Abstract

There are growing concerns for the remaining service life of concrete infrastructure under normal service conditions and the structural resilience under extreme climate events. Therefore, advanced and reliable computational tools are required for the assessment of existing structures’ condition, and the estimation of their serviceability. Traditionally, advanced structural simulations are conducted using nonlinear Finite Element Analysis (FEA) that exhibits major drawbacks hindering its application for large-scale simulations, particularly in real-time or nearly real-time. Those drawbacks include high computational time/power, convergence problems, and limitations in modelling the actual (than ideal or theoretical) condition of the structure and, more importantly, model updating as the structure deteriorates or undergoes changes. This paper proposes a closed-loop and computationally affordable cyber-physical solution for comprehensive structural health monitoring. The proposed approach is based on real-time prediction of the structural response for a concrete structure by creating, updating, validating, and maintaining a Structural Digital Twin founded on the framework of Physics-Informed Neural Networks (PINNs). PINN-powered structural digital twins present a novel simulation scheme that combines the physics-based models (represented by differential equations governing the structural behavior) with data-driven models (trained on the response data collected through sensors) into a robust computational model. The proposed method, implemented in a lab-scale case study, is presented in detail, and future areas of research will be discussed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Structural Digital Twin

- Physics Informed Neural Networks

- Structural Health Monitoring

- Climate Change

- Infrastructure Resilience

- Bridge Structures

1 Introduction

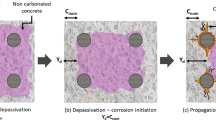

Despite significant advances in Structural Health Monitoring (SHM), over the past five decades, bridge condition assessment still largely consists of intrusive, time-consuming, and in some cases, subjective measures that may compromise road accessibility and safety for passengers and inspectors. Corrosion of steel reinforcement and subsequent cracking are the most common cause of deterioration and failure in reinforced concrete structure (B. Bell, 2004). Wang et al. analyzed the impacts of climate change and showed that the deterioration of concrete structures is expected to become even worse than today, and extreme climatic events are to be expected more often and with more severity (Wang et al., 2010). In addition, the demand for load-carrying capacity often increases over time, e.g., due to the use of heavier lorries for timber transportation in BC, Canada. Thus, there is a growing need for reliable methods to assess the load-carrying capacity and remaining service life of existing structures as well as the structural resilience of the transport network under extreme climate conditions accounting for different climate change scenarios. This has been addressed in a number of multinational research projects; e.g. (Duracrete, 2000), Sustainable Bridges (Skanska Sverige, 2007), and Contecvet (Rodriguez & Andrade, 2001).

Today, the anticipated environmental and economic cost of replacing the aging infrastructure stock is immense and defies true quantification. In the case of bridge infrastructure, the best estimates for the replacement of the 50,000 bridges in Canada, the 600,000 bridges in the US, and the one million bridges in Europe are €10B, €300B, and €400B, respectively. National budget priorities across the continents do not allow this level of funding; consequently, many bridges will be left structurally deficient and vulnerable to extreme climatic events if not properly maintained. The decision on which bridges to repair and the time frame thereof requires frequent inspections and analyses that can provide an accurate assessment of the current condition. Despite the technological developments and SHM advancements in recent years, this process is still costly, prone to human errors, and at times exhibits inconsistent assessments across multiple agencies. For example, in the case of the I-5 bridge collapse in Mount Vernon, WA, the failing span had not been listed by the state as “structurally deficient”, nonetheless it was encountered as “functionally obsolete” by another National Bridge Inventory database (Associated Press & KING 5 News, 2013). This contradictory verdict is evidence of the lack of systematic and consistent assessment and performance prediction of aging bridges. This is significant since as of 2019, more than 12% of all bridges in Canada are classified as structurally poor and/or very poor (Federation of Canadian Municipalities, 2019).

1.1 What is a Structural Digital Twin (SDT)

A Structural Digital Twin (SDT) is a living structural simulation that brings all the data and models related to a building or an infrastructure together and updates itself, automatically or semi-automatically, using multiple data and analysis sources to represent its physical counterpart. The SDT, maintained throughout the life cycle of an asset and easily accessible at any time, can accordingly provide the infrastructure owner/users with early insights into potential risks to mobility induced by climatic events, heavy vehicle loads and even aging of transport infrastructure. While the Digital Twin is initially created upon the geometrical specifications, material properties, and boundary conditions (BC), it continuously updates itself using the sensor data collected from the physical twin, thus creating a closed-loop cyber-physical system for comprehensive structural health monitoring as conceptualized in Fig. 1.

1.2 Components of an SDT Solution

This repository of data and models for transport infrastructures, integral to a comprehensive Structural Health Monitoring (SHM) strategy, consists of a closed loop cyber-physical system that is based on the optimized/customized integration of three technical platforms as shown by Fig. 2.

(1) Autonomous Data Collection – Data is the backbone of SDT and includes two main aspects; the physical asset’s geometrical, mechanical and physical properties; and the external factors including service loads, environmental and climatic conditions, etc. The autonomous inspection methods of collecting data include aerial/remote sensing and terrestrial sensing to minimize intrusion on the transport flow; cover large inspection areas in a minimum of time; provide access to hard-to-reach areas; and minimize exposure to safety hazards for both inspectors and users.

(2) Automated Data Interpretation – Collected data requires to be processed to provide insight about the physical asset. For bridge digital twins, the most important example is vision-based analytics combined with Machine Learning, to detect and quantify geometrical and visual anomalies in 3D both on the surface (cracking and spalling) and sub-surface of reinforced concrete infrastructure.

(3) Advanced Structural Simulation – A bridge SDT is meant to provide a computational platform for monitoring and simulating structural behavior of the infrastructure. Therefore, data analytics should support an ever-up-to-date mathematical model of the structure having roots in its physics, which can reflect the actual (than theoretical) behavior of the structure under various loading and environmental conditions. In this regard, advanced nonlinear structural analysis combining physics-based principles and data-driven analytics can provide a reliable prediction of the performance and the remaining service life of infrastructure under normal service conditions and the structural resilience under extreme climate events.

Over the recent years, significant progress has been made towards the first two components, i.e., autonomous data collection and automated data interpretation platforms. Given these advancements, condition assessment data of cracking and spalling from existing structures are to be collected more accurately and more frequently than ever before. Such a digital repository of 4D (3D + time) condition assessment data may leverage updating leaps in structural digital twin models only if they are coupled with advanced structural simulations. However, Advanced Structural Simulation has only made marginal improvements over the past two decades. In particular, in the advent of big data and Artificial Intelligence (AI), conventional methods of structural analysis fail to incorporate data-driven techniques to better present the structural performance of infrastructures.

Accordingly, in this paper, after a brief introduction of the advancements in the first two components, we will focus on the techniques available to address structural simulation through the big data collected from various SHM sources, as well as the physics of the structural behavior.

2 Autonomous Data Collection and Interpretation

A wide range of technologies is available to capture the data of physical infrastructure. They can be classified under categories; firstly the reality capturing methods to extract the geometry such as digital photogrammetry, LiDaR-based (Light Detection and Ranging) point clouds, digital images, scan to BIM, etc.; secondly, condition assessment through UAV (and UGV) based imaging, point clouds, Ground infrared (IR) cameras, Ground Penetrating Radar (GPR), 3D laser scanning, acoustic and vibration-based methods, etc.; thirdly, the SHM such as strain sensors, vibration sensors, tilt sensors, piezometers, etc.; and fourthly, other external information such as traffic loads, climatic data, river flow data, etc.

Advanced data analysis methods can then process the collected data into information about the structure condition and most importantly, capture the changes (in mechanical and/or structural conditions) as the structure proceeds into later phases of its lifecycle. As an example, Waldäng instrumented a drone with a scanner operated by a tablet mounted on the backside of the scanner. High-definition 2D images and 3D point cloud data were extracted and used to develop crack detection methods through Machine Learning (Waldäng, 2021). As shown in Fig. 3, Luo and Guo developed an AI-enhanced crack detection capable of recognizing and extracting cracks from concrete structures’ photos (Luo & Guo, 2021). Their algorithm consists of classification and segmentation, achieved by two convolutional neural networks (CNNs). They trained their CNN with 30,000 training images and reached an accuracy of 97% and an F1 score of 0.96 on test set images. The combination of the classification and segmentation neural networks achieves an image-based crack detection method with high efficiency and accuracy.

AI-enhanced crack detection method proposed by (Luo & Guo, 2021)

Data extracted from the physical structure and processed through advanced data mining methods result in detailed and ever-up-to-date information about the physical asset. Such information must be then reflected back into the digital twin automatically (or semi-automatically).

3 Advanced Structural Simulation

SDT uses data analytics to create a virtual model of the physical structure in real-time, which enables monitoring, predicting, and controlling behavior and performance of the physical asset during its lifecycle. Structural simulation involves creating a mathematical or computational representation of the physical structure. The most common practice for structural modeling in SDT is Finite Element (FE) modeling. However, a high-fidelity nonlinear FE model usually has high computational demands and needs accurately known physical properties of the structure. Accordingly, the high computational needs, convergence problems, and limitations in modelling the actual (than ideal or theoretical) condition of the structure, particularly as the structure deteriorates or undergoes changes are among the main limitations of using FE models in SDTs. In response to these gaps, different modeling techniques are investigated here, to offer a proper foundation for a feasible structural simulation, applicable in the context of digital twins.

3.1 Methods of Automated Model Updating

Structural modeling methods to be used in SDT can be broadly categorized as forward and inverse modeling (E. S. Bell et al., 2007). Forward modeling is the process of modeling a physical structure under specific loading or boundary conditions based on a mathematical model given a set of input parameters, such as material properties and geometry. The output of the model can be compared with experimental data to evaluate the accuracy of the model. In contrast, the inverse method involves starting with measured data and working backward to determine the unknown input parameters of a model. Inverse modeling is particularly relevant in the context of SDT because it enables the user to define and update the digital twin based on real-world data. Inverse modeling can be considered essential for identifying and improving the properties and characteristics of the physical entity. By collecting and analyzing real-time data from sensors and other sources, the user can update the digital twin to reflect the current state of the physical entity.

In the field of structural engineering, inverse modeling methods can be classified into two main categories: physics-based and data-driven methods. Physics-based methods assume a model structure, either by a prior parameterized model or without any prior model to create a mathematical interpretable model. Data-driven modeling methods, however, use statistical and machine learning techniques to create models based on available data.

For physics-based modeling, in the first approach, the parameters of a defined model will be updated iteratively by minimizing the error between the model's predictions and the corresponding experimental data, to fully capture the behavior of the physical system under consideration. This can be achieved through optimization or stochastic methods, such as Bayesian updating (Ebrahimian et al., 2017). Kalman filter is another method that is commonly used in this approach (Chatzi & Smyth, 2009; Lei et al., 2019; Yang et al., 2006). These methods can be categorized as model updating techniques. Most of these models use a modified Bouc-Wen equation as given in Eqs. (1–2) for considering the nonlinear hysteresis behavior of the structure. Equation (1) is the equation of motion of a dynamic system and Eq. (2) is the modified Bouc-Wen model exhibiting normal softening, hardening, or quasilinear hysteresis loops (Wen, 1989).

While these methods have demonstrated consistent results in past studies, they exhibit two main disadvantages. First, most of these methods are associated with FE models which still suffer from the drawbacks listed earlier. Second, model uncertainties are not implicitly considered by these systems. Two types of nonlinear model uncertainties raise from incorrect physical assumption (including actual boundary conditions, material inhomogeneity, cracked sections, etc.) and physical model limitations (such as the interaction between non-structural and structural components), which is not typically included in a FE model.

The other method of physics-based modeling tries to find differential equations governing the structural behavior of the system and integrate solving them into the structural modeling. This is a comparatively new branch of inverse modeling, and their techniques are referred to as governing equations discovery/approximation methods (Brunton et al., 2016; Champion et al., 2019). The main problem with these methods is that they are highly dependent on data and require big volumes of data to achieve convergence. Moreover, in the past experiments they did not exhibit proper result for multi-degree of freedom problems and highly nonlinear domains (Lai et al., 2021).

Data-driven approach is another technique where a surrogate model is trained using the SHM data. However, the effectiveness of data-driven modeling techniques is only as good as the quantity and quality of the available data. Furthermore, the lack of generalizability can pose a challenge for real-world applications for such methods, as the models may not perform well under new or unseen conditions. Additionally, data-driven models, too, typically require a large amount of data for convergence (Sadeghi Eshkevari et al., 2021).

Figure 4 summarizes different inverse methods and shows their input and output characteristics. As seen in the figure, all these methods take measured data (acquired from the sensory networks) as input and predict the structural responses as output. Physics-based methods, however, are further capable of providing information on the system’s structural properties. It is also worth adding that while non-parametrized physics-based methods do not require theoretical apriori knowledge of the system, they are less robust than the prior parametrized techniques as their single source of prediction is inferences based on the observed data.

Physics-informed machine learning aims to overcome challenges of previous methods by integrating data-driven methods with the known physics of the system that is being modeled. This enhances the data-driven methods while leveraging the prior physic information of domain. There is a significant amount of prior knowledge related to modeling of physical phenomena that is being ignored in stand-alone machine learning methods. Physics-informed machine learning allows incorporating fundamental physical laws and domain knowledge into machine learning techniques to enhance the performance of the learning algorithm. Additionally, the use of physics-informed machine learning is crucial in situations where there is not enough data available to solve complex problems or the data is noisy, but partial knowledge of the physic is known (Karniadakis et al., 2021). Physics-Informed Neural Networks (PINNs) are also more efficient in higher-dimensional settings compared to classical methods like FEM (Grossmann et al., 2023).

Incorporating prior knowledge based on physics into machine learning algorithms is a relatively new line of research. Owhadi (2015) introduced a novel approach for solving numerical homogenization problems by formulating them as Bayesian inference problems using a given partial differential equation (PDE). Later on, for inferring solutions of time-dependent and nonlinear PDE, prior PDE of the problem was encoded into Gaussian process regression (Maziar Raissi et al., 2018). The work was later extended to the context of system identification and PDE discovery (Maziar Raissi & Karniadakis, 2018). However, these studies have a few limitations. First, due to the Bayesian nature of Gaussian process, prior assumptions are necessary, which can cause robustness and brittleness issues in nonlinear problems, which means the model will fail to generalize to new and unseen data if the data distribution or characteristics differ from the training data. Second, linearization is required for nonlinear terms in time, which can reduce the accuracy in highly nonlinear problems and limit the applicability in the continuous time domain. To overcome these limitations. M. Raissi et al., (2019) took the advantage of artificial neural networks’ capabilities as a function approximator and introduced physics-informed neural network (PINN). To better clarify the concepts behind PINNs and to put them in a perspective versus FEM, Table 1 provides a comparison between PINNs and FEM.

3.2 Physics-Informed Neural Network Formulation

PINN is a supervised machine learning that enhances its performance by incorporating structured prior knowledge into its architecture. This knowledge is encoded into the learning algorithm through a residual term added to the loss function, which acts as a regularization agent to limit the range of possible solutions and improve accuracy. By integrating the physical laws that govern the observed data such as partial differential equation into the algorithm, the PINN can quickly converge to the correct solution. The general form of the partial differential equation representing the physical behavior of the system can be considered as:

where \({u}_{t}\) is a given function, \(u\left(t,x\right)\) is the solution and \(\mathcal{L}\left[\cdot \right]\) is a nonlinear differential operator. Given the limited measurements of the system’s behavior, the goal is to inference a data-driven solution for this differential equation (Eq. 4). In other words, knowing the model parameters, the neural network is being trained to find the solution of the system, \(u\left(t,x\right)\). This simulation/solution scheme is integral to PINN-powered structural digital twins.

The PINN model is then trained by minimizing the loss function of the algorithm (MSE–Mean Square Error loss), i.e., the difference between predicted solution \(\widehat{u}\) and true solution as read through the SHM sensory data, as well as the deviation from the known physical laws incorporated into the neural network architecture as additional loss terms. If we define \(f\left(t,x\right)\) as the differential equation with the estimated result \(\widehat{u}\). Then, the loss function, MSE, is defined as:

where \({MSE}_{u}\) refers to training data for the Neural Network portion of the calculation (see the left side network in Fig. 5) and is calculated as:

and \({MSE}_{f}\) is a penalizing term that constrains the space of admissible solutions, calculated as:

Here, \(\left\{{t}_{u},{x}_{u},u\right\}\) denote the initial and boundary training data on \(\widehat{u}\left(t,x\right)\) and \(\left\{{t}_{f},{x}_{f}\right\}\) specify the residual training points in the space-time domain for \(f\left(t,x\right)\) called collocation points.

PINNs can be trained using data from sensors (such as accelerometers, deflectometers, inclinometers, strain gauges, etc.) measuring the response of the structure to external loads. PINNs serve as learners of the governing dynamics of the systems, rather than a simple mapping between input and output relationship. It lends itself for reuse in prediction given new initial conditions or new driving forces that are different to the ones used for training. As a simple static model, using displacement data obtained from a fibre-optic sensor network installed on experimental beam, the deflection of beam at sensor and non-sensor location can be modeled.

4 PINN Implementation

To implementation PINN for a structural problem and to demonstration PINN-powered solutions for structural digital Twin, a simply supported beam and a cantilever beam are selected as examples, mostly to explain the details of the PINN solution. Nevertheless, these beams are broadly used in various engineering applications such as railway tracks and bridges. Static Euler-Bernoulli equation is used to model the beam’s deflection behavior along its length, which is a fourth order differential equation (Bauchau & Craig, 2009; Gregory et al., 2019):

\(E\) and \(I\) are the elastic modules and second moment of inertia, respectively, which are considered as constant for simplification. \(p(x)\) is the distributed load.

4.1 Model Development

Figure 5 depicts the PINN structure employed to solve the Euler-Bernoulli beam equation, with the neural network on the left side serving as a function approximator for the differential equation solution. The right-hand side represents the residual of the differential equation, which is obtained by applying the chain rule to the neural network, through backpropagation, and incorporating the PDE into the algorithm's architecture.

Two different beams and loading conditions (distributed and point load) are examined as depicted in Fig. 6. To simplify the analysis, the EI values, and the length for both cases are assumed to be equal and are taken as 1 kN/m2 and 1 m, respectively. The load applied uniformly along the beam is 0.1 kN/m, while the load applied at a single point is 1 kN. This simplification is only to explain the method and does not violate the validity of the argument.

The python library ‘DeepXDE’ (Lu et al., 2019) is implemented for solving the equation (Eq. 8). The modeling and training processes are identical for both problems. First, the differential equation is defined using automatic differentiation by TensorFlow library. Then boundary conditions and geometry of the problem are defined. A 20 × 3 layers neural network is defined to approximate the solution. At the end, the model is trained using the Adam optimizer and a learning rate of 0.001, with 20,000 iterations. In Fig. 7 the result is compared with actual solution for both beams.

4.2 Results and Discussion

The results demonstrate the effectiveness of the proposed technique. While two simple static examples are used to check the validity of the PINN and to capture the deflection of beams, the model can also be generalised to more sophisticated cases, such as an entire railway bridge in dynamic domain. Considering factors such as solution time and computational cost, it is important to note that while PINN may not outperform FEM for simple problems, such as the ones used in this study, for more complex structures, FEM can become prohibitively expensive. In such cases, upon the availability of the data, PINN can offer a simulation-based, computationally efficient, and cost-effective alternative by effectively integrating incomplete or noisy information with existing physical knowledge.

The use of PINN has shown promising results, with limited data as input. Unlike traditional model updating approaches, PINN not only utilizes observed data to directly improve the physics-based model but also leverages the model to guide the inferred posterior from unmeasured regions of the structural domain. This is valuable as, typically, only specific points on a structure are monitored to observe its behavior to avoid difficult or expensive monitoring systems across the entire domain of the structure in real life (Sazonov et al., 2004). More importantly, it shows the capability of PINN for implementing the real boundary conditions (e.g. partial fixity or deteriorated structure/connections) as an input and solve the problem for the entire domain. Also, PINN has demonstrated strong performance in dealing with noisy data (M. Raissi et al., 2019), which is a common issue for problems that rely on experimental data obtained from sensors. In contrast, FEM updating techniques heavily rely on the accuracy of input data.

5 Conclusions

This paper introduced the concept of Structural Digital Twins, with a specific emphasis on bridge infrastructure systems. While the introduced and applied methodology are not new, the novelty of this study lies with introducing a framework a closed-loop and computationally affordable cyber-physical framework in the context of SDT. Three main components of SDT were identified as Autonomous Data Collection; Automated Data Interpretation; and Advanced Structural Simulation. It was argued that advanced structural simulation requires computational methods that not only have their roots in the system’s physical behavior, but have the capacity of predicting the actual (than ideal or theoretical) structural system’s responses, based on the data collected and interpreted automatically. We discussed that the traditionally used methods for this purpose, i.e., Finite Element Analyses, have their limitations, and introduced Physics Informed Neural Networks as an alternative to overcome the limitations. Two simple examples were presented to show how PINN can be trained based on limited number of inputs (from the actual structure’s boundary condition) to predict the behavior of a beam with different support and loading conditions. The method introduced simplifies the incorporation of measured data obtained from structures into a physics-based model. In addition to its application to elastic beams, this methodology holds promise for the analysis of more complex structures, such as bridges, by accommodating nonlinearity, varying geometries, load scenarios and so on. Future investigations will (a) study the influence of “noise” in training data, (b) deploy real data collected from more complex structural systems to train PINNs, and (c) compare PINN performance versus FEM solutions in a systematic manner.

References

Associated Press, & KING 5 News: I-5 bridge collapse captured on security video. Washington News (2013)

Bauchau, O.A., Craig, J.I.: Euler-Bernoulli beam theory. In: Bauchau, O.A., Craig, J.I. (eds.) Structural Analysis. Solid Mechanics and Its Applications, vol. 163, pp. 173–221. Springer, Dordrecht (2009). https://doi.org/10.1007/978-90-481-2516-6_5

Bell, B.: Sustainable Bridges-Assessment for Future Traffic Demands and Longer Lives (2004)

Bell, E.S., Sanayei, M., Javdekar, C.N., Slavsky, E.: Multiresponse parameter estimation for finite-element model updating using nondestructive test data. J. Struct. Eng. 133(8), 1067–1079 (2007). https://doi.org/10.1061/(ASCE)0733-9445(2007)133:8(1067)

Brunton, S.L., Proctor, J.L., Kutz, J.N.: Discovering governing equations from data by sparse identification of nonlinear dynamical systems. Proc. Natl. Acad. Sci. 113(15), 3932–3937 (2016). https://doi.org/10.1073/pnas.1517384113

Champion, K., Lusch, B., Nathan Kutz, J., Brunton, S.L.: Data-driven discovery of coordinates and governing equations. Proc. Natl. Acad. Sci. U.S.A. 116(45), 22445–22451 (2019). https://doi.org/10.1073/pnas.1906995116

Chatzi, E.N., Smyth, A.W.: The unscented Kalman filter and particle filter methods for nonlinear structural system identification with non-collocated heterogeneous sensing. Struct. Control. Health Monit.16(1), 99–123 (2009). https://doi.org/10.1002/stc.290

Duracrete: General guidelines for durability design and redesign. I. Concrete (2000). https://books.google.com/books/about/General_Guidelines_for_Durability_Design.html?id=CIOwOwAACAAJ

Ebrahimian, H., Astroza, R., Conte, J.P., de Callafon, R.A.: Nonlinear finite element model updating for damage identification of civil structures using batch Bayesian estimation. Mech. Syst. Sig. Process. 84, 194–222 (2017). https://doi.org/10.1016/j.ymssp.2016.02.002

Federation of Canadian Municipalities: The 2019 Canada Infrastructure Report Card (2019)

Gregory, A., Lau, F.D.-H., Girolami, M., Butler, L.J., Elshafie, M.Z.E.B.: The synthesis of data from instrumented structures and physics-based models via Gaussian processes. J. Comput. Phys. 392, 248–265 (2019). https://doi.org/10.1016/j.jcp.2019.04.065

Grossmann, T.G., Komorowska, U.J., Latz, J., Schönlieb, C.-B.: Can physics-informed neural networks beat the finite element method? (2023)

Karniadakis, G.E., Kevrekidis, I.G., Lu, L., Perdikaris, P., Wang, S., Yang, L.: Physics-informed machine learning. Nat. Rev. Phys. 3(6), 422–440 (2021). https://doi.org/10.1038/s42254-021-00314-5

Lai, Z., Mylonas, C., Nagarajaiah, S., Chatzi, E.: Structural identification with physics-informed neural ordinary differential equations. J. Sound Vib.Vib. 508, 116196 (2021). https://doi.org/10.1016/j.jsv.2021.116196

Lei, Y., Xia, D., Erazo, K., Nagarajaiah, S.: A novel unscented Kalman filter for recursive state-input-system identification of nonlinear systems. Mech. Syst. Sig. Process. 127, 120–135 (2019). https://doi.org/10.1016/j.ymssp.2019.03.013

Lu, L., Meng, X., Mao, Z., Karniadakis, G.E.: DeepXDE: a deep learning library for solving differential equations. SIAM Rev. 663, 208–228 (2019). https://doi.org/10.1137/19M1274067

Luo, X., Guo, J.: AI-enhanced Algorithm for Structural Health Monitoring - An Image-based Concrete Crack Detection Method Using Convolutional Neural Networks [Chalmers University of Technology] (2021). https://hdl.handle.net/20.500.12380/303880

Raissi, M., Karniadakis, G.E.: Hidden physics models: machine learning of nonlinear partial differential equations. J. Comput. Phys. 357, 125–141 (2018). https://doi.org/10.1016/j.jcp.2017.11.039

Raissi, M., Perdikaris, P., Karniadakis, G.E.: Numerical Gaussian processes for time-dependent and nonlinear partial differential equations. SIAM J. Sci. Comput.Comput. 40(1), A172–A198 (2018). https://doi.org/10.1137/17M1120762

Raissi, M., Perdikaris, P., Karniadakis, G.E.: Physics-informed neural networks: a deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 378, 686–707 (2019). https://doi.org/10.1016/j.jcp.2018.10.045

Rodriguez, J., Andrade, C.: CONTECVET - A validated Users Manual for assessing the residual service life of concrete structures. SW (2001)

Eshkevari, S.S., Takáč, M., Pakzad, S.N., Jahani, M.: DynNet: physics-based neural architecture design for nonlinear structural response modeling and prediction. Eng. Struct.Struct. 229, 111582 (2021). https://doi.org/10.1016/j.engstruct.2020.111582

Sazonov, E., Janoyan, K., Jha, R.: Wireless intelligent sensor network for autonomous structural health monitoring. Proc. SPIE 5384, 305 (2004). https://doi.org/10.1117/12.540048

Skanska Sverige: Sustainable Bridges: Assessment for future traffic demands and longer lives (SUSTAINABLES BRIDGES) | SUSTAINABLE BRIDGES Project | Fact Sheet | FP6 | CORDIS | European Commission (2007). https://cordis.europa.eu/project/id/1653

Waldäng, H.: Annotated image database of cracked/uncracked concrete - Enabling AI to recognize cracks in concrete structures. Chalmers University of Technology (2021). https://hdl.handle.net/20.500.12380/304025

Wang, C., Nguyen, X., Stewart, M., Syme, M.G., Leitch, M.: Analysis of climate change impacts on the deterioration of concrete infrastructure–synthesis report (2010)

Wen, Y.K.: Methods of random vibration for inelastic structures. Appl. Mech. Rev. 42(2), 39–52 (1989). https://doi.org/10.1115/1.3152420

Yang, J.N., Lin, S., Huang, H., Zhou, L.: An adaptive extended Kalman filter for structural damage identification. Struct. Control. Health Monit.13(4), 849–867 (2006). https://doi.org/10.1002/stc.84

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Radbakhsh, S.H., Nik-Bakht, M., Zandi, K. (2024). Structural Digital Twin of Concrete Infrastructure Powered with Physics-Informed Neural Networks. In: Banthia, N., Soleimani-Dashtaki, S., Mindess, S. (eds) Smart & Sustainable Infrastructure: Building a Greener Tomorrow. ISSSI 2023. RILEM Bookseries, vol 48. Springer, Cham. https://doi.org/10.1007/978-3-031-53389-1_97

Download citation

DOI: https://doi.org/10.1007/978-3-031-53389-1_97

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-53388-4

Online ISBN: 978-3-031-53389-1

eBook Packages: EngineeringEngineering (R0)