Abstract

The 2-Steps Smart Rotor Fault Diagnosis Model (SRFDM) is proposed. This consists of a supervised classic pattern recognition artificial neural network (ANN), which uses parameters extracted from the measured vibration signals from the machine. The Step-1 identifies the machine is healthy or faulty, and then the classification of faults in the Step-2 is performed. Earlier studies have used both time and frequency domain parameters as the input vectors to the ANN model. Currently these parameters are normalised with the speed synchronous vibration amplitude from the frequency domain analysis to remove the influence of the machine unbalance due to change in the machine speeds. Hence, the proposed model is likely to be applied to a typical machine irrespective of the machine operating speeds.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Rotor fault diagnosis

- ANN

- Smart fault detection

- Condition monitoring

- Vibration-based condition monitoring

- Machine learning

1 Introduction

Over the last decades, an increased interest on the application of artificial intelligence (AI) to engineering processes has been observed, being one of the main fields of application the structural health monitoring [1,2,3].

A wide range of methods and techniques are found in literature, from classic machine learning approaches as well more recent developments such as deep learning. Independently of the approach, it is seen that the vast majority of studies targeting the fault diagnosis/detection in rotating machines and their components, are based on vibration signals.

Among the most used classic techniques there are found Support Vector Machine (SVM) [4,5,6,7], k-Nearest Neighbour (k-NN) [8] and Artificial Neural Networks (ANN) [3]. Regarding deep learning, it is found that convolutional neural networks (CNN) is one of the most used approaches [9].

The mentioned techniques have been widely used to assess the fault detection in gearboxes and bearing elements, as well rotor related defects. Despite of the promising results and advances in the field, the smart methods still rely on quantity and quality of available data. This becomes a restriction when the aim is to develop a generic model, capable to perform accurately within certain variations of the operational conditions of the machine.

In previous research study [10], the authors have developed a 2-steps smart fault detection and diagnosis model based on ANN. The model is found to have high accuracy in the detection and diagnosis of rotor related faults [11]. In this paper, the earlier proposed model is further modified by the normalisation the optimised parameters. In the current study, the optimised parameters are normalised with the speed synchronous vibration amplitude from the frequency domain analysis to remove the influence of the machine unbalance due to change in the machine speeds. Hence, the proposed model is likely to be applied to a typical machine irrespective of the machine operating speeds. The papers presents the rotating rig, vibration data and the normalisation of the optimised parameters [11] and their results using the earlier proposed 2-steps ANN model [10].

2 Experimental Rig and Data

The experimental rig, in Fig. 1, is made by 2 shafts, coupled by a rigid coupling, resting over 4 identical beating in pedestals. There are 3 balancing discs, 2 in the longer shaft and 1 in the shorter one. The rig is driven by an electric motor through a flexible coupling.

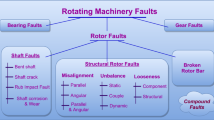

There are 4 rotor related faults simulated in the machine independently from each other, as well the healthy condition. The simulated defects are misalignment, bent shaft, looseness in pedestal and rotor rub. Vibration signals are collected through accelerometers simultaneously from the 4 bearing, B1 to B4. During the data collection the machine is running at a steady speed of 1800 RPM or 30 Hz. A random number of samples is taken for each of the 5 considered machine conditions, where each sample has a standard length of 5 s, and a sampling frequency of 10 k-samples/second. In Fig. 2, there are shown the typical velocity spectra of the studied fault at B3 location, during steady operation.

3 Early Model Developed [10,11,12]

The smart fault detection approach proposed in this study is based on a 2-steps implementation [10] of an earlier developed supervised multilayer perceptron ANN [12]. The developed ANN is made by the input and output layers, and 4 hidden layers. the hidden layers, 1 to 4, have 1000, 100, 100 and 10 non-linear neurons, respectively [11]. The former model is set by using the experimental vibration data [13].

3.1 2-Steps Application of Smart Fault Detection Model

A schematic that summarises the proposed 2-Steps model is shown in Fig. 2. The method uses an ANN with same architecture for both steps, but with different possible outputs at each step, i.e. 2 classes in the output layer at Step-1 and 4 classes in the output layer at Step-2.

The Step-1 is set to detect if the machine is subject of a defect or fault. At this stage there are 2 possible outputs, namely healthy or faulty. Then, the elements identified as faulty in Step-1 are taken into Step-2. In this second stage, the model is set to provide further information on the nature of the defect. In this particular case, there are 4 possible diagnoses, one per faulty condition studied (Fig. 3).

4 Optimised Parameters

The optimised parameters are the time domain parameters [11]—acceleration RMS and acceleration Kurtosis, and the frequency domain parameters—velocity amplitudes at 1x, 2x, 3x and the spectrum energy per bearing. Therefore, a total of 6 parameters per bearing which makes altogether 24 parameters for 4 bearings.

In order to remove the influence of the unbalance forces due the different operational speeds of the machine, further improvements are proposed by normalising the parameters by dividing the unbalance response amplitude at 1x. Hence, the normalised parameters are now reduced to 5 parameters per bearing.

The input matrix, X, will be defined as per Eq. (1); where \({x}_{i}\) with \(i=1\dots p\) are the input vectors, corresponding to the data samples 1 to p.

Each input vector is made by data collected simultaneously from the 4 measuring locations, as per Eq. (2). From the signals collected at each of the bearings, the selected parameters from both domains are calculated. Equation (3) represents the values corresponding to the \(j\)-bearing, with \(j=1\dots 4\), of the \(i\)-sample, with \(i=1\dots p\).

where \({2x}_{n}\) and \({3x}_{n}\) are the normalised amplitudes at 2 and 3 times the rotational speed and \({SE}_{n}\) is the normalised spectrum energy from 0.4x to 7x.

5 Results

In total, there are processed 679 data samples, all collected at the steady speed of 1800 RPM or 30 Hz. The quantities available per machine condition are listed in Table 1.

The samples are randomly allocated into the 3 stages of the learning process, where 70% is used for training and de remaining samples equally distributed into validation and testing (15% each) early stopping method is used in this research, where a cross-validation is carried out [12].

5.1 Step-1:Fault Detection

In the first step, the model has shown a 100% of accuracy to separate the faulty from the healthy samples. This performance is observed over the all 3 stages of the learning process (Fig. 4). The results are listed in Table 2.

5.2 Step-2: Fault Diagnosis

After the samples subject of faults are accurately identified in Step-1, these are now used as inputs in the ANN at Step-2.

The total inputs in Step-2 are 613, which are divided into 3 groups in order to conduct the learning process of the second network. The same allocation than in the first step is used, meaning that a 70% of the inputs are used for training, 15% for validation, and the remaining 15% of the samples is used for testing.

Excellent results are obtained, delivering a 100% of accuracy on the specific fault diagnosis. These results are listed in Table 3. Figure 5 shows the correct diagnoses per rotor fault in the training, validation and test of the ANN in Step-2.

It is important to note that the appropriate selection of features (parameters) can fully map the machine dynamics correctly, and hence this is always advantageous for the development of any reliable machine learning model even using limited data sets. This is successfully demonstrated here.

6 Concluding Remarks

In this study, the normalised vibration-based parameters are used in the earlier developed a 2-Steps SRFDM. The paper has successfully demonstrated the correct classification of the faults through a case study. The use of the normalised parameters is likely to lift limitation of the using SRFDM model for a typical machine operating at different speeds. This study is underway.

References

Zhang W, Jia MP, Zhu L, Yan XA (2017) Comprehensive overview on computational intelligence techniques for machinery condition monitoring and fault diagnosis. Chinese J Mech Eng 30(4):782–795

Belfiore NP, Rudas IJ (2014) Applications of computational intelligence to mechanical engineering. In: 2014 IEEE 15th international symposium on computational intelligence and informatics (CINTI), pp 351–368

Alshorman O et al. (2020) A review of artificial intelligence methods for condition monitoring and fault diagnosis of rolling element bearings for induction motor. Shock Vib 2020, no. Cm

Gangsar P, Tiwari R (2017) Comparative investigation of vibration and current monitoring for prediction of mechanical and electrical faults in induction motor based on multiclass-support vector machine algorithms. Mech Syst Signal Process 94:464–481

Li X, Zheng A, Zhang X, Li C, Zhang L (2013) Rolling element bearing fault detection using support vector machine with improved ant colony optimization. Measurement 46:2726–2734

Xing Z, Qu J, Chai Y, Tang Q, Zhou Y (2017) Gear fault diagnosis under variable conditions with intrinsic time-scale decomposition-singular value decomposition and support vector machine. J Mech Sci Technol 31(2):545–553

Pinheiro AA, Brandao IM, Da Costa C (2019) Vibration analysis in turbomachines using machine learning techniques. Eur J Eng Res Sci 4(2):12–16

Mian T, Fatima S, Choudhary A (2022) Multi-sensor fault diagnosis for misalignment and unbalance detection using machine learning. PESGRE 2022—IEEE international conference “power electronics Smart grid, renewable energy”

Toh G, Park J (2020) Review of vibration-based structural health monitoring using deep learning. Appl Sci 10(5)

Espinoza-Sepulveda NF, Sinha JK (2021) Robust vibration-based faults diagnosis machine learning model for rotating machines to enhance plant reliability Maintenance. Reliab Cond Monit 1(1):2–9

Espinoza Sepulveda N, Sinha JK (2020) Parameter optimisation in the vibration-based machine learning model for accurate and reliable faults diagnosis in rotating machines. Machines 8(4):1–21

Espinoza Sepúlveda NF, Sinha JK (2020) Blind application of developed smart vibration-based machine learning (SVML) model for machine faults diagnosis to different machine conditions. J Vib Eng Technol, 0123456789

Nembhard AD, Sinha JK, Yunusa-Kaltungo A (2015) Development of a generic rotating machinery fault diagnosis approach insensitive to machine speed and support type. J Sound Vib 337:321–341

Acknowledgements

Natalia Fernanda Espinoza Sepúlveda acknowledges the support by CONICYT (Comisión Nacional de Investigación Científica y Tecnológica/Chilean National Commission for Scientific and Technological Research) “Becas Chile” Doctorate’s Fellowship programme; Grant No. 72190062 for her Ph.D. study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Espinoza-Sepulveda, N., Sinha, J. (2024). Generic Smart Rotor Fault Diagnosis Model with Normalised Vibration Parameters. In: Kumar, U., Karim, R., Galar, D., Kour, R. (eds) International Congress and Workshop on Industrial AI and eMaintenance 2023. IAI 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-39619-9_56

Download citation

DOI: https://doi.org/10.1007/978-3-031-39619-9_56

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-39618-2

Online ISBN: 978-3-031-39619-9

eBook Packages: EngineeringEngineering (R0)