Abstract

The performance of reinforced concrete (RC) infill walls for the seismic retrofitting of existing RC-frame buildings is evaluated at various hazard earthquake levels in this research work. The seismic retrofitting of existing multi-storey multi-bay RC frame buildings by the conversion of selected bays into new RC infill walls was studied experimentally within the SERFIN project through a series of experiments, which took place at the European Laboratory of Structural Assessment (ELSA). This was the first time that a full-scale experiment of this type of specimen was performed. This experiment aimed to study the efficiency of the retrofitting method and to examine the required amount of RC wall web reinforcement as well as the connection details between the wall and the bounding frame. To complement the experimental results and to study the interaction between the RC infills and the bounding frame both at the global and local level, a parametric study was performed by reducing the number of dowels starting from a spacing of 100 mm (monolithic) to no dowels. The parametric study was performed by nonlinear response-history analyses of a two-dimensional (2D) finite element (FE) model that was calibrated using the experimental results obtained from the full-scale experiment. The numerical results of the parametric study showed that the number of dowels used in the experimental study can be reduced significantly making the use of this method more attractive. The results from the parametric study and their analysis can lead to design recommendations. In this paper, the results from the performance-based numerical analysis are presented along with the conclusions that are drawn.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Design Recommendations

- Dowels

- Earthquake Hazard Levels

- Finite Element Model

- Performance-Based Numerical Analysis

- Retrofitting Seismic Deficient Structures

1 Introduction

The effective and affordable retrofitting of damaged existing buildings is crucial considering that in recent decades low and medium-rise RC buildings have experienced remarkable damage resulting in casualties and financial loss during earthquakes. Considering that a large percentage of buildings are more than thirty years old, and they can’t withstand an earthquake, that becomes a major safety problem. The seismic upgrading of existing buildings based on global strengthening schemes; increasing the global stiffness and reducing the seismic deformations of a building, may be more cost-effective in comparison with the local intervention techniques [5, 12, 14, 16]. The strengthening of damaged RC buildings by infilling selected bays in both directions of the frames with RC infill walls, especially on the perimeter is one of the most feasible, simple, effective, and economic techniques [2, 6, 12, 17].

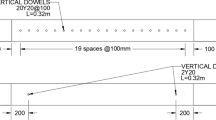

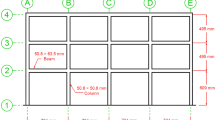

The addition of RC infill walls with the same thickness as the frame members that bound the new wall for the seismic strengthening of RC buildings is a relatively new method that could be applied for an optimal solution considering the performance and the cost of the intervention. Due to the poor knowledge of the behavior of walls created by the infilling of a bay of an existing RC frame, this method is not addressed quantitatively by the codes, and it is extensively applied to guarantee monolithic behavior between the old and the new members. The interaction of new walls with the bounding frame, their design, and connection details between the new web and the surrounding frame members need to be studied and regulated. The effectiveness of seismic retrofitting of multi-storey multi-bay RC frame buildings by converting selected bays into new walls through infilling with RC walls was studied experimentally through a full-scale specimen (shown in Fig. 1(a)) and pseudo-dynamic (PsD) tests within the project “Seismic Retrofitting of RC Frames with RC Infilling” (SERFIN). The description of the experiment and the experimental results are presented in [1,2,3, 9, 13, 15]. The specimen of the test of the project SERFIN was used to develop a numerical model (shown in Fig. 1(b)) of the frame that was experimentally tested. The numerical model was calibrated using the results of the experimental model and the FE model simulation of the test specimen is presented in [8, 10] along with a comparison between the experimental and the numerical results. The validated model was used to formulate a parametric study in which the number of dowels was reduced starting at a spacing of 100 mm (monolithic response of the test specimen) to no dowels. Nonlinear response-history analysis was performed for all cases. The results of these numerical analyses allowed the study of the interaction of RC infill walls with the bounding frames, and the behavior of this structural system in terms of global and local indices. The results of the parametric study that were reported at the global and local level and design recommendations are presented and discussed in [7, 9]. These results provide a basis for the development of a general model for the design of RC infills in existing RC frames, particularly regarding the connection details of the new RC infill walls to the existing bounding frame members.

In this paper, the performance of non-monolithic RC infill walls introduced for the seismic retrofitting of existing RC-frame buildings is numerically studied and evaluated with numerical assessment at various earthquake levels, particularly for earthquake acceleration of 0.25 g, 0.2 g, and 0.15 g in order to provide design guidelines. The selection of these peak ground accelerations (pga) is based on the Cyprus zonation map according to Eurocode 8 (EC8) [4]. The connection details between the existing and the new elements were examined for each hazard level in this paper and these results offer several performances, in earthquake hazard. The calibrated FE model that was developed in [8, 9] was used for this aim. The dowels were simulated to provide local results regarding the connection of such walls to the existing bounding RC frame that are missing from the literature.

2 Numerical Simulations of the Parametric Study

The FE model was simulated and analyzed using the DIANA finite element analysis (FEA) software [8, 9]. Numerical simulations were performed by varying the number and the arrangement of dowels connecting the new wall to the bounding frame. A parametric study was performed that covers a range between monolithic behavior and that of a non-integral infilled frame and is presented in this section.

(a) Proposed system as designed for SERFIN project [15] (b) Numerical model of the proposed system.

The validated model had the same number of dowels as the SERFIN experiment (24 dowels connecting the wall to the columns and 20 dowels connecting the wall to the beams). Details about the modelling, including the elements used to simulate numerically the RC frame member, the RC infill wall, and the dowels, may be found in [8, 9]. It was then decided to perform another eight different cases of the number of dowels in the model. These parametric-study scenarios are shown in Table 1. In Table 1, the name of each case scenario is shown in the first row of the table. Further, in Table 1, the number, diameter, and spacing of the dowels that are connecting the wall to the bounding columns and beams are presented for all the floor levels of the frames. For the last case scenario (Case 8), where there are no dowels in the model, the only connection between the new infill wall and the existing frame members is the cohesion and friction between the two interfaces. The nonlinear dynamic analysis procedure that was followed was the same for all the case scenarios. The time-history of the Herzeg Novi (Montenegro 1979) accelerogram (Fig. 2) was scaled to 0.25 g and it was used for all the parametric-study scenarios. The results of the parametric study are illustrated and analyzed in the mentioned references.

The analysis of the results of the numerical parametric study can be found in [7, 9]. In this section, the conclusions that are drawn from the analysis of the results of the parametric study are given. Specifically, the relations between the number of dowels that were provided in terms of the total area of reinforcement (As, mm2), and the stiffness, the shear strength, the displacement of the frames, and the moment at the base of the frame members were examined in Figs. 3, 4. Furthermore, the arrangement of dowels along the length of the wall in terms of spacing between the dowels (related to the provided diameter of dowels bar, ds) is related to the moment demand at the base of the frame members in Fig. 4, and conclusions are drawn and discussed. The area of reinforcement, As, and the spacing in terms of ds are shown in Table 1 for each case scenario.

As displayed in Fig. 3, the fewer the dowels that are provided, the less the stiffness of the frame is. It is also illustrated that when the dowels that are provided are more than 2000 mm2, the stiffness of the frame is not changing considerably. One can say that there is no need to add dowels of more than 3000 mm2 to add to the stiffness of a frame. However, it is shown that when the provided dowels are less than 2000 mm2, the stiffness of the frame is significantly reduced. On the other hand, in the case of an existing bare frame, by adding just 2Y20 (628.32 mm2) only on beams, or around the perimeter of the frame, or by adding just 4Y20 (1256.64 mm2) around the perimeter of the frame, the addition to the stiffness of the frame is remarkable. The relation of the number of dowels to the shear strength of the frame is similar to the relation to the stiffness of the frame as shown in Fig. 3. Nevertheless, the addition to the shear strength of the frame when the provided dowels are more than 3000 mm2 is increased, in contrast to the increase in stiffness when the provided dowels are more than 3000 mm2. This indicates that in the case where the aim is to increase the shear strength of the frame, the more the number of dowels, the more the shear strength of the frame. In Fig. 4, it is illustrated that there is a linear relationship between the moment demand at the base of the wall and the provided dowels. So, the more the provided dowels, the more is the moment demand at the base of the wall. Also, as shown in Fig. 4, the moment demand at the base of the wall increases with the increase of the number of dowels, while there is a substantial increase at the moment demand when the dowel spacing is less than 15ds. The moment demand at the base of the wall is a polynomial function of the spacing of the dowels at the base of the wall and as the spacing of the dowels is increased, the moment demand at the base of the wall is decreased. This is due to the fewer axial forces that are generated at the base of the wall because of the reduced number of dowels.

Generally, from the numerical parametric study in [10], it was concluded that the lower the number of dowels, the lower the base shear force, the stiffness, and the energy dissipation of the building. However, it was shown that the global characteristics of the building are not varying considerably for the first five case scenarios (dowels spacing 5ds to 25ds). Further, it was shown that even with just two dowels connecting the bounding beams with the wall (seventh case scenario), not only their contribution to the total shear force is notable, but also their contribution to the stiffness of the frame is significant. In general, the overall behavior of the frame changes for the seventh case scenario with a significant decrease in the base shear force, stiffness, and energy dissipation of the frame. As shown from the analysis of results from the numerical parametric study and the comparison of results with existing code recommendations in [10] it was observed that for dowels spacings from 5 to 10ds, the stiffness, and maximum base shear are about the same. Furthermore, it was concluded that the numerical results complement the experimental results and showed that the number of dowels used in the experimental study can be reduced, making the use of this method more cost-effective. Moreover, from the analysis and relations between the results, it was shown that the quantity and spacing of dowels that should be provided are depending on the aim of the strengthening of each building, and it could be less than the suggestions of KANEPE [11].

3 Performance-Based Analysis at Various Earthquake Levels

The pga scenarios 0.25 g, 0.2 g, and 0.15 g that are defined in the National Annex of Eurocode 8 (EC8) for Cyprus were analyzed to examine the proposed retrofitting method at several hazard scenarios and to provide preliminary design guidelines as part of EC8-3. Based on the analysis of the results from the numerical parametric study that was discussed in Sect. 2 of this paper and is shown and discussed in detail in [7, 9], the cases that were examined at different hazard scenarios are cases 3 and 4 (see Table 1). Considering the conclusions of [7, 9], the global results from the parametric study showed that significant changes regarding the global and local results of the frame were observed after the fifth case scenario. In addition, the 200 mm reinforcement spacing is the usual spacing that is applied for the dowels and the web reinforcement of the walls.

Numerical global and local results for the performance-based analysis at various earthquake levels are given in this section in order to obtain some general conclusions about the proposed method. More specifically, the global behavior of the frames and the local results from the analyses are presented and discussed for a distance of 200 mm and 300 mm between the dowels at the interface between the existing frame and the new wall were examined for the three earthquake levels. The results for the validated (monolithic) model with 100 mm spacing between the dowels are also illustrated for the 0.25 g acceleration for comparison reasons.

3.1 Global Results

In this section, the global results from the examined case scenarios are illustrated and discussed. The base shear forces of the frame versus the top-storey displacements (DTX) are illustrated for the examined case scenarios at 0.25 g, 0.2 g, and 0.15 g peak ground acceleration levels in Fig. 5.

As shown in Fig. 5, the top-storey displacement and the total base shear force for the examined cases are about the same for the examined spacing options for each pga scenario. Moreover, the stiffness and the energy dissipation of the frame are about the same for the examined spacing cases for each pga level as shown in Fig. 5. The results in this section, show that for 0.15 g acceleration, the frame is elastic for spacing 200 mm (10 ds) between the dowels, while for spacing 300 mm (15 ds) between the dowels the frame has a nonlinear behavior. For 0.2 g acceleration, the behavior of the frame is similar for both spacing cases. Both frames get in a nonlinear situation, while the base shear of the frame with the 300 mm spacing between the dowels is lower than the base shear of the frame with the 200 mm spacing between the dowels and the deformation of the frame with the 300 mm spacing between the dowels is larger in the one direction than the deformation of the frame with the 200 mm spacing between the dowels. For 0.25 g acceleration, the behavior of the frame is similar for all examined spacing options, including the monolithic model. This indicates that for the 0.25 g acceleration, the frame suffered damage and behaves nonlinearly whether the spacing of dowels is 100 mm or 300 mm.

From these results, it could be concluded that for an earthquake event of 0.25 g or 0.2 g acceleration regardless of the spacing between the dowels, the frame will suffer damage and will exceed its linear limits. On the other hand, for earthquake events with 0.15 g acceleration, the frame may stay in the elastic area for the spacing of dowels no less than 10 ds.

3.2 Local Results

In this section, the local results from the examined case scenarios at 0.25 g, 0.2 g, and 0.15 g peak ground acceleration levels are presented and discussed. More specifically, the behavior of dowels at the base interface of the wall during the analysis is displayed and discussed for the time-steps when the frames experience their maximum top-storey displacements and their maximum base shear forces during the response-history analysis in both directions for the examined cases. In Fig. 5, the graphs show the axial force (Nx) of each dowel at the base interface along the length of the wall. Specifically, each marker on the graphs displays the results of the dowel that is located at the actual position of the dowel in the model. The length of the wall without the bounding columns is 2.1 m [15]. The x-axis of the graphs displays the length of the wall, with 0m on the west edge of the wall and 2.1 m on the east edge of the wall. For instance, in the validated model case where the dowels were spaced at 100 mm at the base of the wall in the x-axis of the graphs, there is a value for each dowel at every 0.1 m. Consequently, for all the case scenarios, the corresponding position of each dowel is shown in the graphs. The y-axis of the graphs displays the corresponding axial force of each dowel. Moreover, the total shear force of dowels at the base interface of the wall for the examined spacings between the dowels for the three earthquake levels when the base shear force and the top-storey displacement of the frames are maximum are discussed.

The graphs in Fig. 6, illustrate the axial forces of dowels when the total base shear and the top-storey displacement of the frames are at a maximum in both directions. The positive values on the graphs display the compressive forces and the negative values are the tensile forces of each dowel. Also, the design yield strength of dowels is shown in graphs. It is illustrated that the dowels of the validated model take the lowest tensile forces in comparison with the other case scenarios since the infill wall behaves monolithically with the bounding frame, resulting in an even distribution of the axial force among the dowels when the frame experiences its maximum base shear and top storey displacement in both directions. Moreover, in the case of the validated model, the position of the neutral axis is in the middle of the wall. For the 0.25 g acceleration, for spacing 200 mm and 300 mm between the dowels, the dowels reach higher axial forces in comparison with the first case scenario and some dowels reach their yield strength capacity when the base shear is maximum. In addition, for these spacings, as already mentioned in [7, 9] the position of the neutral axis is in the middle of the wall, thus, there is an even distribution of the axial force among the dowels for these cases. Overall, for all acceleration levels of the earthquake, the lower the spacing between the dowels is, the lower the tensile force of each dowel. Furthermore, it is illustrated that for spacing 200 mm between the dowels, none of the dowels reach their tensile yield strength capacity at 0.2 g and 0.15 g accelerations. On the other hand, for spacing 300 mm between the dowels, some of the dowels reach their yield strength capacity at all the examined accelerations.

The shear forces of dowels at the base interface results, show that for all cases the more the dowels provided (the less the spacing between the dowels), the more the total shear force that dowels take. Moreover, it is illustrated that the total shear force that dowels take at the base interface of the wall for 0.25 g acceleration is 2.1–2.3 times higher compared to the 0.2 g acceleration for spacing 100 mm between the dowels. For 0.2 g acceleration, the total shear force that dowels take is 3.6–18.9 times higher compared to the 0.15 g acceleration when the spacing among the dowels is 100 mm, 2–2.1 and 1.6–2.1 times higher when the spacing among the dowels is 200 mm and 300mm, respectively. For 0.2 g acceleration, the total shear force that dowels take for spacing 100 mm is 1.5–5 times higher compared to the 200 mm spacing, and for spacing 200 mm is 1.3–1.7 times higher compared to the 300 mm spacing. For 0.15 g acceleration, the total shear force that dowels take does not change considerably. These results show that the larger the earthquake acceleration is, the higher the total shear force that dowels take. Further, the results show that the larger the spacing among the dowels is, the lower the total shear force that the dowels take. As far as the inter-storey drifts are concerned, there is a reduction of 50% between the reduced earthquake acceleration levels of excitation.

4 Conclusions

The results of this paper provide new validated results from numerical analyses from the developed calibrated FE model [8, 9]. The validated FE model allowed more investigations that are necessary for the assessment at a performance-based level at various hazard levels for the proposed retrofitting method. Based on these results, the introduction of non-monolithic connected walls instead of monolithic walls to retrofit existing non-ductile RC frames may be added as a proposal for the seismic strengthening of existing RC frames in EC8-3. The numerical results taken from this paper, are presented and discussed to draw some general conclusions about the proposed method and to provide design recommendations for the connection of new members to existing RC frames.

As shown from the results of the parametric study in [7, 9], the stiffness of the frame is not varying considerably for the first three case scenarios (shown in Table 1). This observation indicates that using 10 dowels (case 3) instead of 20 dowels, the initial stiffness is about the same. It is interesting to note that the stiffness considerably increased for cases 6 and 7 in which two dowels on columns and beams, and two dowels on beams are used, respectively, compared to case 8 in which there are no dowels. This demonstrates how important is the addition of dowels not just on beams but on columns as well and even more, it is shown how dominant is the addition of just two dowels even only on beams compared to a non-integral infill. Also, it is shown that the more dowels that connect the wall to the bounding frame, the more is the moment demand at the base of the wall, due to the large number of dowels that increase the axial capacity at the base of the wall and hence its bending capacity and bending demand on the foundation (shown in Fig. 4). Furthermore, it is shown that the moment demand at the base of the wall is obviously increased when the spacing of the dowels is less than 15ds. Furthermore, from the results of the parametric study, it was concluded that the dowels provided to connect the new RC infill wall to the surrounding existing frame members depend on the aim of the strengthening. More specifically, if the aim is to increase the shear capacity of the building the more dowels provided, the more is the shear strength of the building (shown in Fig. 3). Otherwise, if the goal is to increase the stiffness of the frame as much as possible or to minimize the displacement of the frame, it seems that there is not much difference if one adds more than 3000 mm2 dowels. However, the additional moment demand at the base of the new wall should be considered, since the more the provided dowels the more the moment demand is at the base of the new wall. On the other hand, if the target is to provide the minimum possible dowels to the frame and at the same time to strengthen the building for such an earthquake event as the examined one, even the minimum provided dowels (2Y20, which is less compared to the KANEPE regulation suggested minimum of 3Y16 around the frame members) increase the stiffness as well as the shear strength of the frame and decrease the displacement of the frame significantly relative to the one strengthened with a non-integral infill wall (case 8). The parametric study results showed that the number of dowels used in the experimental study can be reduced, making the use of this method more cost-effective.

For an optimal retrofitting strategy further study is required regarding the parameters and the performance of the studied retrofitting strategy. For this reason, the performance-based analysis at various hazard levels based on the studied retrofitting method was performed for parametric cases 3 and 4. The results in this paper show that at the lowest acceleration for seismic zonation of Cyprus, 0.15 g, for spacing 200 mm between the dowels, which corresponds to 10 ds instead of 5 ds (monolithic), the frame can dissipate the energy during the earthquake and remain elastic, while for spacing 300 mm between the dowels (15 ds) the frame has permanent deformations and has a nonlinear behavior. On the other hand, for the 0.25 g and 0.2 g accelerations, the frame has similar behavior for the examined spacings between the dowels in this paper. Regarding the local results of the dowels, the results of this paper show that only for the validated model (spacing 100 mm) the tensile forces of all dowels are not close to their yield strength capacity. For the non-monolithic cases, some dowels reach or are close to their yield strength capacity at all accelerations that were examined. Further, it is shown that the total shear force that the dowels take at the base interface of the wall is lower for lower earthquake accelerations and higher spacing among the dowels. Nevertheless, further analysis and study of the results from the performance-based analysis should be performed to obtain a better understanding of this structural system, as a method for establishing the connection between the old and the newly designed elements that will allow the development of design guidelines for typical RC buildings retrofitted with the proposed method. Furthermore, the results of this study will allow the development of fragility curves to formulate earthquake vulnerability of buildings in terms of different damage levels for the proposed retrofitting method.

References

Chrysostomou CZ, Kyriakides N, Kotronis P, Georgiou E (2016) Derivation of fragility curves for RC frames retrofitted with RC Infill walls based on full-scale pseudodynamic testing results. In: ECCOMASS congress, Paper 16727. Crete

Chrysostomou CZ, Poljansek M, Kyriakides N, Taucer F, Molina FJ (2013) Pseudo-dynamic tests on a full-scale four-storey reinforced concrete frame seismically retrofitted with reinforced concrete infilling. In: Structural engineering international, 23(2), pp159–166. Journal of the International Association for Bridge and Structural Engineering (IABSE), https://doi.org/10.2749/101686613X13439149156831

Chrysostomou CZ, Kyriakides N, Kotronis P, Georgiou E (2014) RC infilling of existing RC structures for seismic retrofitting. In: Second european conference on earthquake engineering and seismology, Instanbul

EN, CYS (2009) Cyprus National Annex CYS ANtional Annex to CYS EN Design of Structures for waerthquake resistance Part1: General rules, seismic actions and rules for buildings

Fardis MN (2009) Seismic design, assessment and retrofitting concrete buildings: based on EN -Eurocode 8, Geotechnical, geological, and earthquake engineering, vol 8. Springer, Dordrecht, New York

Fardis MN, Schetakis A, Strepelias E (2013) RC buildings retrofitted by converting frame bays into RC walls. Bull Earthq Eng 11(5):1541–1561. https://doi.org/10.1007/s10518-013-9435-6

Georgiou E, Kyriakides N, Chrysostomou CZ (2022a) Nonlinear numerical parametric study of the number and arrangement of dowels connecting the wall to the bounding frame for the seismic strengthening of RC frames with RC infill walls. In: Bulletin of earthquake engineering. Springer. https://doi.org/10.1007/s10518-022-01354-7

Georgiou E, Kyriakides N, Chrysostomou CZ (2022b) Numerical simulation of RC frames infilled with RC walls for seismic strengthening of existing structures. In: Bulletin of earthquake engineering. Springer, https://doi.org/10.1007/s10518-022-01319-w

Georgiou ES (2021) RC-Frames Infilled with RC Infill-Walls for Seismic Retrofitting, Doctoral dissertation. Department of Civil Engineering and Geomatics, Faculty of Engineering and Technology

Georgiou ES, Kyriakides N, Chrysostomou CZ, Kotronis P, Filippou CA (2018) Numerical Simulation of the Experimental Results of the Seismic Strengthening of Existing Structures. In: 16th European Conference on Earthquake Engineering, Paper 11029. Thessaloniki

KANEPE (2017) Code for Intervention in reinforced Concrete Buildings, Earthquake Planning and Protection Organization (OASP)

Kaplan H, Yilmaz S, Cetinkaya N, Atimtay E (2011) Seismic strengthening of RC structures with exterior shear walls, 36(1), pp. 17–34. Sadhana

Kyriakides N, Chrysostomou CZ, Kotronis P, Georgiou E, Roussis P (2015) Numerical simulation of the experimental results of a RC frame retrofitted with RC Infill walls. Earthquake Struct 9(4):735–752. https://doi.org/10.12989/eas.2015.9.4.735

Moehle JP (2000) State of research on seismic retrofit concrete building structures in the US. In: US-Japan Symposium and Workshop on Seismic Retrofit of Conrete Structures

Poljansek M et al (2014) Seismic Retrofitting of RC Frames with RC Infilling (SERFIN Project). Joint Research Centre, Institute for Protection and Security of the Citizen Publications Office,. https://doi.org/10.2788/630

Sonuvar MP, Ozcebe G, Ersoy U (2004) Rehabilitation of reinforced concrete frames with reinforced concrete infills, 101(4). In: ACI Structural Journal

Turk AM, Ugur E, Ozcebe G (2006) Effect of introducing RC infill on seismic performance of damaged RC frames. Struct Eng Mech 23(5):469–486

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Georgiou, E., Kyriakides, N., Chrysostomou, C.Z. (2023). Performance-Based Numerical Analysis at Various Hazard Earthquake Levels for the Retrofitting of Reinforced Concrete Frames with Reinforced Concrete Infill Walls. In: Ilki, A., Çavunt, D., Çavunt, Y.S. (eds) Building for the Future: Durable, Sustainable, Resilient. fib Symposium 2023. Lecture Notes in Civil Engineering, vol 350. Springer, Cham. https://doi.org/10.1007/978-3-031-32511-3_117

Download citation

DOI: https://doi.org/10.1007/978-3-031-32511-3_117

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-32510-6

Online ISBN: 978-3-031-32511-3

eBook Packages: EngineeringEngineering (R0)