Abstract

A number of military fortresses built between 1853 and 1914 by the Austrian‐Hungarian Empire in today’s Republic of Montenegro have been investigated by the Austrian Archaeological Institute. The ongoing survey first focused on three sites dating between 1858 and 1897. Mortars had been diversely used in all of them for different purposes of construction.

Analyses were performed on mortar samples by thin-section microscopy and SEM. The results reveal use of several lime, natural “Roman” cement and Portland cement materials, depending on their application in the building and on the period of construction. All three fort buildings contain mainly air lime mortars as bedding and filling of the stone masonry, while pointing on exterior walls and tamped concretes are usually based on Portland cements. The microscopic features of the Portland cement (PC) clinkers reflect the typical conditions of early PC production. Roman cement (RC) mortars were only occasionally found.

Our contribution includes a presentation of the fortresses and their construction principles, followed by a discussion of the mortars by their binder constituents and aggregates. In the context of the state of the Austro-Hungarian cement industry in the 19th century, the observations reveal one of the earliest applications of Portland cement in the whole Empire.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Historic Army Construction Sites

- Montenegro

- Austro-Hungarian Empire

- Early Portland Cement

- Historic Mortars

1 Introduction

The imperial Austro-Hungarian system of fortifications in the today’s Republic of Montenegro was largely built between 1853 and 1914; it was the former southern extremity of the Empire. As well as marking out the southern boundary with the Ottoman Empire (until 1878) and Montenegro, its purpose was to defend part of the Adriatic fleet based in the Bay of Cattaro (today Kotor). The fortresses and the pathways linking them were largely abandoned after the First World War, so that most of the remaining structures and materials date back to the time of construction in the 2nd half of the 19th century. For the same reason, and due to the impacts during WW-I, most buildings are today in an advanced state of decay.

Inspired by an initiative of the Ministry of Culture of Montenegro in 2017, the Austrian Archaeological Institute of the Austrian Academy of Sciences started its scientific activities within an ongoing project related to the Austro-Hungarian fortification buildings in Montenegro.

This contribution focusses on the material aspects of a larger research project aimed to raise awareness of the existence of these defensive military structures, and in doing so, alert the need to protect and conserve this cultural heritage for future generations.

2 State of Research and Previous Work

Apart from two existing studies on the military architecture around the bay of Kotor which provide a broad overview of the existent building diversity and construction phases [1,2,3], neither detailed building analysis nor extensive historical background research has been published until present. In the autumns of 2018 and 2019, two short on-site campaigns were performed with a team of experts in the areas of building research, stone restoration and surveying. Initially, the topographic peculiarities of the bay of Kotor, surrounded by steep mountain ridges, were examined regarding the positioning of the Austro-Hungarian fortification buildings in their various phases of development. Out of a total of more than eighty objects, the fortifications of Kosmač (1858), Goražda (1884–1886) and Vermač (1894–1897) were selected for a detailed examination (Fig. 1). These three fortification complexes cover a time range of 40 years of structural engineering, a period of rapid advances in technological and industrial development within the 19th century. Though in remote positions, they all are characterised by their vicinity to the heavily touristed destinations of Kotor and Budva, which is why these forts possess great potential to make history come alive to educators and students, tourists, and the broader public. At the same time these fortifications are mostly endangered by possible future construction measures.

In 2020, project activities focused on the preparation of building survey plans for the Kosmač, Goražda and Vrmač fortresses, which had been investigated since 2018 (Fig. 2), and on the analysis of a set of stone and mortar samples taken during the course of both field campaigns. As sampling for laboratory analyses had to follow certain constraints, careful selection of samples was based on the idea to achieve insight into the major construction elements of each of the sites.

An important piece of information related to one of the forts could be found in the Vienna Kriegsarchiv (war archives) of the Austrian State Archives in Vienna [4]: a hand-written record on building materials and techniques of construction of Vermač fort (1894–1897), drafted by the Kotor branch of the Army Engineering Department (“Geniedirektion”). Amongst others, this document provided valuable insight into the types and approximate quantities of mortar binders used their proveniences and producers, as well as information on the origin and type of sand and aggregate. The observations made by laboratory mortar analyses will be discussed later with regard to this record.

By comparison with another record [5] on the construction of the nearby Battery of Vermač (also known as Battery of Skaljari, built 1884–1886), which so far has not been investigated by the authors, conclusions can be drawn on the change of building materials and their suppliers within a time span of 10 years.

Material scientific studies were thus performed on samples taken from selected elements of the three buildings. They comprised concretes, masonry bedding and pointing mortars, exterior and interior renders, as well as natural stones. The analyses were aimed at providing information to the building history including construction processes, origin and procurement routes of the materials as well as achieving basic knowledge needed for their conservation and restoration.

Given the strategic importance of the forts and the administrative management by a big public institution like the Austro-Hungarian Army Command, it can be assumed that building materials and construction methods were at the highest available standards of the time. It seemed of particular interest that the period of construction was marked by significant progresses in the manufacture of cementitious building materials.

3 The Forts of Vermač, Goražda and Kosmač - Inventories and Building Description

In the following, the three fort complexes are briefly described in reverse order, i.e., starting with the latest for which written information is available.

3.1 Vermač (Vrmač)

Constructed in the period 1894–1897, Vermač/Vrmač is the youngest of the fortifications examined. Consisting of several buildings, the complex, located on a ridge above Kotor, had to protect and defend the town against possible attacks from across the Montenegrin border situated on the opposite slopes of the Bay of Kotor. It was largely built below the present ground level which had been partly raised to protect particularly the southern fronts of the fortification. The top deck was later covered with a massive “concrete bonnet”. A several meters wide moat supported by stone walls runs around the central fortress building.

As mentioned above, written records describe in detail the materials and techniques of construction of Vrmač [4]. Similar reports would most probably exist for all the other Austro-Hungarian military buildings in the area, though so far they could not be traced by the authors, with the exception of the nearby Battery of Vermač [5] which was built about 10 years earlier than the fort there (Fig. 3).

Like the older fort buildings, most walls of the Vermač fortress were constructed as core-and-veneer with shells of regular stone ashlars and a core of rubble stone and mortar. Stone was also employed for most of the door and window framings. The barrel vaults of the ground floor were made of brick, while tamped concrete vaults cover the rooms of the first floor. Presumably in a later stage, the second upper floor was spanned by means of a construction of steel girders and tamped concrete.

As we know from [4], while the rubble quarry stone described as a hard and brittle limestone was extracted in the immediate surroundings, much better workability was assigned to limestone varieties from the island of Curzola/Korčula which were used as dressing stone. Several stone samples investigated by thin section microscopy confirmed the report, though this is beyond the scope of the present contribution.

Bricks forming e.g., the vaults of less exposed rooms of the basement and ground floor were set in lime mortar. The source of all bricks used in the Vrmač constructions was the factory of Count Caboga in Kupari near Ragusa/Dubrovnik. The report mentions their low quality due to high magnesium contents, a statement which was not verified during our survey.

Regarding the mortars used in Vermač, it is evidenced both by the historical source of [4] and by the present survey that Portland cement mortars strongly prevail over Roman cement ones. In this respect, the building of Vrmač differs from the older fortresses where more Roman cement was used.

The Portland cement of the Vermač fortress is reported to originate from Lengenfeld in Ober-Krain/Dovje-Mojstrana, Kranjska Gora. The cement plant owned by Ammann & Co. had started its production in 1893 [6]. Though no more detailed information on their products could be found in the literature, it is likely that there “natural” Portland cement was produced from locally extracted marlstones.

Significantly more information is available on the producer of natural “Roman” cement: the company Gilardi- & Betizza in Spalato/Split [7]. Their Roman cement production started in 1871 and was complemented by – most probably again natural – Portland cement after 1880. Both products were certified and recommended for the construction of fortresses in the Kotor area. While Gilardi & Betizza had delivered Roman cement for both Vermač buildings, i.e., the Battery (1884–1886) and the Fort (1894–1897), their Portland cement was supplied only to the earlier Battery [5]; 10 years later, when the Fort of Vermač was built, the army administration had switched to the producer of Kranjska Gora [4] who had by then started their production of Portland cement.

Lime was purchased as lump quicklime from the locations Krašić and Mali Pristan on the peninsula of Luštica situated at the entrance to the bay of Kotor. Its slaking was done at the building site and is not further described, and no pit is mentioned in the report. Accordingly, the binder microstructure of the lime mortar samples points to a short-term slaking (see 4.2.2).

The costs of 100 kg Portland cement delivered to the building site is given in [4] with 3.4 Fl. (Austrian gulden) compared to 2.8 Fl. For Roman cement. According to the present-day currency [9], this amounts to roughly 72 Euro to 60 Euro, respectively. In comparison, quicklime delivered to Kotor by boat costed between 1.6 and 2 Fl. Per 100 kg, corresponding to approx. 23 to 30 Euro.

As to their use in the constructions, Portland cement-based mortars were used in the following elements of the fortress complex: cisterns, sinkholes and sewer tunnels, imposts of those vaults in the ground floor where the shielded batteries were placed, abutments of gun carriages, and the masonry adjacent to chimneys and window or door openings. For a number of elements designed to be artillery-proof or have heavy load bearing functions, concrete elements were called for, even naming the mixing ratios but not specifying the type of cement used; for the Battery of Vermač built 10 years before the Fort, the use of Roman cement in concrete construction is stated [5].

Concerning the aggregate for mortars and concrete of Fort Vermač [4], gravel was obtained by crushing the quarry stone from the nearby outcrops, whilst coarse sand was supplied from torrents of Bianca/ Bijela near Castelnuovo/Herceg Novi, and fine sand from the beaches next to Budva. The latter was stored outdoors over the winter period in order to have the salts washed out.

Samples taken from mortar elements of the Vrmač fortress in course of the present survey included pointing mortars of stone masonry outdoors and indoors, outdoor renders as well as plasterwork on interior walls. No concrete element was sampled so far. The results confirm the use of binders as stated by the report [4]: lime mortars were found just in masonry beddings and interior plaster, while pointing as well as renders revealed based on Portland cement. More details are reported in 4.2.2.

3.2 Goražda

The turret fortress of Goražda is situated a few km SSE of Vermač on a plateau-like extension of the same ridge. By its position it was meant to control a wide area which included Kotor, the roads from Budva to Kotor and Cetinje, the slopes of the Lovćen and the bay of Tivat down to the southern end of historical Dalmatia. Constructed in 1884–86, Goražda is about ten years older and significantly larger than the neighbouring fortification of Vermač. Similar to the latter, Goražda was also partly built below the ground level by backfilling the terrain around the structure. A several metres wide moat, supported by massive stone walls and accomplished by four projecting carponniers, surrounds the building with its casemates and the central armoured turret originally equipped with two siege guns, which is still preserved up to date.

Other than Vermač which suffered several heavy damages during WW I and was then abandoned, the fortification of Goražda was in use beyond the fall of the Empire in 1918, even during WW II and further in the post‐war period until the 1980s. This is confirmed by a variety of repair works as well as by conversions and additions to the original structure as well as by a high amount of paints, whitewashes and graffiti, including more elaborate wall paintings present in different area of the complex.

In contrary to the Vermač fortress, no contemporaneous report specifying details of construction and building materials could be found so far for Goražda. The survey revealed that natural stone – in all places compact limestone of varying lithological features – is the dominant building material of the wall constructions. Analogies with the ashlar stone of the Vermač fortress supplied from Korčula are unlikely under the premise that so far no in-depth analyses were performed to characterize the variety of the Goražda masonry stone. The prevailing construction scheme of most walls is again the core-and-veneer technique; regular dressed stone courses have their joints precisely trimmed in different ways. In most areas of the building interior walls received particular attention by careful execution of the pointing in a raised ribbon style. The structural elements of the walls are beyond doubt from the time of origin, including the core infills of rubble stone and mortar. Most door and window reveals are also original, they are built from equal dimensioned stone ashlars. The barrel vaults in the interior have lunette caps from natural stone, except for those areas spanned and strengthened by steel girders, where ceilings and floors consist of tamped concrete.

Samples taken from mortar elements of the Goražda fortification during this survey comprised tamped concrete, bedding of the stone masonry, pointing on different types of stone masonry outdoors and indoors, outdoor renders as well as plasterwork on interior walls. The results of analysis reveal the use of dolomitic lime mortars for masonry beddings and interior plasters, while the selection of binders for masonry pointing seems to depend on the type of masonry: Roman cement was found in pointing mortars of interior and free-standing single shell stone walls, while Portland cement-based pointing was mainly detected on exterior masonry, repairs and on later added interior walls. Also the concrete samples proved the presence of Portland cement. More details are reported below (Fig. 4).

3.3 Kosmač

The fortification of Kosmač was built in a prominent position at 800 m above sea level above the coastal town of Budva. This complex formed the southernmost fortress of the Austrian‐Hungarian Empire at the borders of Montenegro and (till 1878) the Ottoman Empire. The construction started in the 1840s and was completed in 1858. By the end of WW I in 1918, the Austrian troops retreated from Kosmač and blew up the fortification, thus laying the ground for the ruinous condition in which it appears till our days, even if it had been garrisoned again by Italian troops during WW II.

Due to its earlier date of erection, the position and the strategic disposition, the construction plan and appearance of the Kosmač fortress differ completely from the above addressed forts of Vermač and Goražda. The three-storey high building originally covered by a hipped roof is formed by two symmetrical wings, each with a semi-circular extension at its end. The central tower faces seaward while large arched gun ports face out over the hinterland (parts of the above description are taken from [10]).

The building was almost completely executed in natural stone in the form of uniform courses of dressed stone ashlars. Like the other two fortresses described above, the unrendered masonries were constructed in a core‐and‐veneer mode with two parallel shells filled with quarry stones and mortar. A greyish limestone of local origin was used. The walls in the interior of the building are comparatively less regularly textured, built with quarry stones and chips of stone and platy bricks filling the wide joints. It is thus assumed that the interior walls were plastered and probably whitewashed at least in parts, which is confirmed by a number of mortar residues preserved on the stone surfaces. All interior spaces are covered with barrel vaults made of a lightweight porous karst limestone; just the uppermost ceiling had been reinforced with a thick layer of tamped concrete. Most of this layer had been destroyed by the 1918 explosion, so that fragments of this concrete can be found in the debris which today covers the site, along with stones from the masonry and chips of slate from the former roofing (Fig. 5).

Apart from the stone material originating from the masonry and vaults, a few mortar elements were sampled from the site of Kosmač with its limited accessibility to the ruins. They comprised bedding mortars of the masonry along with interior plaster, pointing mortars from the exterior stone masonry, concrete from the collapsed ceiling reinforcement, and a mortar of unknown origin, the two latter samples collected from the debris on the ground. The laboratory analyses revealed feebly hydraulic lime as binder of bedding mortars, air lime in the interior plasterwork, and Portland cement as binder of the tamped concrete as well as of the exterior pointing. Given the early date of construction (1858), the use of PC was somewhat surprising since it appears just a few years after initiation of the first (natural) Portland cement in the Austro-Hungarian Empire (1856) [12].

More details on the mortars of Kosmač are given in 4.2.2.

4 Mortar Analysis

4.1 Methods

All materials sampled at Vermač, Goražda and Kosmač were analyzed by polarized light microscopy (PLM) and by scanning electron microscopy (SEM) combined with energy-dispersive X-ray spectroscopy (EDS). This approach was considered appropriate to obtain comprehensive information on the type of binders and the composition of mortars. The analyses were performed on polished thin sections made from vacuum-impregnated samples; a blue dye was added to the resin in order to facilitate the visibility of pores.

SEM observations were made under low vacuum to avoid irreversible coating with carbon. Under these conditions, no quantitative EDS analyses could be achieved, though the spectra were reliable enough to identify the nature of binder components and aggregates by their chemical composition.

4.2 Results

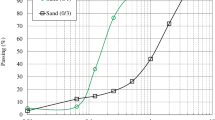

Aggregates in Mortars.

In the present context, aggregates were not considered of primary significance for the classification of the mortars though they form important components of any mortar material and, by their petrographic nature, are of interest in respect to their provenance and the mixing regime. This section will therefore start with a general view on the aggregates found in the mortar samples, before dealing with the binders as the major item of their classification.

As a consequence of the topographic conditions of Montenegro with its rugged slopes and the seashore at close distance, local stone material was used to provide the aggregate of all types of mortar and concrete. The geological situation, with a clear predominance of calcareous rock outcrops, is reflected by the petrographic nature of the carbonate aggregates found in all of the samples. In addition, the presence of radiolarian-rich layers in most of the calcareous bedrocks adds important amounts of chert to the aggregate mix. It is evident that the high weathering resistance of this microcrystalline silica variety accounts for its frequent accumulation in sediments such as gravel and sand.

Considering Vermač Fort, the army report on its construction [4] also refers to the type and origin of aggregates supplied to the site, without further specifying for which type of mortar they were used. It distinguishes between gravel, coarse, and fine sand, and each class was obtained from a different source. It is of interest to classify the aggregate found in the samples in view of the written information.

Coarse gravel for the construction of Vermač was obtained from a nearby quarry by crushing the rock to the required size, usually up to several cm. This kind of aggregate is supposed to be unsorted. It is explicitly stated that attention was paid to use just sound and uncontaminated rock material and that therefore no careful washing was required. The angular chips obtained by crushing reflect the immediate geological environment of each fortress – compact limestone of locally differing lithological character. Silica layers of dark radiolarite are always frequently intercalated, though the form a minor constituent and were probably rather avoided by the stone workers. Such limestone chips (>1.5 cm) eventually mixed with river gravel were found in one concrete sample from Kosmač (Fig. 6), while the concrete of Goražda contains much smaller (<5 mm) subangular gravel of chert with just occasional carbonate gravel.

It should be noted that all micrographs in the Figures of this section are scaled to the same size of magnification in order to make them comparable.

Coarse sand as understood by the authors of [4] includes in fact gravel in the size of a few mm up to about 1 cm in diameter. According to the report, it was taken from some torrents near the coast, at least as far the Vermač fort is concerned. This river sand appears usually well rounded (limestone) to (sub)angular (chert); depending on the source rock of the sediment, it is in many cases chert dominate here thanks to its higher resistance.

River gravel as aggregate was observed in many of the mortar samples from all three sites. They can be attributed either to bedding mortars of the rubble core in cavity walls, or to indoor plaster mortars (Fig. 7), or, as mentioned above, to the tamped concrete of Goražda (Fig. 8, with predominance of chert components).

Fine sand for the Vermač Fort construction was taken from the beaches near Budva as stated by the army report [4]. It can be assumed that the same holds for the other two buildings. The Vermač report mentions that this sand, due to its salt content, was deposited outdoors for a year in order to have the salts washed out by percolating rain water. This beach sand is quite characteristic by the roundness of aggregates and a somewhat broader petrographic composition than the coarser inland counterparts.

Sea sand from Budva beach, composed of limestone and chert components; according to the army report on Vermač [4], such sand was used as “fine sand” for construction purposes; thin section in PPL (a) and XPL (b).

A sediment sample collected from a beach near Budva matches the sand aggregate of the historic mortars to a high extent (Fig. 9): again, limestone and chert form the predominant components of this moderately well sorted sediment, but the former appears spherical with high roundness, while the latter is also isometric though just subangular. Such “fine sand” forms the aggregate in most of the pointing mortars studied, while in some other mortars it was probably mixed with “coarse sand” for a broader grain size distribution (Fig. 10).

Mortars Classified by Binder Types.

Air lime mortars were consistently found in samples from interior plasterwork in all of the fort buildings. In the case of Goražda, Mg-rich inclusions exhibiting a spotted appearance clearly indicated the dolomitic nature of the lime binder (compare e.g., the lumps in Fig. 11 to those in Fig. 12), hence the origin of the raw material differs from the other two fortresses despite the close vicinity to Vermač. The same dolomitic lime constitutes the bedding mortar of the stone masonry of Goražda, while the bedding mortars of Vermač are based on pure lime - occasional lime lumps in these mortars point to a quick or “dry” process of slaking [8] in accordance with the fact that no lime pit is mentioned in the otherwise rather detailed report on the construction of this fort. Kosmač, on the other hand, has slightly hydraulic bedding mortars.

As indicated above, a group of samples which might be related to the intentional use of reactive chert as aggregate can be found in some mortar samples from Kosmač. These mortars, particularly rich in chert, appear as bedding, or core filling mortars, respectively, of the stone masonry. It can be assumed that prolonged conditions of moisture in the specific positions of the wall have contributed to the development of hydrated rims around the chert, as illustrated by Fig. 13 and 14. Thus, even if these mortars are extremely leached, they appear as extraordinary hard and strong.

Binder-related particles in indoor lime plaster samples from Vermač where quicklime was obtained from fossil limestone calcined by local producers in Korčula and short-term slaked on the construction site; residual structure of the raw feed stone (a), and undispersed lime lump (b). Thin section at transmitted light, dark field; in the diffuse light of the dark field mode, microporous areas appear bluish whilst white and compact areas show bright;

c = mortar fracture face.

Roman cement mortars were not found in any of the samples from Kosmač, despite of the fact that these binders had their heydays in Austria-Hungary about a decade before the fort was built. The apparent lack of Roman cement in our samples there may be due to the ruinous conditions of that fortification, with a limited accessibility to several structures restricting the possibility to sample all types of building elements. Also in Vermač, where the use of minor amounts of Roman cement from Split is known although no specific application is mentioned, no such binder was traced in any of the samples. Its use was probably restricted to some minor building elements which have not been studied yet.

However, in Goražda, the largest of the fortresses from which the most samples were taken, Roman cement mortars were found, as pointing mortars from interior and exterior masonries surfaces (see Fig. 15). The typology of binder related nodules found points to a relatively low burned product, where the higher burned portion present in any Roman cement of that period had most probably been removed in the factory.

An exception to Roman cement in the Goražda pointing was found in a sample from a retention wall constructed with stone ashlars, where the otherwise similarly dressed pointing was made with Portland cement.

Portland cement mortars proved to be prevalent in all three of the forts under investigation: in 1890s’ Vermač they are in all indoors and outdoors pointing mortars and at least some of the exterior renderwork, while in 1880s’ Goražda Portland cement was used in parts of the exterior masonry pointing and renders on concrete, which itself revealed to be based on this binder. Also Kosmač exterior pointing made use of Portland cement, although this may be due to maintenance interventions possibly in times of the reinforcement of the roof in the early 20th century.

By microscopy, all the PC-mortars studied clearly revealed their early age of production by the coarseness of clinker residues in the binders, and by their internal phase structure, such as coarse aluminoferrite and calcium silicates pointing to the use of vertical shaft kilns with prolonged times of residence and slow cooling (Fig. 16). Moreover, the use of a single, natural raw feed to calcine the cements is suggested by the range of varying clinker microstructures containing insufficiently calcined residues of the raw material [11] in most of the samples (Fig. 17). This means of production was quite common for the majority of cement plants in the territory of the Empire thanks to the frequent occurrence of appropriate marlstone in the Alpine and Dinaric regions. In particular, Alois Kraft in Kirchbichl/Tyrol, the only known Austrian producer in the 1850s [12], as well as Gilardi-Betizza in Split, who had this binder available since 1880 [7] and would have been an ideal supplier through boat transport to Kotor, were offering natural Portland cement.

Coarse PC clinker residues in a late 1890s pointing mortar of a stone masonry in Vermač; due to an improved quality of calcination, the variety of clinker types is less pronounced here than in the earlier PC clinkers of Kosmač; coarse interstitial phases (mostly calcium-aluminoferrite, see arrows), (a, b) point to low cooling rates of a shaft kiln; thin section at incident light (a) and PPL (b); c = mortar fracture face.

Given the generally early age of the fort buildings in respect to the timeline of the production and use of Portland cement in the Austrian-Hungarian Empire, which started in 1856 and developed just slowly till the 1890s in steadily successful competition to Roman cement, it seemed unlikely to find a significant number of Portland cement mortars in all three of the studied sites, in particular in the earliest one, Kosmač from 1858. No use of this then modern binder was reported so far from any Austrian building of the 1850s, even if some amounts of Portland cement were imported from England or Germany, which has likely occurred for a few applications. However, it seems improbable that the army of a big Empire with plenty of production plants would have imported building materials from abroad, while it seems highly probable that they were among the first users of novel materials at a time when civic architecture and engineering was still hesitant to use them.

5 Conclusions and Outlook

The versatile use of different mineral building materials in the construction works of the 19th century Austro-Hungarian army forts of Montenegro sheds light on the conscious selection of mortar constituents and recipes by the military engineers. Through our approach to identifying binders and aggregates through microscopic laboratory analyses of samples, paralleled by information extracted from the available written sources, it was shown that the most novel cementitious products at their time were employed only for certain elements of construction. This refers in particular to Portland cements, the newest and most expensive of all binders used: their application was, on the one hand, in concrete members of a fortress supposed to carry heavy loads or withstand the enemy’s artillery, or to those areas exposed to the heavy autumn and winter rainfalls, i.e. the joints of the otherwise compact exterior stone faces of the masonries. In contrast, the bulk of mortars used to fill the core cavities of these masonries were prepared with much cheaper, locally available air lime. Roman cement, in turn, was only used in limited quantities, quite different from many civic engineering constructions of that time, where such low calcined natural binders were even employed in concretes.

It has to be acknowledged, however, that the above general conclusions are only preliminary since they are based just on a limited amount of analytical data on just three objects surveyed so far by the authors.

In order to ensure the continuation of the successfully started project, an application for further funding was submitted and recently approved. The planned future research, carried out in close cooperation with Montenegrin colleagues of the University of Montenegro in Podgorica, locally coordinated by Prof. Ilja Lalosević, will focus not only on the fortification architecture, but also on main settlements of the Bay of Kotor area, in order to study the Habsburg defence systems in context to the historical setting of the bay, its surrounding region and the whole Austro-Hungarian Empire. This will also include aspects of architectural transition from the Venetian to the Habsburg settings by necessary archival and library research in Montenegro and Austria. The link between history, architecture and material sciences is believed to contribute to a better understanding of the historical/architectural heritage of the Bay of Kotor.

References

Rolf, R.: Festungsbauten der Monarchie: Die k.k.- und k.u.k.-Befestigungen von Napoleon bis Petit Trianon. Prak, Middelburg (NL), 2011, pp. 69–75 and 242–259 (2011)

Pachauer, V.K.: Blaues Meer und dunkle Bauten. eine umfassende baugeschichtliche Bestandsaufnahme und kulturhistorisch-denkmalfachliche Bewertung der Befestigungsanlagen des ehemaligen k. und k. Kriegshafens Cattaro. Unpublished thesis, TU Graz (2008)

Pavićević, R.R.: Werk: austro-ugarske tvrđave u Crnoj Gori, Nova pobjeda, Herceg Novi (2019)

N.N.: Statistischer Baubericht Nr. 6 über den Bau des Forts Vermač bei Cattaro. Austrian State Archives – Kriegsarchiv, Bibliothek, Fd 15 1/8, Wien (1898)

N.N.: Statistischer Baubericht Nr. 6 über den Bau der Batterie Vermač bei Cattaro. Austrian State Archives - Kriegsarchiv, Bibliothek, Fd 15 1/8, Wien (1890)

http://museums.si/sl-si/Domov/Prispevki/Prispevek?id=20063. Last visited 4 Feb 2022

La prima fabbrica dalmata di cemento Portland Gilardi $ Bettiza-Spalato. https://www.gilardibettiza.it/la_fabbrica.html. Last visited 24 Nov 2022

Hughes, J.J., Leslie, A.B., Callebaut, K.: The petrography of lime inclusions in historic lime based mortars. Annales Geologiques des pays Helleniques, Edition Speciale XXXIX, 359–364 (2001)

https://www.eurologisch.at/docroot/waehrungsrechner/#/. Last visited 02 2022

https://en.wikipedia.org/wiki/Fort_Kosma%C4%8D. Last visited 03 2022

Pintér, F., Gosselin, C.: The origin, composition and early age hydration mechanisms of Austrian natural Portland cement. Cem. Concr. Res. 110, 1–12 (2018)

Kölblinger, F.: Darstellung der wirtschaftlichen und technologischen Entwicklung der Zementindustrie unter Berücksichtigung der Gmundner Zementwerke Hans Hatschek Aktiengesellschaft. Diploma Thesis, Wirtschaftsuniversität Wien (cited in: Riepl, F. Die wirtschaftliche und technologische Entwicklung der Zementindustrie unter besonderer Berücksichtigung der Verdienste von Hans Hauenschild. Master Thesis, University of Vienna, 2008) (1983)

Weber, J., Baragona, A., Pintér, F., Gosselin, C.: Hydraulicity in ancient mortars: its origin and alteration phenomena under the microscope. In: Copuroglu, O. (ed.) Proceedings of the 15th Euroseminar on Microscopy Applied to Building Materials, Delft, The Netherlands, pp. 147–156, 17–19 Jun 2015

Acknowledgements

The Ministry of Culture of Montenegro supervised planning, organisation, and implementation of the campaign from the outset. Further, colleagues from the Centre for Conservation and Archaeology in Cetinje and from the Directorate for the Protection of Cultural Property in Montenegro supported the fieldwork. We would also like to thank the Austrian Embassy in Montenegro for its financial support in the year 2018.

Thanks are due to Christian Kurtze who performed the 3-D laser scans of the buildings and to Nicola Math for the drawings based on them, as well as to Jovo Miladinović for the discussion of the complex historical background.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Weber, J., Zabrana, L., Hackel, A., Leiner, S., Pintér, F. (2023). Mortars and Binders During a Time of Emerging Industries: 19th Century Austro-Hungarian Fortifications in Montenegro. In: Bokan Bosiljkov, V., Padovnik, A., Turk, T. (eds) Conservation and Restoration of Historic Mortars and Masonry Structures. HMC 2022. RILEM Bookseries, vol 42. Springer, Cham. https://doi.org/10.1007/978-3-031-31472-8_11

Download citation

DOI: https://doi.org/10.1007/978-3-031-31472-8_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-31471-1

Online ISBN: 978-3-031-31472-8

eBook Packages: EngineeringEngineering (R0)