sonochemical synthesis and characterization of Ag2S/PVA and CuS/PVA nanocomposite. Ultrason Sonochem 9(2):65–70

Wang H, Zhang J-R et al (2002) Preparation of copper monosulfide and nickel monosulfide nanoparticles by sonochemical method. Mater Lett 55(4):253–258

Cansell F, Chevalier B et al (1999) Supercritical fluid processing: a new route for materials synthesis. J Mater Chem 9:67–75

Aimable A, Muhr H et al (2009) Continuous hydrothermal synthesis of inorganic nanopowders in supercritical water: towards a better control of the process. Powder Technol 190:99–106

Hayashi H, Hakuta Y (2010) Hydrothermal synthesis of metal oxide nanoparticles in supercritical water. Materials 3:3794–3817

Kuznestov VA (1973) Hydrothermal method for the growth of crystals. Sov Phys Crystallogr 17(4):775–804

Labachev AN (1973) Crystallization processes under hydrothermal conditions. Consultants Bureau, New York

Francis RJ, O’Hare D (1998) The kinetics and mechanisms of the crystallisation of microporous materials J Chem Soc Dalton Trans 19:3133–3148

Rickard DT, Wickman FE (1981) Chemistry and geochemistry of solutions at high temperature and pressure. Pergamon, New York

Laudise RA (1987) Hydrothermal crystal growth—some recent results. In: Dryburgh PM, Cockayne B, Barraclough KG (eds) Advanced crystal growth. Prentice Hall, New York, pp 267–286

Whittingham MS, Guo J-D et al (1995) The hydrothermal synthesis of new oxide materials. Solid State Ion 75:257–268

Whittingham MS (1996) Hydrothermal synthesis of transition metal oxides under mild conditions. Curr Opin Solid State Mater Sci 1(2):227–232

Segal D (1997) Chemical synthesis of ceramic materials. J Mater Chem 7:1297–1305

Somiya S, Roy R (2000) Hydrothermal synthesis of fine oxide powders. Bull Mater Sci 23:453–460

Byrappa K, Yoshimura M (2001) Handbook of hydrothermal technology—a technology for crystal growth and materials processing. Noyes, Park Ridge

Feng S, Xu R (2001) New materials in hydrothermal synthesis. Acc Chem Res 34(3):239–247

Yu S-H (2001) Hydrothermal/solvothermal processing of advanced ceramic materials. J Ceram Soc Jpn 109:S65–S75 (Copyright (C) 2013 American Chemical Society (ACS). All Rights Reserved.)

Cundy CS, Cox PA (2005) The hydrothermal synthesis of zeolites: precursors, intermediates and reaction mechanism. Microporous Mesoporous Mater 82(1–2):1–78

Sheets WC, Mugnier E et al (2006) Hydrothermal synthesis of delafossite-type oxides. Chem Mater 18(1):7–20

Tavakoli A, Sohrabi M et al (2007) A review of methods for synthesis of nanostructured metals with emphasis on iron compounds. Chem Pap 61(3):151–170

Querejeta A, Varela A et al (2009) Hydrothermal synthesis: a suitable route to elaborate nanomanganites. Chem Mater 21(9):1898–1905

Shi W, Song S et al (2013) Hydrothermal synthetic strategies of inorganic semiconducting nanostructures. Chem Soc Rev 42(13):5714–5743

Ehrentraut D, Sato H et al (2006) Solvothermal growth of ZnO. Prog Cryst Growth Ch 52(4):280–335

Baruah S, Dutta J (2009) Hydrothermal growth of ZnO nanostructures. Sci Technol Adv Mater 10(1):013001

Chen X, Fan H et al (2005) Synthesis and crystallization behavior of lead titanate from oxide precursors by a hydrothermal route. J Cryst Growth 284:434–439

Liu N, Chen X et al (2014) A review on TiO2-based nanotubes synthesized via hydrothermal method: formation mechanism, structure modification, and photocatalytic applications. Catal Today 225:34–51

Mai H-X, Sun L-D et al (2005) Shape-selective synthesis and oxygen storage behavior of ceria nanopolyhedra, nanorods, and nanocubes. J Phys Chem B 109(51):24380–24385

Zhang J, Liu S et al (2011) A simple cation exchange approach to Bi-doped ZnS hollow spheres with enhanced UV and visible-light photocatalytic H2-production activity. J Mater Chem 21(38):14655–14662

Liu S, Lu X et al (2013) Preferential c-axis orientation of ultrathin SnS2 nanoplates on graphene as high-performance anode for Li-Ion batteries. ACS Appl Mater Interfaces 5(5):1588–1595

Zhang H, Wei B et al (2013) Cation exchange synthesis of ZnS-Ag2S microspheric composites with enhanced photocatalytic activity. Appl Surf Sci 270:133–138

Zhang Y-P, Liu W et al (2014) Morphology–structure diversity of ZnS nanostructures and their optical properties. Rare Metals 33(1):1–15

Weiß Ö, Ihlein G et al (2000) Synthesis of millimeter-sized perfect AlPO4-5 crystals. Micropor Mesopor Mater 35–36:617–620

Baruwati B, Nadagouda MN et al (2008) Bulk synthesis of monodisperse ferrite nanoparticles at water-organic interfaces under conventional and microwave hydrothermal treatment and their surface functionalization. J Phys Chem C 112:18399–18404

Lorentzou S, Zygogianni A et al (2009) Advanced synthesis of nanostructured materials for environmental applications. J Alloys Compd 483(1–2):302–305

Makovec D, Kodre A et al (2009) Structure of manganese zinc ferrite spinel nanoparticles prepared with co-precipitation in reversed microemulsions. J Nanopart Res 11:1145–1158

Goh SC, Chia CH et al (2010) Hydrothermal preparation of high saturation magnetization and coercivity cobalt ferrite nanocrystals without subsequent calcination. Mater Chem Phys 120(1):31–35

Diodati S (2013) Sintesi e caratterizzazione di ferriti nanostrutturate (Synthesis and characterisation of nanostructured ferrites). Ph.D. thesis, Scuola di Dottorato in Scienze Molecolari [Scienze Chimiche], University of Padova, Italy

Diodati S, Pandolfo L et al (2014) Green and low temperature synthesis of nanocrystalline transition metal ferrites by simple wet chemistry routes. Nano Res 7(7):1027–1042

Chen L, Shen Y et al (2009) Large-scale synthesis of uniform spinel ferrite nanoparticles from hydrothermal decomposition of trinuclear heterometallic oxo-centered acetate clusters. Mater Lett 63:1099–1101

Ma Z, Zhou B et al (2013) Crystalline mesoporous transition metal oxides: hard-templating synthesis and application in environmental catalysis. Front Environ Sci Eng 7(3):341–355

Gyergyek S, Drofenik M et al (2012) Oleic-acid-coated CoFe2O4 nanoparticles synthesized by co-precipitation and hydrothermal synthesis. Mater Chem Phys 133(1):515–522

Holden A, Singer P (1971) Crystals and crystal growing. Anchor Books Doubleday & Company Inc., Garden City, New York

Ferey G (2000) Building units design and scale chemistry. J Solid State Chem 152:37–48 (Copyright (C) 2013 American Chemical Society (ACS). All Rights Reserved.)

Ferey G (2000) The zeolites. Recherche: 72

Altmaier S, Behrens P (2003) Modification of ordered mesostructured materials during synthesis. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Lide DR (2004) Handbook of chemistry and physics, 84th edn. CRC Press, Boca Raton

Dolejš D, Manning CE (2010) Thermodynamic model for mineral solubility in aqueous fluids: theory, calibration and application to model fluid-flow systems. Geofluids 10(1–2):20–40

MacLaren I, Ponton CB (2000) A TEM and HREM study of particle formation during barium titanate synthesis in aqueous solution. J Eur Ceram Soc 20:1267–1275

Bacha E, Deniard P et al (2011) An inexpensive and efficient method for the synthesis of BTO and STO at temperatures lower than 200 °C. Thin Solid Films 519(17):5816–5819

Labachev AN (1971) Hydrodrothermal synthesis of crystals. Nauka, Moscow

Cölfen H, Antonietti M et al (2008) Mesocrystals and nonclassical crystallization. Wiley, New York

Cheng H, Ma J et al (1995) Hydrothermal preparation of uniform nanosize rutile and anatase particles. Chem Mater 7(4):663–671

Gopalakrishnan J (1995) Chimie Douce approaches to the synthesis of metastable oxide materials. Chem Mater 7(7):1265–1275

Mao Y, Banerjee S et al (2003) Hydrothermal synthesis of perovskite nanotubes. Chem Commun 3:408–409

Burda C, Chen X et al (2005) Chemistry and properties of nanocrystals of different shapes. Chem Rev 105(4):1025–1102

Antoine C (1888) Tensions des vapeurs; vouvelle relation entre les tensions et les températures. C R Acad Sci 107:681–684

Lide DR (2009) CRC handbook of chemistry and physics (Internet version), 89th edn. CRC Press/Taylor and Francis, Boca Raton

Rajamathi M, Seshadri R (2002) Oxide and chalcogenide nanoparticles from hydrothermal/solvothermal reactions. Curr Opin Solid State Mater Sci 6:337–345

Tighe CJ, Gruar RI et al (2012) Investigation of counter-current mixing in a continuous hydrothermal flow reactor. J Supercrit Fluids 62:165–172

Gimeno-Fabra M, Dunne P et al (2013) Continuous flow synthesis of tungsten oxide (WO3) nanoplates from tungsten (VI) ethoxide. Chem Eng J 226:22–29

Wang Q, Tang SVY et al (2013) Synthesis of ultrafine layered double hydroxide (LDHs) nanoplates using a continuous-flow hydrothermal reactor. Nanoscale 5(1):114–117

Makgwane PR, Ray SS (2014) Synthesis of nanomaterials by continuous-flow microfluidics: a review. J Nanosci Nanotechnol 14(2):1338–1363

Middelkoop V, Tighe CJ et al (2014) Imaging the continuous hydrothermal flow synthesis of nanoparticulate CeO2 at different supercritical water temperatures using in situ angle-dispersive diffraction. J Supercrit Fluids 87:118–128

Moreira ML, Mambrini GP et al (2008) Hydrothermal microwave: a new route to obtain photoluminescent crystalline BaTiO3 nanoparticles. Chem Mater 20(16):5381–5387

Bilecka I, Niederberger M (2010) Microwave chemistry for inorganic nanomaterials synthesis. Nanoscale 2:1358–1374

Pang J, Luan Y et al (2010) Microwave-assistant synthesis of inorganic particles from ionic liquid precursors. Colloids Surf A 360:6–12

Majcher A, Wiejak J et al (2013) A novel reactor for microwave hydrothermal scale-up nanopowder synthesis. Int J Chem Reactor Eng 11:361–368

Zhou Y (2005) Recent advances in ionic liquids for synthesis of inorganic nanomaterials. Curr Nanosci 1:35–42

Lou XW, Archer LA et al (2008) Hollow micro-/nanostructures: synthesis and applications. Adv Mater 20(21):3987–4019

Tanaka D, Kitagawa S (2008) Template effects in porous coordination polymers. Chem Mater 20(3):922–931

Thomas A, Goettmann F et al (2008) Hard templates for soft materials: creating nanostructured organic materials. Chem Mater 20(3):738–755

Yamauchi Y, Kuroda K (2008) Rational design of mesoporous metals and related nanomaterials by a soft-template approach. Chem Asian J 3(4):664–676

Zhang Q, Wang WS et al (2009) Self-templated synthesis of hollow nanostructures. Nano Today 4(6):494–507

Ethirajan A, Landfester K (2010) Functional hybrid materials with polymer nanoparticles as templates. Chem 16:9398–9412 (Copyright (C) 2014 American Chemical Society (ACS). All Rights Reserved.)

Qi L (2010) Colloidal chemical approaches to inorganic micro- and nanostructures with controlled morphologies and patterns. Coord Chem Rev 254:1054–1071

Ariga K, Ji QM et al (2012) Soft capsules, hard capsules, and hybrid capsules. Soft Mater 10(4):387–412

Deleuze H, Backov R (2012) Integrative chemistry routes toward advanced functional hierarchical foams. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Kimling MC, Caruso RA (2012) Templating of macroporous or swollen macrostructured polymers. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Petkovich ND, Stein A (2012) Colloidal crystal templating approaches to materials with hierarchical porosity. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Su B-L, Sanchez C et al (2012) Insights into hierarchically structured porous materials: from nanoscience to catalysis, separation, optics, energy, and life science. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Yan Q, Yu J et al (2012) Colloidal photonic crystals: fabrication and applications. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Zhang H (2012) Porous materials by templating of small liquid drops. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Liu YD, Goebl J et al (2013) Templated synthesis of nanostructured materials. Chem Soc Rev 42(7):2610–2653

Pal N, Bhaumik A (2013) Soft templating strategies for the synthesis of mesoporous materials: inorganic, organic-inorganic hybrid and purely organic solids. Adv Colloid Interface Sci 189–190:21–41

Petkovich ND, Stein A (2013) Controlling macro- and mesostructures with hierarchical porosity through combined hard and soft templating. Chem Soc Rev 42(9):3721–3739

Sanchez C, Boissiere C, Grosso D, Laberty C, Nicole L (2008) Design, synthesis, and properties of inorganic and hybrid thin films having periodically organized nanoporosity Chem Mater 20:682–737

Soler-Illia GJ, Sanchez C et al (2002) Chemical strategies to design textured materials: from microporous and mesoporous oxides to nanonetworks and hierarchical structures. Chem Rev 102:4093–4138

Rouquerol J, Avnir D et al (1994) Recommendations for the characterization of porous solids. Pure Appl Chem 66(8):1739–1758

Seo J, Sakamoto H et al (2010) Chemistry of porous coordination polymers having multimodal nanospace and their multimodal functionality. J Nanosci Nanotechnol 10(1):3–20

Xiao F-S, Meng X (2012) Zeolites with hierarchically porous structure: mesoporous zeolites. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Yokoi T, Tatsumi T (2012) Hierarchically porous materials in catalysis. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Zhang Y-H, Chen L-H et al (2012) Micro-macroporous structured zeolite. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Janiak C, Henninger SK (2013) Porous coordination polymers as novel sorption materials for heat transformation processes. Chimia 67:419–424

Moeller K, Bein T (2013) Mesoporosity—a new dimension for zeolites. Chem Soc Rev 42(9):3689–3707

Crepaldi EL, Soler-Illia GJAA et al (2002) Design of transition metal oxide mesoporous thin films. Stud Surf Sci Catal 141:235–242

Grosso D, Cagnol F et al (2003) Amorphous and crystalline mesoporous materials prepared via evaporation. Self-assembled nanostructured materials. Mat Res Soc Symp Proc 775:91–99, Lu Y, Brinker CJ, Antonietti M, Bai C (eds)

Soler-Illia GJAA, Crepaldi EL et al (2003) Block copolymer-templated mesoporous oxides. Curr Opin Colloid Interface Sci 8:109–126

Hüsing N, Schubert U (2004) Porous inorganic-organic hybrid materials. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Kickelbick G (2004) Hybrid inorganic-organic mesoporous materials. Angew Chem Int Ed 43:3102–3104

Grosso D, Boissiere C et al (2006) Preparation, treatment and characterisation of nanocrystalline mesoporous ordered layers. J Sol Gel Sci Technol 40:141–154

Eder F, Hüsing N (2009) Mesoporous silica layers with controllable porosity and pore size. Appl Surf Sci 256:S18–S21

Hoffmann F, Fröba M (2010) Silica-based mesoporous organic-inorganic hybrid materials. Wiley, New York

Keppeler M, Holzbock J et al (2011) Inorganic-organic hybrid materials through post-synthesis modification: impact of the treatment with azides on the mesopore structure. Beilstein J Nanotechnol 2:486–498

Shi YF, Wan Y et al (2011) Ordered mesoporous non-oxide materials. Chem Soc Rev 40(7):3854–3878

Nakanishi K (2012) Hierarchically structured porous materials: application to separation sciences. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Walcarius A (2013) Mesoporous materials and electrochemistry. Chem Soc Rev 42:4098–4140

Ferey G, Haouas M et al (2014) Nanoporous solids: how do they form? An in situ approach. Chem Mater 26(1):299–309

Ferey G (2007) Hybrid porous solids. Stud Surf Sci Catal 168:327–374

Ferey G (2007) Metal-organic frameworks. The young child of the porous solids family. Stud Surf Sci Catal 170A:66–86

Mu CZ, Xu F et al (2007) Application of functional metal-organic framework materials. Progr Chem 19(9):1345–1356

O'Keeffe M, Peskov MA et al (2008) The reticular chemistry structure resource (RCSR) database of, and symbols for, crystal nets. Acc Chem Res 41(12):1782–1789

Czaja AU, Trukhan N et al (2009) Industrial applications of metal-organic frameworks. Chem Soc Rev 38(5):1284–1293

Ferey G, Sanchez, C et al. (2010) Solid inorganic-organic polycarboxylate hybrid material based on titanium, its method of preparation and uses, Mater thesis, Université Pierre et Marie CURIE, Paris Vi, FR, pp. 42

McKinlay AC, Morris RE et al (2010) BioMOFs: metal-organic frameworks for biological and medical applications. Angew Chem Int Ed 49(36):6260–6266

Betard A, Fischer RA (2012) Metal-organic framework thin films: from fundamentals to applications. Chem Rev 112:1055–1083 (Washington, DC, U.S.)

Morey MS, O'Brien S et al (2000) Hydrothermal and postsynthesis surface modification of cubic, MCM-48, and ultralarge pore SBA-15 mesoporous silica with titanium. Chem Mater 12(4):898–911