Abstract

Reservoir rocks with the potential for storing CO2 are mainly sandstones. In them, four trapping mechanisms facilitate permanent and safe storage: (i) structural trapping below an impermeable caprock, (ii) immobilization via capillary forces in the pore space, (iii) dissolution of CO2 in the formation water, and (iv) mineral trapping via carbonization. Because leaks can occur monitoring of CO2 storage sites is essential. However, the technological risks appear to be manageable. This is emphasized by the experience from the first continental European field laboratory in Ketzin, Germany. The results show that: (i) the geological storage of CO2 is safe and reliable, and poses no danger to humans or the environment, (ii) a well-thought-out combination of different geochemical and geophysical monitoring methods can detect small amounts of CO2 and image its spatial distribution, (iii) the interactions between fluid and rock induced by CO2 injection at the pilot site in Ketzin have no significant impacts and do not influence the integrity of the reservoir or the caprock, and (iv) numerical simulations can depict the temporal and spatial behaviour of injected CO2. In addition, results from studies at Ketzin provide basic and transferable knowledge which is of value for a new integrated concept of CO2 mitigation and utilization in combination with the power-to-gas concept based on a closed carbon cycle approach.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- CO2 storage

- Leakage

- Trapping mechanisms

- Ketzin pilot site

- Field experiment

- Monitoring

- Modelling

- Power-to-gas-to-power concept

1 Introduction and Motivation

Carbon dioxide (CO2) storage research at the GFZ German Research Centre for Geosciences focuses on whether the long-term and safe storage of CO2 is possible in geological formations and whether this could help to mitigate greenhouse gas emissions into the atmosphere. Technologies for monitoring and predicting CO2 storage in porous rocks in the deeper subsurface are being tested and new technologies developed. Near the town of Ketzin/Havel in Brandenburg, the first continental European field laboratory for on-shore CO2 storage was set up as a pilot site in 2004, and active and continuous injection has been in operation from June 2008 until August 2013.

2 Processes of Retaining CO2 in Porous Reservoir Rocks

Suitable reservoir rocks are predominantly porous sedimentary rocks in the subsurface. The most important rocks for geological CO2 storage are sandstones with sufficient porosity and permeability, allowing the CO2 to be injected efficiently into these formations. CO2 is injected into the reservoir via wells with the aid of pumps that ensure injection pressure high enough to overcome the flow resistance in the rock, which depends on permeability and other rock properties but also on the flow resistance of the displaced formation fluid in case of saline aquifers.

Different physical and chemical processes ensure that the injected CO2 is retained in the reservoir rocks (Fig. 6.1). The relative importance and contribution of these different processes on the overall reservoir′s retention potential vary over a logarithmic time scale (IPCC 2005). On the shortest time scale of years, during injection and directly afterwards, the injected CO2 migrates upwards because it is less dense than the formation fluid initially contained in the geological formation. The CO2 accumulates and is physically concentrated below the impermeable caprock, which is usually clay or salt rock (Fig. 6.1).

Within decades, parts of the CO2 are retained by capillary forces (Figs. 6.1 and 6.2) if the pore necks have such a small diameter that the CO2 can no longer migrate upwards despite the density difference compared to the ambient formation fluid. The gas can then only be displaced by other fluids if they flow into the storage formation under elevated pressure.

Trapping mechanisms increase the safety of geological CO2 storage over time (After IPCC 2005. GFZ 2014)

Over a period of centuries, the major fraction of the CO2 dissolves in the formation fluid, and carbonic acid is formed. The binding of CO2 to the water remains stable as long as the pressure on the solution does not decrease and/or the temperature does not rise. This CO2-enriched water has a slightly higher density than the original formation fluid and tends to migrate downwards due to gravity (Fig. 6.1).

In the long term, on a time scale of some thousand years, the process of mineralization binds fractions of the carbon dioxide in the form of carbonates. Carbonization is the chemical neutralization reaction between the earth alkalines of the rock and the carbonic acid. Thus, mineralization of the CO2 leads to permanent trapping in the rock in the form of calcite, dolomite or siderite for example.

Overall, the four trapping mechanisms in the storage formation facilitate permanent and safe storage. Only the fraction of CO2 that exists as a free gas phase is driven upwards by buoyancy forces and could escape from the storage complex. The increasing effect of CO2 trapping over time via the four trapping mechanisms continuously reduces the fraction of the free gas phase in the storage formation (Fig. 6.2), which has been verified, for example, by studies of natural CO2 reservoirs. These studies show that around 18 % of the CO2 mineralizes over a long period of time, and that the major fraction of the CO2 is found dissolved in the formation water (Gilfillan et al. 2009).

3 Potential Leakage from CO2 Storage

Figure 6.3 shows the schematic principle of geological CO2 storage, as well as potential risks associated with the technology. The CO2 is injected into the storage formation underneath an impermeable caprock (Fig. 6.1). A multibarrier system above the storage complex, as shown in Fig. 6.3, comprises alternating layers of potential reservoir rock and caprock. The largest risk of leakage is location specific but in most cases probably posed by existing wells. Both active and abandoned wells are potential migration pathways because firstly they provide a direct connection between the surface of the Earth and the storage formation, and secondly they contain man-made materials (piping and cementing), which can corrode in the long term.

Considering a multibarrier system containing a large number of passive wells (old wells and observation wells), statistical methods can be applied together with an analytical solution in order to estimate the potential leakage rate (Nordbotten et al. 2004). The more barrier units that are present, the smaller the cumulative amount of CO2 that can migrate along corroded wells towards the Earth’s surface because major fractions of the leaking CO2 could be taken up by the formations lying above the storage complex if corrosion connected those layers as well. Calculations show that 10 % of the total amount stored would leak from the storage complex if one caprock layer was present, 1 % if two caprock layers were present (Fig. 6.3), and 0.1 % if three were present, etc. (Nordbotten et al. 2004). If there is only one well 100 m away from the injection well and if this is leaking, then between 0.1 and 0.2 % of the total amount stored in the aquifer is expected above this level (Ebigbo et al. 2007). The potential leakage rate essentially depends on the number of (leaking) wells in the vicinity of the storage facility. During the injection of CO2 into a depleted oil field in America (West Pearl Queen, New Mexico), the real leakage rate near the injection well was measured using tracers. These studies estimated a leakage rate of about 0.0085 % per year of the total CO2 injected (Wells et al. 2007). In this particular experiment, approx. 2,000 tCO2 were injected over a period of 2 months. In addition to direct measurements of CO2 at the surface and in the wells, seismic monitoring can also be used in order to detect CO2 migration and potential leakage at an early stage (Bohnhoff et al. 2010) and facilitate countermeasures. As discussed, leaking wells can occur and need to be observed, which makes monitoring of CO2 storage sites essential.

In addition to wells, potential natural leakage pathways exist. These are flow pathways along fractures and faults (Fig. 6.3). They may be present in the reservoir rock and caprock, as well as in the overlying rock layers, and are more complex than wells because they comprise non-uniform surfaces with variable permeability. Geological faults can be impermeable to fluids, but as natural CO2 seeps have shown, they can also be permeable to gases. One of the largest measured degassings at a natural CO2 source was in Italy, where an emission flux of 2,000 tCO2 per day was measured across an area of approx. 0.5 km2 (Chiodini et al. 2010). The degassing system in this case, however, is located in a mountainous region, and is thus characterized by a very different geological structure than potential CO2 storage sites. This region in Italy is tectonically highly active as evidenced by several earthquakes and thus not a prime target for CO2 storage. Many fracture and fault systems in sedimentary basins (e.g. North German basin), in contrast, are impermeable to fluids, as verified by the discovery of natural gas and crude oil fields millions of years old. If these systems were not predominantly impermeable, then no hydrocarbon deposits would be found in them.

In case of CO2 storage in saline aquifers, another effect that must be investigated in detail for every site is the displacement of saline water (Fig. 6.3). The CO2 injected into the reservoir rock displaces the saline water initially present in the pore space. It must be ensured that the saline water does not flow along migration pathways into the drinking water reservoirs of shallow aquifers, and contaminate the drinking water with so much salt that it would be unusable for the drinking water supply. This necessitates a comprehensive and thorough exploration of each potential site. Such data acquisition then provides the basis for precautionary safety analyses. A theoretical study showed that for undisturbed systems (no fractures or faults or other direct fluid flow conduits), there is no risk of saline water migrating upward into drinking water reservoirs despite pressure increases at a distance of tens of kilometres away from the injection zone of the geological storage formation (Birkholzer et al. 2009). Similar investigations of disturbed systems show a very low tendency towards possible salinization of near-surface aquifers even for highly permeable fault systems (Tillner et al. 2013).

A general evaluation of the suitability of sites in advance cannot be performed effectively. It is therefore essential that a comprehensive exploratory investigation will be performed. This investigation is site-specific, and is the most important and indeed the only possible method of evaluating risks in detail and deciding whether a site is suitable for geological CO2 storage in general. To answer the question if long-term and safe geological CO2 storage can be realized requires CO2 injection accompanied by extensive monitoring.

4 Safety of the Geological Storage of CO2

The most important question that has to be answered about CO2 storage technology is how safe it is for humans and the environment. In order to predict the safety of geological CO2 storage at the present time, two ‘analogues’ are taken into consideration. These are (i) naturally occurring CO2 reservoirs and/or sources and (ii) other sites where gas has been stored in porous rocks (Kühn 2011).

The underground geological storage of CO2 is not a human invention but rather a natural phenomenon. Numerous naturally occurring CO2 reservoirs have existed throughout the world for thousands or even millions of years, e.g. the Rhön region in Germany, the south of France, and Italy. These naturally occurring reservoirs prove that rocks can store CO2 for geologically long periods of time and that caprocks can efficiently retain the gas. If future CO2 storage facilities are chosen accordingly and investigated using state-of-the-art methods, then long-term storage of most of the CO2 will be possible. Naturally occurring reserves of CO2 help us to understand the conditions under which gas can be retained. In contrast, natural CO2 seeps show what consequences are to be expected when CO2 escapes. With their study of 286 natural CO2 sources in Italy, Roberts et al. demonstrate that an appropriate risk management in advance of industrial CO2 storage can minimize the health risk associated with the unintended leakage of CO2 (Roberts et al. 2011). The calculated risk of death in regions surrounding the natural seeps in Italy is 10−8 per year, which is much lower than other everyday risks to human life which are accepted by society. For example, the probability of being killed in a car crash is 1.8 · 10−4 or of being struck by lightning in America 2.3 · 10−5 (Roberts et al. 2011).

On the shorter technological time scale, experience in gas storage technology provides insights for the geological storage of CO2, such as on the diffusion behaviour of gases in porous rocks. The technology of storing large quantities of natural gas in deep underground rock formations to compensate for seasonal fluctuations in demand has proven its worth over decades in many places in the world. The storage volume of the 23 porous gas storage reservoirs in Germany is around 12.5 billion Nm3 natural gas (Sedlacek 2009). An example of successful and safe natural gas storage is the underground storage facility in Berlin, which has been in operation since 1992 at a depth of 800 m. This storage facility stretches underneath a protected natural area as well as directly underneath residential areas, sports grounds, and recreation areas.

These two analogues provide important information for the geological storage of CO2 and also demonstrate that it is possible to control the process technically and to operate it safely. They also confirm that large amounts of CO2 can be stored for long periods of time in reservoir rocks. Despite this, possible leakage pathways and the risks associated with the technology must be identified in order to ensure that geological CO2 storage will not pose any danger to humans or the environment.

Even if CO2 would escape to the Earth’s surface in spite of all of the safety measures, the dangers associated with it are relatively small compared to other gases (e.g. natural gas) because CO2 is non-toxic and neither combustible nor explosive. Depending on the framework conditions such as flow rate, topography, wind speed, and wind direction, fugitive CO2 mixes quickly with the ambient air and is diluted to a harmless level. However, it should be noted that continuously inhaling high concentrations of CO2 (TLV = threshold limit value = 5,000 ppm) poses a health hazard for humans.

An overview of findings from natural CO2 sources and observed leakages from gas storage sites helps us to estimate the hazard potential (Lewicki et al. 2007):

-

Carbon dioxide can accumulate in primary and secondary reservoir rocks underneath impermeable caprock layers but it can also permeate these layers under certain conditions and escape at the Earth’s surface.

-

Many natural releases are directly connected to an event (e.g. earthquakes).

-

Permeable fracture and fault systems can act as migration pathways for CO2, allowing the gas to escape at the Earth’s surface.

-

Wells with construction defects represent the main leakage pathways for CO2.

-

The way in which CO2 is released via leakage pathways and the amount released is always a site-specific phenomenon.

-

The hazard potential for humans is mostly small as the population affected has usually been informed and monitoring systems have been installed. Different naturally occurring events, however, have also led to fatalities, e.g. in residential blocks due to elevated concentrations of CO2 (Lewicki et al. 2007; Chiodini et al. 2010).

-

Changes in groundwater quality associated with the release of CO2 have also been observed, although the respective limits for drinking water were not exceeded in most cases.

As is the case for every technology, there is also a technological risk associated with the geological storage of CO2. However, this appears to be manageable (Roberts et al. 2011), particularly when modern monitoring systems are used.

5 Monitoring of CO2 Storage

In assessing the surveillance of CO2 injected into a geological formation for storage, it must be noted that this is a new technology still in the technical and scientific demonstration phase. Empirical values are currently only available for a few pilot sites. Furthermore, most of these sites are purely scientific projects with comparatively low amounts of injected CO2. Findings from CO2 storage projects on a commercial scale come from the Sleipner project (Norway), where more than 1 MtCO2 per year has been injected since 1996, the In Salah project (Algeria), where around 0.7 MtCO2 per year has been injected since 2004, the Snohvit project (Norway), where about 0.5 MtCO2 per year is injected, and the Weyburn Midale project (Canada), which has injected around 2.8 MtCO2 per year since 2000 within the framework of enhanced oil recovery (EOR). In addition to these projects, recourse can be taken to experience with gas storage technology, as already mentioned. However, the differences between storing natural gas and CO2 in terms of chemical and physical properties must be taken into account here. The volumes and objectives are also different. While natural gas storage aims at the best possible recoverability, i.e. a high fraction of working gas, CO2 storage aims at the best possible trapping of the injected CO2 in the reservoir. This leads to different requirements on geological characteristics in the respective reservoirs. Experience can therefore only be transferred to a limited extent.

A range of direct and indirect methods can be used to monitor the injected CO2. Most of these methods are based on established geophysical and geochemical techniques, which may have to be modified depending on the requirements of CO2 storage. Each storage site has very specific monitoring requirements for the injected CO2, which must be precisely defined before start of storage operation within a needs and risks assessment. This definition requires the creation of a comprehensive geological, hydraulic, and geomechanical model of the storage reservoir. Based on the requirements, a monitoring concept must then be developed under surveillance of the responsible authorities in order to combine different monitoring methods in the most appropriate manner.

Based on current knowledge, such a monitoring concept, which is tailored to the individual storage reservoir, will make it possible to reliably monitor and control the injected CO2. It should be noted that the described methods allow a qualitative description of CO2 distribution, but that the amount of CO2 is difficult to quantify.

A key point for predicting the behaviour of the injected CO2, and for the related risk analysis, is the use of numerical simulations. Modelling and storage site monitoring are iterative processes, and both the modelling results and monitoring concepts can be adjusted accordingly during the storage process and validated. Further, results from monitoring will guide the injection operation in order to allow for a safe storage procedure. While monitoring methods can only reflect the actual situation, numerical modelling can be used to predict long-term behaviour of the storage formation. These predictions can then be used to develop an adaptive monitoring system and to optimize the operation of the storage facility.

In terms of optimal delineation of the storage reservoir and the related determination of the spatial distribution of potential irregularities during storage operation, the spreading of the injected CO2 itself must be differentiated from spreading of the pressure increase in the reservoir caused by the injection process. The latter can cover a significantly larger spatial area than the CO2 itself. While the distribution of CO2 is decisive for the possible leakage of CO2 from the storage facility, the spatial distribution of the pressure increase is decisive for displaced saline formation water potentially migrating upwards. Furthermore, it is important to distinguish between spatial distribution or spreading at reservoir depth and spatial spreading of CO2 at the surface. Whereas CO2 or displaced saline formation water migrates upwards, horizontal migration can occur in overlying rock units, which may extend far beyond the spreading at the depth of the reservoir. Therefore, the underground distribution of the CO2 and the pressure increase cannot be directly transferred to the corresponding distribution at the surface. The spatial distribution of the CO2 and of the pressure increase at depths of the reservoir can be determined using existing monitoring and simulation methods. The potential spatial spread at the surface resulting from this spatial spread at reservoir level must be individually determined for each storage site as part of a risk analysis.

Not only must the monitoring concept and the spatial distribution and/or limitation be specifically designed or defined for each storage site, but a risk analysis is also only possible on a case-by-case basis. Each storage site is characterized by very specific geological conditions, which often differ from each other considerably. Due to these different geological settings, no generalizable criteria for risk assessments can be defined or applied to all storage sites. Exclusion criteria for a storage site include caprock that has not formed fully, as well as migration pathways, and thus hydraulic connections between the storage formation and the aquifers found above the caprock.

6 Experience from the Pilot Site in Ketzin

The underground geological storage of CO2 is being studied near the town of Ketzin/Havel (Brandenburg) around 40 km west of Berlin (Martens et al. 2012). The geological target horizons for CO2 storage at the pilot site in Ketzin are porous sandstone layers at a depth of 630–650 m (Förster et al. 2006; Norden et al. 2010) (Fig. 6.4).

Above the sandstone storage formation are layers of clay, which act as a seal and are more than 165 m thick. From the 1960s until 2000, the Ketzin site was initially used to store town gas and then natural gas in a shallower sandstone formation at a depth of around 280 m. For this reason, the site is well explored. Based on existing knowledge and additional exploratory investigations, in 2007 three new wells were drilled for the geological storage of CO2 with final depths of up to around 800 m each. One of these wells (Ktzi 201) is used to monitor and inject the CO2, while the other two (Ktzi 200 and Ktzi 202) are used to monitor the injection and distribution of the CO2 (Prevedel et al. 2009). In summer 2011, another well (P300) was drilled at the pilot site to a depth of 446 m in order to observe the geochemical and hydrogeological conditions in the first aquifer above the storage formation. The final well (Ktzi 203) was drilled in 2012 into the reservoir especially to retrieve rock samples which were in contact with CO2 for 4 years (Fig. 6.4).

6.1 Storage of CO2 Is Safe and Reliable

From June 2008 until August 2013, mainly food-grade CO2 has been fed into the underground formation via the injection well. Over the entire period, the injection has been safe and reliable. The injection conditions at the injection wellhead are approx. 62 bar and 35 °C. The respective injection regime is determined in accordance with the scientific tasks and requirements. Injection began on 30 June 2008, and 67,271 tCO2 had been injected by August 2013.

The injection led to an initial pressure rise in the reservoir from originally 62 bar to 76 bar. Continuous pressure measurements show that pressure conditions in the reservoir have remained stable between 72 bar and 76 bar since spring 2009 (Möller et al. 2012). The allowed maximal reservoir pressure of 85 bar defined in the storage permission, which was approved by the Brandenburg state agency for mining, geology and raw materials (Landesamt für Bergbau, Geologie und Rohstoffe, LBGR), was neither reached nor exceeded at any time during injection. Overall, the measurements verify a stable and reliable storage operation (Liebscher et al. 2012, 2013).

6.2 Combination of Geochemical and Geophysical Monitoring Methods for Detecting Small Amounts of CO2

At the pilot site in Ketzin, the primary objective is to develop, test and apply geophysical and geochemical monitoring methods. These will provide general information on monitoring of CO2 storage reservoirs, and thus facilitate the monitoring of the spatial distribution of CO2 injected underground. In this context, the most comprehensive monitoring programme in the world is in place at the pilot site in Ketzin (Giese et al. 2009; Fig. 6.4). It comprises permanent monitoring methods, such as pressure and temperature measurements (Möller et al. 2012), as well as periodic measurements, such as surface measurements of CO2 flows in the upper soil layers (Zimmer et al. 2011), borehole measurements (Henninges et al. 2011), deep fluid sampling (Morozova et al. 2011), geoelectric (Kiessling et al. 2010; Labitzke et al. 2012; Schmidt-Hattenberger et al. 2011), and active and passive seismic monitoring (Bergmann et al. 2011; Kazemeini et al. 2009; Lüth et al. 2011; Yordkayhun et al. 2009a, b).

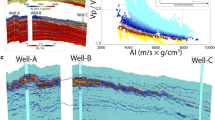

The results of geoelectric and seismic monitoring, in particular, show that even very small amounts of CO2 can be determined indirectly in the subsurface with sufficient precision. Geoelectric methods reliably detect approx. 5,000 tCO2, and seismic methods image the spatial distribution of CO2 for an injected volume of around 22,000 tCO2. The results of both methods also show good agreement with each other.

6.3 Fluid Rock Interactions Do Not Impact the Storage Integrity

Sandstone samples from the Ketzin storage formation were treated in the laboratory with CO2 and saline water with near in situ conditions (55 bar and 40 °C). For comparison, samples were studied with and without CO2 in contact with saline water. Overall, the dissolution of calcium-rich plagioclase, K-feldspar, and anhydrite was observed, while albite appears to be stable (Fischer et al. 2011). The petrophysical properties of the sandstone samples also show changes with a slightly increased porosity (Zemke et al. 2010). The observed chemical reactions occurred on such a small scale that the integrity of reservoir and caprocks is not affected.

6.4 Numerical Simulations Depict the Temporal and Spatial Behaviour of Injected CO2

Static and dynamic modelling complement the monitoring methods at the Ketzin site and provide support to the operational management by delivering predictions.

Dynamic modelling is the only method for predicting the long-term behaviour of a storage site based on the known hydraulic, thermal, chemical, and mechanical processes (Bergmann et al. 2010; Kempka et al. 2010; Lengler et al. 2010).

Based on new findings obtained during injection operation so far, the underlying geological model was and will be continuously further developed and adapted (Liebscher et al. 2012; Martens et al. 2012). Numerical simulations performed to date on the basis of this geological model reveal good agreement between simulation results and monitoring measurements. It can therefore be assumed that site-specific predictions derived for further spreading of the CO2 after stop of injection are reliable (Fig. 6.5).

7 CO2 Storage as a Component of Energy Storage for a Closed Carbon Cycle

The geological storage of CO2, however, does not only play a key role for the mitigation of CO2 emissions in the atmosphere in the long term, but it could also become a central component in the hydrogen economy as ‘dynamic’ storage, as proposed in the power-to-gas concept.

If excess electricity is to be converted into methane and stored, a CO2 source will be required. According to the German federal government’s climate change mitigation targets, CO2 emissions are to be cut by at least 80 % by 2050 in regard to levels of 1990. In order to achieve this target, CO2 from biogas production must be used for any power-to-gas concept because it is not considered to be additional CO2, and is assigned to the natural carbon cycle. Another option is to use process-related CO2 produced in industrial processes.

If we were to go a step further, the power-to-gas concept could be extended to include the separation, storage, recycling and reuse of CO2 produced during the energy generation process (e.g. via combined cycle power plants = CCGT; Fig. 6.6). If all components are integrated in one site, then a local closed carbon cycle is the result (Streibel et al. 2013). This would safeguard the advantages of fossil fuels – the ability to be stored in large quantities and thus supply very energy-intensive industries – in the long term (Kühn et al. 2013). At the same time, the storage of CO2 from biogas combustion gives rise to negative CO2 emissions (Fig. 6.7) and thus helps to stabilize the atmospheric concentration of CO2. Figure 6.6 schematically shows how the individual components can be combined.

This cycle comprises five stages (Kühn 2012, Fig. 6.7). The driving force, which allows the repeated conversion of CO2, is hydrogen, which is produced from excess electricity generated from renewables:

-

1.

Preparation of hydrogen via electrolysis.

-

2.

Reaction of hydrogen with carbon dioxide from a reservoir.

-

3.

Methane is stored temporarily in a geological formation.

-

4.

When electricity is needed, the methane is fed back into the cycle and combusted in a CCGT.

-

5.

The CO2 produced during combustion in the CCGT is then separated and stored.

8 Summary and Conclusions

Reservoir rocks with the potential for storing CO2 are mainly sandstones, as they are characterized by sufficient porosities and permeabilities allowing CO2 to be injected efficiently into these formations. Overall, four trapping mechanisms in the layers of the storage formation facilitate permanent and safe storage: (i) structural trapping below an impermeable caprock, (ii) immobilization via capillary forces in the pore space, (iii) dissolution of CO2 in the formation water, and (iv) mineral trapping via carbonization.

As demonstrated, leaks can occur and must be detected, which makes monitoring of CO2 storage sites essential. A general evaluation of the suitability of sites in advance cannot be performed effectively without a geological site characterization. It is therefore essential that a comprehensive exploration will be performed before a project begins. As is the case for every technology, there is also a technological risk associated with the geological storage of CO2. However, this appears to be manageable, particularly when modern monitoring systems are used.

Near the town of Ketzin/Havel in Brandenburg, the first continental European field laboratory for CO2 storage was set up as a pilot site in 2004, and it is in operation until today with active and continuous injection from June 2008 until August 2013. During that period 67,271 tCO2 have been stored. The pilot site in Ketzin was thus the first and is still the only active CO2 storage project in Germany. The injection of CO2 has been accompanied by one of the most extensive scientific research and development programmes in the world. The results show that: (i) the geological storage of CO2 at the pilot site in Ketzin is safe and reliable, and poses no danger to humans or the environment, (ii) a well-thought-out combination of different geochemical and geophysical monitoring methods can detect small amounts of CO2 and image its spatial distribution, (iii) the interactions between fluid and rock induced by CO2 injection at the pilot site in Ketzin have no significant impacts and do not influence the integrity of the reservoir or the caprock, and (iv) numerical simulations can depict the temporal and spatial behaviour of injected CO2.

Work at the pilot site in Ketzin demonstrates the safety and reliability of CO2 storage on a research scale, and is thus an important milestone on the way to decarbonizing society and making an important contribution to using underground geological formations in an environmentally friendly manner. In addition, results from studies at Ketzin provide basic and transferable knowledge which is of value for a new integrated concept of CO2 mitigation and utilization in combination with the power-to-gas concept based on a closed carbon cycle approach.

References

Bergmann P, Lengler U, Schmidt-Hattenberger C, Giese R, Norden B (2010) Modelling the geoelectric and seismic reservoir response caused by carbon dioxide injection based on multiphase flow simulation: results from the CO2SINK project. Chemie der Erde 70:173–183

Bergmann P, Yang C, Lüth S, Juhlin C, Cosma C (2011) Time-lapse processing of 2D seismic profiles with testing of static correction methods at the CO2 injection site Ketzin (Germany). J Appl Geophys 75:124–139

Birkholzer JT, Zhou Q, Tsang C-F (2009) Large-scale impact of CO2 storage in deep saline aquifers: a sensitivity study on pressure response in stratified systems. Int J Greenh Gas Control 3, 181–194

Bohnhoff M, Zoback MD, Chiaramonte L, Gerst JL, Gupta N (2010) Seismic detection of CO2 leakage along monitoring wellbores. Int J Greenh Gas Control 4:687–697

Chiodini G, Granieri D, Avino R, Caliro S, Costa A, Minopoli C, Vilardo G (2010) Non-volcanic CO2 earth degassing: case of Mefite d’Ansanto (southern Apennines), Italy. Geophys Res Lett 37, L11303

Ebigbo A, Class H, Helmig R (2007) CO2 leakage through an abandoned well: problem-oriented benchmarks. Comput Geosci. doi:10.1007/s10596-006-9033-7

Fischer S, Zemke K, Liebscher A, Wandrey M, CO2SINK Group (2011) Petrophysical and petrochemical effects of long-term CO2-exposure experiments on brine-saturated reservoir sandstone. Energy Procedia 4:4487–4494

Förster A, Norden B, Zinck-Jørgensen K, Frykman P, Kulenkampff J, Spangenberg E, Erzinger J, Zimmer M, Kopp J, Borm G, Juhlin C-G, Cosma C, Hurter S (2006) Baseline characterization of the CO2SINK geological storage site at Ketzin, Germany. Environ Geosci 133:145

Giese R, Henninges J, Lüth S, Morozova D, Schmidt-Hattenberger C, Würdemann H, Zimmer M, Cosma C, Juhlin C, CO2SINK Group (2009) Monitoring at the CO2SINK site: a concept integrating geophysics, geochemistry and microbiology. Energy Procedia 1:2251–2259

Gilfillan SMV, Sherwood Lollar B, Holland G, Blagburn D, Stevens S, Schoell M, Cassidy M, Ding Z, Zhou Z, Lacrampe-Couloume G, Ballentine CJ (2009) Solubility trapping in formation water as dominant CO2 sink in natural gas fields. Nature 458:614–618

Henninges J, Liebscher A, Bannach A, Brandt W, Hurter S, Köhler S, Möller F, CO2SINK Group (2011) P-T-ρ and two-phase fluid conditions with inverted density profile in observation wells at the CO2 storage site at Ketzin (Germany). Energy Procedia 4:6085–6090

IPCC (2005) Special report on carbon dioxide capture and storage. http://www.ipcc.ch/activity/srccs/index.htm. IPCC, 15 Aug 2012

Kazemeini H, Juhlin C, Zinck-Jorgensen K, Norden B (2009) Application of the continuous wavelet transform on seismic data for mapping of channel deposits and gas detection at the CO2SINK site, Ketzin, Germany. Geophys Prospect 57:111–123

Kempka T, Kühn M, Class H, Frykman P, Kopp A, Nielsen CM, Probst P (2010) Modelling of CO2 arrival time at Ketzin – Part I. Int J Greenh Gas Control 4:1007–1015

Kiessling D, Schmidt-Hattenberger C, Schuett H, Schilling F, Krüger K, Schöbel B, Danckwardt E, Kummerow J, CO2SINK Group (2010) Geoelectrical methods for monitoring geological CO2 storage: first results from cross-hole and surface-downhole measurements from the CO2SINK test site at Ketzin (Germany). Int J Greenh Gas Control 4:816–826

Kühn M (2011) Chancen und Risiken – CO2-Speicherung. Chemie in unserer Zeit 45:126–138

Kühn M (2012) Patent WO 2013156611 A1. http://www.google.com/patents/WO2013156611A1?cl=en&hl=de. Last access 12 Oct 2014

Kühn M, Nakaten NC, Streibel M, Kempka T (2013) Carbon neutral and flexible underground storage of renewable excess energy. Erdöl Erdgas Kohle 129(10):348–352 (in German)

Labitzke T, Bergmann P, Kießling D, Schmidt-Hattenberger C (2012) 3D surface-downhole electrical resistivity tomography data sets of the Ketzin CO2 storage pilot from the CO2SINK project phase. Scientific technical report, Data: 12/05. doi:10.2312/GFZ.b103-12051

Lengler U, de Lucia M, Kühn M (2010) The impact of heterogeneity on the distribution of CO2: numerical simulation of CO2 storage at Ketzin. Int J Greenh Gas Control 4:1016–1025

Lewicki JL, Birkholzer J, Tsang C-F (2007) Natural and industrial analogues for leakage of CO2 from storage reservoirs: identification of features, events, and processes and lessons learned. Environ Geol 52:457–467

Liebscher A, Martens S, Möller F, Lüth S, Schmidt-Hattenberger C, Kempka T, Szizybalski A, Kühn M (2012). Überwachung und Modellierung der geologischen CO2-Speicherung – Erfahrungen vom Pilotstandort Ketzin, Brandenburg (Deutschland). Geotechnik 35. doi:10.1002/gete.201200005

Liebscher A, Möller F, Bannach A, Köhler S, Wiebach J, Schmidt-Hattenberger C, Weiner M, Pretschner C, Ebert K, Zemke J (2013) Injection operation and operational pressure-temperature monitoring at the CO2 storage pilot site Ketzin, Germany – design, results, recommendations. Int J Greenhouse Gas Control 15:163–173

Lüth S, Bergmann P, Cosma C, Enescu N, Giese R, Götz J, Ivanova A, Juhlin C, Kashubin A, Yang C, Zhang F (2011) Time-lapse seismic surface and down-hole measurements for monitoring CO2 storage in the CO2SINK project (Ketzin, Germany). Energy Procedia 4:3435–3442

Martens S, Kempka T, Liebscher A, Lüth S, Möller F, Myrttinen A, Norden B, Schmidt-Hattenberger C, Zimmer M, Kühn M, Ketzin Group (2012) Europe’s longest-operating on-shore CO2 storage site at Ketzin, Germany – Progress report after three years of injection. Environ Earth Sci. doi:10.1007/s12665-012-1672-5

Möller F, Liebscher A, Martens S, Schmidt-Hattenberger C, Kühn M (2012) Yearly operational datasets of the CO2 storage pilot site Ketzin, Germany. Scientific technical report, Data: 12/06. doi:10.2312/GFZ.b103-12066

Morozova D, Zettlitzer M, Let D, Würdemann H, CO2SINK Group (2011) Monitoring of the microbial community composition in deep subsurface saline aquifers during CO2 storage in Ketzin, Germany. Energy Procedia 4:4362–4370

Nordbotten JM, Celia MA, Bachu S (2004) Analytical solutions for leakage rates through abandoned wells. Water Resour Res 40, W04204. doi:10.1029/2003WR002997

Norden B, Förster A, Vu-Hoang D, Marcelis F, Springer N, Le Nir I (2010) Lithological and petrophysical core-log interpretation in CO2SINK, the European onshore research storage and verification project. SPE Reservoir Eval Eng 13:179–192

Prevedel B, Wohlgemuth L, Legarth B, Henninges J, Schütt H, Schmidt-Hattenberger C, Norden B, Förster A, Hurter. S (2009) The CO2SINK boreholes for geological CO2-storage testing. Energy Procedia 1:2087–2094

Roberts JJ, Wood RA, Haszeldine RS (2011) Assessing the health risks of natural CO2 seeps in Italy. PNAS early edition: www.pnas.org/cgi/doi/10.1073/pnas.1018590108

Schmidt-Hattenberger C, Bergmann P, Kießling D, Krüger K, Rücker C, Schütt H, Ketzin Group (2011) Application of a Vertical Electrical Resistivity Array (VERA) for monitoring CO2 migration at the Ketzin site: first performance evaluation. Energy Procedia 4:3363–3370

Sedlacek R (2009) Untertage-Gasspeicherung in Deutschland. Erdgas Erdöl Kohle 125:412–426

Streibel M, Nakaten NC, Kempka T, Kühn M (2013) Analysis of an integrated carbon cycle for storage of renewables. Energy Procedia 40:202–211

Tillner E, Kempka T, Nakaten B, Kühn M (2013) Brine migration through fault zones studied in 3D numerical simulations for a prospective CO2 storage site in Northeast Germany. Int J Greenh Gas Control, 19, 689–703. doi:10.1016/j.ijggc.2013.03.012

Wells AW, Diehl JR, Bromhal G, Strazisar BR, Wilson TH, White CM (2007) The use of tracers to assess leakage from the sequestration of CO2 in a depleted oil reservoir, New Mexico, USA. Appl Geochem 22:996–1016

Yordkayhun S, Ivanova A, Giese R, Juhlin C, Cosma C (2009a) Comparison of surface seismic sources at the CO2SINK site, Ketzin, Germany. Geophys Prospect 57:125–139

Yordkayhun S, Juhlin C, Norden B (2009b) 3D seismic reflection surveying at the CO2SINK project site, Ketzin, Germany: a study for extracting shallow subsurface information. Near Surface Geophys 7:75–91

Zemke K, Liebscher A, Wandrey M, CO2SINK Group (2010) Petrophysical analysis to investigate the effects of carbon dioxide storage in a subsurface saline aquifer at Ketzin, Germany (CO2SINK). Int J Greenh Gas Control 4:990–999

Zimmer M, Pilz P, Erzinger J (2011) Long-term surface carbon dioxide flux monitoring at the Ketzin carbon dioxide storage test site. Environ Geosci 18:119–130

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Kühn, M., Liebscher, A., Martens, S., Möller, F., Kempka, T., Streibel, M. (2015). Safe Operation of Geological CO2 Storage Using the Example of the Pilot Site in Ketzin. In: Kuckshinrichs, W., Hake, JF. (eds) Carbon Capture, Storage and Use. Springer, Cham. https://doi.org/10.1007/978-3-319-11943-4_6

Download citation

DOI: https://doi.org/10.1007/978-3-319-11943-4_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-11942-7

Online ISBN: 978-3-319-11943-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)