Abstract

Regular quality control in computed tomography (CT) in Bosnia and Herzegovina is made mandatory by national regulations. Conducting daily quality control (QC) tests is the responsibility of radiographers, also known as radiological technologists. Basic tests prescribed by the Ordinance are: Image noise, and CT number uniformity and accuracy. The purpose of this paper is to perform analysis of daily image QC tests and to compare the results of different imaging methods and reconstruction on CT devices, as well as to evaluate more complex image quality parameters, such as noise power spectrum (NPS). This research was conducted as a retrospective-prospective study done within 4-month period at the Clinical center of the University of Sarajevo. A 100 scans with 3 different CT devices were included in the study. Image noise analysis with standard deviation and NPS, as well as CT number uniformity and accuracy was performed using different scanning parameters and reconstructions utilizing the standard water phantom. All results conformed the criteria from regulations. Overall, the results of this study showed stability over time for all image quality tests that indicates the regularity of CT imaging systems. Image quality tests are very important in accepting operation of any CT device after installation and during maintenance to confirm that the image parameters are acceptable by using the phantom. This research can serve as a guideline for advanced daily image quality control tests for computerized tomography devices, using modern image quality metrics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Computed tomography (CT) is a diagnostic imaging modality that uses X-ray beams to create cross-sectional (axial) images of the scanned object. It is common for regular quality control (QC) of CT devices to be required by national regulations. Quality control (QC) is a process that measures the actual quality performance and compares it with existing standards, including actions necessary to maintain or regain compliance with standards. It is a part of the overall quality assurance (QA) process that is designed to verify that structures, systems, and components meet predetermined requirements.

The content of quality assurance (QA) programme, however, can be different. The QC tests are commonly divided according to their frequency and complexity. Daily QC test are commonly performed by radiographers (technologists), while less frequent are preformed by medical physicists.

Results of test must conform to a specific quality standard. These are a set of accepted criteria by which the quality of individual activities can be evaluated. Recommendations for quality standards in diagnostic radiology have been issued by various national and international organizations such as the International Atomic Energy Agency (IAEA), European Commission (EC), Institute of Physics and Engineering in Medicine (IPEM), National Commission for Radio-logical Protection (NCRP) etc.

In Bosnia and Herzegovina, the Regulation on the ionizing radiation protection in medical exposure, issued by the State Regulatory Agency for Radiation and Nuclear Safety of Bosnia and Herzegovina (SRARNS), lay out the mandatory QC tests for majority of radiological equipment. The daily QC in CT relies on measurements made using a cylindrical phantom filled with distilled water. The evaluated parameters are: CT number accuracy, image noise, uniformity, and visibility of artifacts.

CT number (NCT) is defined as:

where K = 1000 HU (Hounsfield units).

The CT number (NCT) has a value of 0 HU for distilled water, whereas for air, the CT number is −1000 HU if attenuation is not taken into account. It should be noted that NCT depends on the X-ray energy (E). Hence, the accuracy of CT numbers depend on tube voltage, filtration, as well as other parameters that affect the energy spectrum in CT.

When homogeneous material is scanned on a CT scanner, examining the CT values for individual pixels in a localized area shows that the CT numbers are not all the same but fluctuate around a mean value. This random variation is known as image noise and is primarily due to the statistical nature of X-ray production and its interaction with matter. In addition, other sources of noise may include structural and electronic noise. The standard deviation (σ) of CT numbers is a measure of the degree of variation of CT values within the region of interest (ROI). It is, therefore, commonly used as a noise descriptor. It is not uncommon to quantify noise using variance, defined as standard deviation squared (σ2).

Uniformity refers to the ability of a CT scanner to assign the same CT number to a water phantom throughout the field of view (FOV). This means that scanning a water-filled phantom should provide a CT image with similar pixel values and a similar amount of noise across the entire visible field. However, in practice, scanning uniform phantoms often shows gradual variations in CT number and noise values in the image.

Artifacts in CT refer to any distortion or error in the CT image that does not represent the true anatomy or pathology being imaged. Artifacts can arise from various sources, including the patient, the scanner, or the reconstruction algorithm used to generate the image. Some common type of CT artifacts that could be observed in water phantom images include: beam hardening artifact, ring artifact, edge artifact, etc. Others might be seen during the examination (i.e. motion artifacts), or when high atomic number materials are imaged (i.e. streak or metal artifacts).

Evaluation of aforementioned parameters should be a common practice in everyday use of CT scanners. However, simple water-filled phantoms can be used for more advanced analysis of CT functions. It relies on evaluation of noise power spectrum (NPS), which, unlike standard deviation, provides additional information about the texture and structure of the noise. For two-dimensional (2D) images, NPS is defined as:

where DFT is a 2D discrete Fourier transform of difference between pixel values Ii(x, y) and average pixel values in ith ROI I¯i. Parameters ax and ay represent pixel size, Nx and Ny ROI dimensions, and N number of evaluated ROIs. Variables fx and fy represent spatial frequencies in x and y dimension. Three-dimensional (3D) NPS, which can be calculated using 3D voxels in CT, is defined in a similar fashion, using 3D discrete Fourier transform.

The objective of this paper is twofold: firstly, to analyze the outcomes of daily image quality assessments carried out on various CT scanners utilizing distinct imaging and reconstruction techniques; and secondly, to demonstrate the application of NPS in routine quality control procedures.

2 Materials and Methods

In this paper we evaluated daily quality control results conducted on three different CT scanners: Toshiba Aqulion PRIME SP, Toshiba Astelion (Toshiba Corporation, Tokyo, Japan) and General Electric Optima 660 (General Electric, Boston, MA, United States). All CT scanners are equipped with proprietary water phantom. However, for the sake of consistency, we used the same Helios QA Phantom (General Electric, Boston, MA, United States). The phantom is filled with distilled water and has a cylindrical shape with a diameter of 20 cm. Use of non-standard phantom on other manufacturers’ CT scanners limited the use of special phantom holder, and narrowed the possibilities of its accurate positioning.

CT scanners are capable of producing images using different scanning and reconstruction parameters. The scanning parameters were consistent, tube voltage (U) was 120 kV, tube current (I) 200 mA, and rotation time (t) 1 s. The minimum slice thickness differs between vendors. The minimum value of slice thickness for Toshiba scanners in 0.5 mm, and 0.625 mm for the evaluated GE scanner.

CT scanners utilize multiple reconstruction kernels (filters) that are tailored to display different structures, for example, a standard kernel for soft tissue display, a high-resolution kernel for bone structure display, a high-resolution kernel for displaying lung parenchyma, and so on [1]. The image itslef can be reconstructed using different algorithms, mostly filtered-back projection (FBP) or iterative reconstruction (IR), as well as newly developed deep learning image reconstruction (DLIR) algorithm [2, 2].

In this study, daily quality controls were performed on computed tomography devices using both the reconstruction kernel for displaying bone structures and the kernel for displaying soft tissue. For Toshiba Aquilion PRIME we used reconstruction filter “FC07-H” and “FC30” for soft tissue and bone, respectively, while “FC08” and “FC30” were used for Toshiba Astelion. In GE scanners, the used soft tissue and bone reconstruction filters were “Standard” and “Boneplus.” Number of evaluated scans is presented in Table 1.

Daily evaluation of image quality can be a formidable task when done on a CT console. Hence, we utilized the well accepted software “IQ Works” that provides automated analysis for the objective assessment and optimisation of image quality. The IQ Works system is capable of quickly creating models of new commercial and customized phantoms and serves as an effective method for objectively evaluating image quality [3, 4].

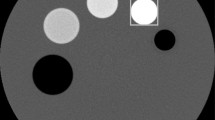

To evaluate basic QC tests (CT number accuracy, image noise, uniformity, visibility of artefacts) the phantom is scanned using the helical mode using the aforementioned scanning protocol, and reconstructed using both soft tissue and bone algorithm. Once the phantom is scanned, DICOM files were transferred to a personal computer with “IQ Works” previously installed. Using the appropriately created “Analysis Tree,” the average CT number is measured in ROIs located in the center of all available slices. Simultaneously, CT numbers were recorded in 12 peripheral ROIs, as shown in Fig. 1a. Together with the average CT numbers in each slice, the software recorded standard deviation, center location, and other relevant parameters. The exported comma-separated value (CSV) file were used for later data analysis.

Figure 1b shows ROI setup for 2D NPS measurements. Six ROIs are positioned at a constant radius of 70 cm from the center of the phantom [4]. The measurements are repeated and averaged across all layers in the scanned volume. The software provides results in graphical form, but also enables numerical evaluation of NPS curves. The dimensions of each individual ROI are 32 pixels × 32 pixels. The typical appearance of the (axial) 2D NPS is that of a torus. Radial averaging of this function, where can give use one dimensional (1D) representation of 2D NPS. On the other hand, “IQ Works” provides two 1D NPS curves as function of frequencies fx and fy.

3 Results

The summary of evaluation of CT numbers in different ROIs is presented in Table 2. It shows mean (x¯) and standard deviation (σ) of CT numbers measured in regions of interest located in the center of water-filled phantom, at a radial distance of 35 mm inner north (IN), inner east (IE), inner south (IS) and inner west (IW), and at a radial distance of 70 mm outer north (ON), outer north-east (ONE), outer east (OE), outer southeast (OSE), outer south (OS), outer southwest (OSW), outer west (OW) and outer northwest (ONW).

Boxplot in Fig. 2 shows CT numbers measured in the water-filled phantom and for different reconstruction kernels at 0.5 mm for 3 examined CT scanners, as well as more detailed obeservation of how CT numbers change with the increase of radial distance from the phantom center in Toshiba Aquilion CT scanner. Results from the same scanner were used to visualize dependence of noise in different regions of interest using soft tissue reconstruction kernel (Fig. 3).

Mean CT number measured in the water-filled phantom and for different reconstruction kernels at 0.5 m slice thickness: a in center, inner and outer north region of interest of Toshiba Aquilion CT scanner the difference is significant between the center and the inner and outer north CT number (Student’s t-test, p < 0.05); and b in center for 3 examined CT scanners. The difference between mean values is significant for Toshiba Astelion CT scanner (Student’s t-test, p – 0.037).

Figure 4 indicates values of uniformity (maximum difference between periphery and center CT numbers) for different CT scanners and reconstruction kernels. Higher values are associated with bone reconstruction kernel.

Evaluation of noise power spectrum (NPS) for x and y axes was conducted on Toshiba Astelion and GE Optima660 CT scanners, for both soft tissue and bone reconstruction kernel (Fig. 5).

ON | ONE | OE | OSE | OS | OSW | OW | ONW | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

\(\overline{x } \sigma \) | \(\overline{x } \sigma \) | \(\overline{x } \sigma \) | \(\overline{x } \sigma \) | \(\overline{x } \sigma \) | \(\overline{x } \sigma \) | \(\overline{x } \sigma \) | \(\overline{x } \sigma \) | |||||||||

\(\to \) | 3.9 | 6.9 | 3.7 | 6.8 | 3.6 | 7.0 | 3.1 | 7.2 | 2.7 | 7.4 | 3.5 | 7.3 | 4.0 | 7.1 | 4.1 | 6.7 |

\(\to \) | 3.9 | 48.8 | 3.7 | 49.6 | 3.7 | 49.7 | 3.4 | 52.0 | 3.6 | 53.5 | 3.8 | 51.8 | 4.0 | 50.3 | 4.1 | 49.1 |

\(\to \) | 0.1 | 11.4 | -0.2 | 11.4 | 0.5 | 11.2 | 0.3 | 12.1 | 0.0 | 13.1 | -0.4 | 13.1 | 0.6 | 12.3 | -0.3 | 11.9 |

\(\to \) | 0.7 | 8.1 | 0.0 | 8.0 | 0.8 | 8.0 | 0.6 | 8.6 | 0.3 | 9.3 | -0.1 | 9.0 | 0.8 | 8.7 | 0.0 | 8.5 |

\(\to \) | 0.2 | 60.0 | -0.3 | 59.3 | 0.4 | 59.6 | 0.5 | 63.7 | 0.6 | 68.2 | -0.5 | 67.3 | 0.5 | 63.8 | -0.4 | 63.0 |

\(\to \) | - 0.7 | 12.1 | -0.8 | 11.8 | -0.8 | 12.0 | -0.3 | 13.0 | -0.4 | 13.4 | -0.1 | 12.9 | -0.3 | 12.0 | -0.6 | 11.9 |

\(\to \) | -0.7 | 46.8 | -0.8 | 47.8 | -0.8 | 48.8 | -0.2 | 52.8 | -0.3 | 53.7 | 0.0 | 50.3 | -0.3 | 47.8 | -0.7 | 47.0 |

4 Discussion

Basic quality control tests described in the paper are based on requirements from the Regulation on Protection from Ionizing Radiation in Medical Exposure, published by the State Regulatory Agency for Radiation and Nuclear Safety in Bosnia and Herzegovina. These tests, however, are based upon criteria from the regulation are based on the Criteria for Acceptability of Medical Radiological Equipment used in Diagnostic Radiology, Nuclear Medicine and Radiotherapy (RP-162) published by European Commission.

One of these tests involves measuring the accuracy of CT numbers. Results obtained from measuring CT numbers on the Toshiba Aqulion device revealed a change in Hounsfield Units (HU) from the center towards the periphery of the image (Fig. 2a) This change is due to beam hardening, where lower-energy radiation is absorbed in the outer part of the phantom, and higher-energy X-rays can penetrate through the central part of the phantom. To correct for this, CT devices apply a gradient filter to produce a uniform image with consistent HU values.

The analysis allowed for monitoring of the actual HU values, which were not exactly equal. However, if there were a significant increase in HU values, this would be visible on the image as an artifact.

The results provide information about the absolute value of CT numbers in distilled water (Fig. 2b). According to the definition of Hounsfield Units (HU), its value is expected to be 0 HU. In the case of the Toshiba Astelion CT device, the mean value of the CT number is 0 HU, while in the case of the Toshiba Aquilion device, this value is 2.5 HU, which raises the question of whether calibration is necessary even though it is still within the regulatory requirements of ±20 HU for water. Our results are consistent with the results of Cropp et al. who measured CT numbers on 36 CT devices and found values less than the acceptable range [5]. It should be noted that in some measurements (1 or 2 days), extreme HU values were observed that significantly deviated from the true values on Toshiba Aquilion and Toshiba Astelion devices. The CT device GE Optima 660 does not show significant deviations from 0 HU, providing a consistent image, and the difference is not significant.

Measurements were repeated in ROIs at different distances from the center. All values are within ±1 HU, which is a very small difference, so we can say that the image is homogeneous in terms of concentric circles for all three CT devices. The difference is more pronounced in the peripheral ROIs, whose values differ from each other compared to the reference northern ROI in the Toshiba Aquilion device. There is a possibility that the presence of the table affects this, i.e. the southern side, which is closer to the table. A similar result is also observed in the analysis of noise, where the results show that the noise is always highest on the southern side of image for all CT devices. This occurs due to the presence of the table, which absorbs some of the ionizing radiation, resulting in a lower dose on that side, and after reconstruction, a higher noise image. Instead of the table, a holder which comes with the CT device can be used. This would be an imperative during service calibrations. In our daily controls, we did not use a stand due to use of a GE phantom for all evaluated scanners. Also, the complicated holder setup process causes valuable time loss for CT scanners with high workload. Although this difference in the southern ROIs is noticeable in our results, it represents a result of the regular operation of the CT device. An example of this difference can be seen in the results shown in Fig. 3.

Uniformity is one of the tests that is intended for radiographers to perform on a daily basis and check whether there is a significant difference between peripheral points and those in the center. In the first part of the discussion, the existence of a growth trend was explained for the Toshiba Aquilion CT device, which can be seen again, i.e. that it has a higher value of non-uniformity compared to other CT devices. It is also noted that for all CT devices, non-uniformity for bone reconstruction kernel is more pronounced, i.e. the difference between the periphery and the center is greater for bone reconstruction compared to soft tissue. The ideal value would be zero, but this is not the case for any CT device. However, the deviation is not large and is within regulatory requirements. Mansour et al. conducted research and obtained an accepted uniformity test, where the mean CT numbers of the periphery and center were measured within ±5 HU (43). However, it is important to note that in this case, we had extreme values.

for the Toshiba Aquilion and GE Optima 660 devices in one case each. Figure 4 shows extreme values that exceed ±8 HU, which is the limit. This suggests the need for the test to be repeated, or CT scanner to be recalibrated. Extreme values may be a result of poor phantom positioning in terms of inclination.

As part of this study, another investigation was conducted, namely the noise power spectrum (NPS). This is a method that is not mentioned in the regulations. It cannot be performed using tools available on the console, so the use of an appropriate software, such as IQWorks, was necessary. It was observed that for soft tissue (Fig. 5a and c), noise is more pronounced at lower frequencies compared to higher ones (Fig. 5b and d). In case of bone reconstruction kernel, where the filter aims to enhance higher frequencies, noise is getting emphasized too. A much lower noise can be observed at lower frequencies and much higher at higher frequencies. This situation was observed for both Toshiba Astelion and GE Optima 660 CT device.

For soft tissue reconstruction kernel, results we got from GE Optima660 were very similar to those of Toshiba Astelion, while it is noticeable that the results for bone are completely different (Fig. 5d). This difference may not have been noticed in the image or by analyzing noise using standard deviation. This test allows us to monitor and compare reconstructions. It is not uncommon for reconstruction filters to change after CT device software updates, so this test would be very significant after equipment supplier services.

Furthermore, in the results of the analysis of the NPS, we observe a difference in the x and y axes. Considering that movement is carried out radially in a circle, noise is not expected to be different on the x and y axes. One of the possible causes of this is the influence of the table. The table is located on the bottom side of the image, so there is a gradient of noise along the y-axis, which we also noticed in the ROI analysis. However, additional analysis is necessary for a more precise evaluation under strictly controlled imaging conditions.

5 Conclusions

An analysis of daily image quality control tests was performed, including noise, uniformity, and accuracy of CT numbers on three different computed tomography devices. The analysis of CT number accuracy allowed us to obtain information about the possible presence of beam hardening artifacts, occurance of extreme values, and any significant deviations, which can indicate the need for calibration. Results of noise analysis suggest that the table could affect image quality by absorbing some of the ionizing radiation. Additionally, the noise power spectrum test showed a difference between measurements at x and y axes. One of the possible reasons was the table’s influence. The use of a phantom holder instead of a table is recommended. All obtained results are within regulatory requirements.

References

K.J. Jang, J.W. Choi, D.C. Kweon, J.W. Lee, E.H. Goo, K.R. Dong, J.S. Lee, G.H Jin, S.B. Seo. J. Korean Phys. Soc. 58 (2011)

Mileto, A., Guimaraes, L.S., McCollough, C.H., Fletcher, J.G., Yu, L.: Radiology 491 (3) (2019)

Greffier, J., et al.: Eur. Radiol. 30, 3951 (2020)

Reilly, A., Thwaites, D.: Intern. J. Rad. Oncol. Biol. Phys. 69(3), S719 (2007)

Ronkainen, A.P., Al-Gburi, A., Liimatainen, T., Matikka, H.: Eur. Arch. Otorhinolaryngol. 279(9), 4407 (2022)

ICRU, Journal of the ICRU 12

Cropp, R.J., Seslija, P., Tso, D., Thakur, Y.: J. Appl. Clin. Med. Phys. 338(6) (2013)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Čorbić, H., Beganović, A., Redžić, M., Šehić, A., Salkica, N., Bajrović, J. (2024). Results of Daily Quality Control in Computed Tomography. In: Badnjević, A., Gurbeta Pokvić, L. (eds) MEDICON’23 and CMBEBIH’23. MEDICON CMBEBIH 2023 2023. IFMBE Proceedings, vol 93. Springer, Cham. https://doi.org/10.1007/978-3-031-49062-0_36

Download citation

DOI: https://doi.org/10.1007/978-3-031-49062-0_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-49061-3

Online ISBN: 978-3-031-49062-0

eBook Packages: EngineeringEngineering (R0)