Abstract

This study investigates the thermal performance of hempcrete, for use as the building envelope in masonry walls. Three samples of hemp hurds were sourced from Canadian harvests and a fourth from France. Each hemp hurds sample was cut to a different particle size distribution, and then incorporated at 5 binder-to-hemp ratios. Portland cement Type GU and hydrated lime were used in equal amounts to form the binder. The resulting mixtures were first tested for thermal conductivity and specific heat capacity. The experimental findings were then incorporated into an ANSYS based model, to predict the thermal energy stored and lost by each mixture when used as a building envelope for a masonry wall. The results show that while smaller hemp particles favour greater volume of interface, larger particles lead to higher porosity. In turn, they result in lower thermal conductivity, lighter hempcrete and hence higher thermal capacitance. Together, these properties result in higher thermal energy storage. The optimum thermal performance was obtained with hemp particles under 3 mm wide and shorter than 10 mm.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Hempcrete is a sustainable alternative to conventional concrete, developed in France in the 1990s using bio-aggregates called hemp hurds, which are extracted from the stalks of the Cannabis plant. Such concrete shows a superior thermal performance with low thermal conductivity and high specific heat capacity, which makes hempcrete a suitable candidate for building envelopes in masonry. This material was approved in Canada in 2012, as a construction material. This triggered the need to optimize its components for thermal and mechanical properties with Canadian hemp. Haika and colleagues [1] conducted measurements on the energy usage of different building materials such as lime hempcrete, hollow concrete blocks, and expanded polystyrene. The findings revealed a significant decrease in overall energy consumption, with heating and cooling needs being 90% lower compared to hollow concrete blocks. Concrete has been utilized as a thermal energy storage (TES) medium in various applications, serving to store thermal energy within solar energy plants. Specifically, concrete subjected to thermal cycles has been employed as a form of thermal energy storage (TES) [2, 3]. In order to support this particular application, it is essential for the heat capacity and thermal conductivity to exhibit significantly higher values. This is necessary to prolong the duration and charging time, particularly during periods of low solar radiation. Arnaud and Gourlay [4] discovered that increasing the size of hemp particles resulted in a relatively lower density compared to finer hurds. This was due to the particles’ increased porosity, leading to lower mechanical properties observed after a 28-day period. Brzyski et al. [5] conducted an experiment where they produced lime hempcrete using both fine and coarse hemp sizes. The researchers observed that the inclusion of coarse particles resulted in a slight reduction in density and thermal conductivity. The presence of fine hemp shiv in the concrete led to a slight decrease (approximately 3%) in both density and thermal conductivity compared to the coarse shives [6]. This can be attributed to the fibers filling the pores, thereby reducing the overall porosity of the material [7, 8]. The specific heat capacity of the concrete containing fine hemp particles exhibited a significant increase, reaching approximately 20%. This phenomenon appears to be attributed to the presence of porosity within the material. Brzyski et al. [9] discovered that fine hemp shivs exhibited comparable density and porosity to the coarse particles. However, the thermal conductivity and diffusivity of the coarse shivs were slightly lower, approximately 6%, compared to the fine ones. Surprisingly, the specific heat capacity remained nearly unchanged between the two particle sizes. Bruijn and Johansson [10] conducted a study and observed that augmenting the amount of hemp hurds led to a reduction in both density (approximately 25%) and thermal conductivity (around 10%). This decrease was attributed to the increase in porosity and the presence of lighter components within the material. In contrast, the specific heat capacity experienced a decline of approximately 15%. Madrid et al. [11] demonstrated that with an increase in the content of sawdust in concrete, there was a noticeable decrease in both density and thermal conductivity. This reduction was attributed to the presence of voids and lighter materials within the mixture. Conversely, the specific heat capacity experienced an increase due to the same reasons. As well, the high thermal storage capacity associated with wood raise the specific heat capacity. The aim of this study is to evaluate the effect of varying hemp size and hemp content on hempcrete for thermal capacitance and thermal energy storage, for use in building envelopes.

2 Material and Sample Preparation

Hempcrete was produced in this study using four hemp sizes and cement-lime binders. Three of the samples were sourced locally from Canadian harvests, while one sample was obtained from France. The hemp hurds samples are shown in Fig. 1. Portland cement Type GU and a hydrated lime were used in equal amounts (50% C + 50% Li) as the binder, along with each hemp hurds variant to produce the hempcrete samples for thermal testing.

The sizes of hemp hurds used in this study was evaluated by an imaging technique and was classified as shown in Table 1. Based on their particle size distribution, the hemp hurd samples are named S1, S2, S4 and S3, in ascending order, based on about 80% of the hemp particles in each variant. Here, CA represents a Canadian hemp, while FR refers to the sample sourced from France.

As shown in Table 2, in all, nine mixtures were prepared for hempcrete. This constitutes the four different hemp sources and five hemp contents to be evaluated experimentally for heat capacity and numerically for storing and lost thermal energy. The mixtures were cast into disc samples, as shown in Fig. 2, to obtain two identical halves for a thermal test. All samples were cured for 7-days in a humidity room, and then dried in an oven at 60 °C for 24 h before testing.

3 Thermal Testing

The thermal test was conducted using TPS 1500 for measuring thermal conductivity and specific heat capacity with transient plane source method (TPS) or hot disk method (HDM) according to ISO 22007-2 [12]. As shown in Fig. 3, the primary components of the setup consist of the TPS-1500, PC, and a hot disc probe. The hot disc probe is composed of a thin, electrically conducting nickel double spiral that is placed horizontally between two insulating layers made of Kapton. It is embedded between the two halves of the specimen being tested.

4 Thermal Model

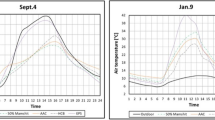

In a recently published study, the authors built a transient thermal model to evaluate different concrete types as building envelopes in masonry walls [13]. The boundary conditions were defined for both wall surface allowing for both convection and radiation. The thermal properties of the target concrete were inserted to run the model. Thus, the model evaluates the thermal energy stored and that which is lost from the wall system (Fig. 4).

Boundary conditions of transient thermal model using Ansys [13]

5 Results and Discussion

In this study two variables were investigated for their thermal performance including hemp size and hemp content for optimizing hempcrete. The hempcrete samples were tested for thermal properties using the transient plane source technique. The thermal conductivity and specific heat capacity were evaluated in dry conditions. The experimental data was then used as input to a thermal model using Ansys Fluent. This model was developed to evaluate the thermal performance of such concrete to be a building envelope by assessing the thermal energy that is stored in the wall and that which is lost from the system.

5.1 Effect of Hemp Size

As shown in Fig. 5, the mass of hempcrete samples varies with the change in the hemp particle size. This may be ascribed to porosity, particle size, shape and arrangement. The particle size as listed in order, S1, S2, S4 and S3 moves from the largest to smallest. Although the size of S4 and S3 are largely different (both in width and in length), the mass of the samples so produced were the same. The lightest of the samples was mixture S2. Therefore, large hemp particles (width >3 mm and length >10 mm) result in lighter hempcrete, as compared to finer hemp. The latter, which contains lengthy flaky shape, leading to highly porous structure [4]. The specific heat capacity of S4 is about 10% higher than the other three hemp sizes, namely S1, S2 and S3. The latter three showed similar, average specific heat capacity, Cp, as shown in Fig. 5. The well-graded hemp size of S4 increased the heat storing capability due to well compacted hemp particles and the high heat capacity of hemp than air voids. The values of thermal capacitance are affected simultaneously by both the mass and Cp of the hempcrete. The highest thermal capacitance is about 120J/K for S4, while the lowest was observed by S2. Therefore, S4 shows the highest stored thermal energy, compared to other hemp particle size. This may be ascribed to the high content of hemp in the hempcrete mixture, due to the well compacted hemp particles. These experimental results were fed as input to the Ansys model to predict the stored and lost thermal energy in the walls, for application in building envelopes. The stored energy for the four hemp sizes varied between 80–88% over 24 h, with about 12–20% of energy lost to the exteriors. The mixture S2, showed the least lost thermal energy over 24 h, which showed the least thermal capacitance. This may be ascribed to low thermal conductivity of S2 samples that hinder the rate of energy loss. Note that the stored thermal energy, Qs, registered a rise while the loss, Ql, was seen to drop. Similarly, mixture S4 witnessed the highest thermal capacitance and displayed the highest thermal energy loss. The high thermal capacitance and stored energy may be attributed to the high thermal conductivity for this hempcrete series. The other two series (containing hemp samples S1 and S3) behaved similarly, due to their similar thermal capacitance and thermal conductivity. In sum, the thermal energy that is stored by the hempcrete depends upon both thermal capacitance and thermal conductivity. Here, the thermal conductivity affects the charging time and the thermal capacitance reflects the storing capability. Thus, for better thermal performance, low thermal conductivity with high thermal capacitance is preferable. In the present study, this was obtained with hemp sample S2.

5.2 Effect of Hemp Content

Hemp hurd particles are porous and flaky, see Fig. 6. An increase in the hemp hurd content led to a drop in the weight of the dry samples. This was due to an increase in the porosity arising from an increase in the hemp content. So that for an increase in the hemp content from 20–100% by mass of the binder, there was a 60% drop in the weight of the dry sample, as seen from Fig. 7.

As shown in Fig. 7, the specific heat capacity, Cp, decreases with an increase in the content of hemp hurds (~10%). This may be attributed to an increase in the porosity, particularly raising the mean pore size. The thermal energy stored is therefore higher. However, this advantage may be reversed if the mixture is over-compacted. The lower values for 20% hemp content might be ascribed to lower content of hemp and porosity due to high availability of binder. The thermal capacitance of hempcrete samples with increasing hemp content reduced significantly following the same trend of mass reduction with about 65%. This is ascribed to the slight variance in Cp values. Numerical results from Ansys suggest that increasing the hemp content increases the stored thermal energy by up to 15%, while at the same time, it decreases the lost energy by up to 45%. Further, the results indicate that a reduction in the thermal capacitance decreased the energy lost, as shown in Fig. 7. However, the thermal conductivity decreases for an increase in the hemp content. That in turn led to a reduced loss in thermal energy. The energy lost was minimal (=14%) when the mass ratio of the hemp to binder was unity.

6 Conclusions

This study examined the effect of hemp size, source and hemp content on the thermal performance of hempcrete. Samples were tested for thermal capacitance and the results were used to predict thermal storage and the energy lost for a model wall using Ansys. The optimal thermo-mechanical performance was seen with Canadian hemp cut shorter than 3 mm in width and 10 mm in length, when incorporated at 40% hurd mass fraction. The following specific conclusions may be drawn:

-

A smaller hemp particle size implies a greater volume of the hurd-paste interface, and thus, lower thermal conductivity. A larger hemp particle size leads to greater porosity and in turn, once again lower thermal conductivity. The optimum range of size was obtained with hemp particles, that were under 3 mm wide and shorter than 10 mm.

-

An increase in the hemp content (to 50% by mass fraction) led to a mass reduction and in turn, to lower thermal capacitance (by 65%) of the resulting hempcrete. On the other hand, there is only a slight drop in the specific heat capacity (<10%) at higher hemp hurd contents. In like manner, the stored thermal energy rose by 15%, while the thermal energy lost dropped by 45%, for that range of hemp content.

-

The thermal energy lost at the model wall as predicted by the numerical study follows the same trend as that of the experimentally obtained thermal capacitance. Well graded hemp hurds led to a denser composite and thus, the highest thermal conductivity. This in turn led to greater loss in the thermal energy.

References

Haik, R., Peled, A., Meir, I.: Thermal performance of alternative binders lime hemp concrete (LHC) building: comparison with conventional building materials. Build. Res. Inf. 49(7), 763–776 (2021)

John, E., Hale, M., Selvam, P.: Concrete as a thermal energy storage medium for thermocline solar energy storage systems. Sol. Energy 96, 194–204 (2013)

Laing, D., Bahl, C., Bauer, T., Fiss, M., Breidenbach, N., Hempel, M.: High-temperature solid-media thermal energy storage for solar thermal power plants. Proc. IEEE, 516–524 (2012)

Arnaud, L., Gourlay, E.: Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 28(1), 50–56 (2012)

Brzyski, P.: The effect of pozzolan addition on the physical and mechanical properties of lime mortar. In: E3S Web of Conferences, pp. 1–8, Solina, Poland (2018)

Gourlay, E., Glé, P., Marceau, S., Foy, C., Moscardelli, S.: Effect of water content on the acoustical and thermal properties of hemp concretes. Constr. Build. Mater. 139, 513–523 (2017)

Stevulova, N., Cigasova, J., Terpakova, E., Junak, J., Sicakova, A., Schwarzova, I.: Properties testing of lightweight composites based on hemp hurds. In: 16th European Conference on Composite Materials, Seville, Spain (2014)

Stevulova, N., Kidalova, L., Junak, J., Cigasova, J., Terpakova, E.: Effect of hemp shive sizes on mechanical properties of lightweight fibrous composites. Procedia Eng. 42, 496–500 (2012)

Brzyski, P., Gładecki, M., Rumińska, M., Pietrak, K., Kubiś, M., Łapka, P.: Influence of hemp shives size on hygro-thermal and mechanical properties of a hemp-lime composite. Materials-MDPI 13(23), 1–17 (2020)

De Bruijn, P., Johansson, P.: Moisture fixation and thermal properties of lime-hemp concrete. Constr. Build. Mater. 47, 1235–1242 (2013)

Madrid, M., Orbe, A., Rojí, E., Cuadrado, J.: The effects of by-products incorporated in low-strength concrete for concrete masonry units. Constr. Build. Mater. 153, 117–128 (2017)

International Standard ISO 22007-2: Plastics-Determination of thermal conductivity and thermal diffusivity (2008)

Qasem, N., Al-Tamimi, A., Bindiganavile, V.: Thermal energy storage and losses in various types of masonry concrete walls. J. Energy Storage 67, 107555 (2023)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Al-Tamimi, A., Bindiganavile, V. (2024). Optimizing Mixture Components, Shiv Size and Content in Hempcrete for Thermal Capacitance. In: Banthia, N., Soleimani-Dashtaki, S., Mindess, S. (eds) Smart & Sustainable Infrastructure: Building a Greener Tomorrow. ISSSI 2023. RILEM Bookseries, vol 48. Springer, Cham. https://doi.org/10.1007/978-3-031-53389-1_58

Download citation

DOI: https://doi.org/10.1007/978-3-031-53389-1_58

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-53388-4

Online ISBN: 978-3-031-53389-1

eBook Packages: EngineeringEngineering (R0)