Abstract

Starch from different food/plant sources varies in their physicochemical as well as nutritional properties. The inherently imperfect nature of high amylose starch limits its industrial application. In order to achieve the desired characteristics of starch, food industries prefer starch modification as per the requirement of specific food processing. There are different methods, i.e., physical, chemical and enzymatic, developed till date for the modification of starch; however, dry heat treatment (DHT) of starch is preferred the most in the current scenario as it avoids the generation of environmental hazards as well as human health risks, and also economical as compared to other modification methods. Researchers found that the DHT of starch with and without ionic gums (carboxymethyl cellulose, guar gum, sodium alginate, xanthan gum, etc.) significantly improve the various physic-chemical properties, i.e., solubility, pasting viscosity, gelatinization temperature, solubility, etc. while slow down the starch digestibility. A significant effect of DHT on starch granule distribution and size of granules from different starch sources was also recorded. DHT can be a very promising method for modification of starch to get desired physic-chemical properties. The current chapter gives a wide insight into changes in starch properties due to DHT alone and in combination with ionic gum pre-treatments.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

The physical modifications of starches are preferred as the safe method to avoid environmental pollution and other health hazards. In the physical modification, pre-gelatinization, annealing, steam treatment, dry heat treatment (DHT), etc., are prectised to alter starch granules’ molecular structure and properties. The multi-functional properties of starch can be achieved through precise control over dry heat treatment conditions. Chiu et al. (1998) were the first who use a dry heating process to formulate physically modified starches and reported that the starch functionality on heat treatment is similar to that of the chemically modified starches. In continuation to these claims, several researchers illustrated similar reports that the heat-treated starches could be a better substitute for the starches modified by chemical cross-linking methods like chlorination, to manufacture hydrophobic starch with enhanced oil-binding properties (Ozawa et al., 2009; Seguchi, 2001). Due to the release of toxic and reactive components during chemical treatment methods that may travel to food products during processing, components made from physical methods have a preference for food producers as well as consumers in recent times. Commonly, the temperature used during dry heating varies between 110 and 150 °C with low humidity conditions for 1–4 h (Bae & Lee, 2018).

The moist-heat treatment has been studied extensively as a physical modification method of starch compared to the dry heat treatment method. But, nowadays, dry heat treatment (DHT) has received greater attention for modifying starch, among other methods, due to its simplicity and safety. The structure of starch granules remains unaffected during physical modification through DHT, but physicochemical properties change (Sun et al., 2014b). Several studies reported the change in structural and functional properties of starch derived from sources like waxy corn, waxy rice, potato, sweet potato, taro, and cassava starch (Sun et al., 2014b; Li et al., 2013; Pramodrao & Riar, 2014). The origins of starch and the treatment conditions (temperature and time) significantly influence starch’s structural and physicochemical properties. DHT of starch in combination with ionic gums at high temperatures for a predetermined time could be used to modify starch with functionality equivalent to that obtained through chemical modification. DHT can be used as an effective alternative to chemical modification for tailoring starch. The alteration of physicochemical characteristics of starch (viscosity, swelling power, solubility, colour, etc.) through DHT can improve its functional characteristics like coating, filler, texturizing, and whitening properties as per the requirement for specific food applications (Chandanasree et al., 2016).

Su et al. (2018) studied the effect of DHT and xanthan gum on rice starch of different amylose content (high 37.85%, medium 27.55% and low 9.98%). The physicochemical, pasting and rheological properties of xanthan gum-added native starches with different amylose content were significantly influenced after DHT compared to the native counterpart. The absence of breakdown indicated that the samples pretreated with xanthan gum achieved higher pasting stability under shear force and high temperature during pasting compared to the untreated native starch. The pasting property of xanthan gum pretreated low amylose rice starch was more impressive than high and medium amylose rice starches. The morphological evaluation of modified starch samples after gelatinization shows that DHT induced some interactions between xanthan gum and rice starch molecules resulting in restricted granule swelling. The modification of starch not only enhances the paste clarity and sheen, film formation, texture of paste and gel, and adhesion but also reduces the retrogradation, pastes gelling tendency and syneresis of gel (BeMiller, 1997). Several starch based food items like, bakery goods, vermicelli, syrups, jellies and edible coating are having starch as a prime component (Abegunde et al., 2013). Hence, DHT of starches is a budding method for modification without any harmful impact of chemical treatments. In this chapter, we further discuss the process of DHT, effect of DHT on different properties of starch, applications of dry heated starches and types of dry heat treatment methods.

7.2 Process of Dry Heat Treatment of Starch

For the DHT of starch, it is important to extract and purify the starch from plant/food sources. Several starch extraction methods are reported in different research studies, which might vary depending on the nature and the type of raw material. However, the most common way of extracting starch from the plant/food source includes the following steps: cleaning, slicing, drying, crushing and sieving. The obtained powder of the sample source must then be suspended in water and repeatedly centrifuged up to a certain time to remove impurities. The precipitate is further suspended repeatedly with 95% alcohol to remove the remaining impurities from the starch. The finally obtained starch pallet should be dried at a temperature of up to 40 °C for sufficient time to reduce the final moisture content <10%, followed by crushing and sieving to obtain a high-purity starch sample. The purity of obtained starch sample can be determined using the starch purity analysis kit (Liu et al., 2019, 2022a). The dehydrated starch sample (moisture content <10%) can be kept for dry heat treatment (repeated/continuous) in a hot air oven at a temperature between 110 and 150 °C for a predetermined time. The treated sample is then cooled for 1 h, packed and stored under ambient conditions for further use or studies (Liu et al., 2022a).

7.3 Mechanish of Dry Heat Treatment

DHT is a physical modification of starch which involves relatively very low moisture content, <10% and heating at temperature around 130 °C for varied time interval. The mechanism of DHT lies on movement of heat from the outer surface to the core of starch granules through conduction mode which damages granular surface as well as internal chemical structure to a certain extent. The crystalline structure and amorphous regions of starch greatly varies with the nature of DHT. High temperature accelerates the movement of molecules which might lead to rupturing and collapsing the starch granule and results leach out of amylose. The breakdown of hydrogen bonds promotes the swelling of starch granules and decreases the pasting onset temperature.

7.4 Effect of Dry Heat Treatment on Various Properties of Starch

Nowadays, several studies have been performed to understand the effect of dry heating on various characteristics of starch with and without treatment of ionic gums (Carboxymethyl cellulose, Guar gum, Xanthan gum, Sodium alginate, etc.) (Gou et al., 2019). The DHT of starches may harm the native starch granules to a certain extent depending on the treatment conditions that result in certain structural changes in the amorphous and crystalline regions of the starch granule (Lim et al., 2006). To elaborate, the DHT of rice starch at varied time-temperature combinations showed that the native crystalline structure was unaffected upto 150 °C for 4 h; however, X-ray diffraction patterns showed the decline in peak intensities with an increase in heating time further (Bae & Lee, 2018). Parboiled rice showed a noteworthy decline in the crystalline behavior of starch on treatment with dry heat and a slight restructuring of crystalline polymorphs at some point during cooling and storage (Dutta et al., 2016). In addition, when potato starch was heat treated (130 °C for 2–4 h) along with carboxymethyl cellulose, the high compactness in the colloidal structure was noticed (Sun et al., 2013). Moreover, physicochemical behavior, viz. swelling-solubility and viscosity, were influenced by dry heating action, enhancing starches’ functional characteristics. The dry heat treatment is considered to have non-toxic behavior, and the non-generation of any detrimental by-product allows the food industry to have an increased preference for this method (Zhou et al., 2019). In recent studies, several physicochemical variations have been claimed to occur in the starches modified by dry heating. The lower starch crystallinity, decreased gelatinization temperature and increased oil binding capacity are various changes described in smaller molecular fractions of rice starch treated with dry heat (Zhou et al., 2019). Similar changes were observed in the waxy corn starch, where the dry heating method modified the starch structure with a significant impact on the physic-chemical properties, and the aggregation of starch granules was noted (Zou et al., 2019).

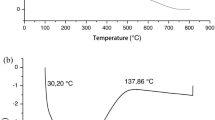

The change in temperature and time during DHT has a significant change in gelatinization temperature and enthalpy, as well as the semi-crystalline region of starch. Starch’s pasting property and gel strength are directly proportional to the heating temperature, whereas, indirectly, to heating time (Table 7.1). An in vitro study reported that DHT of starch lowers the rapid digestibility and glycemic index compared to native starch. However, in vitro starch digestibility, pasting viscosity, and gel strength negatively correlate with DHT heating temperature. It has also been observed that DHT could be useful for enhancing starch’s physical and nutritional properties (Oh et al., 2017) (Fig. 7.1).

7.5 Properties of Dry Heated Starch

7.5.1 Moisture Content

The changes in molecular structure and granule size of starches occur on heating; these modifications depend upon moisture availability. If the moisture is inadequate, a temperature for the heating is selected to modify the physical properties without starch’s gelatinization (Hoover & Manuel, 1996). A certain amount of free water in flour is relatively easy to remove by vaporization at temperatures below 100 °C. In contrast, H-bond formation between starch chains and water molecules has been reported due to the high affinity of starch chains toward water molecules (Trommsdorff & Tomka, 1995). Based upon this observation, it was suggested that on DHT of wheat flour above 100 °C, the water exclusion might relate to the water that was bonded to the components of flour, i.e. proteins and starch (González et al., 2021).

7.5.2 Color

The effect of DHT on the color of wheat flour (González et al., 2021) and whole grain barley (Boyd et al., 2017) was studied on a Lab scale, and an increase in darkness, redness and greenness was observed in both types of flours. The results indicated that DHT caused browning of the flour, possibly due to caramelization and Maillard reactions stimulated by flour constituents (Chung et al., 2012).

7.5.3 Structural Characteristics

Mobility of starch units is directly related to the temperature (Chen et al., 2015) and the heat treatment showed increased starch mobility, which eventually aids the interaction of amylose and amylopectin units. An enhancement in the mobility and deduction in the amount of water molecules resulted in the reorganization as well as precision of crystalline sections of starch granules after cooling. Similar findings were claimed with FTIR analysis of millet flour, where the potency of FTIR band (1047 cm−1) was perceived after the dry heating method (Sun et al., 2014a). Hence, an augmentation of this band up to 150 °C indicated that the water loss performs a major function in rearranging and recrystallization of starch chains.

The relative crystallinity of different dry heat-treated starches from cereals and millets was studied using XRD, and a significant change was observed with the increased temperature of dry heating. A decrease in relative crystallinity of high amylose rice starch was noticed on treatment with dry heat (110, 130 and 150 °C for 1, 2 and 4 h) (Bae & Lee, 2018). Similar results were observed for proso millet starch, where a reduction in relative crystallinity was seen after DHT at 130 °C for 2–4 h (Sun et al., 2014a). This trend might be due to the distortion of the crystalline state or amplification of the amorphous area. Also, the decreased crystallinity may be because of the binary helical shift throughout the treatment, due to which there might be an interruption or alteration in starch crystalline region or orientation, respectively (Singh et al., 2011). Moreover, the alterations in the amorphous region during heating and the presence of non-starch ingredients may also decrease the crystallinity of DHT starches. However, an opposite trend has been observed for waxy rice starch, where the crystallinity was increased after DHT which might be due to the partial restructuring of the amorphous region during dry heating (Li et al., 2013). The researcher also postulated that the crystallinity might also be raised under depleted moisture heat treatment, suggesting that the amorphous region was more susceptible to heating methods than the crystalline area, irrespective of the moisture availability.

7.5.4 Morphological Characteristics

The morphological characteristics of starches after DHT were studied for various categories of sources. Researchers developed micrographs from scanning electron microscope (SEM) and studied the same for the analysis of starch granule structure. Starch granule distribution and size are considered to be the significant properties imparting a substantial impact on starch functionality (Rasper, 1971).

Liu et al. (2019) studied the micrographs of waxy potato starch using SEM and observed that native starch granule surface was smooth without the presence of fracture or pores. However, DHT caused the changes in the starch surface. The umbilical point (reffered as the initial point for the development of starch granules) was observed to be easily destructed by DHT and the potholes were developed. This showed that DHT loose the structure of starch molecules to some extent. DHT of Dioscorea starch at 130 °C for 2 h and 4 h showed the ruptured starch granules (Vashisht et al., 2017). Similarly, chestnut starch showed the loss of smooth surface and the occurance of cracking was observed after DHT (Gul et al., 2014). Also, an increase in the fractures on granule surface was observed with an increase in temperature. This cracked appearance might be because of the amylose leaching and increased heating effect that fasten the movement of molecules. The SEM analysis of sweet potato starch using (continuous dry heat treatment) CDHT and (repeated dry heat treatment) RDHT showed that both the treatment methods caused the surface rupturing of few starch granules which was comparable to popcorn (Gou et al., 2019). Moreover, there was non-significant variation in the appearance of ruptured starch granules with an increase in RDHT cyclying and CDHT time. The SEM results indicated that the DHT may influence the starch structure as well as the order of starch crystallites.

Lei et al. (2020) studied the morphological structure of native and dry heat treated maize starches and observed the significant changes in the starch granule structure after DHT. The polygonal and irregular shapes along with smooth surfaces, without any pores and fractures have been observed in native maize starch granules (Liu et al., 2016). The granular shape and appearance of dry heat treated maize starch was retained during DHT, indicated that the typical granular structure was not destructed. This indicated that the DHT caused the accumulation of starch granules into big lumps that might be due to the reduced moisture and association between the particles at elevated temperatures (Zou et al., 2019). SEM of millet starch granules (native and dry heat treated) was also studied by Sun et al. (2014a) and it was observed that the surface of DHT starch granules was smoother and plumer as compared to that of native starch. Moreover, no lump formation after DHT was noticed that might be due to the interaction of starch molecules with other components of non-starch part during DHT and the similar notion was claimed by Chiu et al. (1998, 1999). The DHT of starches above 100 °C for a longer period of time presented the functionality similar to chemical cross-linking (Chiu et al., 1998, 1999; Sun et al., 2013).

7.5.5 Solubility and Swelling Power

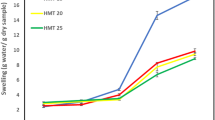

Starch’s solubility and swelling power are used to define the degree of amylose leaching out and the water absorption capacity of starch during processing. Studies show that the DHT treatment increased the leaching property of the amylose content of starch. The increase in DHT treatment temperature positively correlated with starch’s solubility and leach out. The amylose content of starch has a great association with the solubility of starch, while amylopectin is responsible for the influence on the swelling power of DHT starch. Starch’s solubility and swelling power also vary with the kind of treatment conditions used during DHT, i.e., CDHT or RDHT. The change in treatment temperature and time also influences the solubility and swelling power of starch. Liu et al. (2022a) found that the solubility of starch was increased while swelling power decreased during both CDHT and RDHT conditions. Similar results of increase in solubility of quinoa starch after RDHT and CDHT were claimed by Zou et al. (2020). The DHT promotes the leaching of amylose while inhibiting its swelling power. The studies show that at low DHT temperature (50 °C) the swelling power of starch granules is found to be the lowest, while the increase in treatment temperature leads to a slight increase in swelling power. The morphological changes in starch granules, especially, increased aggregation of starch granules at low temperatures could be a probable reason for decreased starch swelling power at low-temperature DHT. However, the increase in DHT temperature cause an increase in starch solubility which might lead to partial gelatinization, and hence results in a slight increase in swelling power (Vashisht et al., 2017; Liu et al., 2022a).

7.5.6 Paste Clarity

DHT influences the paste clarity of native starch, and the addition of ionic gum to starch prior to DHT further restricts the swelling property of starch granules. This can be assessed in terms of the change in % transmittance of starch gel. For instance, when the sample of native starch is modified at a certain temperature, the starch granules are ruptured and dispersed, followed by leaching out of amylose in the suspension with the increase in temperature. However, ionic gum pre-treatment of starch prior to DHT restricted the complete gelatinization and swelling of granules leading to relatively high integrity compared to native starch and forming a heterogeneous suspension. This change in suspension results in light scattering when a beam of light passes through the heterogeneous suspension and leads to the non-availability of % transmittance of ionic gums-modified samples (Su et al., 2018).

7.5.7 Pasting Properties and Gel Strength

The effect of the dry heat treatment method on the pasting behavior of different cereal starches was studied by various researchers. Li et al. (2013) studied the pasting profile of waxy rice starch using a dry heating technique and observed a decrease in onset temperature after dry heating at 130 °C for 4 h. This may be due to the breakdown of hydrogen bonds, resulting from which the distension of starch granules could be endorsed, hence the decline in onset temperature. Also, a decrease in peak viscosity of the starch extracted from millet was examined after dry heating (130 °C for 2–4 h), whereas an increase in final viscosity and trough viscosity was noted with the same DHT (Sun et al., 2014a). Continuous and repeated dry heating methods showed a decrease in pasting viscosities too. The highest swelling rate of the starch before breakdown is considered peak viscosity, which is indicative of the swelling power of starches (Zavareze & Dias, 2011). Millet starch showed a decline in the peak viscosity after DHT (130 °C at 2-4 h) (Sun et al., 2014a). Similar changes in peak and final viscosity of corn and pea starch were observed on DHT under similar conditions of temperature-time combination (Sun et al., 2014b). By using different DHT methods on sweet potato starches, the reduction in peak viscosity was calculated with an increase in CDHT time and RDHT cycles (Gou et al., 2019). This decline might be attributed to the improved alliance between the starch chains and strong forces among intra-granular bonds during the equilibrium period of DHT. The minimum viscosity in the late heating phase is represented as the Trough viscosity (TV). DHT showed a decrease in TV, indicating the rupturing of swollen starch granules (Gong et al., 2017). Also, this decline could be due to the strengthened configuration of starch after treatment. This indicated that the thermal stability of sweet potato starch could be improved by DHT (Gou et al., 2019).

Final viscosity (FV) is indicative of retrogradation, gel hardness and the amount of leached amylase (Xu et al., 2018a). Irrespective of the type of DHT, a significant decrease in FV was observed, possibly because the DHT could reduce the shortened amylopectin structure and help in précised crystalline arrangement. Setback viscosity is indicative of the possible deterioration of starches, and the inferior setback signifies that starch would be hard to depreciate. This trend of setback was observed for RDHT and CDHT treatments on sweet potato starch. The heat-paste stability is referred to as Breakdown viscosity (BV), and it is calculated as peak viscosity minus final viscosity (Xu et al., 2018b). An enhancement in the paste stability is revealed with a reduced breakdown viscosity after DHT, which showed that the starch turned out to be more resistant to elevated temperature and shearing after DHT (Sun et al., 2014b).

The peak time is indicative of the time period needed to achieve the highest viscosity, and the temperature at which the paste viscosity of starch starts amplifying is called as pasting temperature; both suggest the gelatinization behavior of starches (Kim et al., 2007). The peak time of sweet potato starches decreased with increased time and cycles of dry heating treatment, indicating that starch swelling could occur in less time. This might be because DHT could damage the surface configuration of starch, making it easy for the water molecules to move into the granules of starch effortlessly.

Sun et al. (2014a, b) compared the pasting curve of native and DHT starch with the viscosity curve of native and DHT flours for Proso millets. No significant change was observed in the starch curve after DHT, whereas the viscosity curves of DHT flour were near that of native and DHT starches. The results suggested that in the high-viscosity products, the dry heated flour could be the better choice than that of starches because flour remains a rich source of nutrients and also overcome the problem of starch extraction. However, The gelling property of starch is greatly associated with their amylose content as well as the kind of treatment. The gelling strength of DHT starch is also associated with storage temperature. Gel stored at a low storage temperature (4 °C) shows higher strength as compared to that stored at room temperature (25 °C) (Su et al., 2018).

7.5.8 Starch Digestibility and Glycemic Index

The in vitro starch digestibility of wheat bread showed significant changes in the digestibility behavior at varied dry heat treatment temperatures. A significant decrease in RDS (Rapidly digestible starch) and an increase in SDS (Slowly digestible starch) with the increase in DHT temperature was recorded by González et al. (2021). The researcher claimed that the trend might be due to the ease of access of amylolytic enzyme to starch molecules getting destabilized by the structural alterations of starch as persuaded by DHT. Bae and Lee (2018) reported similar evidence of an increase in SDS and RS (Resistant starch) in rice starch with distinctive heat treatment methods, and it is apparent to have desired nutritional attribute of starchy foods.

Resistant starch (RS), considered dietary fiber, primarily gets fermented in the gut by colon microbes after passing unhydrolyzed from the upper gastrointestinal tract (GIT). It is evident that RS provides health benefits to humans by producing short-chain fatty acids and modifying the composition of the gut microbiome (Gu et al., 2020). An enhancement in the level of RS in the sample of rice starch was observed, and it stated that the dry heating could be responsible for the reorganization between starch molecules and the restructuring of starch crystallites which ultimately improved the integrity of starch crystallization and hence the RS level (Bae & Lee, 2018). Therefore, the increase in RS can be achieved using the dry heating method as a promising processing means.

7.6 Effect of Repeated and Continuous Dry Heat Treatment

The effect of repeated and continuous DHT on starch properties was studied by various researchers, and significant results were observed. The time required to reach an equilibrium point between the situation of treatment and the degree of alteration in physicochemical and structural behavior of starch might be reduced in continuous DHT. Moreover, the effect of continuous treatment was observed to control the degree of alterations. On the other hand, if the cooling of granules of starches at room temperature is done after the point of stability is reached and then the reheating for numerous succession phases, the more significant modifications would be recorded. The pasting behavior of CDHT and RDHT sweet potato starches was also compared and it was observed that all the pasting viscosities and peak time of CDHT starches were lesser than those of RDHT starches (Gou et al., 2019). Although the difference was insignificant, the lower paste viscosity of CDHT starch signifies the high potency of intramolecular bond forces, which was more effective during CDHT than RDHT. Conversely, it was also noticed that during RDHT cycles, the structure of starch granules might be partially damaged, which is indicative of a reduced amount of energy required to paste RDHT starches. The effect of CDHT and RDHT was studied on physicochemical and digestive properties of mung bean starch by Liang et al. (2021) and the results showed that the alteration in swelling and solubility, amylose content and pasting parameters of mung bean starch was more prominent in CDHT as compared to that of RDHT. Zhou et al. (2021) performed CDHT and RDHT on quinoa starch and reported the effect on physicochemical and structural properties. A significantly higher water absorption index, relative crystallinity and RDS were examined in RDHT quinoa starch samples than that of CDHT for the similar period of time. However, RDHT starch had lower swelling power, solubility and paste viscosities as compared to that of CDHT sample. Overall, it was concluded that RDHT had superior performance in changing the physicochemical and structural characteristics of quinoa starch than CDHT.

7.7 Role of Ionic Gums on Starch Modification

Ionic gums play an important role in strengthening the gel-forming ability of DHT starch (Liu et al., 2022b). Su et al. (2018) found that the gel strength of DHT starch was influenced significantly by their native counterpart when pretreated with xanthan gum. The starch with high amylose content was found to have significantly higher gelling strength as compared to native starch as well as the starch with low and medium amylose content. Xanthan gum pretreated DHT-modified low amylose starch gel shows higher flowability due to low amylose content. Li et al. (2013) found that the swelling of the granules was restricted, and viscosity was increased continuously during pasting due to DHT of waxy rice starch impregnated with xanthan. After pasting, the ability of gel formation of the treated starch was strengthened, and the particle size was increased due to the cross-linking of starch granules with xanthan polymer. The crystallinity of DHT starch was also increased, but the amorphous region of treated starch granules became more resistant to DHT when impregnated with xanthan. However, crystallinity was found to be correlated with melting enthalpy. Furthermore, Chandanasree et al. (2016) studied the effect of DHT with and without ionic gums on various properties of cassava starch. Ji et al. (2016) investigated the properties of corn starch modified with lysine using dry heat treatment. Their study shows that dry heat treatment of starch with lysine reduced the pasting temperature and degree of crystallinity while increased viscosity and particle size of the starch granule due to the formation of a cross-link between native starch granule and lysine.

7.8 Applications of Dry Heat Treated Starch

7.8.1 Dry Heat Treatment and Starch-Based Bakery Products

The impact of DHT on wheat flour and the products formed from it, viz. bread, cakes etc., is another remarkable study investigating wheat characteristics. Several studies claim improved changes in whole wheat flour, wheat dough, bread etc., on treating with dry heat. As an example, the enhancement in the functionality of whole wheat flour to use in bread making was observed by Sudha et al. (2016). DHT of wheat dough at 100 °C for 12 min showed an improvement in mechanical stability, especially the viscosity of the dough (Bucsella et al., 2016). Further, an interesting change in the composition of volatile components was observed when the wheat flour was treated at temperatures more than 120 °C range. At elevated temperatures, an increase in the amount of furans, pyrazines and sulphur-containing components is claimed to improve flours’ aroma (roasty) (Xu et al., 2017).

DHT has been observed to have a potentially beneficial impact on the shelf-life augmentation of different flours by way of decreasing enzyme activity and moisture content of fat-rich compounds (Purhagen et al., 2011). Along with such biological outcomes, DHT has a noteworthy influence on the physicochemical and functional behavior of flours. Starch molecules and gluten proteins are the major determinants of such properties, where the gluten proteins show unfolding above 50 °C. Due to this, the hydrophobic regions of protein fragments get more revealed, allowing the reorganization of disulfide bonds (Jeanjean et al., 1980). This leads to the formation of gluten aggregates, the alteration in molecular weight dispersal, and reduced extractability. These changes may lead to a durable dough production that can endure an elevated sugar content which is appropriate for cake/biscuit manufacturing (Nakamura et al., 2008; Chesterton et al., 2015).

Nakamura et al. (2008) observed that the DHT of wheat flour showed an increment in the springiness of pancakes as well as the volume of bread and sponge cake. This increase was claimed to be related to the enhanced hydrophobic behaviour of wheat starch which makes it available to bind to the surface of air bubbles and ultimately adds stability to the dough and batter of bread and cake, respectively (Seguchi, 2001). Based upon this, it was suggested that cereal flours’ increased oil binding capacity was due to the modifications in the starch surface protein to hydrophobic from hydrophilic via DHT.

7.8.2 Dry Heat Treatment in 3D Food Applications

Three-dimensional printing is an innovative technique which is now used for attaining ingenious and individualized food items. In order to achieve this, the food formulations generally called as “inks” needs to be studied thoroughly before being processes through 3D printing. Maniglia et al. (2020a) used DHT to enhance the wheat starch characteristics with a motive to develop hydrogels to be utilized as “inks” for 3D printing. The method was observed to be easy and safe. DHT of wheat starch was done at 130 °C for 2 h and 4 h and an increase in granule size was recorded without any alteration in granule surface and shape. No change in the functional group of starch after DHT was witnessed which is an indicative of negligible oxidation. Further, the developed hydrogel “inks” from modified starch had more resistance to stress, more gel firmness, more structural strength at rest and lower synersis as compared to those based on native starch. Also, the hydrogels based on the starch dry heat treated for 4 h displayed the best results for printability and better reproducibility.

Similarly, the preparation of hydrogels was done by using cassava starch for the application in 3D printing (Maniglia et al., 2020b). DHT was conducted using similar time-tempeature combinations (130 °C for 2 h and 4 h) as used for wheat starch hydrogel preparation. An increase in granule size and carbonyl content was observed with an elevation in DHT time. Hence, the hydrogels obtained from the starches after DHT had improved gel texture, pasting behaviour and pritability that supports the usage of cassava starch for 3D printing.

7.8.3 Dry Heat Treatment in Functionality Enhancement of Dry Milk

DHT was used in the improvement of functional properties of low heat nonfat dry milk with the results of enhanced foaming properties and heat stability (Alan et al., 2019). When compared with high heat dry milk, low heat product had the improved functionality in context to emulsification and heat steadiness and the results were comparable or surpassed the properties of high heat products. The use of radio frequency dielectric heating technique alongwith dry heating could be a promising approach for the production of certain food items that can utilize the low heat nonfat dry milk, like, bakery, ice cream and meat products.

7.8.4 Dry Heat Treatment in Shelf Life Enhancement

The storage stability of pearl millet flour is a big challenge with respect to rancidity and organoleptic acceptability. In order to retain the quality of pearl millet flour during storage, DHT was performed before storage (Arora et al., 2002). It was observed that the rise in free fatty acid content and lipase activity was reduced in DHT flour during storage when compared with untreated flour. Also, the acceptability study revealed that the flour as well as chapatti made from heat treated pearl millet were organoleptically acceptable throughout the storage period. The bitterness and rancidity of pearl millet flour during storage is caused by the activity of lipase enzyme which caused the breakdown of glycerides and subsequent increase of free fatty acids (Pruthi, 1981). Hence, in order to retard the lipase activity before grinding, DHT of pearl millet grains for 2 h was found to be the most efficient for the reduction of the activity of lipase enzyme during storage (Kadlag et al., 1995). Singh and Goyal (2005) used DHT as one of the pre treatment methods for the processing of pearl millet to yield the flour with more shelf stability (Fig. 7.2).

7.9 Conclusion

A positive influence of DHT on various properties of diverse varieties of starch isolated from different food sources gives rise to a reliable and safe method of starch modification. Also, the variations in the treatment conditions with respect to time and temperature under CDHT and RDHT show significant variations in various properties of starch. Hence, DHT may prove to be an effective method for starch modifications. However, most studies investigated DHT modification of starch under limited treatment conditions such as heating temperature, reaction time and origin characteristics of starch. Therefore, extensive investigations need to be conducted under DHT conditions to understand the phenomenon precisely. Nevertheless, DHT is an effective technology that can be used in the starch processing industries to provide benefits to human health and the environment.

References

Abegunde, O. K., Mu, T. H., Chen, J. W., & Deng, F. M. (2013). Physicochemical characterization of sweet potato starches popularly used in Chinese starch industry. Food Hydrocolloids, 33(2), 169–177.

Alan, K. S., Subbiah, J., & Schmidt, K. A. (2019). Application of a dry heat treatment to enhance the functionality of low-heat nonfat dry milk. Journal of Dairy Science, 102(2), 1096–1107.

Arora, P., Sehgal, S., & Kawatra, A. (2002). The role of dry heat treatment in improving the shelf life of pearl millet flour. Nutrition and Health, 16(4), 331–336.

Bae, I. Y., & Lee, H. G. (2018). Effect of dry heat treatment on physical property and in vitro starch digestibility of high amylose rice starch. International Journal of Biological Macromolecules, 108, 568–575.

BeMiller, J. N. (1997). Starch modification: Challenges and prospects. Starch/Starke, 49, 127–131.

Boyd, L., Storsley, J., & Ames, N. (2017). Effect of heat treatments on starch pasting, particle size, and color of whole-grain barley. Cereal Chemistry, 94, 325–332.

Bucsella, B., Takács, Á., Vizer, V., Schwendener, U., & Tömösközi, S. (2016). Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chemistry, 190, 990–996.

Chandanasree, D., Gul, K., & Riar, C. (2016). Effect of hydrocolloids and dry heat modification on physicochemical, thermal, pasting and morphological characteristics of cassava (Manihot esculenta) starch. Food Hydocolloid, 52, 175–182.

Chen, X., He, X., Fu, X., & Huang, Q. (2015). In vitro digestion and physicochemical properties of wheat starch/flour modified by heat-moisture treatment. Journal of Cereal Science, 63, 109–115.

Chesterton, A. K. S., Wilson, D. I., Sadd, P. A., & Moggridge, G. D. (2015). A novel laboratory scale method for studying heat treatment of cake flour. Journal of Food Engineering, 144(1), 36–44.

Chiu, C. W., Schiermeyer, E., Thomas, D. J., & Shah, M. B. U. S. (1998). U.S. Patent, 5,725,676.

Chiu, C. W., Schiermeyer, E., Thomas, D. J., Shah, M. B., Hanchett, D. J., & Jeffcoat, R. (1999). U.S. Patent 5,932,017.

Chung, S. Y., Han, S. H., Lee, S. W., & Rhee, C. (2012). Effect of Maillard reaction products prepared from glucose–glycine model systems on starch digestibility. Starch-Stärke, 64(8), 657–664.

Dutta, H., Mahanta, C. L., Singh, V., Das, B. B., & Rahman, N. (2016). Physical, physic-chemical and nutritional characteristics of Bhoja chaul, a traditional ready-to-eat dry heat parboiled rice product processed by an improvised soaking technique. Food Chemistry, 191, 152–162.

Gong, B., Xu, M., Li, B., Wu, H., Liu, Y., Zhang, G., Ouyang, S., & Li, W. (2017). Repeated heat-moisture treatment exhibits superiorities in modification of structural, physicochemical and digestibility properties of red adzuki bean starch compared to continuous heat-moisture way. Food Research International, 102, 776–784.

González, M., Vernon-Carter, E. J., Alvarez-Ramirez, J., & Carrera-Tarela, Y. (2021). Effects of dry heat treatment temperature on the structure of wheat flour and starch in vitro digestibility of bread. International Journal of Biological Macromolecules, 166, 1439–1447.

Gou, M., Wu, H., Salesh, A. S. M., Jing, L., Lui, Y., Zhao, K., Su, C., Zhang, B., Jiang, H., & Lo, W. (2019). Effects of repeated and continuous dry heat treatments on properties of sweet potato starch. Biological Macromolecules, 129, 869–877. https://doi.org/10.1016/j.ijbiomac.2019.01.225

Gu, F., Li, C., Hamaker, B. R., Gilbert, R. G., & Zhang, X. (2020). Fecal microbiota responses to rice RS3 are specific to amylose molecular structure. Carbohydrate Polymers, 243, 116475.

Gul, K., Riar, C. S., Bala, A., & Sibian, M. S. (2014). Effect of ionic gums and dry heating on physico-chemical, morphological, thermal and pasting properties of water chestnut starch. LWT Food Science and Technology, 59, 348–355.

Hoover, R., & Manuel, H. (1996). Effect of heat—Moisture treatment on the structure and physicochemical properties of legume starches. Food Research International, 29(8), 731–750.

Jeanjean, M. F., Damidaux, R., & Feillet, P. (1980). Effect of heat treatment on protein solubility and viscoelastic properties of wheat gluten. Cereal Chemistry, 57(5), 325–331.

Ji, Y., Yu, J., Xu, Y., & Zhang, Y. (2016). Impact of dry heating on physicochemical properties of corn starch and lysine mixture. International Journal of Biological Macromolecules, 91, 872–876.

Kadlag, R. V., Chavan, J. K., & Kachare, D. P. (1995). Effect of seed treatments and storage on the changes in lipids of pearl millet meal. Plant Foods for Human Nutrition, 45, 279–285.

Kim, S. H., Lee, B. H., Baik, M. Y., Joo, M. H., & Yoo, S. H. (2007). Chemical structure and physical properties of mung bean starches isolated from 5 domestic cultivars. Journal of Food Science, 72(9), C471–C477.

Li, Y., Zhang, H., Shoemaker, C. F., Xu, Z., Zhu, S., & Zhong, F. (2013). Effect of dry heat treatment with xanthan on waxy rice starch. Carbohydrate Polymers, 92(2), 1647–1652.

Liang, S., Su, C., Saleh, A. S., Wu, H., Zhang, B., Ge, X., & Li, W. (2021). Repeated and continuous dry heat treatments induce changes in physicochemical and digestive properties of mung bean starch. Journal of Food Processing and Preservation, 45(3), e15281. https://doi.org/10.1111/jfpp.15281

Lei, N., Chai, S., Xu, M., Ji, J., Mao, H., Yan, S., ... & Sun, B. (2020). Effect of dry heating treatment on multi-levels of structure and physicochemical properties of maize starch: A thermodynamic study. International Journal of Biological Macromolecules, 147, 109–116.

Lim, H. S., Han, J. A., BeMiller, J. N., & Lim, S. T. (2006). Physical modification of waxy maize starch by dry heating with ionic gums. Journal of Applied Glycoscience, 53(4), 281–286.

Liu, H., Lv, M., Wang, L., Li, Y., Fan, H., & Wang, M. (2016). Comparative study: How annealing and heat-moisture treatment affect the digestibility, textural, and physicochemical properties of maize starch. Starch-Starke, 68(11–12), 1158–1168.

Liu, K., Hao, Y., Chen, Y., & Gao, Q. (2019). Effects of dry heat treatment on the structure and physicochemical properties of waxy potato starch. Biological macromolecules, 132, 1044–1050. https://doi.org/10.1016/j.ijbiomac.2019.03.146

Liu, W., Pan, W., Li, J., Chen, Y., Yu, Q., Xiao, W., Wen, H., & Xie, J. (2022a). Dry heat treatment induced the gelatinization, rheology and gel properties changes of chestnut starch. Current Research in Food Science, 5, 28–33.

Liu, W., Zhang, Y., Wang, R., Li, J., Pan, W., Zhang, X., Xiao, W., Wen, H., & Xie, J. (2022b). Chestnut starch modification with dry heat treatment and addition of xanthan gum: Gelatinization, structural and functional properties. Food Hydrocolloids, 124, 107205.

Maniglia, B. C., Lima, D. C., da Matta Júnior, M., Oge, A., Le-Bail, P., Augusto, P. E., & Le-Bail, A. (2020a). Dry heating treatment: A potential tool to improve the wheat starch properties for 3D food printing application. Food Research International, 137, 109731.

Maniglia, B. C., Lima, D. C., Junior, M. D. M., Le-Bail, P., Le-Bail, A., & Augusto, P. E. (2020b). Preparation of cassava starch hydrogels for application in 3D printing using dry heating treatment (DHT): A prospective study on the effects of DHT and gelatinization conditions. Food Research International, 128, 108803.

Nakamura, C., Koshikawa, Y., & Seguchi, M. (2008). Increased volume of kasutera cake (Japanese sponge cake) by dry heating of wheat flour. Food Science and Technology Research, 14(5), 431–436.

Oh, I. K., Bae, I. Y., & Lee, H. G. (2017). Complexation of high amylose rice starch and hydrocolloid through dry heat treatment: Physical property and in vitro starch digestibility. Journal of Cereal Science, 79, 341–347.

Ozawa, M., Kato, Y., & Seguchi, M. (2009). Investigation of dry-heated hard and soft wheat flour. Starch – Stärke, 61(7), 398–406.

Pramodrao, K., & Riar, C. (2014). Comparative study of effect of modification with ionic gums and dry heating on the physicochemical characteristics of potato, sweet potato and taro starches. Food Hydrocolloid, 35, 613–619.

Pruthi, T. D. (1981). Free fatty acid changes during storage of bajra (Penmselum typhoideum) flour. Journal of Food Science and Technology, 18(6), 257–258.

Purhagen, J. K., Sjöö, M. E., & Eliasson, A. C. (2011). The use of normal and heat treated barley flour and waxy barley starch as anti-staling agents in laboratory and industrial baking processes. Journal of Food Engineering, 104(3), 414–421.

Qiu, C., Cao, J., Xiong, L., & Sun, Q. (2015). Differences in physicochemical, morphological, and structural properties between rice starch and rice flour modified by dry heat treatment. Starch-Starke, 67, 756–764.

Rao, H., Sindhu, R., & Panwar, S. (2022). Morphology and functionality of dry heat-treated and oxidized quinoa starches. Journal of Food Processing Preservation, e16672. https://doi.org/10.1111/jfpp.16672

Rasper, V. (1971). Investigations on starches from major starch crops grown in Ghana: III.—Particle size and particle size distribution. Journal of the Science of Food and Agriculture, 22(11), 572–580.

Seguchi, M. (2001). Oil binding ability of chlorinated and heated wheat starch granules and their use in breadmaking and pancake baking. Starch-Stärke, 53(9), 408–413.

Singh, S., & Goyal, M. (2005). Potential of using pearl millet in the development of value added flour products. Paper presented at the conference on alternative use of pearl millet, 30th July 200, RAU, Bikaner.

Singh, H., Chang, Y. H., Lin, J.-H., Singh, N., & Singh, N. (2011). Influence of heat–moisture treatment and annealing on functional properties of sorghum starch. Food Research International, 44, 2949–2954.

Su, J., Chotineeranat, S., Laoka, B., Chatakanonda, P., Vanichsriratana, W., Sriroth, K., & Piyachomkwan, K. (2018). Effect of dry heat treatment with xanthan gum on physicochemical properties of different amylose rice starches. Starch-Stärke, 70(3–4), 1700142.

Sudha, M. L., Soumya, C., & Prabhasankar, P. (2016). Use of dry-moist heat effects to improve the functionality, immunogenicity of whole wheat flour and its application in bread making. Journal of Cereal Science, 69, 313–320.

Sun, Q., Si, F., Xiong, L., & Chu, L. (2013). Effect of dry heating with ionic gums on physicochemical properties of starch. Food Chemistry, 136(3–4), 1421–1425.

Sun, Q., Gong, M., Li, Y., & Xiong, L. (2014a). Effect of dry heat treatment on the physicochemical properties and structure of proso millet flour and starch. Carbohydrate Polymers, 110, 128–134.

Sun, Q., Xu, Y., & Xiong, L. (2014b). Effect of microwave-assisted dry heating with xanthan on normal and waxy corn starches. International Journal of Biological Macromolecules, 68, 86–91.

Trommsdorff, U., & Tomka, I. (1995). Structure of amorphous starch. 2. Molecular interactions with water. Macromolecules, 28(18), 6138–6150.

Vashisht, D., Pandey, A., Hermenean, A., Yáñez-Gascón, M. J., Pérez-Sánchez, H., & Kumar, K. J. (2017). Effect of dry heating and ionic gum on the physicochemical and release properties of starch from Dioscorea. International Journal of Biological Macromolecules, 95, 557–563. https://doi.org/10.1016/j.ijbiomac.2016.11.064

Xu, J., Zhang, W., Adhikari, K., & Shi, Y. C. (2017). Determination of volatile compounds in heat-treated straight-grade flours from normal and waxy wheats. Journal of Cereal Science, 75, 77–83.

Xu, M., Saleh, A. S., Gong, B., Li, B., Jing, L., Gou, M., Jiang, H., & Li, W. (2018a). The effect of repeated versus continuous annealing on structural, physicochemical, and digestive properties of potato starch. Food Research International, 111, 324–333.

Xu, M., Saleh, A. S., Liu, Y., Jing, L., Zhao, K., Wu, H., Zhang, G., Yang, S. O., & Li, W. (2018b). The changes in structural, physicochemical, and digestive properties of red adzuki bean starch after repeated and continuous annealing treatments. Starch-Stärke, 70(9–10), 1700322.

Zavareze, E. D. R., & Dias, A. R. G. (2011). Impact of heat-moisture treatment and annealing in starches: A review. Carbohydrate Polymers, 83, 317–328.

Zhou, W., Song, J., Zhang, B., Zhao, L., Hu, Z., & Wang, K. (2019). The impacts of particle size on starch structural characteristics and oil-binding ability of rice flour subjected to dry heating treatment. Carbohydrate Polymers, 223, 115053.

Zhou, Y. L., Cui, L. H., You, X. Y., Jiang, Z. H., Qu, W. H., Liu, P. D., et al. (2021). Effects of repeated and continuous dry heat treatments on the physicochemical and structural properties of quinoa starch. Food Hydrocolloids, 113, 106532.

Zou, J., Xu, M., Tian, J., & Li, B. (2019). Impact of continuous and repeated dry heating treatments on the physicochemical and structural properties of waxy corn starch. International Journal of Biological Macromolecules, 379–385. https://doi.org/10.1016/j.ijbiomac.2019.05.147

Zou, J., Xu, M., Tang, W., Wen, L., & Yang, B. (2020). Modification of structural, physicochemical and digestive properties of normal maize starch by thermal treatment. Food Chemistry, 309, 125733. https://doi.org/10.1016/j.foodchem.2019.125733

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Pandey, A.K., Thakur, S., Yadav, D.K. (2023). Dry Heat Treatment of Starch. In: Sharanagat, V.S., Saxena, D.C., Kumar, K., Kumar, Y. (eds) Starch: Advances in Modifications, Technologies and Applications. Springer, Cham. https://doi.org/10.1007/978-3-031-35843-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-35843-2_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-35842-5

Online ISBN: 978-3-031-35843-2

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)