Abstract

In several situation when bone integrity is prejudiced, advanced regenerative medicine approaches are involved in order to get a good result, being designed and applied synthetic tissue engineered architectures. This rapidly evolving interdisciplinary domain, tissue engineering, is centered on developing three-dimensional scaffolds, which can be prepared from ceramics, polymers or the combination between those two, resulting a complex material mimicking the composition of the natural bone. Among polymers, polysaccharides are a remarkable class, due to the inexhaustible source, great biocompatibility and versatility in terms of processability. Alginate and guar gum, included in this class have the ability to crosslink in the presence of Ca2+ ions, resulting easy to handle beads. Due to the similarity with human inorganic matter, calcium phosphates are used in orthopedy, frequently combined with polymers to overcome one of the main disadvantages of ceramics: brittleness, which negatively influences mechanical behavior. All these aspects being considered, the aim of the study was to obtain alginate–calcium phosphate beads with inclusion of carboxymethyl guar gum nanoparticles as scaffolds for bone tissue engineering and analyze them in terms of morphology and composition (Field Emission Scanning Electron Microscope and Energy-dispersive X-ray Spectrometer), chemical structure (Fourier Transform Infrared Spectrometer) and behavior in simulated body fluids.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As an ever-changing and highly interdisciplinary field, bone tissue engineering might be a solution for serious bone defects, caused by fractures, crucial accidents, infections or tumors, when bone integrity is seriously compromised and advanced regenerative medicine approaches are required [1].

Biomaterials play a critical role in tissue engineering, functioning as artificial ex-tracellular matrices or three-dimensional scaffolds for cells, used to repair or regenerate damaged tissues. There are several forms of presentation for artificial matrices and scaffolds, and biomaterials are processed as macroporous scaffolds, injectable systems, beads, fibrous and nano-fibrous films and membranes, compact plates, tubes, gels, hydrogels and so on [2].

Carbohydrates, mainly polysaccharides, represents 90% of all biomass and are a popular choice for fabrication of tissue engineered scaffolds [3] or drug carrier systems due to this large availability and great biocompatibility [1]. Polysaccharides, such as chitosan, hyaluronic acid, alginate, dextran and agarose, are thoroughly included in bone tissue engineering applications, unmodified or functionalized, as pure polymeric systems or most frequently, in combination with ceramics (natural hydroxyapatite, calcium phosphates and so on) [1].

Calcium phosphate ceramics (CaPs) are commonly used in orthopedic surgery and intensively studied for various bone tissue repair and augmentation application, due to their bioactivity, osteoinductivity and ability to stimulate new bone formation, and in some cases surface roughness, which can promote cell adhesion and finally cell differentiation [4].

Alginate (ALG) and guar gum (GG) are two safe and environmentally friendly polymers, with remarkable properties for biomedical applications: biodegradability, non-toxicity and high viscosity [5]. Both of them are vegetable polysaccharides isolated from renewable and inexpensive sources: the seeds of the Cyamopsis tetragonolobus plant, in case of GG and from kelp or Sargassum algae of brown algae, in case of ALG [6]. In the case of ALG and GG, ionic crosslinking using Ca2+ ions is a common method used to obtain matrix, using an easy method, without additional steps or reagents [3]. ALG has a great water solubility, but in case of GG some chemical modifications are necessary in order to facilitate this important property, carboxymethylation being one of them [7]. Furthermore, nanoparticles based on carboxymethylated guar gum (CMGG) proved to be suitable drug carriers [8, 9].

Based on the great properties of the biomaterials briefly described above, for this study were selected alginate, nanoparticles based on CMGG and calcium phosphates, designed as beads, since they are easily obtained, due to the ALG ability to crosslink in the presence of Ca2+. The obtained biopolymer-ceramics beads were analyzed from the perspective of using them as scaffolds for bone tissue engineering.

2 Materials and Methods

2.1 Materials

Two natural polymers have been used for the preparation of the beads: alginic acid, sodium salt, abbreviated ALG (from Sigma-Aldrich, Norway) and guar gum, abbreviated GG (from Sigma-Aldrich, Pakistan – since the source is popular in the region [10]). Guar gum was first carboxymethylated, abbreviated CMGG, prepared after a protocol described before in the literature [7] and finally designed as nanoparticles, abbreviated CMGG NPs [9]. Also, were acquired, from Sigma-Aldrich, Germany, calcium phosphate tribasic, abbreviated CaPs (from Alfa Aesar, Germany) and CaCl2 dihydrate. For the characterization of the beads, a phosphate buffer solution (PBS, 0.01 M, pH 7.4) was obtained from tablets (Sigma-Aldrich, Germany). All the solutions used in this study were prepared with ultrapure water obtained from Arium® mini Ultrapure Water System.

2.2 Beads Preparation and Characterization

Two aqueous ALG solutions of different concentrations were prepared: 2% and 3% and then mixed separately with 10% CMGG NPs, reported to the dry content of ALG and homogenized (magnetically stirred for 1 h). The following step was to com-bine the biopolymer-NPs mixtures with CaPs, in order to have a theoretical proportion of 33% organic matter and 67% inorganic matter, mimicking the composition of human bone [11]. For uniform distribution of CaPs an ultrasonic homogenizer was used, and repeated cycles of 20 s (UP50H homogenizer, Hielscher Ultrasonics, Germany) were applied. The mixtures were drop wised into a CaCl2 solution (0.2 M), using a syringe with a 18G needle, and kept to crosslink, 2 h at room temperature. Then the beads, were intensively washed with ultrapure water and dried: from each mixture, half of the beads were dried in an oven for 48 h, 37 ℃, and half were lyophilized for 24 h, at −55 ℃, 0.055 mBar.

The obtained beads were analyzed, in terms of physico-chemical features morphology, chemical structure and composition) and in vitro behavior in simulated body fluids. The flowchart of the study is schematically represented in Fig. 1.

The morphology of the beads was analyzed using a Field Emission Scanning Electron Microscope (FESEM), coupled with an Oxford Energy-dispersive X-Ray Spectrometer (EDX), at a 20 kV accelerating voltage. The complex system FESEM-EDX is from Hitachi, UK. The EDX module was used to quantify the composition of the beads.

A Fourier Transform Infrared Spectrometer with Attenuated Total Reflection mod-ule (ATR–FTIR), from Thermo Scientific, USA, was used to confirm the composition of the beads. The scans, in the range 4000–400 cm–1, were performed at a resolution of 4 cm–1.

The study of in vitro behavior of the beads in simulated body fluids, was accomplished by a gravimetric method. First, three aliquots from the four types of beads were weighed (these values, representing the initial weight of the samples, were codified with wi) and then each aliquot was immersed in 1 mL PBS 0.01 M, pH 7.4, in a well from a 24 well plate, which was placed at 37 ℃, in an oven. At specific times, the samples were carefully removed, dabbed on a filter paper to absorb the excess liquid and weighed, the values determined being codified with wt, meaning the weight of the bead at time t. Finally, the results were quantified in terms of the swelling degree (1):

3 Results and Discussions

Four types of beads, based on alginate and calcium phosphates with inclusion of CMGG NPs, were prepared by ionic crosslinking, and their codification and composition are indicated in Table 1.

One of the main features of a scaffold intended for bone tissue engineering is an adequate porosity. The demands are represented by interconnected pores network having homogenously distributed pores with suitable size and geometry, which will facilitate cell infiltration and proliferation, nutrient and oxygen flow and vascularization [12].

As expected, the beads obtained by lyophilization have a superior porosity, com-pared with those dried at 37 ℃ (Fig. 2). On FESEM micrographs it can be observed that the calcium phosphate microparticles and the CMGG NPs are unitary distributed in the alginate matrix. Even if the pores have different geometry, this is not a negative remark, since it was shown that irregular pores, triangular, elliptic or rectangular, better encourage cell infiltration due to a greater curvature [12].

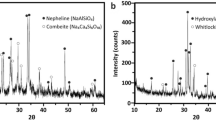

By FTIR-ATR spectra (Fig. 3) were identified characteristic absorption to the beads theoretical composition: ALG, CMGG and CaPs.

The peaks distinguished for the organic matter, observed at 1598, 1599, 1600 cm–1, were assigned to COO– asymmetrical bond stretching, those from 1412, 1419 cm–1, were attributed to COO– symmetrical stretching and 1023, 1027, 1029 cm–1 to the elongation of the ester C−O [13]. In case of the ceramic component, peaks from 1023, 1027, 1029 cm–1 were assigned to ν3 PO43–, while 560, 563, 599 and 600 cm–1 to ν4 PO43–) [14]. The high intensity of the peaks from the region 1023 – 1029 cm–1 can be related with the fact that are common to both organic and inorganic matter and also to the binding of Ca2+ to the glucuronic acid, highlighting the crosslinking [15].

EDX is a useful tool to assess the composition of the biomaterials intended for tis-sue engineering. Regarding the study of bone or bone implants, Prati et al. [16] proved that this innovative technique can offer valuable data about the composition of mineral deposits, allowing the identification of calcium phosphate types, by calculation of Ca/P ratio. Moreover, it can determine some elements that moved from the implant to the bone tissue.

EDX mapping and elemental analysis, showed in Fig. 4 and Fig. 5, sustained the data presented by FESEM: which highlighted a more porous structure for lyophilized beads: specific elements to the used biopolymers were identified (O and C), as well as those specific to calcium phosphates (Ca and P). Also, it can be observed the presence of Cl in small amounts, acquired from the crosslinking process.

As can be seen in Table 1, from elemental analysis (Fig. 5) was determined Ca/P ratio, which can help us to identify the calcium phosphate type. In this study, in the preparation process were used CaPs, with an approximate empirical formula: Ca10(OH)2(PO4)6 (hydroxyapatite) and theoretical Ca/P ratio of 1.67. Since CaCl2 was used as crosslinking agent, it is obvious the presence of a significant amount of Ca, which explains the fact that values higher than 1.67 were determined.

Another key feature for bone tissue engineering scaffolds is a proper behavior in simulated body fluids, PBS being one of the most used [17]. The results of this assay, monitored for 24 h, can be seen in Table 2 and Fig. 6.

The four beads have disintegrated in 24 h and formed a paste, which indicate the possibility to consider them also for bone cement applications and as delivery systems of drugs or other bioactive molecules.

The data pointed out that a concentration of 2% ALG generated beads that are unstable in PBS, anticipating an inappropriate behavior in vivo. The beads with 2% ALG dried at 37 ℃ showed more stability, due to a more compact structure (Fig. 2 and Fig. 4).

In the case of the beads prepared form 3% ALG, it can be observed that at the be-ginning the SD values for dried ones are smaller than those lyophilized, phenomena explained by the compact structure of the dried ones, which will make PBS difficult to initially penetrate the structure, but after certain time (240 min), similar values were determined.

All these remarks have as general observation, the fact that ALG can be a promising component of bone tissue engineering scaffolds at a concentration higher than 3%.

4 Conclusions

Beads obtained by ionic crosslinking for bone tissue engineering, have been prepared by an affordable method, ionic crosslinking from natural biopolymers and calcium phosphates. The beads composition was confirmed by FTIR-ATR spectroscopy, combined with EDX mapping and elemental analysis, whereas FESEM micrographs pointed out their porous structure. The aim of inclusion of carboxymethylated guar gum processed as NPs is to future functionalize them with bioactive molecules. Moreover, the study will continue with the implantation of the beads at Wistar females’ rat, in a femur defects. The regeneration of the bone defect implanted with the prepared beads in comparison with those without any support, or with a commercial product will be studied using micro-computed tomography (μ-CT) system, in order to demonstrate their in vivo potential.

References

Witzler, M., et al.: Polysaccharide-based systems for targeted stem cell differentiation and bone regeneration. Biomolecules 9(12), 840 (2019). https://doi.org/10.3390/biom9120840

Loh, Q.L., Choong, C.: Three-dimensional scaffolds for tissue engineering applications: role of porosity and pore size. Tissue Eng. Part B Rev. 19(6), 485–502 (2013). https://doi.org/10.1089/ten.TEB.2012.0437

Singh, R., Maity, S., Sa, B.: Effect of ionic crosslink on the release of metronidazole from partially carboxymethylated guar gum tablet. Carbohyd. Polym. 106, 414–421 (2014)

Samavedi, S., Whittington, A.R., Goldstein, A.S.: Calcium phosphate ceramics in bone tissue engineering: a review of properties and their influence on cell behavior. Acta Biomater. 9(9), 8037–8045 (2013). https://doi.org/10.1016/j.actbio.2013.06.014

Bachra, Y., Grouli, A., Damiri, F., Zhu, X.X., Talbi, M., Berrada, M.: Synthesis, characterization, and swelling properties of a new highly absorbent hydrogel based on carboxymethyl guar gum reinforced with bentonite and silica particles for disposable hygiene products. ACS Omega 7(43), 39002–39018 (2022). https://doi.org/10.1021/acsomega.2c04744

Zhang, H., Cheng, J., Ao, Q.: Preparation of alginate-based biomaterials and their applications in biomedicine. Mar. Drugs 19, 264 (2021). https://doi.org/10.3390/md19050264

Dodi, G., Hritcu, D., Popa, M.I.: Carboxymethylation of guar gum: synthesis and characterization. Cellul. Chem. Technol. 45, 171–176 (2011)

Gupta, A.P., Verma, D.K.: Preparation and characterization of carboxymethyl guar gum nanoparticles. Int. J. Biol. Macromol. 68, 247–250 (2014). https://doi.org/10.1016/j.ijbiomac.2014.05.012

Dodi, G., et al.: Carboxymethyl guar gum nanoparticles for drug delivery applications: preparation and preliminary in-vitro investigations. Mater. Sci. Eng., C 63, 628–636 (2016). https://doi.org/10.1016/j.msec.2016.03.032

Mudgil, D., Barak, S., Khatkar, B.S.: Guar gum: processing, properties and food applications-a review. J Food Sci Technol. 51(3), 409–418 (2014). https://doi.org/10.1007/s13197-011-0522-x

Dey, P.: Bone mineralisation. Contemporary Topics About Phosphorus in Biology and Materials (2020). https://doi.org/10.5772/intechopen.92065

Abbasi, N., Hamlet, S., Love, R.M., Nguyen, N.T.: Porous scaffolds for bone regeneration. J. Sci. Adv. Mater. Devices 5(1), 1–9 (2020). https://doi.org/10.1016/j.jsamd.2020.01.007

Pereira, R., Carvalho, A., Vaz, D.C., Gil, M.H, Mendes, A., Bártolo, P.: Development of novel alginate based hydrogel films for wound healing applications. Int. J. Biological Macromolecules 52, 221–230 (2013). https://doi.org/10.1016/j.ijbiomac.2012.09.031

Duarte Moreiraa, A.P., Soares Sader, M., de Almeida Soares, G.D., Miguez Rocha Leãoa, M.H.: Strontium incorporation on microspheres of alginate/β-tricalcium phosphate as delivery matrices. Materials Res. 17, 967–973 (2014). https://doi.org/10.1590/S1516-14392014005000095

Cojocaru, F.D., et al.: Polysaccharides-calcium phosphates composite beads as bone substitutes for fractures repair and regeneration. Polymers 15, 1509 (2023). https://doi.org/10.3390/polym15061509

Prati, C., et al.: The use of ESEM-EDX as an innovative tool to analyze the mineral structure of peri-implant human bone. Materials (Basel) 13(7), 1671 (2020). https://doi.org/10.3390/ma13071671

Kaewsichana, L., Riyapana, D., Prommajana, P., Kaewsrichanb, J.: Effects of sintering temperatures on micro-morphology, mechanical properties, and bioactivity of bone scaffolds containing calcium silicate. Sci. Asia 37, 240–246 (2011). https://doi.org/10.2306/scienceasia1513-1874.2011.37.240

Acknowledgments

This work was supported by a grant from the Ministry of Research, Innovation and Digitization, Romania, CNCS/CCCDI—UEFISCDI, project number PN-III-P1–1.1-PD-2019–0937, within PNCDI III.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Cojocaru, F.D. et al. (2024). Ionic Crosslinked Biopolymer-Ceramic Beads for Bone Tissue Engineering. In: Sontea, V., Tiginyanu, I., Railean, S. (eds) 6th International Conference on Nanotechnologies and Biomedical Engineering. ICNBME 2023. IFMBE Proceedings, vol 91. Springer, Cham. https://doi.org/10.1007/978-3-031-42775-6_45

Download citation

DOI: https://doi.org/10.1007/978-3-031-42775-6_45

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-42774-9

Online ISBN: 978-3-031-42775-6

eBook Packages: EngineeringEngineering (R0)