Abstract

In this paper, the adsorption behavior of both unoxidized pullulan and its C6 oxidized correspondent, onto cellulose films derived from trimethylsilyl cellulose (TMSC), was monitored using one of the most sensitive techniques namely Quartz Crystal Microbalance with Dissipation (QCM-D). Pullulan (Pu) was converted into its oxidized counterpart using a selective oxidation protocol that targets only the C6 atom of the anhydroglycosidic unit and involves the presence of a trio of reagents: sodium hypochlorite, sodium bromide (co-oxidants), and a stable radical, i.e., 2,2,6,6-tetramethylpiperidin-1-yl (TEMPO), in the role of mediator in water. The oxidation reaction was carried out at room temperature, and the resulted product, oxidized pullulan (OxP) analyzed using FTIR and 13C-NMR. Buffer solutions of Pu and OxP were prepared at various pH values, and added into contact with thin cellulose layers, the interaction being in situ monitored by QCM-D. The cellulosic matrix deposited on the QCM-D crystals has been prepared by using trimethylsilyl cellulose (TMSC) as a precursor, following spin coating procedure and subsequent hydrolysis under acidic environment. Under the experimental conditions, the QCM-D studies demonstrate that at pH 5 and higher electrolyte concentrations, the highest adsorption occurs. Pullulan that hasn't been oxidized, adsorbs more effectively than its 6-carboxy derivative, which may be explained by the former's low water solubility and the potential for weak repulsive forces to form between OxP's anionic charged groups and the surface of the cellulose.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Pullulan is a biodegradable water-soluble extracellularly polysaccharide, produced from starch by the yeast-like fungus Aureobasidium pullulans, consisting of maltotriose units connected through α-(1 → 4) glycosidic bonds, whereas consecutive maltotriose units are linked to each other by α-(1 → 6) glycosidic bonds. Pullulan is known for its non-toxicity and biocompatibility [1, 2]. It has several commercial applications, primarily in the food and pharmaceutical industries. Pullulan is also being investigated for its biomedical applications in several areas, for example targeted drug and gene delivery, tissue engineering, and wound healing. Due to greater reactivity and lower steric hindrance than other two hydroxyl groups in pullulan, the primary OH group, which exists on two out of the three glucose units, has attracted considerable attention for chemical modifications [1,2,3].

Thereby, the incorporation of carboxylic acid groups in the pullulan backbone will provide anionic compounds, which allows obtaining polymer solutions with various properties and viscosity. Today, 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) is widely used for surface carboxylation of different polysaccharides, employing sodium hypochlorite, sodium bromide in homogeneous conditions, using water as solvent, at pH ~ 10, the primary hydroxyl groups being selectively converted to sodium carboxylates [4]. Notably, other non persistent nitroxyl radicals such as phthalimide-N-oxy (PINO) were tested as efficient mediators in the case of different polysaccharides’ oxidation [5,6,7,8,9]. The degree of oxidation can be easily controlled by adjusting the sodium hypochlorite stoichiometry. The oxidized product, in the case of pullulan, OxP, is even more water-soluble than pullulan itself, and possesses exceptional features for drug delivery and other applications. [10, 11].

The purpose of this study was to investigate the attachment efficiency of pullulan (Pu) and oxidized pullulan (OxP) onto thin cellulose films derived from trimethylsilyl cellulose (TMSC), deposited on quartz crystals by using quart crystal microbalance with dissipation (QCM-D) and surface plasmon resonance (SPR) techniques.

2 Experimental Section

2.1 Materials

Pullulan (Mw = 150 kDa) purchased from TCI Europe was dried under vacuum at 120 ℃ overnight prior to use. 2,2,6,6-tetramethylpiperidin-1-yl (TEMPO) 99% Sigma-Aldrich, sodium hypochlorite (NaOCl, 9% chlorine, Chemical Company Romania) and sodium bromide (99% Alfa Aesar) were used as received. Trimethylsilyl cellulose (TMSC, degree of substitution 2.8, Mw = 185,000 g mol−1) from TITK, Rudolstadt, Germany. The water used for sample solution preparation and rinsing was of Milli-Q ultrapure grade with a resistivity of 18.2 MΩ−1 cm−1.

2.2 Pullulan Oxidation

Oxidation of pullulan was carried out as follows: 1 g of pullulan was dispersed in 30 mL distilled water, then 0.1 mmol TEMPO and 1 mmol sodium bromide were added to the pullulan dispersion. After the pH was adjusted to 10 with a few drops of 0.5 M hydrochloric acid, a volume of sodium hypochlorite corresponding to 10 mmol/g pullulan was added. The pH was carefully checked with a pH meter instrument and maintained at 10 by adding 0.4 M sodium hydroxide solution. After 4 h, the reaction was stopped with 5 mL of methanol and then acidified to a pH of 6.8. A large volume of ethanol has been used to precipitate the reaction products and the formed precipitate was collected by centrifugation. The oxidized pullulan was re-dissolved in water, dialyzed and finally freeze-dried.

2.3 Sensors Cleaning, Preparation of Cellulose Films and Adsorption Studies

Prior to spin coating, both QCM-D and SPR gold sensors were subject to an intensive cleaning treatment, in a 5:1:1 mixture of Milli-Q water, H2O2 (30%) and NH4OH (25%) for 5 min at 70 ℃, then extensively rinsed with MilliQ water and blow dried with nitrogen gas. All QCM-D experiments were performed at 30 ℃. 50 µl toluene solution of TMSC were spin coated at 2,000 rpm at an acceleration of 2,500 rpm s−1 for 120 s onto a 14-mm quartz crystal. The spin-coated TMSC films were subsequently exposed for 120 s in a 2 M HCl vapor chamber, which caused the full conversion of the TMSC into cellulose. The cellulose films thus prepared were used for anchoring the pullulan (Pu) and the oxidized pullulan (OxP). Pu and OxP solutions (0.1%) were prepared by dissolving 0.1 g Pu or OxP in 99.9 mL of 1 mM or 100 mM NaCl solution.

2.4 NMR Determinations

The NMR spectra were obtained on a Bruker Avance DRX 400 MHz spectrometer, equipped with a 5 mm QNP direct detection probe and z-gradients.

2.5 QCM-D Measurements

The QCM-D experiments were performed with a quartz crystal microbalance with a dissipation unit (QCM-D) type Q-Sense (Goteborg, Sweden). The analyses were performed on cellulose surfaces, prepared using spin coating technique. The quartz crystals (supplied by Q-Sense AB) were AT-cut quartz with gold plate electrodes and with gold on the active surface. The fundamental frequency of quartz crystals is f0 ≈ 4.95 MHz and sensitivity constant C = 0.177 mg/m2 Hz.

3 Results and Discussion

TEMPO-Mediated Oxidation of Pullulan.

Pullulan has been oxidized by using sodium hypochlorite and sodium bromide, at room temperature, and TEMPO serving as mediator for the oxidation reaction. The possibility for complete oxidation of pullulan to its carboxylate, and the high regioselectivity of this reaction for C6-OH were the motivation to employ this methodology to obtain pullulan derivatives containing carboxyl groups. The oxidized sample is fully oxidized at C6-OH (all OH groups are converted to carboxyl groups), confirmed by means of 13C NMR spectroscopy (Fig. 1), since the CH2OH peak is absent. Moreover, there is no resonance in the 195–205 ppm region in the spectra, indicating that no ketone group is present after the oxidation. The spectrum of unmodified pullulan, showing the signal of C6 atom (6g1 → 4) at 69.26 ppm and C6 atom (4g1 → 4 and 4g1 → 6) at 63.19 ppm. Also the signals of the C1 atom around 100.68–102.99 ppm, C4 atom at 80.56 ppm and C2,3,5 atoms between 72.26 and 76.21 ppm can be observed (Arnosti & Repeta, 1995).

The FTIR spectra of oxidized pullulan and pullulan were recorded to evaluate possible structural changes after oxidation (Fig. 2). The FTIR spectra of oxidized pullulan in acidic form shows a carboxylic acid band at 1701 cm−1, showing that there is evident transformation from hydroxyl to carboxylic acid group upon oxidation of pullulan.The main absorption bands of pullulan can be found at: 3500 cm−1 region due to OH stretching vibration (νOH), 2926 cm−1 corresponding to the CH stretching vibration (νCH), 1653 cm−1 adsorption band of bounded water, 1458 cm−1 assigned to symmetric CH2 bending vibration and 930 cm−1 assigned to COC stretching at β-(1 → 4)-glycosidic linkages. The adsorption band at 1610 cm−1 can be also attributed to the CO stretching of free carboxylate groups, since the adsorption band at 1417 cm−1 represents the CO symmetric stretching of dissociated carboxyl groups (Saito et al., 2009). The other bands appear nearly unchanged and therefore a successful oxidation could be concluded.

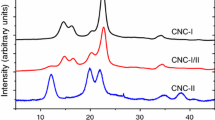

The cellulose films, were prepared starting from trimethylsilyl cellulose (TMSC), by spin coating, followed by the cellulose regeneration by exposing the films to the 10% (by weight) vapors of aqueous hydrochloric acid, at room temperature. The cleavage of trimethylsilyl side groups by acid vapor leads to well-defined regenerated cellulose films (Fig. 3).

Characterization of TMSC and Regenerated Cellulose Films.

TMSC is a quite suitable precursor to obtaining cellulose films. The solubility of TMSC depends of degree of substitution (DSSi), thus the TMSC with DSSi smaller than 1.5 is soluble in polar solvents, like ethanol or DMSO while TMSC with DSSi bigger than 2.5 is soluble in unpolar solvents, like toluene and chloroform (our case). The solubility of TMSC is an important parameter when studying the interaction of regenerated cellulose with other polymers, the morphology and thickness of the layers depending on the TMSC solubility. For the preparation of the cellulose films, TMSC was deposited on the QCM crystals by spin coating, followed by cleavage of the silyl groups under a vapors precinct of HCl.

Adsorbtion of Pullulan and Oxidized Pullulan on Cellulose Film Monitored by QCM-D and SPR.

The QCM-D technique provides valuable information in real time on the adsorption of various components onto a quartz crystal. The method principle is based on the change in resonance frequency of a quartz crystal, due to an increase of mass as a consequence of deposition of different materials. Regeneration of cellulose from TMSC provides free –OH groups, which serves for further anchoring of Pu and OxP as proposed in Fig. 4.

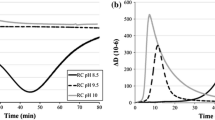

To ensure the anchoring of Pu and OxP to cellulose films, all the reactions were performed in situ, in the QCM-D chamber, by introducing a continuous flow of a 0.1 mL min−1 of 0.1% solution of Pu or OxP either in 1 mM or 100 mM NaCl solutions respectively, in order to emphasize the role of the added salt concentration. Pullulan adsorb better than OxP on cellulose films in both 1 and 100 mM NaCl solutions. Another parameter that can influence decisively the adsorption processes is pH value. Therefore, we considered useful to carry out the study of the adsorption of the Pu and OxP at three different pH values, ranging from 2 to 8. The pH value has a great influence on the adsorption behavior. The optimum value of the maximum adsorption of both Pu and OxP is found to be 5, which is close to isoelectric point of the pullulan.

Figure 5 shows the changes in the frequency and dissipation after in situ deposition of Pu in 100 mM NaCl at pH = 5 on cellulose films. It can be seen that the Pu in the 100 mM salt solution at pH = 5, exhibits the highest adhesion with a change in the vibration frequency of −12.5 Hz and the dissipation shows an increase of Pu immobilized on the cellulose film and a change of 1.40 at the time of washing with the 100 mM salt solution.

4 Conclusions

One of the most challenging polysaccharides with applications in the healthcare and pharmaceutical industries, pullulan has seen significant growth in recent years in the adsorption of active principles. In this paper, the pH and electrolyte type influence on pullulan and 6-carboxy pullulan adsorption on the cellulose thin films is studied using one of the most sensitive, mass-dependent techniques, i.e. QCM-D. Pullulan was oxidized using a selective system, which includes the stable radical 2,2,6,6-tetramethylpiperidin-1-yl (TEMPO) as mediator, sodium hypochlorite and sodium bromide, as actual oxidants, at pH = 10, at ambient temperature. The QCM-D experiments show that the maximum adsorption occur at pH 5 using larger concentration of electrolyte. Unmodified pullulan adsorbs better in comparison with its 6-carboxy derivative, which could be explain by the poor water solubility of the first and the weak repulsive forces might appear between the anionic charged groups in OxP and cellulose surface.

References

Spatareanu, A., Bercea, M., Budtova, T., Harabagiu, V., Sacarescu, L., Coseri, S.: Synthesis, characterization and solution behaviour of oxidized pullulan. Carbohyd. Polym. 111, 63–71 (2014). https://doi.org/10.1016/j.carbpol.2014.04.060

Coseri, S., et al.: Green synthesis of the silver nanoparticles mediated by pullulan and 6-carboxypullulan. Carbohyd. Polym. 116, 9–17 (2015). https://doi.org/10.1016/j.carbpol.2014.06.008

Coseri, S., Spatareanu, A., Sacarescu, L., Socoliuc, V., Stratulat, I.S., Harabagiu, V.: Pullulan: a versatile coating agent for superparamagnetic iron oxide nanoparticles. J. Appl. Polym. Sci. 133(5), 42926 (2016). https://doi.org/10.1002/app.42926

Denooy, A.E.J., Besemer, A.C., Vanbekkum, H.: Highly selective nitroxyl radical-mediated oxidation of primary alcohol groups in water-soluble glucans. Carbohyd. Res. 269(1), 89–98 (1995). https://doi.org/10.1016/0008-6215(94)00343-e

Coseri, S.: A new and efficient heterogeneous system for the Phthalimide-N-oxyl radical (PINO) generation. Eur. J. Org. Chem. 11, 1725–1729 (2007). https://doi.org/10.1002/ejoc.200601072

Coseri, S.: N-Hydroxyphthalimide (NHPI)/lead tetraacetate, a peculiar system for the Phthalimide-N-Oxyl (PINO) radical generation. Mini-Rev. Org. Chem. 5(3), 222–227 (2008). https://doi.org/10.2174/157019308785161675

Coseri, S.: N-Hydroxyphthalimide (NHPI)/lead tetraacetate reactions with cyclic and acyclic alkenes. J. Phys. Org. Chem. 22(5), 397–402 (2009). https://doi.org/10.1002/poc.1466

Coseri, S.: Phthalimide-N-oxyl (PINO) radical, a powerful catalytic agent generation and versatility towards various organic substrates. Catal. Rev. Sci. Technol. 51(2), 218–292 (2009). https://doi.org/10.1080/01614940902743841

Coseri, S., Biliuta, G., Simionescu, B.C.: Selective oxidation of cellulose, mediated by N-hydroxyphthalimide, under a metal-free environment. Polym. Chem. 9(8), 961–967 (2018). https://doi.org/10.1039/c7py01710c

Dulong, V., Le Cerf, D., Picton, L., Muller, G.: Carboxymethylpullulan hydrogels with a ionic and/or amphiphilic behavior: swelling properties and entrapment of cationic and/or hydrophobic molecules. Colloids Surfaces A-Physicochem. Eng. Aspects 274(1–3), 163–169 (2006). https://doi.org/10.1016/j.colsurfa.2005.08.045

Posey-Dowty, J.D., Watterson, T.L., Wilson, A.K., Edgar, K.J., Shelton, M.C., Lingerfelt, L.R.: Zero-order release formulations using a novel cellulose ester. Cellulose 14(1), 73–83 (2007). https://doi.org/10.1007/s10570-006-9079-7

Acknowledgments

This work was supported by a grant of the Ministry of Research, Innovation and Digitization, CNCS/CCCDI – UEFISCDI, project number PN-III-P4-ID-PCE-2020–0476, within PNCDI III.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

The Authors Declare that They Have no Conflict of Interest.

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Coseri, S., Biliuta, G., Chibac-Scutaru, A.L. (2024). Interaction Between Thin Layers of Polysaccharides Studied by Quartz Crystal Microbalance with Dissipation (QCM-D). In: Sontea, V., Tiginyanu, I., Railean, S. (eds) 6th International Conference on Nanotechnologies and Biomedical Engineering. ICNBME 2023. IFMBE Proceedings, vol 91. Springer, Cham. https://doi.org/10.1007/978-3-031-42775-6_36

Download citation

DOI: https://doi.org/10.1007/978-3-031-42775-6_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-42774-9

Online ISBN: 978-3-031-42775-6

eBook Packages: EngineeringEngineering (R0)