Abstract

Oleogels (or organogels), which are made with vegetable oils or fish oils and have similar physical properties to conventional solid fats with highly saturated fats, can be incorporated in a variety of foods in place of conventional fats to promote the health benefits of unsaturated fatty acids. Wax-based oleogels (wax oleogels) have some advantages over other kinds of oleogels including low critical gelation concentration, high gel strength, high physical and oxidative stability during storage, relatively low effects on sensory properties of foods, and potential additional health benefits of waxes. Waxes form a dense network of platelet crystals where oil is entrapped. Faster cooling rates during gel formation can produce denser networks of these platelet wax crystals in wax oleogels, which result in increased gel strength. Overall properties of wax oleogels indicate their high potential as alternatives to solid fats rich in saturated fatty acids in food products. This chapter summarizes the recent advances in wax oleogels focusing on the effects of wax types, oils, and polar compounds in oil on the oleogel properties as well as the sensory and other properties of recently developed oleogel-containing food products compared to those with conventional fats.

Mention of trade names or commercial products in this article is solely for the purpose of providing scientific information and does not imply recommendation or endorsement by the USDA. The USDA is an equal opportunity provider and employer.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

6.1 Introduction

Wax-based oleogels (wax oleogel) are one of the most common types of oleogel that have been studied. In a search of the Scopus® database for the keyword “oleogel” within article titles, abstracts, and keywords in December 2022, the keyword “wax” co-occurred with the highest number of research articles (217 articles) followed by “monoglyceride” (71 articles) and “ethylcellulose” (49 articles). Waxes are hydrophobic mixtures composed of long carbon-chain containing components with melting points above room temperature, and they can be derived from crude petroleum oil, or are produced naturally from plants and animals. Waxes are often made up of mixtures of components, the most common of which are long-chain hydrocarbons, wax esters (ester of a fatty alcohol and a fatty acid), free fatty alcohols, free fatty acids, resins, and various other components [1,2,3]. In addition, within each wax component, there may be a diversity of carbon chain lengths, and the wax esters may include di-esters, tri-esters, as well as hydroxy fatty acid moieties [1, 4]. Most oleogel studies have focused on natural waxes derived from plants and animals, and the results of these studies are summarized in this chapter. So far, the most commonly studied waxes have been beeswax, candelilla wax, carnauba wax, rice bran wax, and sunflower wax. Beeswax, candelilla wax, and carnauba wax are diverse mixtures of hydrocarbons, wax esters, fatty acids, and alcohols and other wax components, while the commercially available pure forms of rice bran wax and sunflower wax are mainly (>90% w/w) composed of wax esters with small percentages of other components such as free fatty acids [3, 5, 6].

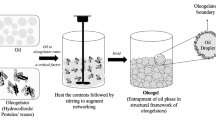

Wax oleogels are usually prepared using the direct method [7, 8]. In this case, waxes are melted completely in an oil, and upon cooling, the waxes crystallize, forming a porous network that traps liquid oil, seemingly through a combination of adhesive and capillary forces, depending on the nature of the oil and the wax types [5, 9]. While most studies have focused on the directly prepared oleogels, a recent study also evaluated rice bran wax oleogels as part of bigel systems, prepared by emulsifying the molten wax oleogel mixtures with a hydrogel to form hydrogel-in-oleogel, oleogel-in-hydrogel, or bicontinuous emulsions [10]. In addition, wax oleogels have been studied in a variety of food products where they are directly substituted for a conventional fat, or are used as the base hard stock to form margarines [11, 12]. Some of the promising results as well as the pitfalls or further work needed for the application of wax oleogels into food products are also summarized in this chapter.

6.2 Advantages of Waxes as Oleogelators

Based on many studies, it can be concluded that natural waxes have many advantages over other oleogelators studied. Natural waxes are inexpensive and nontoxic, and many of them are already listed as generally recognized as safe (GRAS) by the Food and Drug Administration (FDA) for some applications. They can form strong gels at relatively low concentrations, have high physical and oxidative stability, and have high potential for practical application in foods [13,14,15]. Total cholesterol level in rats fed on 0.5–1.0% sunflower wax in their diets was lower than that in rats fed control diets [16], and antilipogenic and antiadipogenic effects were observed with beeswax and carnauba wax in an in vitro study [17] indicating that wax oleogels may have additional health benefits beyond the general health benefits of oleogels by replacing saturated fats with unsaturated fatty acids [18] and controlled release of oil [19,20,21].

Gelation ability of waxes and physical properties of wax oleogels have been reported to be excellent. For example, sunflower wax formed a gel in soybean, almond, canola, corn, grapeseed, safflower, and sunflower oils at concentrations as low as 0.3% (w/w) [22]. Oleogels of virgin olive oil with 7 and 10% carnauba wax had greater firmness than those with monoglyceride [13]. Oleogels formed with rice bran wax in extra virgin olive oil had higher firmness than those with monoglycerides and ethylcellulose, but lower firmness than an oleogel prepared with a mixture of γ-oryzanol and β-sitosterol [23]. Similarly, oleogels prepared with beeswax, sunflower wax, or rice bran wax in sunflower oil had higher G′ and G″ moduli than those prepared with monoglyceride, octadecanol, or stearic acid, but they were not as high as those of oleogels made with a γ-oryzanol and β-sitosterol mixture [24].

Wax oleogels may also have less of an effect on sensory properties and higher physical and oxidative stability than other oleogels. A sensory acceptability test showed that burgers made with beeswax oleogels had no significant effect on any of the sensory parameters evaluated while those made with ethyl cellulose oleogels had negative effects [25]. Öğütcü et al. [14] reported that sunflower wax-fish oil oleogels had higher oxidation stability than monoglyceride oleogels during storage at 4 and 20 °C. Another study found that carnauba wax oleogels had higher physical and oxidative stability than monoglyceride oleogels during storage at 4 and 20 °C [13].

6.3 Limitations of Wax Oleogels

In general, the melting point of wax oleogels is higher than conventional solid fats, which may result in an undesirable waxy mouthcoating when consumed [2, 11, 26]. The melting point of wax oleogels decreases with decreasing amount of wax [11], but the low level of wax will result in decreased firmness. Efforts have been made to lower the melting point of wax oleogels. Among the possible solutions to the problem, binary mixture systems having eutectic properties seemed to be very promising, which will be discussed in Sect. 6.4.2.

Since the strength of wax oleogels is basically attributed to the dense network of thin platelet wax crystals in oil [27, 28], and this network can be easily destroyed by shearing and other mechanical forces, wax oleogels have strong shear sensitivity and weak thixotropic recovery [29]. This property may limit the application of wax oleogels for some food products, and efforts are being made to overcome this limitation. For example, improvements in the elasticity and mechanical recovery after shear of candelilla wax oleogels were observed by adding tripalmitin [30], saturated fat [31], monoglycerides [32], and mixtures of ethylcellulose and monoglycerides [33].

6.4 Properties of Wax Oleogels

6.4.1 Needle Versus Platelet Crystals

Earlier studies typically used polarized light microscopy to investigate the morphology of wax crystals in wax oleogels and reported that waxes formed needle-shaped crystals. However, when needle-shaped crystals were scrutinized with phase-contrast microscopy, scanning electron microscope (SEM), and atomic force microscopy (AFM), it was found that needle-shaped objects under polarized light microscope were actually the edges of platelet-shaped crystals [28]. Figure 6.1a shows a microphotograph of sunflower wax oleogel taken by polarized light microscope, which is very similar to photographs in the previous studies that claimed needle-shaped crystals. However, when the same spot of the sample was observed under a phase-contrast microscope, these needle-shaped objects were found to be the edges of platelet crystals (Fig. 6.1b). SEM and AFM further confirmed platelet crystals in sunflower wax oleogels. Hwang et al. [28] also reported that these platelet crystals formed a dense network, with increased network density observed with higher concentrations of sunflower wax or with faster cooling rates, resulting in higher firmness.

Microphotographs taken by (a) polarized light microscope and (b) phase-contrast microscope at the same spot of the oleogel sample made with 5% sunflower wax in soybean oil. (Reproduced from [28] with permission from Elsevier)

Blake and Marangoni [34] also demonstrated that rice bran wax, sunflower wax, and candelilla wax formed platelet-shaped crystals in peanut oil by cryogenic-SEM (cryo-SEM). Later studies with cryo-SEM further proved that sunflower, rice bran, berry, and candelilla waxes formed platelet-shaped crystals in oleogels [5, 27, 35]. Fig. 6.2 shows cryo-SEM pictures of de-oiled oleogels formed by sunflower, candelilla, and berry waxes. The major components in waxes, wax esters, also formed platelet-shaped crystals [36]. Therefore, polarized light microscopy is not as useful for studying the morphology of wax crystals in wax oleogels, and phase-contrast microscopy and cryo-SEM are recommended.

Cryo-SEM of rice bran oil oleogels with (a) sunflower wax, (b) candelilla wax, and (c) berry wax. (Reproduced from [5] with permission from Elsevier)

6.4.2 Effect of Wax Type

As expected, since different waxes have different compositions [5], their gelation abilities are significantly different. For example, Hwang et al. [2] reported that sunflower wax, candelilla wax, rice bran wax, beeswax, Japan wax, and shellac wax had significantly different minimum gelation concentrations (or critical concentration) ranging from 0.5 to 5% (w/w) in soybean oil. Shi et al. [37] found that beeswax, candelilla wax, and carnauba wax had minimum gelation concentrations of 3, 2, and 4%, respectively, in camellia seed oil.

The minimum gelation concentration of wax is also largely dependent on the origin of wax as well as the detailed composition of individual wax components. For example, rice bran wax samples obtained from three different suppliers had 0.5, 1, and 5% minimum gelation concentrations in soybean oil [2]. This was likely due to differences in the composition and/or purity of waxes. Doan et al. [5] summarized the literature values from composition analyses of seven different waxes, which were shown to differ widely across different studies. For example, four separate studies reported the content of wax esters in carnauba wax to be 75–85 [38], 34.3 [39], 84–85 [40], and 59–62% [3]. The wax ester content in sunflower wax was reported to be 66% by Kanya et al. [41] while another study reported 96–97% wax esters [3]. The detailed composition of natural waxes may depend on growing environments, separation processes, and purification methods.

Wax esters are the major components in many natural waxes. Waxes with a high content of wax esters can produce strong but brittle oleogels [3]. The chain length and structure of wax esters also significantly affected the gelation ability and the properties of oleogels. In a study with wax esters with narrow chain length distributions, it was found that the minimum gelation concentration was lower with longer-chain wax esters [2]. However, in other studies with pure wax esters, lower G′ and G″ moduli were observed with oleogels with longer wax esters [42, 43]. Longer wax esters had higher melting points than shorter wax esters, and their oleogels also had the same trend [2, 42]. Symmetric wax esters (wax esters with the same chain lengths of fatty acid and fatty alcohol moieties) had higher melting points than asymmetric wax esters [42]. Fig. 6.3 shows the melting point of wax esters with different chain lengths and symmetries. Therefore, properties of wax oleogels are affected not only by the amounts of wax esters, but also by their length and structure.

Melting temperature of wax esters with different symmetries and total carbon number (CN). ΔCN = CNFaOH – CNFA, where CNFaOH is the carbon number of the fatty alcohol (FaOH) and CNFA is that of the fatty acid (FA). (x): determined by [42]. (o): determined by other studies. (Reproduced from [42] under open access agreement)

-

Comparisons between waxes: Although as mentioned above, the gelation ability of waxes and properties of wax oleogels can vary with the origin of wax samples, several comparative studies give information on general characteristics of a few waxes on oleogelation. Hwang et al. [11] compared gelation properties of sunflower, rice bran, and candelilla waxes and found that oleogels and margarines made with sunflower wax had higher firmness than those made with rice bran and candelilla waxes. Oil-binding capacities of sunflower wax-hazelnut oil oleogels were higher than carnauba wax oleogels [44]. Oleogel with 1% sunflower wax in peanut oil had the highest oil-binding capacity, followed by candelilla wax and rice bran wax oleogels [9]. Sunflower wax and beeswax at 5% (w/w) were able to form gels in medium-chain triacylglycerols while rapeseed wax did not make a gel at the concentration [45]. Canola oil oleogel with candelilla wax had the highest hardness, followed by carnauba and beeswax oleogels at 10% wax concentration while beeswax oleogel had the highest adhesiveness and cohesiveness [46]. Oleogels formed with 2.5–10% (w/w) candelilla wax in microbial oil or sunflower oil had higher oil-binding capacity than the corresponding carnauba wax oleogels [47]. In another comparative study, oleogel with 10% beeswax in sunflower oil had the highest storage (G′) and loss (G′′) moduli followed by sunflower wax oleogel and then rice bran wax oleogel [24]. Oleogel with 10% monoglyceride was not as firm as wax oleogels in this study. In general, sunflower wax had greater gelation ability and provided stronger oleogels than other waxes.

-

New waxes studied: Some new waxes have recently been studied in efforts to develop oleogels with better properties and to utilize waxes obtained as by-products. Gelation abilities of tea, rapeseed, orange peel, rose, and berry waxes were evaluated in sunflower oil, and their minimum gelation concentrations were determined to be 7.0, 25.0, 15.0, 8.0, and 5.0%, respectively [48]. Minimum gelation concentrations of sorghum waxes from sorghum bran, sorghum distiller’s dried grains with solubles (DDGs), and sorghum kernels were measured to be 6, 6, and 4% in fish oil, respectively [49]. The highest oil-binding capacity was observed with sorghum DDG wax oleogels followed by those with sorghum bran wax and sorghum kernel wax. Propolis wax was also evaluated as oleogelators in canola, sesame, sunflower, and flaxseed oils, and it was found that this wax could form a gel in these oils at 2% concentration [50]. Another study [51] compared propolis wax-pomegranate seed oil oleogels with the corresponding beeswax oleogels and found that propolis wax oleogels had lower firmness and G′ and G″ moduli compared to beeswax oleogels, which was attributed to the larger propolis wax crystals with a less organized network. Cetyl wax esters produced by the enzymatic reaction of cetyl alcohol with carotenoid-rich microbial oil or soybean fatty acid distillate, a by-product during soybean oil production, were evaluated as oleogelators in soybean oil or extra virgin olive oil [52, 53]. These wax esters at 20% could form an oleogel while 7 and 10% wax esters could not form an oleogel. Gelation ability of animal waxes including whale spermaceti wax, lanolin wax, shellac wax, and beeswax was compared in sunflower oil, and their minimum gelation concentrations were determined to be 2, 20, 2, and 1%, respectively [54]. The order of the firmness of oleogels with 5% wax was whale spermaceti wax ≈ beeswax > shellac wax.

-

Binary systems: Due to the potential problem of wax oleogels’ melting points that are higher than those of conventional solid fats, efforts have been made to lower their melting points by use of binary systems of waxes. Jana and Martini [55] reported the eutectic behavior of the mixture of beeswax with sunflower wax or rice bran wax. Winkler-Moser et al. [26] also conducted studies on binary wax mixtures and observed that oleogels made with the mixture of beeswax and candelilla wax had not only lower melting points, but also higher firmnesses than those made with either wax alone. Margarines prepared from these oleogels also showed eutectic melting properties and increased firmness than those with each wax (Fig. 6.4) [56]. In addition, oleogels made with mixtures of candelilla wax and glyceryl monostearate in grapeseed oil or canola oil had lower melting points and higher firmness than those with candelilla wax or glyceryl monostearate alone [57, 58].

Melting profiles of (a) oleogels and (b) margarines with 5% mixture of candelilla wax (CLW) and beeswax (BW) in soybean oil and (c) their firmness. BW0, BW25, BW50, BW75, and BW100 stand for the ratios of 0:100, 25:75, 50:50, 75:25, and 100:0 BW:CLW. (Reproduced from [56] with permission from Wiley)

The major components in candelilla wax are hydrocarbons (72.9%) while those in beeswax are wax esters (58.0%) [3]. The eutectic properties of oleogels with the binary wax system of candelilla wax and beeswax were thought to be attributed to the interaction between hydrocarbons and wax esters [26]. This explanation was supported by another study conducted with the fractions separated from beeswax [4]. Eutectic behaviors were observed when the fraction containing 94.8% hydrocarbons was mixed with the other fraction rich in wax esters, free fatty acids, or fatty alcohols. The increased gel strength by mixtures of beeswax and candelilla wax was also thought to due to a synergistic interaction between hydrocarbons and wax esters at an optimum ratio, which resulted in smaller crystals and a denser network [26]. Firmness of oleogels made with these beeswax and candelilla wax combinations were recently shown to be enhanced greatly by the addition of 0.5% sunflower wax, without impacting the solid fat content at temperatures near body temperature [6]. Choi et al. [57] explained the higher firmness of grapeseed oil oleogel with the mixture (75:25) of candelilla wax and glyceryl monostearate than that with each component by the formation of smaller crystals and a denser crystal network (Fig. 6.5).

Phase-contrast micrographs of grapeseed oil oleogels with (a) candelilla wax, (b) 75:25 mixture of candelilla wax and glyceryl monostearate, and (c) glyceryl monostearate. The dimension of each picture is 410 μm × 275 μm. (Reproduced from [57] with permission from Wiley)

Although the melting point was not lowered, mixtures of rice bran wax and berry wax at the ratios of 3:7 and 2:8 and those of sunflower wax and berry wax at the ratios of 9:1 to 5:5 provided the firmer oleogels in rice bran oil than each wax alone [35]. While the major components in rice bran and sunflower waxes are wax esters, berry wax is primarily composed of fatty acids [3]. It was hypothesized that rice bran wax or sunflower wax crystallized first, and then berry wax formed solid bridges between the already present wax crystals to increase the hardness. Several studies have also demonstrated synergistic firmness of rice bran wax and sunflower wax mixtures in oleogels [59, 60].

6.4.3 Effect of Oils

Beeswax had minimum gelation concentrations of 3, 3, 3, and 4% in camellia oil, soybean oil, sunflower oil, and flaxseed oil, respectively [61]. In another study, the minimum gelation concentration of rice bran wax in eight different vegetable oils ranged from 8% to 10 % (w/v) [62]. Hwang et al. [22] reported that the minimum gelation concentration of sunflower wax in 13 different vegetable oils varied from 0.3% to 1% (w/w). Firmness of 5% sunflower wax oleogels with these oils was also significantly different ranging from 3.81 (flaxseed oil oleogel) to 7.72 N (soybean oil oleogel). Margarines prepared with these oleogels also had significantly different firmness ranging from 2.62 N with flaxseed oil oleogel to 6.67 N with sesame oil oleogel. Pang et al. [61] reported that oleogels with 6% beeswax in four different oils had the firmness order of soybean oil > flaxseed oil > sunflower oil > camellia oil. These studies did not find any specific correlations between the firmness of oleogels or margarines and fatty acids composition.

Some recent studies reported that waxes had greater gelation ability in oils with a higher degree of unsaturation, and their oleogels had higher gel strength. In a study conducted with oleogels of beeswax in different oils including camellia, sunflower, corn, and linseed oils, it was found that beeswax could form a gel at 1% (w/w) in linseed oil while it formed a gel at 1.2, 1.3 and 1.4% in corn, sunflower, and camellia oils, respectively [63]. It was postulated that an oil with a higher degree of unsaturation accelerated the crystallization rate, and formed denser and more stable networks of wax crystals, and produced oleogels with stronger van der Waals forces. In another study with oleogels made with sunflower wax or rice bran wax in sunflower, mustard, soybean, sesame, groundnut, rice bran, palm, and coconut oils, it was found that, in general, oils with higher polyunsaturated fatty acids (PUFAs) or higher unsaturation had lower minimum gelation concentrations, and their oleogels had higher oil-binding capacity [62]. Studies with other oleogels than wax oleogels have reported similar results. For example, 10% (w/w) ethylcellulose oleogels were firmer with oils rich in highly unsaturated fatty acids, which was explained by a greater degree of conformation freedom with oils with higher unsaturation that resulted in tight packing of molecules [64]. In contrast, the opposite trend was observed in a study with 6% carnauba wax oleogels prepared with hempseed, almond, rice, sesame, grapeseed, and pumpkin seed oils [65]. In this study, oils with higher saturated fatty acid contents provided oleogels with higher strength and yield stress. Therefore, it is obvious that oil affects the oleogel properties, but more studies are needed for better understanding of the effects of oil composition.

The fatty acid chain length of oil also significantly affects oleogel properties. In a study with beeswax oleogels prepared with medium-chain triglycerides and long-chain triglycerides, it was found that long-chain triglyceride oleogels had higher G′ and G″ values, which was thought to be due to lower mobility of the gelator and the formation of a strengthened network of gels by longer chains [66]. Another study with beeswax oleogels made with hempseed, almond, rice, sesame, grapeseed, and pumpkin seed oils found that, in general, oils with more long-chain saturated fatty acids had a more interconnected structure providing higher complex viscosity [65].

6.4.4 Effect of Polar Compounds in Oil

Very weak negative correlations (R2 = 0.34, 0.20, and 0.16 for 3, 5, and 7% sunflower wax, respectively) between the firmness of margarine and the amount of polar compounds in oil were observed in a study with margarine samples prepared with sunflower wax oleogels of 13 different vegetable oils [22]. However, a later study reported that the firmness of sunflower wax oleogels increased when polar compounds were removed from high stearic soybean oils indicating that polar compounds in these oils negatively affected the firmness of oleogels [67]. Sunflower wax, rice bran wax, candelilla wax, and beeswax formed highly ordered wax crystal structures and had lower wax solubility in oils when polar compounds were removed from sunflower oil and canola oil, but they also had higher minimum gelation concentration and their oleogels had lower resistance to deformation [68].

6.4.5 Effect of Cooling Rate

Sunflower wax-soybean oil oleogels had about three- to sixfold higher firmness when the cooling rate increased from 1 to 4 °C/min, which was thought to be due to the larger number of smaller crystals that formed a denser crystal network during faster cooling [2]. Blake and Marangoni [9] also reported that rapid cooling increased oil-binding capacity and decreased crystal length in wax-peanut oil oleogels. Many other studies reported that the faster cooling rate during the formation of oleogels increased the gel strength. Therefore, firmness and other physical properties of oleogels can be tailored by the cooling rate during the production of oleogels and oleogel-containing food products.

6.4.6 Sensory Properties

Many studies on sensory properties of wax oleogels or food products containing wax oleogel reported that they were acceptable or had high potential to be accepted with some modifications. For example, a study with oleogels made with 5% beeswax or sunflower wax in hazelnut oil or olive oil found that their sensory attributes including appearance, odor, and flavor were scored about 3.0 where the score of 2.5 was the neutral point, but they were lower than those of commercial breakfast margarine and butter. Hazelnut oleogels had higher spreadability scores than the commercial breakfast margarine [69]. When cooked burgers prepared with beeswax oleogel were compared to control burger made with animal fat, no significant effects on any of the sensory parameters including texture, color, flavor, and overall acceptability were observed by replacing animal fat with oleogel [25].

Virgin olive oil oleogels with 1% (w/w) sunflower wax and 1% (w/w) thyme or cumin spice had high acceptability scores by consumers [70]. Consumer preference scores of the odor and flavor of fish oil oleogels were enhanced by adding strawberry or lemon flavor [71]. Spermaceti wax-virgin olive oil oleogels flavored with turmeric or red pepper had very high appearance scores, and their aroma and flavor were also liked by consumers [72]. Therefore, adding a flavor in oleogels helps increase their acceptability by consumers. More sensory properties of food products containing wax oleogels will be discussed in the next section.

6.5 Properties of Food Products Containing Wax Oleogels

While earlier studies focused on the basic understanding on the properties of oleogels, many recent studies have been conducted on the application of wax oleogels in actual food products. The success in achieving the desired physical and sensory properties seems to have encouraged scientists to pursue the practical applications of wax oleogels.

Table 6.1 summarizes the most recent studies of food products prepared with wax oleogels and their properties compared to those with conventional fats.

In some studies, cookie samples with wax oleogels had similar spread factor, hardness, fracturability, appearance, flavor, smell, and acceptability to those with commercial margarine or shortening [73,74,75]. Frolova et al. [76] also reported that cookies made with oleogels of beeswax, fractions of beeswax, or candelilla wax in sunflower oil had high scores on taste, texture, surface condition, shape, and fracture view although no direct comparisons with conventional cookies were made. However, other studies found that cookie samples had somewhat different textual and sensory properties compared to control cookies. Cookies with wax oleogels had higher breaking force than those with commercial shortening [77, 78], and some properties, including snapping force, surface cracks, color, smell, and apparency, were somewhat different from the control [79,80,81,82]. Cake samples prepared with wax oleogels were somewhat different from the control samples prepared with commercial shortening in cohesiveness, resilience, adhesiveness, hardness, chewiness, and specific volume [83,84,85] while some samples had higher overall acceptability than the control samples [86]. The feasibility of wax oleogels in muffin and bread samples was also evaluated [87,88,89,90]. In general, physical properties of muffin and bread samples made with wax oleogels were slightly different or similar to those with commercial shortening, and the slight differences could be overcome by partial replacement.

Meat products are one of the major contributors to dietary intake of saturated fats, and many studies have been conducted to incorporate oleogels in meat products such as meat batters, patties, burgers, frankfurters, sausages, and pates. Although it is straightforward that replacing saturated fats in meat products with healthy oil-based oleogels will promote health, it seems it is still very challenging to achieve acceptable texture, spreadability, flavor, and oxidative stability with products with oleogels [91]. As shown in Table 6.1, it is encouraging that recent studies with meat products containing wax oleogels reported that their appearance, taste, texture, smell, and overall acceptance scores were similar to those of the control samples containing animal fat [25, 92,93,94]. Even higher scores on flavor and overall acceptance than the control samples with animal fat were observed with beef burger samples where beef fat was replaced with beeswax-sesame oil oleogel [95]. It was thought to be due to preferred taste and smell of sesame oil, indicating that sensory scores can be improved by using tasty oils or by adding a flavor. In contrast, a study with sucuk (a Turkish style of beef sausage) made with 10% sunflower wax or beeswax-flaxseed oil oleogels reported that further improvements were needed [96].

Some cheese products with wax oleogels were reported to have similar hardness, storage modulus, meltability, spreadability, mouthfeel, and sweetness and higher flavor and bitterness scores than those made with milk fat [97, 98]. Another study with cheese products made with 3–9% carnauba wax in canola oil oleogels reported that they had higher firmness and elasticity and lower oil mobility and meltability than those with palm oil [99]. Ice cream prepared by replacing 50% milk fat with 6% carnauba wax-soybean oil oleogel had similar flavor, texture, appearance, and overall consumer scores and slower melting rate than the original ice cream [100]. When 100% milk fat was replaced with this oleogel, lower flavor and overall scores were observed indicating that only partial replacement was recommended for this application.

6.6 Other Applications of Wax Oleogels

-

Peanut butter stabilizer: Stabilizers are used to prevent oil separation and to improve texture and spreadability of peanut butter. Conventional peanut butter stabilizers are typically composed of hydrogenated oils, and studies were conducted to replace these stabilizers with wax oleogels. Waxes can be directly added in peanut butter and heated to form oleogels and also wax oleogels can be prepared by dissolving wax in peanut oil with heat before adding in peanut butter. Desired firmness and spreadability as well as prevention of oil separation could be achieved with wax oleogels, depending on the wax type and the amount added [12, 101, 102].

-

Frying medium: Chicken samples fried in 5 or 10% (w/v) carnauba wax-canola oil oleogel had lower oil uptake (8.53 and 9.15%, respectively) compared to samples fried in canola oil (15.10%) [103]. Similarly, mathri, an Indian traditional fried snack cracker made with wheat flour, was prepared by frying in soybean oil oleogels with 5, 10, or 15% carnauba wax and compared with that fried in soybean oil [104]. Oil uptake was 27.1, 19,6, 21.0, and 21.2% for the samples fried in oil and oleogels with 5, 10, and 15% carnauba wax, respectively. The sensory analysis of these samples revealed that overall acceptability and taste scores were similar between the mathri samples fried in oil and 10% wax oleogel while the sample fried with 15% wax oleogel had a waxy feel and taste. These studies showed that wax oleogels can be used in place of oil to reduce oil uptake of fried foods.

6.7 Conclusions

The number of studies on wax oleogels has increased, the fastest among other oleogels due to their advantages of high gel strength, low critical gelation concentrations, high physical and oxidative stability during storage, and relatively low effects on sensory properties of reformulated foods. Waxes form a dense network of many small platelet-shaped crystals that provide high gel strength. The type and origin of waxes significantly affect the properties of wax oleogels. Sunflower wax, rice bran wax, candelilla wax, carnauba wax, and beeswax have been the most studied among other waxes due to their strong gelation ability. Some binary or ternary systems of waxes and mixtures of wax and monoglyceride could provide oleogels with a lower melting point and a higher firmness than those with either component alone. Although more studies are needed, based on studies thus far, it appears that polar compounds in oil negatively affect the physical properties of wax oleogels and that oils, while higher levels of oil triacylglycerol unsaturation produce stronger gels. Many recent studies have reported that food products where conventional fats were replaced with wax oleogels had similar physical and sensory properties to commercial products while others have reported that further improvements were needed. Acceptable physical and sensory properties of food products containing wax oleogels can be achieved by finding right types of wax and oil and using the optimized wax amount. From the review of recent studies, it can be concluded that wax oleogels have high potential for the development of healthy food products.

Abbreviations

- AFM:

-

Atomic force microscopy

- cryo-SEM:

-

Cryogenic-scanning electron microscopy

- DDGs:

-

Distiller’s dried grains with solubles

- FDA:

-

Food and Drug Administration

- GRAS:

-

Generally recognized as safe

- PUFA:

-

Polyunsaturated fatty acids

- SEM:

-

Scanning electron microscopy

References

Tulloch AP (1973) Comparison of some commercial waxes by gas liquid chromatography. J Am Oil Chem Soc 50(9):367–371. https://doi.org/10.1007/BF02640842

Hwang HS, Kim S, Singh M et al (2012) Organogel formation of soybean oil with waxes. J Am Oil Chem Soc 89(4):639–647. https://doi.org/10.1007/s11746-011-1953-2

Doan CD, To CM, De Vrieze M et al (2017) Chemical profiling of the major components in natural waxes to elucidate their role in liquid oil structuring. Food Chem 214:717–725. https://doi.org/10.1016/j.foodchem.2016.07.123

Sarkisyan V, Sobolev R, Frolova Y et al (2021) Beeswax fractions used as potential oil gelling agents. J Am Oil Chem Soc 98(3):281–296. https://doi.org/10.1002/aocs.12451

Doan CD, Tavernier I, Okuro PK et al (2018) Internal and external factors affecting the crystallization, gelation and applicability of wax-based oleogels in food industry. Innov Food Sci Emerg Technol 45:42–52. https://doi.org/10.1016/j.ifset.2017.09.023

Winkler-Moser JK, Hwang HS, Felker FC et al (2023) Increasing the firmness of wax-based oleogels using ternary mixtures of sunflower wax with beeswax:candelilla wax combinations. J Am Oil Chem Soc. (in press). https://doi.org/10.1002/aocs.12679

Barroso NG, Santos MAS, Okuro PK et al (2022) Composition and process approaches that underpin the mechanical properties of oleogels. J Am Oil Chem Soc 99(11):971–984. https://doi.org/10.1002/aocs.12635

Silva PM, Cerqueira MA, Martins AJ et al (2022) Oleogels and bigels as alternatives to saturated fats: a review on their application by the food industry. J Am Oil Chem Soc 99(11):911–923. https://doi.org/10.1002/aocs.12637

Blake AI, Marangoni AG (2015) The use of cooling rate to engineer the microstructure and oil binding capacity of wax crystal networks. Food Biophys 10(4):456–465. https://doi.org/10.1007/s11483-015-9409-0

Saffold AC, Acevedo NC (2022) The effect of mono-diglycerides on the mechanical properties, microstructure, and physical stability of an edible rice bran wax–gelatin biphasic gel system. J Am Oil Chem Soc 99(11):1033–1043. https://doi.org/10.1002/aocs.12640

Hwang HS, Singh M, Bakota EL et al (2013) Margarine from organogels of plant wax and soybean oil. J Am Oil Chem Soc 90(11):1705–1712. https://doi.org/10.1007/s11746-013-2315-z

Winkler-Moser JK, Anderson J, Byars JA et al (2019) Evaluation of beeswax, candelilla wax, rice bran wax, and sunflower wax as alternative stabilizers for peanut butter. J Am Oil Chem Soc 96(11):1235–1248. https://doi.org/10.1002/aocs.12276

Öǧütcü M, Yilmaz E (2014) Oleogels of virgin olive oil with carnauba wax and monoglyceride as spreadable products. Grasas Aceites 65(3):e040. https://doi.org/10.3989/gya.0349141

Öğütcü M, Temizkan R, Arifoğlu N et al (2015) Structure and stability of fish oil organogels prepared with sunflower wax and monoglyceride. J Oleo Sci 64(7):713–720. https://doi.org/10.5650/jos.ess15053

Demirkesen I, Mert B (2020) Recent developments of oleogel utilizations in bakery products. Crit Rev Food Sci Nutr 60(14):2460–2479. https://doi.org/10.1080/10408398.2019.1649243

Kanya TCS, Lokesh BR, Sastry MCS (2008) Effect of sunflower wax supplemented diet on lipid profiles in albino rats. J Food Biochem 32(1):60–71. https://doi.org/10.1111/j.1745-4514.2007.00146.x

Issara U, Park S, Park S (2019) Determination of fat accumulation reduction by edible fatty acids and natural waxes in vitro. Food Sci Anim Resour 39(3):430–445. https://doi.org/10.5851/kosfa.2019.e38

Limpimwong W, Kumrungsee T, Kato N et al (2017) Rice bran wax oleogel: A potential margarine replacement and its digestibility effect in rats fed a high-fat diet. J Func Foods 39:250–256. https://doi.org/10.1016/j.jff.2017.10.035

Marangoni AG, Idziak SHJ, Vega C et al (2007) Encapsulation-stucturing of edible oil attenuates acute elevation of blood lipids and insulin in humans. Soft Matter 3(2):183–187. https://doi.org/10.1039/b611985a

Rush JWE, Jantzi PS, Dupak K et al (2009) Acute metabolic responses to butter, margarine, and a monoglyceride gel-structured spread. Food Res Int 42(8):1034–1039. https://doi.org/10.1016/j.foodres.2009.04.013

Tan SY, Wan-Yi Peh E, Marangoni AG et al (2017) Effects of liquid oil vs. oleogel co-ingested with a carbohydrate-rich meal on human blood triglycerides, glucose, insulin and appetite. Food Funct 8(1):241–249. https://doi.org/10.1039/c6fo01274d

Hwang HS, Singh M, Winkler-Moser JK et al (2014) Preparation of margarines from organogels of sunflower wax and vegetable oils. J Food Sci 79(10):C1926–C1932. https://doi.org/10.1111/1750-3841.12596

Alongi M, Lucci P, Clodoveo ML et al (2022) Oleogelation of extra virgin olive oil by different oleogelators affects the physical properties and the stability of bioactive compounds. Food Chem 368:130779. https://doi.org/10.1016/j.foodchem.2021.130779

Fayaz G, Calligaris S, Nicoli MC (2020) Comparative study on the ability of different oleogelators to structure sunflower oil. Food Biophys 15(1):42–49. https://doi.org/10.1007/s11483-019-09597-9

Gómez-Estaca J, Herrero AM, Herranz B et al (2019) Characterization of ethyl cellulose and beeswax oleogels and their suitability as fat replacers in healthier lipid pâtés development. Food Hydrocoll 87:960–969. https://doi.org/10.1016/j.foodhyd.2018.09.029

Winkler-Moser JK, Anderson J, Felker FC et al (2019) Physical properties of beeswax, sunflower wax, and candelilla wax mixtures and oleogels. J Am Oil Chem Soc 96(10):1125–1142. https://doi.org/10.1002/aocs.12280

Doan CD, Tavernier I, Sintang MDB et al (2017) Crystallization and gelation behavior of low- and high melting waxes in rice bran oil: a case-study on berry wax and sunflower wax. Food Biophys 12(1):97–108. https://doi.org/10.1007/s11483-016-9467-y

Hwang HS, Kim S, Evans KO et al (2015) Morphology and networks of sunflower wax crystals in soybean oil organogel. Food Struc 5:10–20. https://doi.org/10.1016/j.foostr.2015.04.002

Patel AR, Babaahmadi M, Lesaffer A et al (2015) Rheological profiling of organogels prepared at critical gelling concentrations of natural waxes in a triacylglycerol solvent. J Agric Food Chem 63(19):4862–4869. https://doi.org/10.1021/acs.jafc.5b01548

Chopin-Doroteo M, Morales-Rueda JA, Dibildox-Alvarado E et al (2011) The effect of shearing in the thermo-mechanical properties of candelilla wax and candelilla wax-tripalmitin organogels. Food Biophys 6(3):359–376. https://doi.org/10.1007/s11483-011-9212-5

Ramírez-Gómez NO, Acevedo NC, Toro-Vázquez JF et al (2016) Phase behavior, structure and rheology of candelilla wax/fully hydrogenated soybean oil mixtures with and without vegetable oil. Food Res Int 89:828–837. https://doi.org/10.1016/j.foodres.2016.10.025

Toro-Vazquez JF, Mauricio-Pérez R, González-Chávez MM et al (2013) Physical properties of organogels and water in oil emulsions structured by mixtures of candelilla wax and monoglycerides. Food Res Int 54(2):1360–1368. https://doi.org/10.1016/j.foodres.2013.09.046

Rodríguez-Hernández AK, Pérez-Martínez JD, Gallegos-Infante JA et al (2021) Rheological properties of ethyl cellulose-monoglyceride-candelilla wax oleogel vis-a-vis edible shortenings. Carbohydr Polym 252:117171. https://doi.org/10.1016/j.carbpol.2020.117171

Blake AI, Marangoni AG (2015) Plant wax crystals display platelet-like morphology. Food Struc 3:30–34. https://doi.org/10.1016/j.foostr.2015.01.001

Tavernier I, Doan CD, Van De Walle D et al (2017) Sequential crystallization of high and low melting waxes to improve oil structuring in wax-based oleogels. RSC Adv 7(20):12113–12125. https://doi.org/10.1039/c6ra27650d

Brykczynski H, Hetzer B, Flöter E (2022) An attempt to relate oleogel properties to wax ester chemical structures. Gels 8(9):579. https://doi.org/10.3390/gels8090579

Shi Z, Cao L, Kang S et al (2022) Influence of wax type on characteristics of oleogels from camellia oil and medium chain triglycerides. Int J Food Sci Technol 57(4):2003–2014. https://doi.org/10.1111/ijfs.15344

Endlein E, Peleikis KH (2011) Natural waxes–properties, compositions and applications. SOFW J 137(4):1–8

Hwang KT, Cuppett SL, Weller CL et al (2002) HPLC of grain sorghum wax classes highlighting separation of aldehydes from wax esters and steryl esters. J Sep Sci 25(9):619–623. https://doi.org/10.1002/1615-9314(20020601)25:9<619::AID-JSSC619>3.0.CO;2-J

Akoh CC, Min DB (2008) Food lipids: chemistry, nutrition, and biotechnology. CRC Press, Boca Raton. https://doi.org/10.1201/9781420046649

Kanya TCS, Rao LJ, Sastry MCS (2007) Characterization of wax esters, free fatty alcohols and free fatty acids of crude wax from sunflower seed oil refineries. Food Chem 101(4):1552–1557. https://doi.org/10.1016/j.foodchem.2006.04.008

Brykczynski H, Wettlaufer T, Flöter E (2022) Revisiting pure component wax esters as basis of wax-based oleogels. J Am Oil Chem Soc 99:925–941. https://doi.org/10.1002/aocs.12589

Avendaño-Vásquez G, De la Peña-Gil A, Charó-Alvarado ME et al (2020) Self-assembly of symmetrical and asymmetrical alkyl esters in the neat state and in oleogels. Front Sustain Food Syst 4:132. https://doi.org/10.3389/fsufs.2020.00132

Ögütcü M, Yilmaz E (2015) Characterization of hazelnut oil oleogels prepared with sunflower and carnauba waxes. Int J Food Prop 18(8):1741–1755. https://doi.org/10.1080/10942912.2014.933352

Fayaz G, Polenghi O, Giardina A et al (2021) Structural and rheological properties of medium-chain triacylglyceride oleogels. Int J Food Sci Technol 56(2):1040–1047. https://doi.org/10.1111/ijfs.14757

Lim J, Hwang HS, Lee S (2017) Oil-structuring characterization of natural waxes in canola oil oleogels: rheological, thermal, and oxidative properties. Appl Biol Chem 60(1):17–22. https://doi.org/10.1007/s13765-016-0243-y

Mavria A, Tsouko E, Protonotariou S et al (2022) Sustainable production of novel oleogels valorizing microbial oil rich in carotenoids derived from spent coffee grounds. J Agric Food Chem 70(35):10807–10817. https://doi.org/10.1021/acs.jafc.2c03478

Yilmaz E, Keskin Uslu E, Öz C (2021) Oleogels of some plant waxes: Characterization and comparison with sunflower wax oleogel. J Am Oil Chem Soc 98(6):643–655. https://doi.org/10.1002/aocs.12490

Liu L, Ramirez ISA, Yang J et al (2020) Evaluation of oil-gelling properties and crystallization behavior of sorghum wax in fish oil. Food Chem 309:125567. https://doi.org/10.1016/j.foodchem.2019.125567

Fayaz G, Goli SAH, Kadivar M (2017) A novel propolis wax-Based organogel: effect of oil type on its formation, crystal structure and thermal properties. J Am Oil Chem Soc 94(1):47–55. https://doi.org/10.1007/s11746-016-2915-5

Fayaz G, Goli SAH, Kadivar M et al (2017) Pomegranate seed oil organogels structured by propolis wax, beeswax, and their mixture. Eur J Lipid Sci Technol 119(10):1700032. https://doi.org/10.1002/ejlt.201700032

Papadaki A, Kopsahelis N, Mallouchos A et al (2019) Bioprocess development for the production of novel oleogels from soybean and microbial oils. Food Res Int 126:108684. https://doi.org/10.1016/j.foodres.2019.108684

Papadaki A, Kopsahelis N, Freire DMG et al (2020) Olive oil oleogel formulation using wax esters derived from soybean fatty acid distillate. Biomolecules 10(1):106. https://doi.org/10.3390/biom10010106

Yılmaz E, Uslu EK, Toksöz B (2020) Structure, rheological and sensory properties of some animal wax based oleogels. J Oleo Sci 69(10):1317–1329. https://doi.org/10.5650/jos.ess20081

Jana S, Martini S (2016) Phase behavior of binary blends of four different waxes. J Am Oil Chem Soc 93(4):543–554. https://doi.org/10.1007/s11746-016-2789-6

Hwang HS, Winkler-Moser JK (2020) Properties of margarines prepared from soybean oil oleogels with mixtures of candelilla wax and beeswax. J Food Sci 85(10):3293–3302. https://doi.org/10.1111/1750-3841.15444

Choi KO, Hwang HS, Jeong S et al (2020) The thermal, rheological, and structural characterization of grapeseed oil oleogels structured with binary blends of oleogelator. J Food Sci 85(10):3432–3441. https://doi.org/10.1111/1750-3841.15442

Kim M, Hwang HS, Jeong S et al (2022) Utilization of oleogels with binary oleogelator blends for filling creams low in saturated fat. LWT 155:112972. https://doi.org/10.1016/j.lwt.2021.112972

Jana S, Martini S (2016) Physical characterization of crystalline networks formed by binary blends of waxes in soybean oil. Food Res Int 89:245–253. https://doi.org/10.1016/j.foodres.2016.08.003

Ghazani SM, Dobson S, Marangoni AG (2022) Hardness, plasticity, and oil binding capacity of binary mixtures of natural waxes in olive oil. Curr Res Food Sci 5:998–1008. https://doi.org/10.1016/j.crfs.2022.06.002

Pang M, Shi Z, Lei Z et al (2020) Structure and thermal properties of beeswax-based oleogels with different types of vegetable oil. Grasas Aceites 71(4):e380. https://doi.org/10.3989/GYA.0806192

Holey SA, Sekhar KPC, Mishra SS et al (2021) Effect of oil unsaturation and wax composition on stability, properties and food applicability of oleogels. J Am Oil Chem Soc 98(12):1189–1203. https://doi.org/10.1002/aocs.12536

Han W, Chai X, Liu Y et al (2022) Crystal network structure and stability of beeswax-based oleogels with different polyunsaturated fatty acid oils. Food Chem 381:131745. https://doi.org/10.1016/j.foodchem.2021.131745

Laredo T, Barbut S, Marangoni AG (2011) Molecular interactions of polymer oleogelation. Soft Matter 7(6):2734–2743. https://doi.org/10.1039/c0sm00885k

Borriello A, Antonella Miele N, Masi P et al (2022) Effect of fatty acid composition of vegetable oils on crystallization and gelation kinetics of oleogels based on natural wax. Food Chem 375:131805. https://doi.org/10.1016/j.foodchem.2021.131805

Martins AJ, Cerqueira MA, Fasolin LH et al (2016) Beeswax organogels: Influence of gelator concentration and oil type in the gelation process. Food Res Int 84:170–179. https://doi.org/10.1016/j.foodres.2016.03.035

Hwang HS, Gillman JD, Winkler-Moser JK et al (2018) Properties of oleogels formed with high-stearic soybean oils and sunflower wax. J Am Oil Chem Soc 95(5):557–569. https://doi.org/10.1002/aocs.12060

Scharfe M, Niksch J, Flöter E (2022) Influence of minor oil components on sunflower, rice Bran, candelilla, and beeswax oleogels. Eur J Lipid Sci Technol 124(7):2100068. https://doi.org/10.1002/ejlt.202100068

Yilmaz E, Ögütcü M (2015) Oleogels as spreadable fat and butter alternatives: Sensory description and consumer perception. RSC Adv 5(62):50259–50267. https://doi.org/10.1039/c5ra06689a

Yilmaz E, Demirci Ş (2021) Preparation and evaluation of virgin olive oil oleogels including thyme and cumin spices with sunflower wax. Gels 7(3):95. https://doi.org/10.3390/gels7030095

Yılmaz E, Öǧütcü M, Arifoglu N (2015) Assessment of thermal and textural characteristics and consumer preferences of lemon and strawberry flavored fish oil organogels. J Oleo Sci 64(10):1049–1056. https://doi.org/10.5650/jos.ess15113

Yilmaz E, Demirci Ş, Uslu EK (2022) Red pepper and turmeric-flavored virgin olive oil oleogels prepared with whale Spermaceti wax. J Oleo Sci 71(2):187–199. https://doi.org/10.5650/jos.ess21167

Hwang HS, Singh M, Lee S (2016) Properties of cookies made with natural wax-vegetable oil organogels. J Food Sci 81(5):C1045–C1054. https://doi.org/10.1111/1750-3841.13279

Yilmaz E, Ögütcü M (2015) The texture, sensory properties and stability of cookies prepared with wax oleogels. Food Funct 6(4):1194–1204. https://doi.org/10.1039/c5fo00019j

Li S, Zhu L, Li X et al (2022) Determination of characteristic evaluation indexes for novel cookies prepared with wax oleogels. J Sci Food Agric 102(12):5544–5553. https://doi.org/10.1002/jsfa.11909

Frolova YV, Sobolev RV, Kochetkova AA (2021) Comparative analysis of the properties of cookies containing oleogel based on beeswax and its fractions. IOP Conf Ser Earth Environ Sci 941(1):012033. https://doi.org/10.1088/1755-1315/941/1/012033

Mert B, Demirkesen I (2016) Reducing saturated fat with oleogel/shortening blends in a baked product. Food Chem 199:809–816. https://doi.org/10.1016/j.foodchem.2015.12.087

Mert B, Demirkesen I (2016) Evaluation of highly unsaturated oleogels as shortening replacer in a short dough product. LWT 68:477–484. https://doi.org/10.1016/j.lwt.2015.12.063

Kim D, Oh I (2022) The characteristic of insect oil for a potential component of oleogel and its application as a solid fat replacer in cookies. Gels 8(6):355. https://doi.org/10.3390/gels8060355

Jang A, Bae W, Hwang HS et al (2015) Evaluation of canola oil oleogels with candelilla wax as an alternative to shortening in baked goods. Food Chem 187:525–529. https://doi.org/10.1016/j.foodchem.2015.04.110

Li S, Wu G, Li X et al (2021) Roles of gelator type and gelation technology on texture and sensory properties of cookies prepared with oleogels. Food Chem 356:129667. https://doi.org/10.1016/j.foodchem.2021.129667

Schubert M, Erlenbusch N, Wittland S et al (2022) Rapeseed oil based oleogels for the improvement of the fatty acid profile using cookies as an example. Eur J Lipid Sci Technol 124(11):2200033. https://doi.org/10.1002/ejlt.202200033

Alvarez-Ramirez J, Vernon-Carter EJ, Carrera-Tarela Y et al (2020) Effects of candelilla wax/canola oil oleogel on the rheology, texture, thermal properties and in vitro starch digestibility of wheat sponge cake bread. LWT 130:109701. https://doi.org/10.1016/j.lwt.2020.109701

Wettlaufer T, Flöter E (2022) Wax based oleogels and their application in sponge cakes. Food Funct 13(18):9419–9433. https://doi.org/10.1039/d2fo00563h

Oh IK, Amoah C, Lim J et al (2017) Assessing the effectiveness of wax-based sunflower oil oleogels in cakes as a shortening replacer. LWT 86:430–437. https://doi.org/10.1016/j.lwt.2017.08.021

Pehlivanoglu H, Ozulku G, Yildirim RM et al (2018) Investigating the usage of unsaturated fatty acid-rich and low-calorie oleogels as a shortening mimetics in cake. J Food Process Preserv 42(6):e13621. https://doi.org/10.1111/jfpp.13621

Jeong S, Lee S, Oh I (2021) Development of antioxidant-fortified oleogel and its application as a solid fat replacer to muffin. Foods 10(12):3059. https://doi.org/10.3390/foods10123059

Lim J, Jeong S, Lee J et al (2017) Effect of shortening replacement with oleogels on the rheological and tomographic characteristics of aerated baked goods. J Sci Food Agric 97(11):3727–3732. https://doi.org/10.1002/jsfa.8235

Zhao M, Rao J, Chen B (2022) Effect of high oleic soybean oil oleogels on the properties of doughs and corresponding bakery products. J Am Oil Chem Soc 99(11):1071–1083. https://doi.org/10.1002/aocs.12594

Jung D, Oh I, Lee J et al (2020) Utilization of butter and oleogel blends in sweet pan bread for saturated fat reduction: dough rheology and baking performance. LWT 125:109194. https://doi.org/10.1016/j.lwt.2020.109194

López-Pedrouso M, Lorenzo JM, Gullón B et al (2021) Novel strategy for developing healthy meat products replacing saturated fat with oleogels. Curr Opin Food 40:40–45. https://doi.org/10.1016/j.cofs.2020.06.003

Issara U (2022) Improvement of Thai sweet sausage (Goon Chiang) properties by oleogel made of rice bran wax and rice bran oil: a textural, sensorial, and nutritional aspect. IOP Conf Ser Earth Environ Sci 995(1):012045. https://doi.org/10.1088/1755-1315/995/1/012045

Gómez-Estaca J, Pintado T, Jiménez-Colmenero F et al (2020) The effect of household storage and cooking practices on quality attributes of pork burgers formulated with PUFA- and curcumin-loaded oleogels as healthy fat substitutes. LWT 119:108909. https://doi.org/10.1016/j.lwt.2019.108909

Wolfer TL, Acevedo NC, Prusa KJ et al (2018) Replacement of pork fat in frankfurter-type sausages by soybean oil oleogels structured with rice bran wax. Meat Sci 145:352–362. https://doi.org/10.1016/j.meatsci.2018.07.012

Moghtadaei M, Soltanizadeh N, Goli SAH (2018) Production of sesame oil oleogels based on beeswax and application as partial substitutes of animal fat in beef burger. Food Res Int 108:368–377. https://doi.org/10.1016/j.foodres.2018.03.051

Yılmaz E, Toksöz B (2022) Flaxseed oil-wax oleogels replacement for tallowfat in sucuk samples provided higher concentrations of polyunsaturated fatty acids and aromatic volatiles. Meat Sci 192:108875. https://doi.org/10.1016/j.meatsci.2022.108875

Huang H, Hallinan R, Maleky F (2018) Comparison of different oleogels in processed cheese products formulation. Int J Food Sci Technol 53(11):2525–2534. https://doi.org/10.1111/ijfs.13846

Bemer HL, Limbaugh M, Cramer ED et al (2016) Vegetable organogels incorporation in cream cheese products. Food Res Int 85:67–75. https://doi.org/10.1016/j.foodres.2016.04.016

Moon K, Choi KO, Jeong S et al (2021) Solid fat replacement with canola oil-carnauba wax oleogels for dairy-free imitation cheese low in saturated fat. Foods 10(6):1351. https://doi.org/10.3390/foods10061351

Airoldi R, da Silva TLT, Ract JNR et al (2022) Potential use of carnauba wax oleogel to replace saturated fat in ice cream. J Am Oil Chem Soc 99(11):1085–1099. https://doi.org/10.1002/aocs.12652

Ferdaus MJ, Blount RJS, Silva RCD (2022) Assessment of natural waxes as stabilizers in peanut butter. Foods 11(19):3127. https://doi.org/10.3390/foods11193127

Huang Z, Guo B, Deng C et al (2020) Stabilization of peanut butter by rice bran wax. J Food Sci 85(6):1793–1798. https://doi.org/10.1111/1750-3841.15176

Adrah K, Adegoke SC, Nowlin K et al (2022) Study of oleogel as a frying medium for deep-fried chicken. J Food Meas Charact 16(2):1114–1123. https://doi.org/10.1007/s11694-021-01237-6

Chauhan DS, Khare A, Lal AB et al (2022) Utilising oleogel as a frying medium for deep fried Indian traditional product (Mathri) to reduce oil uptake. J Indian Chem Soc 99(3):100378. https://doi.org/10.1016/j.jics.2022.100378

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Hwang, HS., Winkler-Moser, J.K. (2024). Wax-Based Oleogels. In: Palla, C., Valoppi, F. (eds) Advances in Oleogel Development, Characterization, and Nutritional Aspects. Springer, Cham. https://doi.org/10.1007/978-3-031-46831-5_6

Download citation

DOI: https://doi.org/10.1007/978-3-031-46831-5_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46830-8

Online ISBN: 978-3-031-46831-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)