Abstract

Since the mid-eighties, there has been an increasing amount of experimental evidence which shows that many of the concepts underlying current-code provisions for the design of reinforced-concrete (RC) structures are in conflict with fundamental properties of concrete at both the material and the structure levels.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Reinforce Concrete

- Shear Capacity

- Compressive Zone

- Transverse Reinforcement

- Reinforce Concrete Structure

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1.1 Introduction

Since the mid-eighties, there has been an increasing amount of experimental evidence which shows that many of the concepts underlying current-code provisions for the design of reinforced-concrete (RC) structures are in conflict with fundamental properties of concrete at both the material and the structure levels [1]. More recently, it has been shown that this conflict has been the cause of the unexpected (in accordance with current codes such as, for example, ACI318 [2] and EC2 [3]/EC8 [4]) damage suffered at mid height by the vertical (column and structural-wall) elements of RC buildings during the 1999 Athens earthquake [5]. In fact, this finding has been confirmed from the results of tests that reproduced this type of damage under controlled laboratory conditions [6–8]. Moreover, the latter tests not only revealed additional weaknesses of the provisions of current codes for earthquake-resistant design [9], but also indicated that it is, in fact, possible to obtain design solutions that satisfy the performance requirements of the codes through the use of alternative design approaches that allow for a realistic description of structural-concrete behaviour [6–9].

To this end, the aim of the present chapter is to collate all available information on the conflict between the concepts underlying current-code provisions and the causes of the observed and/or measured structural behaviour, and present it in a unified form. Such information involves fundamental aspects of RC design which are associated with, not only flexural and shear design, but also with elements of the design of earthquake-resistant RC structures such as, for example, the design of hoop reinforcement for the “critical regions” [2–4] and the regions of points of contraflexure (points, other than simple supports, along the span of a linear structural element, also known as points of inflection, where the bending moment is zero) [1, 5, 7]. Moreover, through the use of the above information, it will be demonstrated in subsequent chapters that the substitution of the concepts underlying the design methods adopted by current codes with alternative ones capable of providing a realistic description of structural-concrete behaviour, not only may improve the theoretical basis of RC design, but also simplify the design process and result in more efficient solutions without compromising the aims of structural design for safety, serviceability and economy.

1.2 Truss Analogy

1.2.1 Background

The truss analogy (TA), since its inception at the turn of the 20th century [10, 11], has always formed the basis of RC design. It became attractive for its simplicity and was first implemented in RC design through the permissible-stress philosophy. With the introduction of the limit-state philosophy in the 1970s, its use was extended for the description of the physical state of RC structures at their ultimate limit state by incorporating concepts such as strain softening [12], aggregate interlock [13, 14], dowel action [13, 15], etc. TA has remained to date the backbone of RC design, with more refined versions of it (in the form of the compression-field theory [16] and strut-and-tie models [17]) becoming increasingly popular.

The simplest form of such a truss describing the function of a beam-like element at its ultimate-limit state is shown in Fig. 1.1. In fact, this beam-like element is considered to start behaving as a truss once inclined cracking occurs, with the compressive zone and the flexural reinforcement forming the longitudinal struts and ties, respectively, the stirrups forming the transverse ties, whereas the cracked concrete of the element web is assumed to allow the formation of inclined struts.

1.2.2 Auxiliary Mechanisms of Shear Resistance

A characteristic feature of the implementation of the above model in current design practice is that the truss is often considered to sustain only a portion of the shear forces acting on a beam-like element; the remainder is considered to be sustained by the combined resistance to shear deformation offered by (a) the “uncracked” concrete of the compressive zone, (b) the “cracked” concrete of the tensile zone and (c) the flexural reinforcement, with the latter two auxiliary mechanisms of shear resistance being widely referred to as “aggregate interlock” [13] and “dowel action” [15], respectively.

-

(a)

Incompatibility with cracking mechanism

The mechanisms of “aggregate interlock” and “dowel action” can only be mobilized through the shearing movement of a crack’s faces; and yet, such a movement is incompatible with the well-established cracking mechanism of concrete: a crack extends in the direction of the maximum principal compressive stress and opens orthogonally to its plane [18–20]. Therefore, a shearing movement cannot occur, and, as a result, the mechanisms of “aggregate interlock” and “dowel action” cannot be mobilised so as to contribute to the structural element’s shear resistance.

-

(b)

Incompatibility with mechanic’s principles

Had it been possible for a shear movement to mobilize “aggregate interlock”, its contribution to shear resistance could only be possible once the shear resistance of “uncracked” concrete in the compressive zone had been overcome. This is because, unlike “uncracked” concrete which exhibits strain-hardening behaviour, the behaviour of cracked concrete (within which aggregate interlock could only develop) is described by post-peak stress-strain material characteristics [20], and, hence, its stiffness is negligible, if any (as it will be discussed later), when compared with the stiffness of uncracked concrete. With such large difference in stiffness the contribution of “aggregate interlock” to the combined shear resistance can only be negligible.

-

(c)

Incompatibility with observed structural behaviour

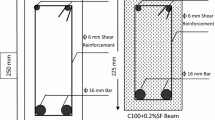

The validity of the concept of auxiliary mechanisms of shear resistance has been investigated experimentally by testing simply-supported beams under two-point loading (see Figs. 1.2 and 1.3) [21–23]. Figure 1.2a and b depict the geometric characteristics, together with the reinforcement details, of two types of beams with values of the shear span-to-depth ratio equal to approximately 1.5 and 3.3, respectively. The beams have the same geometric characteristics and longitudinal reinforcement but, with regard to the transverse reinforcement, they have beam classified as beams A, B, C, and D in Fig. 1.2a and beams A1, B1, C1 and D1 in Fig. 1.2b. The beams in Fig. 1.3 are similar to beams A in Fig. 1.2a or A1 in Fig. 1.2b, but they differ in the longitudinal reinforcement arrangement as indicated in the figure.

Beams under two-point loading [21]. Design details (beams differ in the arrangement of stirrups only): a beams with \({{{a_{\text v}}/d\approx}1.5}\); b beams with \({{{a_{\text v}}/d\approx}3.3}\)

Cross-sectional details of simply-supported beams tested under two-point loading in order to investigate the validity of the hypothesis of “dowel action” [23]; (2T10, two 10 mm dia. high-yield deformed bars; 3T8, three 8 mm dia. high-yield deformed bars; 12R4, twelve 4 mm dia. mild steel smooth bars; fifty 2 mm dia. mild smooth bars)

In accordance with current code provisions, for all beams, the load-carrying capacity corresponding to flexural capacity is significantly larger than the load-carrying capacity corresponding only to the contribution of the auxiliary mechanisms to shear resistance. Moreover, it should be noted that, for the beams in Fig. 1.2, the transverse reinforcement provided is sufficient, in accordance with current code provisions, to safeguard against “shear” types of failure within the portions of the beams where it is placed. Since, therefore, the shear capacity of the portions of the shear span without transverse reinforcement corresponds to a value of the applied load significantly smaller than that leading to flexural failure, it would be expected that the load-carrying capacity of beams A and D in Fig. 1.2a and beams A1, C1, and D1 in Fig. 1.2b corresponded to shear capacity. Yet, the experimental results depicted in Fig. 1.4 show that, in contrast with beams A and A1, which did indeed fail in “shear”, beams D, C1 and D1 exhibited a flexural mode of failure. It may also be noted that the load-deflection curves of beam D and beams C1 and D1 are similar to those of beams B and C and beam B1, respectively, the latter being designed in accordance with current code provisions.

The ductility which characterises the behaviour of beam D1 is directly related to the large width of the cracks forming within the tensile zone as the beam approaches its ultimate-limit state. It is important to note that the width of the inclined crack which formed within the portion of the shear span without shear reinforcement exceeded 1 mm [21]. It has been established experimentally that such a crack width precludes “aggregate interlock” even if there were a shearing movement of the crack interfaces [24]. In conclusion, the test results clearly demonstrate that there can be no contribution to shear capacity through “aggregate interlock” at the interfaces of inclined cracks (a conclusion also corroborated by numerical modelling [25, 26]).

A similar conclusion is drawn for the case of “dowel action” from the results obtained from the tests on the beams of Fig. 1.3 [23]. “Dowel action” is effected by the bending and shear stiffness of a steel bar, and, as a result, it must be affected by the diameter of such bars. A reduction in bar diameter should lead to a considerable reduction of the flexural and transverse stiffnesses and, hence, it is realistic to expect a significant reduction in the contribution of “dowel action” to shear capacity. However, a reduction in the diameter of the bars used as longitudinal reinforcement for beams, such as beams A and A1 in Fig. 1.2, in a manner that maintains the total amount of longitudinal reinforcement essentially constant (see Fig. 1.3), was found to have no effect on the shear capacity of the beams (see Fig. 1.5) [23].

-

(d)

Mechanism of “shear” resistance

The experimental results presented in the preceding section clearly demonstrate that, of the auxiliary mechanisms of shear resistance, only “uncracked” concrete in the compressive zone may contribute to the shear capacity of an RC structural element. The causes for such behaviour may be explained by using the results obtained from tests on RC T-beams tested under six-point loading (see Fig. 1.6) [27]. Figure 1.7 shows typical crack patterns of such an RC T-beam for values of the applied load equal to 63 and 135 kN. The former of the applied values is nearly double the value predicted by current codes, while the latter is about four times larger than the code prediction of load-carrying capacity.

Design details and loading arrangement of RC T-beam tested under six-point loading [27]

It is interesting to note in the figure that, in spite of the considerable increase of the applied load, the crack patterns differ only in the width of the inclined crack, which attained a value exceeding 3 mm for the case of the higher load [27]. As for the case of beam D1 in Fig. 1.2b, such a crack width precludes “aggregate interlock” along the crack surfaces [24]. However, the main characteristic of the crack pattern—in both cases—is the deep penetration of the inclined crack into the compressive zone which, at the cross-section including the tip of the inclined crack, has a depth of merely 10 mm. For the two values of the applied load considered above, the shear force acting at this cross-section attains values of 10.5 and 25 kN, respectively. As the size of the crack width precludes any contribution to shear capacity other than that of the compressive zone, the mean values of shear stress corresponding to the above values of shear force are 5.25 and 12.5 MPa, respectively. These values of shear stresses are indicative of the magnitude of the tensile stresses expected, in accordance with current design methods, to develop within the compressive zone in the region of the tip of the deep inclined crack. As the magnitude of the tensile stresses exceeds by a large margin the tensile strength (f t ) of concrete (f t ≈ 0.1 × f c = 0.1 × 32 = 3.2 MPa, where f c = 32 MPa the compressive strength of the concrete used for manufacturing the beams), failure should have occurred well before the lower of the values of the applied shear force considered above was attained.

However, current design methods ignore the existence of a triaxial compressive-stress field, within the region between the extreme compressive fibre and the location of the tip of the deepest inclined crack, which, as discussed later, is inevitably caused by the local volume dilation of concrete under the large longitudinal compressive stresses developing on account of bending at a cross-section with a small depth of the compressive zone [1, 20]. The existence of such a triaxial compressive stress state counteracts the tensile stresses due to the shear forces acting in the same region in the manner schematically described in Fig. 1.8; hence, the stress conditions remain compressive in this region, in spite of the presence of exceedingly high shear stresses. However, as the applied load further increases, the shear force eventually obtains a value for which the tensile stresses developing cannot be counteracted by the compressive stresses due to volume dilation and, thus, failure occurs in the manner described in Sect. 1.3.

1.2.3 Inclined Strut

The inclined struts of the truss model of an RC structural element at its ultimate-limit state forms within the web of the structural element where concrete is characterised by the presence of densely spaced inclined cracks; such cracks, for the case of cyclic/earthquake loading intersect one another as shown in Fig. 1.9 [28]. Moreover, a prerequisite for the formation of inclined struts is that concrete retains a sufficient amount of its compressive strength, after the onset of “visible” cracking, which would allow it to sustain the compressive forces assumed to be carried by the truss model’s struts. As it is well known that the behaviour of “cracked” concrete is described by post-peak stress (σ)-strain (ε) characteristics [20], the above prerequisite is considered to be satisfied if concrete is characterised by strain-softening behaviour once the peak-load level is exceeded.

However, it is well known that the σ − ε curves describing the behaviour of concrete in compression are usually obtained from tests on concrete specimens, such as, for example, cylinders or prisms, loaded through steel plates. Inevitably, therefore, the difference in the mechanical properties between concrete and steel causes the development of frictional forces at the specimen/platen interfaces. These forces restrain the lateral expansion of concrete at the end zones of the specimen, and, hence, modify the intended stress conditions in these zones.

Although one of the main objectives of current test techniques is the elimination of the above frictional forces, this objective has proved impossible to achieve to date [29]. Figure 1.10 shows characteristic stress-strain curves established from tests on cylinders in uniaxial compression by using various techniques for reducing friction at the specimen/platen interfaces [30]. From the figure, it can be seen that, in contrast with the ascending branch, which is essentially independent of the technique used to reduce friction, the slope of the descending branch increases with the efficiency of the friction-reducing medium employed. In fact, the increase in slope is such that it leads to the conclusion that, if it were possible to eliminate friction entirely the descending branch would have a 90° slope, which is indicative of an immediate and complete loss of load-carrying capacity as soon as the peak stress is attained.

Axial stress-axial strain curves obtained from uniaxial-compression tests on concrete cylinders using various means to reduce friction at the specimen-loading platen interfaces [30]

It appears from the above, therefore, that the “softening” branch of a stress-strain curve essentially describes the interaction between specimen and loading platens and not, as widely considered concrete behaviour. Concrete behaviour is described only by the ascending branch of an experimentally established σ − ε curve, and loss of load-carrying capacity occurs in a brittle manner. (A similar conclusion may also be drawn from the experimental information presented in Ref. [31], as well as that obtained from an international co-operative project organised by RILEM TC-148SSC [29].) Due to its brittle mode of failure, therefore, concrete does not have sufficient residual strength that would allow the formation of inclined cracks within an RC structural element’s web.

1.3 Flexural Capacity

Amongst the assumptions underlying the assessment of flexural capacity is that the behaviour of concrete in the compressive zone is adequately described by σ − ε curves, comprising both an ascending and a gradually descending branch, established from tests on cylinders or prisms in uniaxial compression. This assumption, on the one hand attributes the strains, of the order of 0.35 %, measured at the extreme compressive fibre of an RC beam at its ultimate-limit state in flexure, to the strain-softening behaviour of concrete, and, on the other hand, implies that the effect of small transverse stresses, which invariably develop in any RC structural element, on concrete behaviour is insignificant.

And yet, this assumption is not valid on both counts: as discussed in the preceding section, concrete is, in nature, a brittle, rather than a softening, material, whereas the small transverse stresses have a considerable effect on concrete behaviour [20]. In fact, Fig. 1.11 shows that a transverse stress of the order of 0.1 f c may either increase load-carrying capacity by over 50 %, when compressive, or reduce it to zero, when tensile.

Further to the discussion of the post-peak behaviour of concrete in Sect. 1.2.3, the irrelevance of strain softening to structural-concrete behaviour may be demonstrated by reference to the results obtained from tests on three simply-supported RC beams, with a rectangular cross-section, subjected to two-point loading [32]. The details of a typical beam are shown in Fig. 1.12, with the central portion in pure flexure constituting one-third of the span. Besides the load measurement, the deformational response was recorded by using 20 mm long electrical resistance strain gauges and linear-voltage differential transducers (LVDTs). The strain gauges were placed on the top and side surfaces of the beams in the longitudinal and transverse directions as shown in Fig. 1.13. The figure also indicates the position of the LVDTs which were used to measure deflection at mid-span and at the loaded cross-sections.

RC beams under two-point loading: design details [32]

RC beams under two-point loading: beam instrumentation [32]

Of the results obtained from the above tests, Fig. 1.14 shows the relationships between longitudinal (i.e. along the beam axis) and transverse (i.e. across the beam width) strains, as measured on the top surface of the girders, throughout the middle third of the beam span. Also plotted in the figure is the relationship between longitudinal and transverse strains derived from σ − ε relationships (shown in Fig. 1.15) established from tests on cylinders under uniaxial compression [1]. Now, if the relationships of Fig. 1.15 were to provide a realistic description of concrete behaviour in the compressive zone of the beams tested in flexure, then one would expect the relationships between longitudinal and transverse strains measured on the top surface of the beams to be compatible with their counterparts established from the cylinder test. Furthermore, longitudinal macrocracks ought to appear on the top surface of the beams, as indicated in Fig. 1.15, where typical crack patterns of axially-compressed concrete cylinders around (B–C) and beyond (C–D) the peak-load level are depicted schematically. It is apparent from Fig. 1.14, however, that, for the region of the cross-section including a primary flexural crack, only the portion of the deformational relationship based on the uniaxial cylinder test up to a level (B) close to the peak-load level can provide a realistic description of the behaviour of concrete in the compressive zone of the beam. Beyond this level, there is a dramatic deviation of the cylinder strains from the beam relationships. Not only does such behaviour support the view that the post-peak branch of the deformational response of the cylinder in compression does not describe material response but, more importantly, it clearly proves that, while uniaxial σ − ε data may be useful prior to the attainment of the peak stress, they are insufficient to describe the behaviour of concrete in the compressive zone once this maximum-stress level is approached.

RC beams under two-point loading: stress–strain relationships and crack patterns under uniaxial compression for the concrete mix used [1]

An indication of the causes of behaviour described by the relationships of Fig. 1.14 may be seen by reference to Fig. 1.16, which shows the change in shape of the transverse deformation profile of the top surface of one of the beams (but typical for all beams tested) with load increasing to failure [32]. The characteristic feature of these profiles is that, within the ‘critical’ central portion of the beam, they exhibit large local tensile strain concentrations which develop in the compressive regions of the cross-sections where primary flexural cracks, that eventually cause collapse, occur. Such a large and sudden increase in transverse expansion near the ultimate load is indicative of volume dilation and shows quite clearly that, even in the absence of stirrups, a triaxial state of stress can be developed in localised regions within the compressive zone. The local transverse expansion is restrained by concrete in adjacent regions (as indicated by the resultant compression forces F in Fig. 1.16), a restraint that has been found to be equivalent to at least 10 % of f c [32]; hence, as Fig. 1.11 indicates, the compressive region in the plane of the main flexural crack is afforded a considerable increase in strength so that failure does not initiate there. Concurrently, the expanding concrete induces tensile stresses in the adjacent regions (these are indicated by the resultant tension forces F and F/2 in Fig. 1.16), and this gives rise to a compression/tension state of stress. Such a stress state reduces the strength of concrete in the longitudinal direction, and collapse occurs as a result of horizontal splitting of the compressive zone in regions between primary flexural cracks, as illustrated schematically in Fig. 1.17. Concrete crushing, which is widely considered to be the cause of flexural failure, thus appears to be a post-failure phenomenon that occurs in the compression zone of cross-sections containing a primary flexural crack due to loss of restraint previously provided by the adjacent concrete.

Typical failure mode of RC beams in flexure: a a schematic representation of crack pattern at collapse; b observed failure of test beams following collapse [32]

It may be concluded from the above, therefore, that the large compressive and tensile strains measured on the top surface of the central portion of the beams should be attributed to a multiaxial rather than a uniaxial state of stress. A further indication that these large strains cannot be due to post-ultimate σ − ε characteristics is the lack of any visible longitudinal cracking on the top surface for load levels even near the load-carrying capacity of the beams. As shown in Fig. 1.15, such cracks characterise the post-ultimate strength behaviour of concrete under compressive states of stress.

1.4 Critical Regions

In regions—referred to in Codes [3, 4] as critical regions—of linear RC elements (such as, for example, beams and columns) where a large bending moment and a large shear force develop concurrently, current code provisions for earthquake-resistant design specify an amount of stirrup reinforcement significantly larger than that safeguarding against shear types of failure. This additional stirrup reinforcement is placed in order to provide confinement to concrete within the compressive zone, which restrains its lateral expansion and increases its strength and ductility in the longitudinal direction, thus leading to a significant improvement of the ductility of the RC member.

However, there has been published experimental evidence [6, 9], in recent years, obtained from tests on beam/column elements exhibiting points of contraflexure, which shows that there are cases for which the additional amount of transverse reinforcement may cause a brittle type of failure, rather than safeguard ductile structural behaviour. Such types of failure, which are characterised by the presence of inclined cracks penetrating deeply into the compressive zone of the critical regions, are indicated in Fig. 1.18 (top) and (bottom). The former of these figures shows the mode of failure of a simply-supported beam with an overhang, reinforced in compliance with EC2/EC8, which was subjected to sequential point loading; a point load was first applied at mid span and increased to a value close, but, not beyond, the beam flexural capacity, where it was maintained constant while a second point load was applied in the overhang and increased monotonically to failure [9]. The latter figure shows the mode of failure of the critical region of the portion of a two-span linear element, also designed in compliance with EC2/EC8, modelling to a 1:3 scale a column between consecutive floor levels [6]. This element was subjected to the action of a constant axial load combined with lateral cyclic loading.

The causes of the above brittle types of failure are considered to relate to the experimental information used by the code methods for assessing the transverse reinforcement required for the critical regions of RC beam-like elements. This experimental information was obtained from uniaxial-compression tests on concrete cylinders or prisms subject to lateral confinement through the use of spiral or stirrup reinforcement. And yet, unlike the cylinders or prisms which are subjected to uniaxial compression, the critical regions of beam-like elements are subject to the combined action of a bending moment and a shear force which causes the formation of inclined cracks. Such cracks penetrate deeply into the compressive zone and have the tendency to extend near horizontally (in the direction of the maximum principal compressive stress) due to the presence of large, near vertical tensile stress concentrations which develop in the region of the crack tips [18, 19]. The magnitude of these tensile stresses is such that their resultant may eliminate the vertical component of the confinement considered to be provided by the stirrups, and, therefore, the expansion of concrete in the vertical direction may remain essentially unaffected by the stirrups. Moreover, the presence of significant inclined cracking reduces the strength of concrete within the element’s web, and this reduction, combined with the larger transverse compression applied to concrete by the excess amount of stirrup reinforcement anchored to it, may lead to premature failure within the critical regions [1].

1.5 Points of Contraflexure

During the 7/9/1999 Athens earthquake many reinforced concrete (RC) structures [particularly those lacking symmetric plan configuration and containing a “soft” ground-floor storey (pilotis)] suffered unexpected brittle damage that cannot be attributed to either non-compliance with code provisions or defective work [5]. Examples of this damage are presented in Fig. 1.19, which shows the unexpected failure suffered by vertical structural members at the location of the point of contraflexure usually situated within the mid-height region of the member. This type of failure, which has been reproduced under controlled laboratory conditions, is not taken into consideration by the methods adopted by current codes of practice for the design of RC structures (invariably based on the truss analogy (TA) [10, 11]) [2–4].

Examples of damage suffered by columns of RC structures during the 1999 Athens earthquake [5]

The relevant feature of the modes of failure shown in Fig. 1.19 is not the occurrence of criss-crossing diagonal cracking, but the location of the region where cracking occurred. In all cases, the location of failure was found to lie within the region of the point of contraflexure. Such an event could not be simply attributed to coincidence, since, as discussed above, this location of failure repeatedly characterises a large number of structural elements that suffered the above type of damage during the 7/9/99 earthquake in Athens.

It appears realistic to seek the causes of the above mode of failure in the form that the truss model takes in the region of the point of contraflexure. Figure 1.20 depicts a truss modelling a vertical linear structural element subjected at its end-faces to the combined action of an axial force (N), a bending moment (M) and a shear force (V). The figure shows that the vertical element is modelled by means of two antisymmetric trusses, connected in the region of the location of the point of inflection with a transverse tie. The shaded portions of the trusses represent the flow of the compressive stresses from the cross-sections with zero bending moment to the cross-sections with a near-constant depth of compressive zone.

The above model implies that in the region of the point of inflection concrete is locally subjected to a direct transverse tensile, rather than shear, force causing failure when the tensile strength of the material is exceeded. This type of failure may be prevented by specifying stirrups, forming the transverse tie indicated in Fig. 1.20, in a quantity sufficient to sustain the tensile force in excess of that which can be sustained by concrete alone, and this being a simple strength requirement. Here, it is essential to appreciate that contraflexure (i.e. points of inflection) is associated with the kind of response exhibited by a beam-column in a building subjected to lateral sway (but applicable to any beam or frame with a point of inflection) as shown in Fig. 1.21: it is evident that the tie is needed to prevent separation of the two ends of the constituent members.

Now, designing the reinforcement in the region of the point of inflection for shear, rather than direct tension, leads to a considerable underestimate of the quantity of stirrups required to prevent failure. This is because the provisions of the code adopted for shear design allow, not only for the contribution to shear resistance of the auxiliary mechanisms discussed in Sect. 1.2.2, but, also, for the beneficial effect of the axial force. And yet, within an essentially tensile stress field the above auxiliary mechanisms cannot develop, whereas it is well established that the presence of an axial force is likely to reduce the tensile strength of concrete in the orthogonal direction.

1.6 Effects on Structural Behaviour

From the discussion in the preceding sections, it becomes clear that the conflict between the concepts underlying current code design methods and the causes of structural behaviour mainly relates with the ultimate limit state of a structure or structural member. It should be expected, therefore, that were there any effects of this conflict on the observed behaviour of a structural element designed by using code methods, these should be sought in situations where the structural element reaches its ultimate limit state. In real structures, such situations may arise in cases of overload; alternatively, they may be reproduced through the testing of model elements under controlled laboratory conditions.

Although shortcomings of current-code methods such as those described in the preceding section may, to some extent, be counteracted by implementing the code requirements for nominal reinforcement and detailing, there have been some notable structural failures that may have been prevented, had the design methods been based on sound concepts providing a realistic description of concrete behaviour as a material. One such failure is the collapse of the “Sleipner 4” platform in the North Sea at a depth of 40 m, during the sinking operation for positioning it on the seabed at a depth of some 140 m; this has been blamed on the inadequacy of the ACI shear-design provisions [33]. Another has been the collapse of a multilevel car park, in Wolverhampton, U.K., which occurred due to punching of the top level flat slab under dead load only [34]. It has been reported that such premature punching was preceded by loss of bond of the longitudinal reinforcement [35]; loss of bond may lead to a brittle type of failure in the manner discussed in Chap. 2.

Unexpected types of brittle failure often occur in earthquake-stricken regions; typical is the case (discussed in Sect. 1.5) of the significant damage suffered by the vertical elements of RC buildings in the region of points of inflection during the 1999 Athens earthquake [5]. Such damage occurred not only in structures designed to old code provisions, but, also, in structures satisfying the performance requirements of current codes which are widely deemed to safeguard ductile behaviour. In fact, it is interesting to note in Fig. 1.19 that the damage suffered by the “slender” column in Fig. 1.19 (left) was similar not only to that of the “short” column in Fig. 1.19 (middle) (both these columns had been designed to current code provisions), but, also, to that of the “slender” column in Fig. 1.19 (right) which had been designed to older, less stringent code provisions based on the permissible-stress philosophy [5]. This type of damage is a typical example of damage reflecting the lack of a sound theory underlying the methods adopted by current codes for the design of RC structures. Serious doubts regarding the validity of the concepts underlying earthquake-resistant design have already been expressed elsewhere [36–38], whereas a thorough account of failures suffered by RC structures has been the subject of other publications [39].

1.7 Alternative Design Methods

It appears from the above that the time is ripe for considering radical changes in RC design involving the replacement of the concepts underlying the methods currently adopted by codes with new ones compatible with structural concrete behaviour. Such radical changes have already been attempted [1, 40, 41]; as early as the mid-sixties, the shortcomings of the methods adopted by the codes were attributed to the criteria used for the prediction of brittle types of failure [40], which code provisions have always linked with the shear capacity of RC structural elements. In fact, it has been proposed that a more realistic criterion should treat brittle failure as a premature loss of flexural capacity due to the combined action of bending moment and shear force [40]. Not only has such a failure criterion [41] (in a form suitable for practical applications) been developed and incorporated in a design guidance report [42], but, also, it has been employed in practice for the design of original structures such as, for example, the Calgary coliseum [43], the grandstand roof of the rugby stadium at Twickenham, etc. More recently, combined with concepts that allow for a realistic description of concrete behaviour (as established from comprehensive investigations of the fundamental characteristics of the deformational response and failure mechanism of concrete at both the material and structure levels), the above failure criterion led to the development of a unified design method—the method of the compressive-force path—found to consistently satisfy the performance requirements of current codes [1, 20].

Design methods such as those described in Refs. [1, 41, 42] are considered to point towards the orientation that should be given to research efforts, if such efforts are to lead to a significant improvement of the codes of practice for RC design.

1.8 Concluding Remarks

The concepts which form the basis of current codes of practice for the design of RC structures are in conflict with fundamental properties of concrete at both the material and the structure levels.

This conflict is reflected on the premature brittle types of failure unexpectedly suffered by RC structures in situations of overload.

Such types of failure, which have been reproduced under controlled laboratory conditions, may be prevented through the use of alternative design methods that allow for “true” structural-concrete behaviour.

Already published work aiming to developing alternative design methods points towards the type of research required for achieving a significant improvement of the provisions of current codes of practice for the design of RC structures.

References

Kotsovos MD, Pavlovic MN (1999) Ultimate limit-state design of concrete structures: a new approach. Thomas Telford (London), p 164

American Concrete Institute (2002) Building code requirements for structural concrete (ACI 318-02) and commentary (ACI 318R-02)

EN 1992-1, Eurocode 2 (2004) Design of concrete structures—part 1-1: general rules and rules for buildings

EN 1998-1, Eurocode 8 (2004) Design of structures for earthquake resistance—part 1: general rules, seismic actions and rules for buildings

Kotsovos MD, Pavlovic MN (2001) The 7/9/99 Athens earthquake: causes of damage not predicted by structural-concrete design methods. J Struct Eng 79(15):23–29

Kotsovos MD, Baka A, Vougioukas E (2003) Earthquake-resistant design of reinforced-concrete structures: shortcomings of current methods. ACI Struct J 100(1):11–18

Kotsovos GM, Zeris C, Pavlovic MN (2005) Improving RC seismic design through the CFP method. In: Proceedings of ICE, buildings and structures, vol 158(SB5), pp 291–302

Kotsovos GM, Zeris C, Pavlovic MN (2007) Earthquake-resistant design of indeterminate reinforced-concrete slender column elements. Eng Struct 29(2):163–175

Jelic I, Pavlovic MN, Kotsovos MD (2004) Performance of structural-concrete members under sequential loading and exhibiting points of inflection. Comput Concr 1(1):99–113

Ritter W (1899) Die Bauweise Hennebique. Schweisserische Bauzeitung, vol 33, pp 59–61

Morsch E (1902) Versuche uber Schubspannungen in Betoneisentragen. Beton und Eisen, Berlin, vol 2(4), pp 269–274

Barnard PR (1964) Researches into the complete stress-strain curve for concrete. Mag Concr Res 16(49):203–210

Fenwick RC, Paulay T (1968) Mechanisms of shear resistance of concrete beams. J Struct Div. ASCE proceedings, vol 94(ST10), pp 2325–2350

Taylor HPJ (1974) The fundamental behaviour of reinforced concrete beams in bending and shear. Shear in reinforced concrete, ACI publication SP-42, American concrete institute, pp 43–77

Taylor HPJ (1969) Investigation of the dowel shear forces carried by tensile steel in reinforced concrete beams. Technical report 431 (publication 42.431), cement and concrete association, London

Collins MP, Mitchell D (1980) Shear and torsion design of prestressed and non-prestressed concrete beams. Prestressed Concr Inst 25(5):32–100

Schlaich J, Schafer K, Jennewein M (1987) Toward a consistent design of structural concrete. Prestressed Concr Inst 32(3):74–150

Kotsovos MD (1979) Fracture of concrete under generalised stress. Mater Struct RILEM 12(72):151–158

Kotsovos MD, Newman JB (1981) Fracture mechanics and concrete behaviour. Mag Concr Res 33(115):103–112

Kotsovos MD, Pavlovic MN (1995) Structural concrete: finite-element analysis for limit-state design. Thomas Telford, London, p 550

Kotsovos MD (1987) Shear failure of reinforced concrete beams. Eng Struct 9(1):32–38

Kotsovos MD (1987) Shear failure of RC beams: a reappraisal of current concepts. CEB Bull 178/179:103–111

Jelic I, Pavlovic MN, Kotsovos MD (1999) A study of dowel action in reinforced concrete beams. Mag Concr Res 51(2):131–141

Reinhardt HW, Walraven JC (1982) Cracks in concrete subject to shear. J Struct Div, proceedings of the ASCE 108(ST1):207–224

Kotsovos MD (1984) Behaviour of reinforced concrete beams with a shear span to depth ratio between 1.0 and 2.5. ACI J. Proceedings 81(3):279–286. May–June 1984

Kotsovos MD (1986) Behaviour of RC beams with shear span to depth ratios greater than 2.5. ACI J. Proceedings 83(115):1026–1034. Nov–Dec 1986

Kotsovos MD, Bobrowski J, Eibl J (1987) Behaviour of RC T-beams in shear. Struct Eng 65B(1):1–9

Kotsovos G (2005) Improving RC seismic design through the CFP method. In: Proceedings of the institution of civil engineers, structures and buildings, vol 158(SB5), pp 291–302. Oct 2005

van Mier JGM, Shah SP, Arnaud M, Balayssac JP, Bascoul A, Choi S, Dasenbrock D, Ferrara G, French C, Gobbi ME, Karihaloo BL, Konig G, Kotsovos MD, Labuz J, Lange-Kornbak D, Markeset G, Pavlovic MN, Simsch G, Thienel K-C, Turatsinze A, Ulmer U, van Geel HJGM, van Vliet MRA, Zissopoulos D (1997) Strain-softening of concrete in uniaxial compression. Mater Struct RILEM 30(198):195–209. (Report of the round robin test carried out by RILEM TC 198-SSC: test methods for the strain-softening response of concrete.)

Kotsovos MD (1983) Effect of testing techniques on the post-ultimate behaviour of concrete in compression. Mater Struct RILEM 16(91):3–12

Van Mier JGM (1986) Multiaxial strain-softening of concrete. Mater Struct RILEM 19(111):179–200

Kotsovos MD (1982) A fundamental explanation of the behaviour of reinforced concrete beams in flexure based on the properties of concrete under multiaxial stress. Mater Struct RILEM 15(90):529–537

Collins MP, Vecchio FJ, Selby RG, Gupta PR (1997) The failure of an offshore platform. Concr Int 28–34. Aug 1997

Shock collapse sparks lift slab fears and safety experts urge car park review (1997) New civil engineer, pp 3–4. 27 Mar/3 April 1997

Kellermann JF (1997) Riper row car park, Wolverhampton: results of the investigation. Conference on concrete car parks: design and maintenance issues held at the Cavendish Centre, London, 29 Sept 1997, British Cement Association

Priestley MJN (1997) Myths and fallacies in earthquake engineering: conflicts between design and reality. Concr Int 54–63. Feb 1997

Hansford M (2002) Seismic codes oversimplified and unsafe. New civil engineer, 8/15 Aug 2002, p 28. (Report on seminar by V. Bertero organised jointly by ICE society for earthquake and civil engineering dynamics and Wessex institute of technology

Priestley MJN Revisiting myths and fallacies in earthquake engineering, the ninth Mallet-Milne lecture organised by the society for earthquake and civil engineering dynamics

Carpaer KL (1998) Current structural safety topics in North America. Struct Eng 76(12):233–239

Kani GNJ (1964) The riddle of shear and its solution. J Am Concr Inst Proc 61(4):441–467

Bobrowski J, Bardham-Roy BK (1969) A method of calculating the ultimate strength of reinforced and prestressed concrete beams in combined flexure and shear. Struct Eng 47(5):197–209

The Institution of Structural Engineers (1978) Design and detailing of concrete structures for fire resistance, interim guidance by a joint committee of the institution of structural engineers and the concrete society, April 1978, p 59

Il≪Saddledome≫: stadio olimpico del ghiaccio a Calgary (Canada) (1984) Progetto strutturale: Jan Bobrowski and Partners Ltd. Progetto architettonico: Graham McCourt. L’ Industria Italiana del Cemento. No. 5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Kotsovos, M.D. (2014). Reappraisal of Concepts Underlying Reinforced-Concrete Design. In: Compressive Force-Path Method. Engineering Materials. Springer, Cham. https://doi.org/10.1007/978-3-319-00488-4_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-00488-4_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-00487-7

Online ISBN: 978-3-319-00488-4

eBook Packages: EngineeringEngineering (R0)