Abstract

The general step reduction and enlargement (GeneSteR + E) method and the general forging die design (GeneDie) method can exhaustively generate forging processes and dies for non-axisymmetric forged products. However, the variation of generated plans are limited, potentially excluding optimal solutions. This paper proposes an optimization support method that generates alternative design plans for non-axisymmetric forged products. The proposed method generates various die design plans according to various shapes of a workpiece and relative positions of the forged product and workpiece to dies. The shape of an initial work material is generated by resizing the shape in an original process plan while keeping the same volume as planned, and the parting lines of dies are defined by rotating the forged product around its center of gravity. The positions of the workpiece are generated by distributing the workpiece around its center of gravity. The shape of a forged product is modified so that undercut constraints are satisfied on the premise of subsequent blanking or punching processes. A large number of design candidates are evaluated by a finite element method analysis tool using a robotic process automation (RPA) tool. An experimental design knowledge base and RPA workflows were developed and applied to the forging dies of automotive parts. The experimental results show that the proposed method can generate alternative forging dies including those nearly equivalent those designed by an experienced engineer but in less time.

R. Okamoto — The author is currently working for Hitachi Ltd.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Parting line

- Non-axisymmetric forged product

- Finite element method

- Robotic process automation

- Sequential forging press method

1 Introduction

The production design of cold- and warm-forged products involves forged product design to determine the shapes of the products formed by the forging processes, forging process design from the initial work material to the final product, die design to form forged products at each stage of a process plan, and evaluation of the die design plans. The die design affects the product quality, cost, and delivery. These tasks require extensive knowledge and experience in plastic forming, forging, blanking, and punching and are time consuming and difficult even for experienced engineers. It is thus important to improve the efficiency and quality of the production design of forged products.

Case-based [1,2,3,4] and rule-based [5,6,7,8,9,10] approaches have been proposed for planning the forging process. However, these methods are limited to products similar to those in design cases or mainly axisymmetric products. The general step reduction and enlargement (GeneSteR + E) method [11] and the general forging die design (GeneDie) method [12] can generate multiple process and die design plans for totally non-axisymmetric forged products, such as hexagon-head bolts, yokes, and electronic connectors. However, the generated die design plans are limited on the relative positions of a forged product and a workpiece to dies and the shape of the initial work material. Therefore, an optimal or suboptimal die design plan may not always be included in the generated plans. It is important to support the optimization of die design plans because the design and evaluation of a large number of design candidates are troublesome and time consuming owing to trial and error.

In this paper, we propose an optimization support method for forging processes and dies to form non-axisymmetric forged products. The proposed method combines the exhaustive generation of die design plans and the automation of finite element method (FEM) analysis using a robotic process automation (RPA) tool. The die design plans are generated by modifying given process and die design plans regarding the relative positions of the forged product and the workpiece to dies and the shape of the initial work material. The modification of forging process and die design plans assumes the existence of the subsequent blanking and punching process. A large number of generated design candidates are automatically analyzed by the FEM analysis tool controlled by the RPA tool. The present study developed an experimental knowledge base and RPA workflows and applied them to automotive parts. The experimental results show that the proposed method generates alternative forging dies including dies nearly equivalent to those designed by an experienced engineer but in a shorter time. The proposed method thus improves the efficiency and quality of process planning and die design.

The scope and issues of forging die optimization support are described in Sect. 2. Strategies for resolving undercuts caused by the rotation of a forged product are described in Sect. 3. The detailed design and evaluation procedures of forging dies are described in Sect. 4. The experimental results obtained when the proposed method is applied to automotive parts are presented in Sect. 5.

2 Issues of Forging Die Optimization Support

2.1 Scope and Issues of Forging Die Optimization

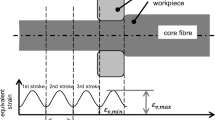

In this study, the scope of forged products is thick plates formable by the sequential forging press (SFP) method [14] as shown in Fig. 1a. The SFP method was proposed for forming hollow parts, such as Universal Serial Bus (USB) Type-C connectors, which are conventionally fabricated by metal injection molding, or for thick plates made through shearing processes such as fine blanking. The SFP method uses upper and lower dies to hold a space for the work material and forges the work material by inserting a pair of punches into this space from the left and right sides as shown in Fig. 1b.

The GeneSteR + E method generates process plans exhaustively by combining simple shape transformation rules over forged products. The GeneDie method also generates die design plans exhaustively by combining the basic die structure types and the forming surface configurations. However, the variation in the relative positions of a forged product and workpiece to dies and the shape of the initial work material is limited to simple cases. Taking the example of the forged product shown in Fig. 1a, there are various possibilities for the position of the forged product as shown in Fig. 2a, and the initial position is not always optimal or suboptimal. The positions of the forged product and workpiece affect both the process and die plans, but hereinafter only the die is referred to unless it is necessary to distinguish the plans.

The scope of die design optimization is the position of the forged product and workpiece relative to the dies and the shape of the initial work material. The position of a forged product is changed by rotating the forged product around its center of gravity as shown in Fig. 2a and the position of a workpiece is changed by rotating the workpiece around its center of gravity as shown in Fig. 2b. The shape of an initial work material is changed by resizing its width and height while keeping the planned volume as shown in Fig. 2c.

The rotation and resizing operations themselves are simple but the rotation of a forged product may introduce an undercut. Figure 3 presents an example of undercuts (shown in yellow) resulting from the rotation of a forged product. The adoption of an undercut countermeasure may affect the volume of the initial work material. Countermeasures against undercuts are discussed in Sect. 3.

2.2 Issues in Evaluating Die Design Candidates

If a large number of design candidates are obtained, it is necessary to evaluate them to find the best one. Prototyping or trial production is best from the point of view of accuracy but is costly and time consuming. Physical simulation using alternative materials such as clay and wax is less accurate than prototyping but can be done more quickly and at lower cost. However, physical simulation is not suitable for evaluating a large number of die design plans. Numerical analysis is generally less accurate than physical simulation but is quicker and less expensive than the former two approaches. In this study, FEM analysis is adopted for die evaluation because the purpose of the evaluation is to eliminate unlikely design candidates and narrow the range of potential solutions. However, if an FEM analysis tool cannot be controlled via an application program interface such as Windows Object Linking & Embedding, engineers need to interactively operate the tool via a graphical user interface. There is a limit to manual processing as the number of design candidates increases, and it is thus important to automate the analysis without manual intervention.

3 Countermeasures Against Undercuts

3.1 Undercut Problems

An undercut refers to a state in which the forged product cannot be removed from the dies after forming owing to interference between the dies and forged product. Generally, several approaches are adopted to solve undercut problems. In this study, subsequent blanking and punching processes are assumed after the forging processes. The undercut problems are thus solved through the shape modification of a forged product.

Undercuts do not occur if the shape of a forged product tapers off from the parting line in the pressing direction. Therefore, the undercut problem can be simplified to the first quadrant of a forged product divided by the parting line and one or two line segments perpendicular to it as shown in Fig. 4. In the following, we discuss only the first quadrant, and the X, Y, and Z axes respectively correspond to the right, upper, and front directions in figures.

3.2 Classification of Undercuts

Undercuts can be classified into two types from the point of view of the interfering object. One type occurs between the forged product and the parting line and the other occurs within the forged product. Figure 5 shows examples of these two types. In this paper, the former is referred to as the work-parting line undercut and the latter as the inter-workpiece undercut.

3.2.1 Classification of Work-Parting Line Undercuts

Work-parting line undercuts can be further classified into the four types shown in Fig. 6. Let P1 be the vertex of the convex portion in the Y-axis direction where the undercut occurs and let P2 be the vertex of the concave portion in the X-axis direction. The undercuts are classified along the edge from the parting line of the workpiece to the maximum coordinate in the pressing direction of the workpiece according to the order of occurrence and the X-coordinate value.

A press direction undercut refers to the state in which P1 is followed by P2 and the X coordinate of P2 is smaller than that of P1. A release direction undercut refers to the state in which P1 follows P2 and the X coordinate of P2 is greater than that of P1. A sharp-tip undercut refers to the state in which P1 is equal to the maximum coordinate in the pressing direction. A basic work-parting line undercut refers to the state in which P1 is different from all of the above. Currently, only the basic work-parting line undercut, which is likely to happen often if a forged product is rotated, is supported by the proposed method.

3.2.2 Classification of Inter-workpiece Undercuts

Inter-workpiece undercuts can be further classified into the two types shown in Fig. 7. A basic inter-workpiece undercut refers to the state in which there is a dent in the direction perpendicular to the pressing direction. A folded shape undercut refers to the state in which there is a dent in the pressing direction and there is an undercut on the top surface of the dent. This type of undercuts is currently beyond the scope of the proposed method.

3.3 Shape Modification Procedure for Basic Work-Parting Line Undercuts

If a basic work-parting line undercut exists in the shape of a forged product, the shape of the forged product is modified in three steps.

-

(1)

The forged product is cut along a Y–Z plane at the vertex of convex portion in Y-axis direction.

-

(2)

The cut surface of the forged product is extruded to the location of the parting line.

-

(3)

The forged product is combined with the extruded model.

An example of the shape modification of a forged product for the basic work-parting line undercut is shown in Fig. 8.

3.4 Undercut Type Convergence Through Shape Division

The type of undercut may be changed by dividing the shape of a forged product. In the case of inter-workpiece undercuts, the type can be converged to work-parting line undercuts by dividing the shape. The position where the shape is divided differs depending on the feature of the shape as shown in Fig. 9. The dashed lines in the figure indicate the division of the forged product by a plane at that position. The conditions of shape division are as follows.

-

(a)

There is no concave section in the pressing or release direction

The shape of a forged product is divided at the vertex in the Y-axis direction nearest to the parting line.

-

(b)

There is a concave section in the release direction

The shape of a forged product is divided at the point nearest to the parting line from either the vertex of the concave in the Y-axis direction or the vertex of the convex in the pressing direction.

-

(c)

There is a concave section in the pressing direction

One of the above division procedures is applied to the lower surface of the concave section.

4 Optimization of Forging Dies

4.1 Detailed Design Procedure of Forging Dies

The detailed design of forging dies takes basic process plans generated by the GeneSteR + E method and die design plans generated by the GeneDie method as inputs. The positions of the forged product are enumerated in a given range by rotating the product around its center of gravity. The position of the forged product determines the parting line between dies, and the shape of the forged product is thus modified as described in Sect. 3 to satisfy undercut constraints if necessary. If the shape of the forged product is modified, the volume of the initial work material is also changed according to the volume change of the forged product. The width and height of the initial work material are then enumerated in given ranges without changing the volume or thickness. The positions of the workpiece are enumerated in a given range by rotating the workpiece around its center of gravity. The rotation axis is perpendicular to the pressing direction. The die design plans for optimization are then generated for each modified process plan using the GeneDie method. A data flow diagram of the overall detailed design process is shown in Fig. 10.

4.2 Procedure for Evaluating Die Design Candidates Using RPA

A large number of detailed die design plans will be generated, and the automation of the evaluation of the plans using an FEM analysis tool is thus essential for optimization support. Generally, the control method of an application depends on the platform and the application itself. In this study, RPA was adopted to automate the interaction with an FEM analysis tool. RPA is a framework or an application that automates computer-based tasks such as mouse clicks and text input.

RPA was used to prepare an analysis model and analysis conditions for an FEM analysis tool based on a generated die design plan, and to direct the tool to analyze the model. After the completion of the analysis, analysis results such as the forming stress were obtained through the RPA tool. Figure 11 is a sequence diagram of this procedural flow.

5 Implementation and Experimental Results

5.1 Overview of the Experiment

An experimental knowledge base for die optimization support and RPA workflows for dies evaluation were developed and applied to the die design of forged parts for automobiles. The knowledge base generates dies design candidates, and the candidates are analyzed with an FEM analysis tool through an RPA tool. It is the role of an engineer to evaluate analysis results and select the optimal solution candidates for prototyping. In this experiment, we evaluated whether the proposed method obtained the same result as the optimization work of an engineer, who has over 30 years of practical experience in forging, and improved the efficiency of the work. The knowledge base was developed in the knowledge representation language DSP [10], and basic shape operation functions were implemented in Inside Prolog [13] using the Windows Object Linking & Embedding interface of the SolidWorks 3D CAD system.

The basic process plan used in the experiment was a single stage that forms automotive partsFootnote 1 from initial work materials as shown in Fig. 12. The design conditions of rotation angles and sizes are given in Table 1. These values were selected from within the range expected to give a reasonable solution and allow the evaluation of the design plans to be completed in a realistic time. The initial work material and the workpiece were the same because of the single forming stage. The volume of the initial work material was not updated according to the shape modification of the forged product in this experiment. The FEM analysis is performed in 3D, and the analysis conditions are given in Table 2.

5.2 Experimental Results

For the single-process plan, 114 die design plans were generated in approximately 148 min. Examples of the generated results are shown in Fig. 13. Figure 13a shows examples of rotated forged products with shape modification due to undercuts. Figure 13b and 13c show examples of initial work materials of different sizes and their rotated examples. Figure 14 shows an example of die design plans generated from the knowledge base. The figures results show that the shape of a forged product was modified according to its relative position to dies to avoid undercuts.

The die design plans generated from the knowledge base were analyzed with an FEM analysis tool using RPA. The FEM analysis took about 84 min per an analysis model in average. Examples of the analysis results are shown in Fig. 15. The execution times of manual operation and the proposed method are compared in Table 3. The results show that the use of the proposed method shortens the execution time while avoiding a quality loss.

6 Conclusions and Future Work

This paper proposed an optimization support method for cold- and warm-forging dies of non-axisymmetric forged products. The proposed method generates various die design plans based on basic process plans and initial die design plans generated using the GeneSteR + E and GeneDie methods, respectively. The die design plans are generated according to the modified process plans having various relative positions of the forged products and workpieces to the dies and various sizes of the initial work materials. A large number of generated die plans are evaluated automatically by combining an FEM analysis tool and an RPA tool.

An experimental knowledge base was developed and applied to automotive parts. The experimental results show that the proposed method can generate various die design plans and evaluate them automatically. The results also show that the proposed method is effective in shortening the work time required for engineers to create various die design plans and evaluate them one by one.

Only limited types of undercut can be handled as described in Sect. 3. Because subsequent blanking and punching processes can produce complex shapes, it is necessary to extend the range of available types of undercut. This is left as future work.

Notes

- 1.

The forged parts are then formed into additional shapes such as gears as automotive parts.

References

Lange, K., Du, G.: A formal approach to designing forming sequences for cold forging. Trans. of the NAMRI/SME, pp. 17–22 (1989)

Numthong, C., Butdee, S.: The knowledge based system for forging process design based on case-based reasoning and finite element method. Asian Int. J. Sci. Technol. Prod. Manufacturing Eng. 5(2), 45–54 (2012)

Takata, O., Nakanishi, K., Yamazaki, T.: Forming-sequence design expert system for multistage cold forging: Forest-d. In: Proceedings of Pacific Rim International Conference on Artificial Intelligence 90, pp. 101–113 (1990)

Ohashi, T., Imamura, S., Shimazu, T., Motomura, M.: Computer-aided die design for axis-symmetric cold forging products by feature elimination. J. Material Processing Technol. 137, 138–144 (2003)

Kumar, S., Singh, R.: A low cost knowledge base system framework for progressive die design. J. Mater. Process. Technol. 153, 958–964 (2004)

Takata, O., Mure, Y., Nakashima, Y., Ogawa, M., Umeda, M., Nagasawa, I.: Knowledge-based system for process planning and die configuration design in cold forging. In: Proceedings of the 8th International Conference on Technology of Plasticity, p. 8 (2005)

Xuewen, C., Siyu, Z., Jun, C., Xueyu, R.: Research of knowledge-based hammer forging design support system. Int. J. Advanced Manufacturing Technol. 27, 25–32 (2005)

Lee, R.-S., Hsu, Q.-C., Su, S.-L.: Development of a parametric computer-aided die design system for cold forging. J. Mater. Process. Technol. 91, 80–89 (1999)

Umeda, M., Mure, Y.: Knowledge management strategy and tactics for forging die design support. In: Abreu, S., Seipel, D. (eds.), Applications of Declarative Programming and Knowledge Management, Vol. 6547 of Lecture Notes in Computer Science, Springer-Verlag New York Inc, pp. 188–204 (2011). https://doi.org/10.1007/978-3-642-20589-7_12

Kim, H.S., Im, Y.T.: An expert system for cold forging process design based on a depth-first search. J. Mater. Process. Technol. 95, 262–274 (1999)

Umeda, M., Mure, Y., Katamine, K., Matsunaga, K.: General Step Reduction and Enlargement Method for Knowledge-Based Process Planning of Totally Non-Axisymmetric Forged Products with Blanking and Punch Proceedings of the 13th International Conference on the Technology of Plasticity (ICTP2021), pp. 1161–1171 (2021)

Matunaga, K., Umeda, M., Mure, Y., Katamine, K.: Knowledge-based design method of forging dies based on the stereotypes of die structures and the functions of forming surfaces. In: Proceedings of the 18th International Conference Metal Forming, pp. 475–482 (2020)

Umeda, M., Katamine, K., Nagasawa, I., Hashimoto, M., Takata, O.: Multi-threading inside prolog for knowledge-based enterprise applications. In: Umeda, M., Wolf, A., Bartenstein, O., Geske, U., Seipel, D., Takata, O. (eds.) INAP 2005. LNCS (LNAI), vol. 4369, pp. 200–214. Springer, Heidelberg (2006). https://doi.org/10.1007/11963578_16

Mure, Y., Higashi, D., Higashi, N.: Development of forming techniques based on sequential forging method for waterproof USB Type-C connectors (in Japanese). In: Proceedings of Research Report of Kagoshima Prefectural Institute of Industrial Technology, pp. 8–9 (2021)

Acknowledgement

This research was supported by TOGO CO., Ltd., Kagoshima Prefecture.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Okamoto, R., Umeda, M., Mure, Y., Katamine, K., Imanaga, K. (2024). Optimization Support Method for Cold and Warm Forging Dies of Non-axisymmetrical Forged Products. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-41023-9_1

Download citation

DOI: https://doi.org/10.1007/978-3-031-41023-9_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41022-2

Online ISBN: 978-3-031-41023-9

eBook Packages: EngineeringEngineering (R0)