Abstract

Moths have compound eyes, meaning they are faceted and consist of many repeated, anatomically identical unites called ommatidia (Stavenga et al., Proc Biol Sci 273(1587):661–667, 2005). Every ommatidium detects signals that are neurologically processed to form a whole image and is composed of retinula cells, a rhabdom, a crystalline cone, and a corneal lens covered in nano-scale structures called corneal nipples (Lee and Erb, Beilstein J Nanotechnol 4:292–299, 2013). Corneal nipples are covered in protuberances that are responsible for the antireflective property of moth eyes (Parker, Am Sci 87(3):248–255, 1999). This optical mechanism relies on the fact that the wavelength range of incident light is less than the dimensions of the corneal nipples. The antireflective surface of moth eyes is critical to their survival, because they allow moths to camouflage with their surroundings at night and impart superhydrophobic properties, lending anti-adhesive, anti-fogging, and self-cleaning abilities (Boden and Bagnall, Moth-eye antireflective structures. In: Bhushan B (ed) Encyclopedia of nanotechnology. Springer, Netherlands, pp 1467–1477, 2012). Moth-eye antireflective (AR) structures have been produced by engineers to enhance the surfaces of materials such as glass and silicon to an extent that surpasses the antireflective properties provided by traditional antireflection coatings, or ARCs (Boden, Biomimetic nanostructured surfaces for antireflection in photovoltaics. PhD thesis, University of Southampton, School of Electronics & Computer Science, p 18, 2009). Researchers in the solar energy field have taken particular interest in the antireflective properties of moth eyes in hopes of applying them to photovoltaic (PV) systems to increase light-efficiency and minimize energy waste (Yamada et al., Prog Photovolt Res Appl 19(2):134–140, 2010). Perhaps one of the most exciting, up-and-coming applications of the moth-eye nano-structure is an X-ray enhanced with a film of protuberances modeled after corneal nipples. Using a moth-eye based film in addition to a traditional scintillator could allow a decrease in radiation dosage and offer higher-resolution imaging—both things that would be a huge step forward for medical care and, best of all, patient treatment (The Optical Society, Insects inspire X-ray improvements: nanostructures modeled after moth eyes may enhance medical imaging, http://www.osa.org/en-us/about_osa/newsroom/newsreleases/2012/insects_inspire_x-ray_improvements_nanostructures/, 2012). Though tiny, moth eyes have the potential to contribute enormously to engineering endeavors, serving as a reminder of the infinite amount of knowledge hidden even among nature’s smallest creations.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Retinula Cell

- Interference Lithography

- Crystalline Cone

- Superhydrophobic Property

- Antireflective Property

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Award-Winning Theatrical Actors

Everyone’s head turns as a slick black limousine pulls up to the red carpet, and before the door even opens, light bulbs from cameras flash left and right with no sign of ceasing. The noise is relentless: journalists, photographers, and fans shout and scream, trying to get a better look at the emerging pair of celebrities. Jaws hang open in awe of her shiny, brown hair, falling in light waves around her shoulders. Her dress is a shimmery gold, draping down to the floor like liquid metal, and her lips are bright and bold, the color matching that of the red carpet. Her arm is hooked around the arm of a man with a tailored black suit and perfectly styled hair. His shoes are so shiny that they reflect the flashes coming from the cameras, which are all trained on them. Together, they drift up the red carpet, the sound of their names and of their latest hit movie following after them like the gold train of her dress.

Actors and actresses are some of the most famous and loved people in America. They are surrounded in glamour, beauty, and fame, and experiences like the above are a given. If the insect world had celebrities, surely they would be the flashy, iridescent butterfly or the delicately spotted ladybug. Perhaps spiders would make the cut as well, as they could play the terrifying villains. Moths, on the other hand, seem to go rather unnoticed compared to other types of insects. In the event that they do get noticed, it is usually followed up by a trip to the store for mothballs. However drab, pesky, and relatively average moths may seem compared to some of their flashy friends, these little furry-winged insects have their own secret talent.

Just like humans look to methods of biomimicry to solve real world problems, it turns out moths know a thing or two about mimicry as well. As a means of survival, Brenthia moths thwart jumping spider predators by mimicking them, as in Fig. 7.1. When encountering jumping spiders, these particular moths survive more often than controls. The territorial behavior of jumping spiders upon meeting a Brenthia moth while it is mimicking is further evidence that the spiders recognize the moths as their own kind (Rota and Wagner 2006).

Brenthia moths mimic spiders for survival (Drawing by Virginia Wagner. Reproduced with kind permission from Rota and Wagner (2006))

Amazingly, moths are capable of mimicking predators that are much larger than them, such as foxes and snakes. According to retired entomologist Professor Philip Howse, moths can fool snakes with the patterns on its wings; in an effort to fool a predator even further, the mimicking moths will even fall and writhe on the ground, adding the perfect touch to their theatrical acts. Other species use the patterns on their wings to look like foxes and rodents peeking out from greenery. The reason this works so well with animals and not humans is that animals have more focused vision, and they tend to train their eyes on small details (Gray 2010).

The ability to mimic a predator for survival is a talent that not many animals have—it is considered both rare and exceptional (Rota and Wagner 2006). In a sense, moths are actors and actresses that excel in mimicry, and their award is survival in the face of danger, despite their small size. Moths are an example of the outstanding properties and capabilities of nature, and this chapter will explore yet another one of moths’ natural wonders: the surface of their eyes. Moth eyes’ special nano-structured surface has garnered much attention from the scientific community, and you will be able to see just why once you read on.

Basic Structure of Moth Eyes

Optical System

Classified as having optical superposition eyes, moths use several facet lenses to allow light to reach the rhabdom, which is a long, cylindrical structure that has the visual pigment molecules of photoreceptors. This optical system makes moths much more sensitive to light compared to butterflies, who have apposition eyes that channel light into the rhabdom through a single facet lens and crystalline cone (Stavenga et al. 2005).

General Morphology

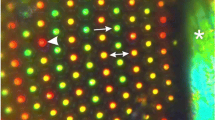

The eyes of the African Armyworm Moth (Spodoptera exempta) are hemispherical with a diameter of about 1 mm (Meinecke 1981), which gives an idea of general size and scale. Moths have compound eyes, which can be seen in Fig. 7.2, meaning they are faceted and consist of many repeated, anatomically identical units called ommatidia (Stavenga et al. 2005). The number of ommatidia depends on the type of moth: Spodoptera exempta has about 8,000 ommatidia on its eye (Meinecke 1981), while Antheraea polyphemus has about 10,000 (Anton-Erxleben and Langer 1988). Every ommatidium detects signals that are neurologically processed to form a whole image. Each is composed of retinula cells, a rhabdom, a crystalline cone, and a corneal lens covered in nano-scale structures called corneal nipples (Lee and Erb 2013), which will be discussed in detail later in the chapter. The crystalline cone is composed of crystalline cone cells, whose cytoplasm is granular, electron dense, and lacks organelles except a few mitochondria and a nucleus (Meinecke 1981). See Fig. 7.3 for an SEM image of the array of corneal nipples and a crystalline cone cell.

A moth eye as seen in scanning electron microscopy (SEM) images with scale bars (a) 1 mm and (b) 2 μm (Reprinted from Phillips and Jiang (2013). With permission from Elsevier)

Corneal Nipples

Antireflective Mechanism

Corneal nipples, which cover the corneal lens as mentioned earlier, were first observed and termed in 1962 by Bernhard and Miller, who discovered the regularly arrayed set of cuticular protuberances (Stavenga et al. 2005). Corneal nipples are often found in ordered hexagonal arrays (Meinecke 1981), where the spacing between them ranges from 180 to 240 nm, while their height varies from 0 to 230 nm (Yamada et al. 2010).

Slightly tapered from bottom to top, these protuberances are responsible for the antireflective property of moth eyes. The gradual change in diameter of the nanostructure provides a smooth transition for light as it transfers from air to the surface of each ommatidium, which is made of chitin. Each incident photon encounters the slimmer tops of the protuberances first, causing the effective index of refraction to be only slightly higher than that of air. Then, as the protuberance increases in diameter and the photons get closer to the bottom, the index of refraction approaches that of chitin (Parker 1999). This optical mechanism relies on the fact that the wavelength range of incident light is less than the dimensions of the corneal nipples (Boden and Bagnall 2012). Therefore, despite the large difference between the indices of refraction of air and chitin, which are 1 and 1.55 respectively (Parker 1999), the smooth transition such as in Fig. 7.4c prevents light from encountering an abrupt change in refractive index such as in Fig. 7.4a, b, which would cause part of the light to be reflected. A helpful way to think of this transition is considering the tapered profile as infinitesimal layers that are infinitely stacked allowing the refractive index to change gradually and ever so slightly between each layer (Boden and Bagnall 2012).

Analogous profiles of refractive indices with their respective surface profiles consisting of (a) ridges, (b) steps, and (c) triangles (Reproduced with kind permission from Boden (2009))

Purposes of Antireflective Corneal Nipple Array

The antireflective surface of moth eyes is critical to their survival, particularly at night. By significantly reducing the amount of light reflected from moths’ eyes, corneal nipples help moths be stealthier and less visible to potential predators in the night, since glints from their eyes will not be giving them away (The Optical Society 2012). Remarkably, this array of protuberances is not limited to moth eyes. They have been found on moth wings as well, allowing them to camouflage with their surroundings. Cryptotympana aquila and Cephonodes hylas are examples of moths who have this feature on their wings; the nipple arrays on the wing of Cephonodes hylas can be seen in Fig. 7.5. The array of corneal nipples can be found on both the dorsal and ventral sections of their wings. As a result, moths are unseen by prowling predators, with optical transmission over 90 % for a wide range of wavelengths (Boden and Bagnall 2012).

Scanning helium ion microscope images showing (a) corneal nipple protuberances on the wing of Cephonodes hylas (scale bar: 1 μm) and (b) magnified version (scale bar: 100 nm) (Reprinted from Boden and Bagnall (2012), Fig. 1. With kind permission from Springer Science + Business Media)

Corneal nipples give moths other advantages in addition to heightened safety from predators. The high transmission of light aids with low-light vision, which is particularly useful for nocturnal moths (Lee and Erb 2013). Overall, the reduction in reflectivity and increase in light absorption enhances the quality and sensitivity of the moth’s visual system. Lastly, the nano-scale protuberances impart superhydrophobic properties, lending anti-adhesive, anti-fogging, and self-cleaning abilities (Boden and Bagnall 2012).

Engineering Applications

Moth-Eye Antireflective (AR) Structures

Researchers and scientists have utilized biomimicry of the moth-eye nano-structures to enhance the surfaces of materials such as glass and silicon to an extent that surpasses the antireflective properties provided by traditional antireflection coatings, or ARCs. The superior antireflective performance of moth-eye structured surfaces can be seen in Fig. 7.6, where a comparison of silicon with fabricated moth-eye structures, bare silicon, and thin-film ARCs shows that the application of moth-eye structures generated less reflectance over a wide range of wavelengths and angles of incidence (Boden 2009).

A comparison of silicon with moth-eye surface structure to thin-film anti-reflection coatings (ARCs) and bare silicon: (a) reflectance versus wavelength and (b) reflectance versus angle of incidence (Reprinted from Boden and Bagnall (2012), Fig. 8. With kind permission from Springer Science + Business Media)

However, the corneal nipple pattern, which is on the scale of several hundred nanometers, is too small to be manufactured using standard photolithography techniques, requiring other processes such as electron-beam lithography and nanoimprint lithography (Boden and Bagnall 2012). Using a combination of injection-molding and hot-process embossing, the Fraunhofer Institute in Germany fabricated glass that has visual transmission of over 98 % and plastic of over 99 % (Leydecker 2008).

Interference lithography is another process that has been developed to obtain the moth-eye-like antireflective surface structure, like the one in Fig. 7.7. Clapham and Hutley were the first to demonstrate fabrication of artificial moth eyes by interference lithography, which can now be used to produce replications on a large, industrial scale. In addition, the moth-eye surface can be produced on a wide range of flexible substrates, which makes the surface structure viable for solar cells, among many other applications (Forberich et al. 2008).

Fabricated moth eye replica as seen in scanning electron microscopy (SEM) micrograph (Reprinted from Forberich et al. (2008). With permission from Elsevier)

Efficient Solar Energy Capture

Researchers in the solar energy field have taken particular interest in the antireflective properties of moth eyes. Photovoltaic (PV) systems, the processes of which can be seen in Fig. 7.8, are considered to be a powerful potential option in remediating the environmental and energy crisis that looms before us. However, because photovoltaic (PV) solar cells are made of materials that have high indices of refraction such as Si, GaAs, and InP, the absence of antireflective technology will allow them to lose more than 35 %. Ideally, a light-efficient solar energy cell does not waste energy, so minimizing optical reflection is an important challenge to overcome in order to obtain maximum benefits. Because a reduction in optical reflection can lead to a direct increase in the efficiency of such systems, applying anti-reflective techniques to PV cells has become of utmost importance (Yamada et al. 2010).

The processes of a silicon photovoltaic cell (PV) cell (Reprinted from Papadopoulou (2011), Fig. 4.4. With kind permission from Springer Science + Business Media)

One concern that has challenged researchers is the robustness of potential moth-eye nano-structures. Given that solar cells will be continuously exposed to outdoor conditions, the question of whether fabricated structures will be able to endure the abrasion that harsh conditions may create remains. Therefore, the mechanical properties of the substrate are essential factors when it comes to producing moth-eye structures on materials that will be subject to such conditions (Boden and Bagnall 2012). If success in creating solar energy cells textured with the moth-eye surface could be achieved, however, the overall performance of PV systems can be improved by as much as 15 % (Leydecker 2008).

X-Rays of the Future: Safer and High-Performance

Perhaps one of the most exciting, up-and-coming applications of the moth-eye nano-structure is an X-ray enhanced with a film of protuberances modeled after corneal nipples. Yasha Yi, a professor at the City University of New York, and his colleagues are taking a look at the potential improvements that applying a thin, moth-eye-like film to X-rays can have on its performance. In short, X-rays work by absorbing the energy of X-ray photons and reemitting the energy in light form, which is then detected and formed into an image. The material that performs this conversion is called a scintillator. In order to improve the performance of X-rays—that is, increase the intensity of emitted light signals that is detected and formed into an image—there are two options: increase the dosage of X-ray light or increase the efficiency of X-ray to light conversion. The first option, however, is dangerous for patients, as they would be exposed to increased doses of harmful radiation. Therefore, Yi et al. aimed to utilize the second method (The Optical Society 2012).

Specifically, they added a thin film of cerium-doped lutetium oxyorthosilicate with pyramid-shaped protuberances resembling corneal nipples onto the scintillator of an X-ray. Even the density of the fabricated protuberances—100,000 to 200,000 in a 100×100 μm square—resembled that of a real moth eye. Experiments comparing a scintillator with the moth-eye film addition to a traditional scintillator showed a 175 % increase in the intensity of emitted light from the new set-up. According to Yi, much more work needs to be done, but potential achievements with the moth-eye based film could include lower doses of radiation and higher-resolution imaging—both things that would be a huge step forward for medical care and, best of all, patient treatment (The Optical Society 2012).

The surface structure and antireflective mechanism of moth eyes is a true natural wonder. Just as the antireflection and textured surface can save moths’ lives by protecting them from predators at night, applying the technology to X-rays may save human patients and enhance their quality of life through higher-resolution imaging. Furthermore, significant improvements in PV solar cells can be made with moth eye surface replication. Though tiny, moth eyes have the potential to contribute enormously to engineering endeavors, serving as a reminder of the infinite amount of knowledge hidden even among nature’s smallest creations.

References

Anton-Erxleben F, Langer H (1988) Functional morphology of the ommatidi in the compound eye of the moth, Antheraea polyphemus (Insecta, Saturniidae). Cell Tissue Res 252:385–396

Boden SA (2009) Biomimetic nanostructured surfaces for antireflection in photovoltaics. PhD thesis, University of Southampton, School of Electronics & Computer Science, p 18

Boden SA, Bagnall DM (2012) Moth-eye antireflective structures. In: Bhushan B (ed) Encyclopedia of nanotechnology. Springer, Netherlands, pp 1467–1477. doi:10.1007/978-90-481-9751-4_262

Forberich K, Dennler G, Scharber MC, Hingerl K, Fromherz T, Brabec CJ (2008) Performance improvement of organic solar cells with moth eye anti-reflection coating. Thin Solid Films 516(20):7167–7170. doi:10.1016/j.tsf.2007.12.088

Gray R (2010) Butterflies and moths mimic snakes and foxes to fool predators, claims researcher. http://www.telegraph.co.uk/earth/wildlife/8082739/Butterflies-and-moths-mimic-snakes-and-foxes-to-fool-predators-claims-researcher.html. Accessed 24 Aug 2013

Lee KC, Erb U (2013) Grain boundaries and coincidence site lattices in the corneal nanonipple structure of the Mourning Cloak butterfly. Beilstein J Nanotechnol 4:292–299. doi:10.3762/bjnano.4.32

Leydecker S (2008) Nano materials in architecture, interior architecture and design. Birkhäuser, Basel. doi:10.1007/978-3-7643-8321-3

Meinecke CC (1981) The fine structure of the compound eye of the African Armyworm Moth, Spodoptera exempta Walk. (Lepidoptera, Noctuidae). Cell Tissue Res 216:333–347. doi:10.1007/BF00233623

Papadopoulou EVM (2011) Photovoltaic industrial systems. Photovoltaic energy. Springer, Berlin/Heidelberg, pp 31–55

Parker AR (1999) Light-reflection strategies: natural selection has produced a wealth of surfaces that interact efficiently with light. Technological applications abound, from better windows to stealth. Am Sci 87(3):248–255

Phillips BM, Jiang P (2013) Chapter 12: Biomimetic antireflection surfaces. In: Lakhtakia A, Martín-Palma RJ (eds) Engineered biomimicry. Elsevier, Boston, pp 305–331. doi:10.1016/B978-0-12-415995-2.00012-X

Rota J, Wagner DL (2006) Predator mimicry: metalmark moths mimic their jumping spider predators. PLoS One 1(1):e45. doi:10.1371/journal.pone.0000045

Stavenga DG, Foletti S, Palasantzas G, Arikawa K (2005) Light on the moth-eye corneal nipple array of butterflies. Proc Biol Sci 273(1587):661–667. doi:10.1098/rspb.2005.3369

The Optical Society (2012) Insects inspire X-ray improvements: nanostructures modeled after moth eyes may enhance medical imaging. http://www.osa.org/en-us/about_osa/newsroom/newsreleases/2012/insects_inspire_x-ray_improvements_nanostructures/. Accessed 29 July 2013

Yamada N, Kim ON, Tokimitsu T, Nakai Y, Masuda H (2010) Optimization of anti-reflection moth-eye structures for use in crystalline silicon solar cells. Prog Photovolt Res Appl 19(2):134–140. doi:10.1002/pip.994

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Lee, M. (2014). Moth Eyes: A New Vision for Light-Harnessing Efficiency. In: Lee, M. (eds) Remarkable Natural Material Surfaces and Their Engineering Potential. Springer, Cham. https://doi.org/10.1007/978-3-319-03125-5_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-03125-5_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-03124-8

Online ISBN: 978-3-319-03125-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)