Abstract

This article contains interesting results from numerical modelling of forging tool wear. It concerns tools with hybrid layers combining hardfacing and nitriding. These are original layers that significantly improve tool life in hot forging processes, which is also confirmed by the results presented here. The authors developed their own wear model based on the Archard model. The new model takes into account the hardness of the material in the surface layer that is given by hardfacing and by nitriding. In addition, it takes into account changes in hardness as a result of exploitation in hot forging processes. The results of the tests confirmed the model's consistency with experiment at a level of 70–90%.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Tool life is a significant factor impacting the effectiveness of die-forging processes. There are many studies on tool wear in forging techniques, but there needs to be a universal method to estimate their durability in complex hot die-forging processes. Previous studies have shown that the main mechanisms responsible for the wear of tools in hot forging processes are abrasive wear, ductile deformation and fatigue cracking.

Attempts to estimate wear of forging tools using computer programs based on the finite element method (FEM) have been made for a long time. Numerical methods allow us to describe the conditions in which forging processes are carried out, and to predict the amount of wear grounded on the available wear models. However, without comparing FEM results with experimental results, there is no certainty as to the accuracy of these models. Therefore such approach limits predictions about tool wear only to processes with simple geometry and stable forging conditions on the basis of which the models have been developed.

The most widespread wear model developed by Archard [1] is formed on the premise that the main destructive mechanism is abrasive wear. In many subsequent modifications, amongst others, these values were added to the model: the hardness of the material [2] and even the dependence of the hardness on the surface temperature of the die as a function of time by Kang [3, 4]. The impact of abrasive particles, that is abrasive wear [5] and the impact of adhesive wear [6] were also considered. Accordingly to Archard's model wear rate at any time of forging can be marked as Eq. (1):

wear rate in one cycle as Eq. (2):

On the premise that the same volume of material and hardness of the material is used in each cycle, wear for any number of cycles is Eq. (3):

where:

w – total value of wear [mm]), σ – normal stress [MPa], Vrel – relative velocity in contact [mm/s], H – hardness of material [MPa], k – non-dimensional wear factor, t – time.

The assumption in Eq. (3) that the hardness of the material does not change is not accurate, as the study of the episode of tempering of the die material has confirmed. Hardness may alter only due to tempering in higher temperatures, where tribological conditions also change significantly. Therefore, in this paper [7], it has been assumed that the Archard theory is appropriate to define wear process, taking into account that both hardness and wear factors are not constant. The proposed wear model is described by Eq. (4), in which the wear factor k and hardness H are functions of temperature:

The hardness H(T) and the wear factor k(T) functions can be obtained from the hardness test and wear test performed at higher temperatures. During forging, force, temperature and velocity fields are determined by the position on the die cavity and the contact time. Therefore, the Eq. (4) may be modified to Eq. (5):

where:

Wij – wear depth w i - position in the die cavity in the j - period Δtj. Lij- friction path, Pij – force (pressure) i T - the temperature can be determined in the numerical simulation of the forging process. In this case, wear depth of the i-th position on the die cavity for a single forging operation can be denoted as Eq. (6):

where n is the sum of the simulated forging process cycles. Next, by adding up wear in subsequent forging cycles, the final wear value is obtained.

The results of many studies demonstrate that Archard model can be applied to some forging processes and the distribution of wear is determined with only a minor error.

The Archard model may be efficient when calculating wear of tools made of commonly used H11 or H13 tool steels, assuming that the surface layer of a tool was not previously modified, especially in an instance of complex structures, which are presented in the work hybrid layers combining hardfacing and nitriding.

This work demonstrates the results obtained from numerical modelling of a tool wear process used in the selected hot die forging process. An innovatory model was used to describe wear of a hybrid surface layer of a tool in the die-forging process. The result of FEM modelling was compared with the industrial results measured on tools after forging process.

Comparing to typical approach with Archard equation, the proposed solution allows to take into account properties changes resulting from both new coating techniques, as well as surface parameter changes related to accumulation of existing wear. In the typical Archard model, only one coefficient and hardness is used, while more advanced implementations use hardness vs temperature profile. In the proposed approach, the material parameters are identified relative to the material layer thickness, the material diffusion area, as well as temperature dependency. Additionally, the Archard equation includes coefficient changes with degradation.

Many years of forging tool life research conducted by the authors’ team have led to the development of innovative solutions, especially hybrid layers to improve tool life [8]. The original concept of combining surfacing with nitriding was presented in the work [9]. Further research confirmed the expected properties of hybrid layers combining surfacing and nitriding [10]. The present work is a continuation of research in this area because it uses two such layers to increase the durability of forging tools.

2 Methodology

The research generally involved 2 parts. The first is numerical modeling based on a newly built wear model of the surface layer, which allows to take into account property changes resulting from both new coating techniques, as well as surface parameter changes related to accumulation of existing wear. Section 2.1 describes the model and Sect. 2.2 describes how to perform its implementation. The second part (Sect. 2.3) is an experimental study in the hot forging process, which was used to evaluate and correct the wear model.

2.1 Model Description

In a typical Archard equation (Eq. 1) for calculating wear depth w, the coefficient C is usually constant, while the normal stress (p) and velocity in contact (v) are obtained from numerical stimulation. In regular implementations, it is acquired from integration phase using contact velocity and computation step time. The hardness (HV) relates to the tool material and in its basic form is also remains constant.

The explication is numerically shown in Eq. (7), which calculates the total wear during calculating using the adapted Archard equation [11], in which the coefficient C is dependent on existing wear. Additionally, material hardness HV is also calculated relatively to the existing degradation, which allows to detect any changes of material properties with in boundary of hardfaced and nitrided layers.

The relation of the C coefficient is described as using 2 values switched by the threshold. It has been proven sufficient even for complex tool materials as considered in this paper.

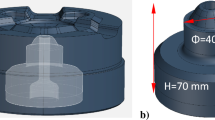

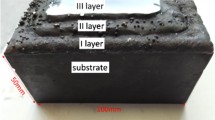

To introduce the tool hardness value of the multi-layer material, the tool has been divided to 3 sub-models (as in Fig. 1): The nitrided layer, the hardfaced (welded-on) layer and the base material. Each of these parts has its own hardness HV(T) profile. In the course of numerical computation, the current hardness is calculated. This involves using both layer thickness values and interpolation ranges, a and b based on existing wear. If an existing wear points to the depth in the interpolation range, the hardness value is linearly interpolated from these values.

While thickness parameters can be identified from measurements, the ranges have to be identified by comparing simulation with total wear measurements.

2.2 Model Implementation

The implementation has been made using Fortran routine developed for Forge NxT numerical simulation software. The model has been split into to parts responsible for temperature dependency, final hardness calculation and the adapted Archard equation, as shown in the Fig. 2. It is possible, using this alignment, to obtain current estimated hardness values.

For the hardness evolution routine, the input parameters are:

-

- Hardness in function of the distance from the surface for various parts of the material,

-

- Current wear depth at the specific point – obtained from the previous computation step,

-

- Layer depth values identified as model coefficients,

-

- Transition widths between layers, identified as model coefficients.

For the parameter identification purpose, the raw abrasive wear value at the specific time (Wt) has been calculated by not using any of the adapter parameters, using the Eq. (8):

The identification is performed for each block backwards using increasingly complex processes. Firstly, it is the identification of some coefficients and thresholds needed for Archard equation. For this stage, a simple repetitive forging process is employed, with dies made of a single material. However, to identify parameters for other parts, material hardness measurements are required.

The first step consists of the computation of the coefficient-less value for Archard’s equation, which is calculated from the sliding distance and normal stress. At this stage the material hardness may be measured by using a specific value when en it's given, or a thermal dependency. This value is then used to identify the C coefficients and their margins by dividing the measured and calculated wear by various degradation depths. It is then possible to include wear as a result of multiple forgings, so the identification is done using wear measurements for various number of forgings.

Secondly, it is the identification of hardness thermal evolution for considered material. The hardness values are parametrized from measurements to obtain HV(t) profile used in calculation. It then may be possible to obtain better parameters in adapted Archard solution for processes with a single material. To correctly predict the wear at this stage, the simulation must contain a proper thermal parameters of the workpiece-die interface including possible thermal steady state situation.

The last step of the parameter identification, is the identification of material thickness values and their transition shares. It is performed for tools with coatings only. While the material thickness itself can be taken from measurements, the transition share values (a and b in Fig. 1) have been identified by comparing the degradation result with wear.

2.3 Performance Tests on the Tools with Hybrid Layers

Performance tests were carried out in idustrial conditions for a selected forging tool, which was a hot forging tool made of H11 steel (Fig. 3).

The tests were performed on three tools. The first of them was a reference tool, made of the base material without modification of the surface layer. The other two tools were welded with different materials: DO*04 (Fe-Cr-Co-Mo) and DO*15 (Fe-Cr-Mo-W). The chemical composition for the DO*04 and DO*15 wires measured with a spark spectrometer was presented in the Table 1. After welding and processing, the tools were gas nitrided by ZeroFlow method with the same parameters to achieve a diffusion layer, without a precipitations of nitrides on the surface.

Finally, the tools were tested in industrial conditions. According to the previous assumption, a similar number of forgings were forged using each of them. Working surfaces of the studied dies were scanned before and after exploitation; then, data obtained were compared using the local best-fit algorithm in GOM Inspect software. The results of wear measurements are presented in the form of a color map of deviations, showing losses (red) and excesses (blue) within the range < −1.0 mm, 0.0 mm >. The results of analysis of individual dies are presented in Fig. 5.

3 Results

The tools were analysed after industrial testing. First, their surface was observed for a visual, macroscopic assessment of wear. In addition, the tools were scanned with a structured light scanner before and after forging to measure wear depth across the surface of their die cavity. The result of this measurement was used for comparison with the FEM result, which also determined the wear depth.

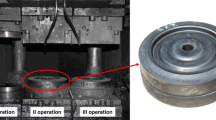

Photos of tools taken after the explotation performance tests taken for macroscopic observations are presented below in the Fig. 4.

Macroscopic observations of the surfaces made it possible to assess that there were significant differences in wear. The use of combined hardfacing and nitriding layers increased wear resistance. In addition, tools with layers wore differently - they were less susceptible to abrasion and more susceptible to fracture. The dominant wear mechanism for H11 steels is abrasive wear (as confirmed in the literature) and for hybrid layers abrasive wear is first accompanied by thermo-mechanical fatigue. The results of the comparative analysis of the scans are shown in the next Fig. 5.

The results of FEM model were presented which are calculated for the same 3 material configutrations. The model has been tested on the selected operation of a hot forging process. The parameters for materials used have been identified by using the same parameter set for the base material, while different identified parameters for surface layers. The simulation of wear for various materials has been shown in Fig. 6.

The results of modeling and scanning of tools after the hot forging process showed similar wear in terms of its location on the surface and depth. To enable quantitative evaluation of wear, measurements were made at the points marked on the scan in Fig. 5 and on the model in Fig. 6. The results of the comparison of wear according to the model to the measurement by scanning are shown in Tables 2–4. The average value of the deviation Δ [%] between the model and the measurement is 9.64% for the tool made of H11 steel, for the tool with DO*04 + nitriding layer is 32% and for the tool with DO*15 + nitriding layer is 22.4%.

4 Conclusion

The model determined tool wear with high probability. Especially in the case of the tool with the base material H11 steel, the actual wear is very similar to the modelling results. Similarly, in the case of tools with hybrid layers combining hardfacing and nitriding, less wear was predicted for the DO*15 + nitriding layer, which is confirmed by the experiment.

There are discrepancies between the modelling results and the actual wear depth results of about 10–30%. This is a problem that may be due to the fact that the model does not take into account the phenomenon of thermo-mechanical fatigue, crack development and material spalling, which occurs as a destructive mechanism with hard layers. The discrepancy between the model and reality may also be due to the irregularity of industrial forging processes and the imperfection of the model itself.

Hybrid layers combining surfacing and nitriding effectively increase forging tool life. It is therefore worth using these layers to effectively increase tool life in hot forging processes.

References

Archard, J.F.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24(8), 981–988 (1953)

Hansen, P.H., Bay, N.: A flexible computer based system for prediction of wear distribution in forming tools. In: Advanced Technology of Plasticity, pp. 19–26. Kyoto (1990)

Kang, J.H., Park, I.W., Jae, J.S., Kang, S.S.: Study on a die wear model considering thermal softening: (I) construction of the wear model. J. Mater. Process. Technol. 96(1–3), 53–58 (1999)

Kang, J.H., Park, I.W., Jae, J.S., Kang, S.S.: Study on a die wear model considering thermal softening (II): Application of the suggested wear model. J. Mater. Process. Technol. 94(2–3), 183–188 (1999)

Kragelsky, I.V., Zolotar, A.I., Sheiwekhman, A.O.: Theory of material wear by solid particle impact - a review. Tribol. Int. 18(1), 3–11 (1985)

Stolarski, T.A.: Adhesive wear of lubricated contacts. Tribol. Int. 12(4), 169–179 (1979)

Lee, R.S., Jou, J.L.: Application of numerical simulation for wear analysis of warm forging die. J. Mater. Process. Technol. 140(1–3), 43–48 (2003)

Widomski, P., Gronostajski, Z.: Comprehensive review of methods for increasing the durability of hot forging tools. Procedia Manuf. 47, 349–355 (2020)

Gronostajski, Z., Widomski, P., Kaszuba, M., Zwierzchowski, M., Hawryluk, M.: Influence of both hardfaced and nitrided layers on the durability of hot forging tools. Surf. Innovat. 6(4–5), 301–310 (2018)

Kaszuba, M., Widomski, P., Białucki, P., Lange, A., Boryczko, B., Walczak, M.: Properties of new-generation hybrid layers combining hardfacing and nitriding dedicated to improvement in forging tools’ durability. Arch. Civil Mech. Eng. 20(3), 1–12 (2020). https://doi.org/10.1007/s43452-020-00080-8

Wilkus, M., Polak, S., Gronostajski, Z., Kaszuba, M., Rauch, Ł, Pietrzyk, M.: Modelling of the die wear in the hot forging process using the archard model. Comput. Meth. Mater. Sci. 15(2), 311–321 (2015)

Acknowledgments

This study was funded by National Center for Research and Development, Poland (grant no. Lider X/0028/L-10/2018).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Widomski, P., Gronostajski, Z., Kaszuba, M., Wilkus, M., Rychlik, M., Krawczyk, J. (2024). Improvement of Forging Tool Life by Hybrid Layers Combining Hardfacing and Nitriding Supported by Numerical Modelling of the Surface Layer. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-41341-4_35

Download citation

DOI: https://doi.org/10.1007/978-3-031-41341-4_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41340-7

Online ISBN: 978-3-031-41341-4

eBook Packages: EngineeringEngineering (R0)