Abstract

Reactor developers continue to recognize opportunities for further enhancing fast spectrum reactor designs with advanced core materials, but all the material test reactors currently available to the United States are thermal spectrum designs. Fortunately, the Advanced Test Reactor and High Flux Isotope Reactor are versatile high flux facilities where spectral modification strategies can be used to reduce undesirable thermal neutron capture transmutation damage and augment fast flux delivered to specimens. New opportunities to leverage high flux regions and specially designed fast flux boosting experiment configurations can be used to achieve meaningful fast fluences on large specimens in ATR. New optimization potentials can be employed to achieve even higher fluences, albeit for smaller specimens, using thermal neutron filters in HFIR test positions. These capabilities, while not true fast reactors, can provide highly relevant environments for researchers needing to study the effects of fast neutron damage in bulk material specimens.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Nuclear fuel and materials

- Irradiation testing

- Fast neutron irradiation

- Fast reactor cladding

- Fast neutron damage

Introduction

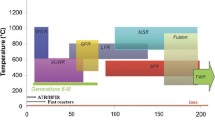

The United States (US) Department of Energy (DOE) is presently supporting research and development programs in pursuit of advanced material technologies for use in nuclear reactors. Projects such as the long running Advanced Fuels Campaign and recently established Innovative Nuclear Materials program have key focus areas on researching in-core materials for application in fast spectrum reactors, or more commonly “fast reactors”. Widespread deployment of fast reactors continues to be a prominent aspiration for advanced nuclear technology developers. Unlike thermal spectrum reactors, fast reactors are designed so that the chain reaction is sustained primarily through fast neutrons. This abundance of fast neutrons can be advantageous for breeding fissile isotopes from fertile materials and splitting minor actinides to significantly reduce the inventory of long-lived radioisotopes in spent fuel. Fast reactors can also be designed to maximize benefits associated with the use of non-hydrogenous coolants such as increased outlet temperature for electrical conversation efficiency (inert gas, liquid metals, molten salts), enhanced power density without the need for high pressurize reactor vessels (liquid metals), and dramatic reduction of corrosion behaviors (inert gas, liquid sodium) [1]. This high quantity of fast neutrons, however, also creates a challenging environment for core materials to endure.

Fast neutrons cause microstructural damage by atom displacement which can cause material swelling and significant changes in physical properties. This effect can be simulated to some degree with ion bombardment, but due to their electrical charge, ions do not penetrate nearly as far into test materials as neutrons. Thus, neutron irradiation of bulk specimens is crucial for understanding the engineering scale behavior of reactor materials. Thermal neutrons are not well suited for the task either as their energy is too low to create significant levels of atom displacement. Thermal neutrons are also more readily adsorbed by materials leading to transmutation (such as helium production in nickel) which can have a dramatic effect on mechanical properties that is not representative of true performance in a fast reactor. Similarly, thermal neutrons are more likely to be absorbed by fissionable isotopes, so they do not penetrate as far into dense fuel materials. This self-shielding effect causes high levels of fission damage in the exterior regions of fissile materials which, once again, is not representative of true fast reactor performance.

Most US fast reactor materials technologies were developed alongside irradiations in sodium fast reactors including the Experimental Breeder Reactor-II and the Fast Flux Test Facility. Both of these facilities were shut down in the mid 1990’s which dramatically hampered subsequent development of fast reactor fuels and materials in the US. A few years after the turn of the millennium, the Fenix reactor (France) was permanently shut down and the Joyo reactor (Japan) entered into an extended non-operational period which has yet to end. There are currently no operating fast spectrum reactors available in the US or in countries where collaborations are politically feasible. Recognizing the need for a fast spectrum test facility, DOE established the Versatile Test Reactor (VTR) project which achieved notable milestones in the process toward its construction [2] but has yet to graduate from the “paper reactor” phase as congressional funding continues to be deferred. Based on the current situation, it appears that a whole generation of nuclear technology developers will have lived out their careers without access to a fast spectrum material test reactor.

Despite the apparent difficulties in constructing new irradiation test facilities, industry-led momentum towards design, licensing, and construction of advanced nuclear demonstration plants is at a remarkably high level, perhaps surpassed only by the first era of nuclear expansion in the 1960’s. Credible companies, with varying levels of financial support from DOE partnerships, cooperate sources, and/or private investments, are all moving forward with detailed plant design, and in some cases siting/licensing, toward construction of first-of-a-kind plants including fast reactors. A unique situation is developing where these plants will be designed to capitalize on historic nuclear material technologies, but where further optimization and advancement of these materials is impeded by the lack of fast neutron irradiation test facilities and difficulties in testing new materials in facilities licensed under frameworks typical of commercial plants.

While this whole situation creates some major quandaries, there are some near term opportunities which, if seized, can still help develop advanced fast reactor materials to a meaningful level of readiness to support their irradiation in these future commercial fast reactors. There are two existing thermal spectrum material test reactors operating in the US which have high flux capabilities and are uniquely adaptable so that experiment configurations can alter neutron energy spectra. These reactors include the Advanced Test Reactor (ATR) [3] and the High Flux Isotope Reactor (HFIR) [4]. ATR and HFIR reside at the Idaho National Laboratory and Oak Ridge National Laboratory, respectively. Both reactors have been operational since the 1960s and are high flux thermal spectrum water-cooled reactors, but configurable experiment positions can be adapted to modify local spectra. When comparing these two reactors, ATR’s strength is a larger core with more real estate for test specimens while HFIR offers superior flux, but for smaller specimens. This study examined past examples and future potentials for spectral modification designs in these reactors including the three options summarized below.

Option 1: ATR, Cd-Baskets in Outboard-A Positions

An established method used at ATR utilizes capsules inside of cadmium (Cd) lined baskets. Cadmium absorbs thermal neutrons more than fast neutrons and thus creates a higher fast-to-thermal neutron ratio. These Cd-baskets are replaced regularly during reactor outages to compensate for cadmium depletion during irradiation. This filtering approach has helped achieve conditions representing fast reactors for fuel pins for numerous tests [5]. In this design, precision-engineered inert gas gaps between specimen and capsule wall help insulate the test material from the cooling water so that the specimen’s nuclear heating causes it to be irradiated at elevated temperature. Various types of material test specimens can be included in this type of capsule for post irradiation examinations such as discs for microstructural characterization, diffusion couples, tensile test specimens, crack test specimens, and cladding tubes. Figure 1 shows a rendering of an example capsule with miniature tensile test specimens. Figure 2 shows renderings of the Cd-basket design.

The Cd-basket design can house multiple test capsules stacked vertically across ATR’s 1.2 m active core height. This approach can be used in numerous test positions in ATR’s neck shim housing (A and H positions) and inner beryllium reflector (B positions). For present purposes the Outboard-A positions are of the greatest interest because they are large enough to house full diameter cladding tubes (representative of sodium fast reactor fuel pins) and exhibit a slightly higher fast flux than other options. Figure 3 shows the location of these test positions in ATR.

The Outboard-A positions in the southwest (SW) lobe of ATR are of particular interest for this study because ATR will begin operating this part of the reactor at higher power (~32 MW lobe power) starting in 2027, based on current plans, in so-called High Temperature Steady State “HTSS cycles”. This new operational plan will also include occasional cycles at ~23 MW SW lobe power (what is currently considered and hereafter referred to as “normal cycles”) and much higher powered ~45–60 MW short duration cycles (referred to as “PALM cycles” for the Powered Axial Locator Mechanism that is often used in these cycles). This future variability in SW lobe power from cycle to cycle will complicate temperature management for fuel-bearing capsules due to their high heating rates and tight tolerance capsule gas gap. This situation could be an opportunity for fast reactor material-only tests to occupy these positions as it should be more tenable for gamma heated structural materials tests. Figure 4 illustrates the difference between ATR current SW lobe operation scheme and that planned for the future with HTSS cycles.

Option 2: ATR, Boosted Fast Flux in a Flux Trap

Cadmium baskets have proven effective in increasing the fast-to-thermal neutron flux ratio, but they do not increase total fast neutron population. In fact, cadmium slightly reduces the total fast flux slightly compared to an unmodified test position. The ideal fast neutron test capability in ATR would also increase fast neutron flux. Past efforts have been undertaken to develop boosted fast flux capabilities where the main principle has been to surround test specimens by booster fuel which captures thermal neutrons, fissions, and emits roughly twice the number of fast neutrons. This method can be used to create a boosted fast flux test position, especially when combined with thermal flux filtering and minimization of moderation (noting that some must be present for heat removal via ATR’s water coolant system). One historic example successfully made use of this principle in ATR’s outer reflector for material irradiations (Flux-Enhanced Large-I [6]) and a similar academic study recently investigated viability of a sodium loop in reflector positions [7], but even with booster fuel these outer reflector positions cannot produce fast neutron populations high enough for fast reactor core material irradiations.

Another concept was investigated at length using this same principle in an inner core flux trap, but the project was never realized as it included the cost of a complex gas loop, qualification of booster fuel specimens at undemonstrated power densities, and challenges in modeling the safety performance with analysis tools of the day [8]. A recent study revived this idea with new computational treatment and showed that such a concept could provide a significant increase in fast flux [9]. As a result, DOE’s Advanced Fuels Campaign began pursuing detailed design of the Boosted Energy Advanced Spectrum Test (BEAST) test capability. The exact deployment schedule for BEAST is presently uncertain as it depends on the timing of program funding and flux trap availability. The BEAST concept has been developed thus far to irradiate fuel pins but has not focused on materials-only specimens. Thus, the present work included assessments of scenarios to determine how to best include material test specimens in BEAST. Figure 5 shows one of the leading BEAST concepts and candidate flux trap locations for its irradiation in ATR. Figure 6 shows a top view of the BEAST design with fuel pins in the peripheral positions and material test specimens in the center hole.

Option 3: HFIR, Peripheral Target Position

HFIR’s single flux trap in the center of the core offers very high fast flux, even approaching that of a true fast reactor (>1E15 n/cm2 sec), but the real challenge for spectral modification in HFIR is taming its extremely high thermal flux (>2E15 n/cm2 sec). The Peripheral Target Positions (PTP) are of greatest interest because they reside closest to the driver fuel ring, and thus have the highest innate fast-to-thermal flux ratio. The key aim of the HFIR PTP option in this study was to assess the impacts and limitations of thermal neutron filtering in these PTP positions. Figure 7 shows the location of these PTP locations.

HFIR core map with PTP locations highlighted [10]

ATR can shuffle fuel assemblies with varying burnups and burnable absorber contents to compensate for differences in lobe power and experiments with negative reactivity worth, such as those with Cd-baskets, in order to operate up to a full 60-day cycle. HFIR’s fuel management scheme is different since its driver fuel loading, which consists of two rings of fuel plates, is entirely replaced every 24-day cycle. Thus, use of experiments with thermal neutron absorbers in the HFIR flux trap must be minimal to maintain cycle length and operational efficiency. A key mission for the irradiation targets in HFIR’s flux trap is production of special isotopes through thermal neutron interactions, which is another reason why experiments with thermal neutron absorbers must be minimal to avoid significant thermal flux reduction in adjacent positions. It is for these reasons that general guidance for use of PTP positions states that experiments containing significant neutron poisons “are discouraged because of their adverse effects on isotope production rates, fuel cycle length, and fuel element power distribution.” [11] While HFIR is uncontested in offering the highest fast flux available in the US, the key questions revolve around how much experimental volume could reasonably be allocated for such experiments without undue impact on HFIR’s other mission priorities.

Neutronic Assessments

This section describes the neutronics work that has been done to assess each of the options previously described. For each of the options, the primary calculational items of interest are the incident neutron flux (both fast and thermal), the total neutron fluence/cumulative atom displacements, helium production rate due to thermal neutron capture in nickel, and the potential impact that the thermal neutron filter material, either cadmium or gadolinium, has on the cycle length of a given reactor’s irradiation cycle. The latter point is important because both cadmium and gadolinium have very high thermal absorption cross sections. This makes them excellent thermal neutron filters, but the removal of those neutrons means that there are fewer thermal neutrons to sustain the chain reaction in the reactor itself. To compensate, the control shims must be removed/rotated out farther than a reactor without a thermal neutron filter installed. This directly impacts how long the reactor can stay critical in a given irradiation cycle. There are many materials that are envisioned for irradiation in these types of irradiations, but Inconel 625 is used as the target material in this assessment for the purposes of determining neutron flux, atom displacements, and helium production. This alloy was selected because its composition is well known and its high nickel content makes it an interesting test case for assessing helium production through thermal neutron capture and transmutation.

Calculations for Option 1 are made using the Common Monte Carlo Design Tool (CMCDT) system as well as the Monte Carlo N-Particle (MCNP) code. The CMCDT system is developed and maintained by the Naval Nuclear Laboratory and MCNP is developed and maintained by Los Alamos National Laboratory. The CMCDT system includes the Monte Carlo code MC21 and the Physics Unified Modeling and Analysis (PUMA) system. MC21 is a highly optimized code for the reactor core physics analysis by supporting several complex physical phenomena, including material depletion, thermal and xenon feedbacks, and photon and neutron heating. PUMA is used to process problem dependent specifications, such as geometry and material data, and create MC21 input files.

Neutronics Assessment of Option 1: ATR, Cd-Baskets in Outboard-A Positions

As previously discussed, the use of a cadmium-lined basket in the ATR is not a novel concept. However, Cd-baskets are not typically used in outboard-A positions due to their impact on the neutron economy in the reactor. In this assessment, a standard Cd-basket filled with Inconel 625 is placed in both outboard-A positions as well as both small-B positions in the southwest (SW) lobe of the ATR to evaluate the maximum impact to cycle length. The diameter of the basket is scaled to fit the diameter of the experiment position and the basket is modeled over the entire 48″ ATR core height. A cross section of the MC21 model can be seen in Fig. 8.

Depletion calculations were made with MC21 to simulate a 40-day HTSS cycle in the ATR with and without the Cd-baskets installed. In both cases, the ATR remained critical for the full 40-day cycle, but the amount of excess reactivity at the end of the cycle was significantly reduced when the Cd-baskets were installed. In practice, the ATR tends to operate with some amount of extra excess reactivity to ensure planned cycle lengths are met, so this change is probably tenable, but more detailed evaluations are needed to assess specific core configurations.

Table 1 shows the peak neutron flux in the Inconel 625 regions, averaged across the 40-day cycle. Results are normalized to a 32 MW SW lobe power, which is the planned nominal power for an HTSS cycle. The total fluence is calculated via time integration of the neutron flux. The end-of-cycle (EOC) total fast fluence is also shown in Table 1.

Neutron fluxes were also calculated in the outer aluminum portion of the Cd-basket to assess the effectiveness of using cadmium as a thermal neutron filter. As can be seen in Table 2, the cadmium sleeve surrounding the Inconel 625 reduces the thermal neutron flux by approximately a factor of ten, while the fast flux remains relatively unchanged.

Due to the ATR being a thermal spectrum reactor, there are more thermal neutrons present in the cadmium-shrouded test specimen than there would be in a true fast spectrum reactor. As such, helium production in nickel via thermal neutron capture in 59Ni and subsequent alpha decay becomes a concern. To estimate the amount of helium present in the Inconel 625 after a 40-day HTSS cycle, the helium production reaction rate from 59Ni was tallied and integrated with respect to time. Table 3 shows the calculated 58Ni concentration, 59Ni concentration, and helium density at the end of a 40-day HTSS cycle in the ATR.

Neutronics Assessment of Option 2: ATR, Boosted Fast Flux in a Flux Trap

Detailed calculations for the BEAST geometry have yet to be performed, but a recent scoping study for fuel specimen testing [10] can provide insight into the capabilities. In that study, seven U–Zr fuel pins were placed inside the BEAST booster element geometry in the south flux trap (SFT) of the ATR and the neutron flux was calculated in the central pin. The BEAST geometry from the study can be seen in Fig. 5. The scoping study also provided atom displacement values for various materials and although Inconel 625 was not explicitly examined, it is approximately 58% nickel so the nickel data from the study is a reasonable approximation. Flux and atom displacement information can be seen in Table 4.

Neutronic Assessment of Option 3: HFIR, Peripheral Target Position

Unlike the ATR, HFIR typically uses gadolinium as a thermal neutron filter, which is functionally very similar to cadmium. In this assessment, a small gadolinium-lined capsule filled with Inconel 625 was created in an MCNP model of HFIR Cycle 400 and placed near the core midplane in each of the PTP positions. Figure 9 shows the geometry for this assessment.

It should be noted that the ATR assessment assumed that the Cd-basket ran the entire fueled height of the core (48″). However, HFIR is a much smaller reactor than the ATR so adding that much thermal neutron filter material would severely impact the results. As such, it was decided to just place a single experiment capsule in the axial center of each PTP position for assessing the impact to cycle length.

Similar to the ATR studies, a depletion was performed to simulate 25 days of HFIR operation at 85 MW. A baseline depletion with no experiment capsules installed was also performed for comparison of cycle length. Due to the compact nature of the HFIR core, the neutron filter material does have a measurable effect on the achievable cycle length. This study estimates that the maximum cycle length of HFIR will be reduced by approximately one day if one gadolinium-lined capsule is placed in each of the six PTP positions. If fewer gadolinium-lined capsules were used, or if they were moved away from HFIR core centerline, the impact to cycle length would likely be reduced. Table 5 shows the peak neutron flux in the Inconel 625 regions, averaged across the 24-day cycle. Results are normalized to an 85 MW core power. Calculated EOC atom displacement values are also shown in Table 5.

Another thing to consider with HFIR is the impact of thermal neutron absorbing materials on surrounding target positions. One of the primary missions for HFIR is isotope production which relies heavily on an abundance of thermal neutrons. Thus, the presence of the thermal neutron absorbing material could have an adverse effect on isotope generation. Figure 10 shows the percent change in thermal flux in the areas directly adjacent to the gadolinium-lined experiment capsules relative to the baseline case with no gadolinium. As can be seen in the figure, the presence of the experiment capsules causes a decrease in thermal neutron flux of 10–20% across the entire flux trap, with local reductions of 20–30% in the test positions directly adjacent to the experiment capsules. The impact that this reduction in thermal flux would have on isotope production rates has yet to be predicted explicitly but is presumed to be untenable for HFIR’s isotope production missions.

Summary and Discussion

In this assessment, three options for fast neutron testing were evaluated for neutronic feasibility. For each of the options, the primary calculational items of interest were the incident neutron flux (both fast and thermal), the total neutron fluence/cumulative atom displacements, helium production rate due to thermal neutron capture in nickel, and the potential impact that the thermal neutron filter material has on the cycle length of a given reactor’s irradiation cycle. A summary of the calculated neutron flux information is shown in Table 6.

Overall, HFIR produces the highest fast neutron flux of all the investigated options, but the amount of test volume that can be utilized without impacting the reactor operating tempo and other mission goals (e.g., isotope production) could be an issue. The size and number of PTP Gd-shielded would need to be sizably reduced to find a viable configuration. Future work should investigate this option. While not assessed explicitly, it should be noted that HFIR PTP irradiations could be very well suited to fast reactor materials which are not so sensitive to spurious thermal neutron effects and can thus be performed without thermal neutron shielding. While this category excludes many alloys of interest since they contain iron and nickel, this category could include materials such as silicon carbide composites.

The BEAST option in ATR provides the next highest fast flux and provides ample space for test specimens but is still under development and its commissioning schedule is uncertain. The outboard-A positions in the ATR provide slightly less fast flux than the BEAST option, but they are readily available now and provide adequate volume for several specimens. Since their test cavities are the same diameter, a practical approach should be considered where capsules begin irradiation in ATR Cd-basket outboard-A positions and are later shuffled into BEAST after it is deployed. This strategy is likely the most expeditious path one can pursue to achieve high fast fluences on significant volumes of test specimens.

References

Jensen CB, Woolstenhulme NE (2021) Irradiation performance: fast reactor fuels, vol 2, sec 5. Encyclopedia of Nuclear Energy, 2021 Elsevier Inc, pp 392–406

Final Versatile Test Reactor Environmental Impact Statement Summary, DOE/EIS-0542, May 2022

Advanced Test Reactor User Guide, September 2021, INL Report INL/EXT-21–64328. https://inldigitallibrary.inl.gov/sites/sti/sti/Sort_53406.pdf

High Flux Isotope Reactor (HFIR) User Guide, Revision 2, November 2015. https://neutrons.ornl.gov/sites/default/files/High%20Flux%20Isotope%20Reactor%20User%20Guide%202.0.pdf

Harp JM, Hayes SL, Medvedev PG, Porter DL, Capriotti L (2017) Testing fast reactor fuels in a thermal reactor: a comparison report. INL/EXT-17–41677, Revision 0, Sep 2017

Ingram FW, Ambrosek RG, Chang GS, Utterbeck DJ (2001) JAPEIC irradiation report for the SFT-1, SFT-2, SFT-3 and FELI-2/3 Specimens. INEEL/EXT-01–01174, Sep 2001

LaBrier DP, Lilley B, Higgins AM, Palmer TS, Marcum WR (2019) Comparison of fuel meat materials for boosted fast flux concepts at the advanced test reactor. Proceedings of Top Fuel 2019 Conference

Boosted Fast Flux Loop Final Report. INL/EXT-09–16413, Sep 2009

Curnutt B, Woolstenhulme N, Nielsen J, Oldham N, Weaver K, Jensen C, Fradeneck A (2022) A neutronics investigation simulating fast reactor environments in the thermal-spectrum advanced test reactor. Nucl Eng Des 387

Daily CR, McDuffee JL (2019) Design studies for the optimization of 238Pu production in NpO2 targets irradiated at the high flux isotope reactor. Nucl Technol. https://doi.org/10.1080/00295450.2019.1674594

In-Vessel Irradiation Experiment Facilities at HFIR. Oak ridge national laboratory, neutron sciences directorate. https://neutrons.ornl.gov/hfir/in-vessel-irradiation#ptp

Woolstenhulme N, Brookman J, Jesse C, Downey C, Murdock C (2023) Scoping study for fast flux testing in the advanced test reactor. INL/RPT-23–72212, April 2023

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Woolstenhulme, N., Worrall, M., Downey, C. (2024). Challenges and Solutions for Fast Neutron Irradiation of Bulk Material Specimens. In: TMS 2024 153rd Annual Meeting & Exhibition Supplemental Proceedings. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50349-8_130

Download citation

DOI: https://doi.org/10.1007/978-3-031-50349-8_130

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50348-1

Online ISBN: 978-3-031-50349-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)