Abstract

Technological capabilities are a determinant for innovation in companies since they permeate different aspects of the development of the organization. The research objective was to determine the influence that technological capacity has on innovation results, for this 50 metalworking SMEs from the Metropolitan District of Quito participated, which were identified as innovative and potentially innovative, due to the efforts and innovation results obtained in products and processes. The level of technological capabilities is medium, and its most relevant components are investment and learning, and technological relationships. Through the correlation analysis of Spearman, it was determined that there is a positive correlation significant between technological capacity and innovation in both product and process, therefore, the more developed this technological skill, there is a greater likelihood of innovation impact that enables SMEs to gain a more competitive business.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The transformational changes in the world economy and the current requirements demanded by globalization have forced companies in emerging economies to assimilate, use, adapt, change, create and improve technologies to face the current demands imposed by the markets [1]. Several studies mention that exist disadvantages in emerging countries due to their lack of technological capabilities because this condition limits the possibilities of innovation compared to mature economies [2]. Based on this reality, Figueiredo [3] proposes that companies should resort to technological learning to create technological capabilities, that is, to propose technological development and innovation based on the successful experiences of mature economies.

In emerging economies, small and medium-sized enterprises (SMEs) have become an essential pillar in the development of a country, due to their important representation in the economy and their contribution to the generation of employment sources [4]. In recent years, in this business sector, it has been proven that technology is one of the main engines of sustainable economic growth; therefore, there is an increase in efforts to invest in obtaining technological knowledge, as well as the development of technological capabilities, where these actions become the set of knowledge typical of the industrial field that facilitates the creation of innovative products or processes [5].

Technology constitutes the knowledge and the use that is given to it, as an essential asset of companies in the practical application to obtain benefits [6]. This application is based on the ability to manage technology as a social learning process from which new possibilities for business growth are derived from the perspective of innovation [7].

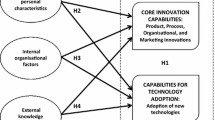

From the approach of the theory of resources and capabilities, organizations are unique because of their differences in terms of resources and capabilities. Technological capabilities constitute the faculty to make use of scientific and technological resources that facilitate the integration of new knowledge with existing knowledge for its subsequent exploitation [8, 9]. Two approaches are derived from this theory. The first is based on the knowledge exposed by Nonaka and Takeuchi [8] who highlight the importance of intangible resources. The second is the dynamic capabilities approach based on the development of resources and capacities, as well as their renewal according to the changes in the environment [10].

The knowledge-based approach suggests that the latter is the main input of innovation processes on the basis that resources are heterogeneous, non-imitable, substitutable, and transferable, so they generate a sustainable competitive advantage [11]. On the other hand, the theory of dynamic capabilities emerged at the end of the 90s as a response to the need for companies to adapt and innovate according to the dynamism of the environment [12]. In this context, SMEs need to develop competencies in the global era, strengthening the ability to absorb new knowledge and assimilate it to achieve business purposes, this is called technological capacity [13].

Exist various definitions of technological capacity from a general context, it is defined as the ability to make effective use of knowledge that allows assimilating, using, and modifying available technologies [14]. From the business perspective, it is stated that technological capability is the ability of the company to perform technical functions, develop new products and processes, and operate the company’s facilities effectively [15].

Technological capacity is related to technological management factors that lead to sustained growth and development, as well as knowledge, techniques, and skills to acquire, use, absorb, adapt, improve and generate new technologies that contribute to business growth [16]. Among the most relevant benefits of technological capabilities are the design of appropriate strategies, openness to innovation in products and processes, and the ability to efficiently allocate available resources [1, 17].

Several studies affirm that technological capacity plays an important role in innovation [13]. The determinants of technological capacity, such as exploring and exploiting technological opportunities, core technological capacity, and R&D autonomy are important elements for innovation in the company [18]. In this regard, Hsieh and Tsai [19] revealed that technological capability is the driving force of a company’s innovation.

These revelations align with the neoclassical approach to innovation, considering that innovation comes from a rational decision of companies when investing resources in Research and Development (R&D) activities as the main element of competitive advantage [20]. However, in contrast to this, the neo-Schumpeterian approach highlights the importance of those inputs other than R&D, such as design, development and experimental engineering, learning, the exploitation of new products and markets, and marketing for the development of innovations [21]. In this sense, innovation represents a knowledge-based change that requires a high degree of imagination and represents a significant break in the way of doing things integrally based on knowledge [22].

Innovation is related to dynamic economic and social environments, responsible for the production and transformation of scientific and technological knowledge that translates into economic wealth, social well-being, and human development [5]. Therefore, it is important to understand the management of technology in SMEs, since it makes science and technology instruments of innovation, well-being, and development [5].

In this context, innovation is the action and effect that allow significant improvements in things by changing novel and is the key to success for companies being the technological capability, the main factor in obtaining these results [23]. However, authors such as Berry and Taggart [24] suggest distinguishing between innovation and technological innovation, in this sense posit that innovation is the introduction and diffusion of new products and processes and/or improvements, while technological innovation goes beyond that, due to its relationship with the advances in knowledge and technology, as well as the exploitation of these.

Therefore, the technological capacity has an important influence on the results of innovation at the enterprise level, due to which the innovation is comprised of two processes of technological learning, the first of the ability of technology development, which can be seen in technological innovations that include changes in the products and services, as well as in the technology of production processes, therefore, may be subdivided into product innovations and process, these are characterized by developing or adopt technologies for its implementation. The second process is the changes in management routines, which can be called administrative innovations, which involve the organizational structure, administrative processes, and management systems [25, 26].

The objective of this research is to analyze the technological capabilities and their impact on the innovation of SMEs in the metalworking sector of the Metropolitan District of Quito, through a quantitative, cross-sectional, and correlational study. The metalworking sector is one of the economic sectors with the greatest possibilities for generating development, well-being, and employment, due to the assimilation of technologies, design features, quality, and differentiation in its products and processes, in addition to its interrelation with other sectors [27].

2 Materials and Methods

2.1 Participants

The sample is composed of 50 metalworking SMEs from the Metropolitan District of Quito affiliated with the Chamber of Small and Medium Industry (CAPEIPI). Of these, 62% are small businesses and 38% are medium-sized enterprises. Its activity is 28% the manufacture of metal accessories, 22% the assembly of metal structures, 18% providing metalworking services, and 8% carrying out electrical and electronic related activities.

2.2 Instrument

The instrument consists of 7 sections, which respond to the characteristics of companies, technological capabilities, and innovation. Section 1, describes the company’s data, and Sects. 2 and 3 to innovation activities and innovation results in products and processes (technological innovation). In the measurement of innovative activity and innovation results, an adaptation of the National Survey of Applied Science, Technology and Innovation Activities in the period 2012–2014 was carried out; and the Oslo Manual 2018. These measurement systems respond to international parameters and represent a guide for the measurement, analysis, and interpretation of innovation data.

Sections 4, 5, and 6 evaluate technological management [28] and technological capabilities based on the proposal of Domínguez and Brown [29] based on Lall’s taxonomy [30], which distinguishes between investment, production, and linkage capabilities, with the proposal to assimilate, adapt and improve the acquired technology.

2.3 Process

2.3.1 Validation of the Measuring Instrument

The questionnaire was evaluated by experts who judged the instrument’s ability to evaluate the dimensions of interest and the content of the questions [31]. According to Clemen and Winkler [32], the judgment can be given by between 3 and 5 experts. The research convened a committee of 5 experts, 2 professionals with experience in technology management and innovation, and 2 university professors from the Management area. Each of the experts evaluated the instrument according to four criteria proposed by Escobar and Cuervo [33]: i) clarity, ii) coherence, iii) relevance, and iv) sufficiency; according to a Likert scale of 1 to 4 points.

2.3.2 Application of Questionnaire

The application of the instrument was made through an online request to the general managers, and heads of departments or R& D & I managers of the companies in March, April, and May of the year 2021. The instrument contains questions of order scales, multiple-choice, and 5-point Likert that includes a midpoint as proposed by the literature [34].

2.3.3 The Internal Consistency

The instrument was evaluated by the Cronbach’s Alpha coefficient whose values range from 0 to 1 [31]. To this end, the elements of each of the different dimensions proposed were evaluated: innovative activity, technological innovation, investment and learning, technological management, production, and technological relationship.

The internal consistency of the sections measuring the innovative activity and technological innovation (Sects. 2 and 3) has a Cronbach’s alpha of 0.9 each. The sections measuring technological capabilities (Sects. 4, 6, 7) have a Cronbach’s alpha greater than 0.85. Whereas, the section evaluating technology management (Sect. 5) has a Cronbach’s alpha of 0.93. In all cases, Cronbach’s alpha exceeds the value of 0.7, corroborating an acceptable level of reliability.

2.3.4 Data Processing and Analysis

It was carried out using the statistical software SPSS Statistics since it allows to execution of descriptive and inferential analysis of a large volume of data [34]. The statistical correlation analysis and the graphs were performed using the R software, where the normality tests were executed, and the correlation with the Spearman coefficient to determine the relationship between technological capacity and innovation results in product and process.

3 Results and Discussion

The results analyze the data to verify the hypothesis through the collection of fundamentals based on the numerical measurement and statistical analysis [34]. The study observes the phenomena in their natural context and the data collection is carried out in a single period between March and May 2021.

3.1 Innovation Activities

The innovative activity was evaluated concerning all the development, financial and commercial actions carried out by a company that gives rise to innovation [35].

The results of innovation, from the typology of product innovation and process innovation [36]. Product innovation is highlighted by new or significantly improved features, this includes the significant improvement of technical features, components, and materials, change of functional parts, and other utilitarian distinctive. For its part, process innovation adopts methods that may involve significant changes in techniques, materials, and computer programs in the equipment or the organization of production and may result from the use of new knowledge [36, 37].

The systematic mechanism that evaluates the innovative potential of a company is defined through characteristics that represent the innovative effort, activities that create a favorable environment, and the type of innovation implemented by SMEs [37] (see Table 1).

Among the main innovation activities, the research and development processes that are carried out in the company’s areas stand out, where the creation of R& D projects and actions is promoted to apply them in production processes, another important effort is the industrial engineering and design activities, to create product design requirements, generate prototypes, determine manufacturing processes and finally evaluate the results that are implemented through new products and processes.

The implementation of technological innovation in products is the one that stands out about innovation in processes in the metalworking company’s object of the research (see Table 1). The technological innovation of the product emphasizes the significant improvement of existing products, through the incorporation of new materials and technological components, however, a smaller proportion has implemented new functional features and has introduced radically new technologies, which may indicate that due to this, companies don’t stand out in the creation of new products recognized by the company or the industry (see Table 2).

Otherwise, the percentage of companies that don’t conduct innovation in processes exceeds 40%. However, of the companies that have implemented technological innovation in processes, most of them opt for the significant improvement in their processes, from the incorporation of new tools or technology, equipment, and new methods of logistics to improve the productivity, efficiency, and control of their products, to a lesser extent, the adoption of new or significantly improved technology of information and communication (see Table 3).

SMEs in the metalworking sector have developed innovative processes in recent years through the improvement of their technical characteristics that, even in some cases, have led to product innovations. However, few companies have introduced innovations characterized by a high degree of novelty to the market, considered new [37].

In this context, Carvache and others [38] point out that Ecuadorian SMEs have since medium to a low level in terms of innovation and technology, showing a high concentration in primary products and a low technological level [38]. SMEs in the industrial sector, despite investing in technology, mainly the acquisition of software and hardware, and automating some administrative activities, still show poor technological capacity and there is no significant improvement in the development of new production processes [39].

Based on the results of technological innovation in product and process and the innovative effort, SMEs can be grouped into three categories: innovative, potentially innovative, and non-innovative (see Table 4).

Innovative companies are those whose innovation activities or efforts have resulted in technological innovations. Potentially innovative companies are those that have carried out innovation activities but abandoned efforts before achieving results, or in turn continue to carry out innovation activities that have not yet led to concrete results. And non-innovative companies are those that have not managed to introduce some kind of technological innovation, nor have they developed innovation activities [37].

In this context, SMEs investigated mostly located as innovative companies and potentially innovative, due to efforts for the development of innovations and the results of innovation mainly in the improvement of the products, however, are still deficient in efforts to give way to the improvement of technical processes within the industry. In the reality of emerging economies, it is stated that there are companies considered potentially innovative, where the role played by market forces as stimulants of innovative activity are highlighted [40].

SMEs identified as “innovative” and “potentially innovative” are mainly engaged in the manufacture of metal accessories and the assembly of metal structures. Meanwhile, “non-innovative” SMEs manufacture machinery and equipment, parts and pieces, and there are those that offer services for the industry in general.

At present, SMEs make efforts to create favorable scenarios for innovation, however, it has not been enough to realize disruptive technological innovations, this may be due to the inadequate capacity for knowledge acquisition or the lack of integration of disincorporated technology. In this sense, the importance of technology transfer as a mechanism to promote the culture of innovation in companies is highlighted [41]. Where knowledge-generating entities such as research centers and universities play a fundamental role in strengthening innovation.

Collaboration between the business sector, the state, and knowledge-generating entities is a vital process to promote innovation, however, in countries such as Ecuador and Colombia, the number of innovative companies is really low, due to this lack of integration and an innovative culture [41].

3.2 Technological Capabilities

The level of technical skills is determined through the evaluation of its components: investment and learning, production, and technological relationship [13]. The study by Domínguez and Brown [29] identified that technological capability, due to its effect on the innovation behavior of companies, positively influences business performance and helps to understand the differences between companies in a heterogeneous situation that characterizes developing economies.

Technological capacity was transformed into a categorical variable for descriptive analysis. Considering the minimum and maximum values exposed in the research of Moreno et al. [28], three levels were established: high, medium, and low (see Table 5).

In this sense, SMEs in the Ecuadorian metalworking sector has managed to develop an average level of technological capabilities, since more than half of the companies have developed investment and learning skills and technological relationship. However, it is necessary to improve production capacities (see Table 6).

Concerning investment and learning capabilities, investment in the acquisition of machinery and equipment, technological R& D, acquisition of administrative technology, technical advice, and, to a lesser extent, the acquisition of trademarks and patents stands out. Although investment in these areas favors an innovative environment, these are not decisive actions to obtain innovative results [28]. Therefore, SMEs accompany their investments with organizational learning activities, such as feedback on the operation of the operating system, the implementation of technical changes in processes, and, to a lesser extent, the development of attraction plans and training of human resources.

The results of production capacities, concerning the implementation of “just time” production systems, safety benefits, occupational health, training for human resources, and statistical control of the production process, reveal deficiencies in the production processes carried out by SMEs. However, the processes are improving, due to the interest of these companies in the development of R& D activities, and the establishment of formal rules and procedures, for the quality control of production processes.

Finally, the technological relationship capacities in SMEs are strengthened by the association with the national and international sectors, where they maintain formal links thanks to the different technology transfer mechanisms through institutions such as universities and government institutions. However, deficiencies in participation in R&D projects with other institutions, as well as the lack of rules regulating technological interrelationships, still limit the strengthening of technological relationship capacities.

Studies on technological capabilities have increased in recent years, different variables are postulated that through a joint analysis explain the level of this type of capabilities. For example, technological innovation, efficiency in processes, the design of industrial plants, the execution of projects, and technological learning [42]. This last is related to the theoretical basis that is part of the taxonomy proposed by Lall [30]: investment & learning, production, and relationship-building technology, which together enable the development and strengthening of technological capabilities, which affect the development of innovations, and in the performance of an organization [29]. Therefore, it is relevant to differentiate between the activities that contribute to capacity development and what gives rise to technological innovation, as a result of a set of efforts and skills.

3.3 Relationship Between Technological Capabilities and Innovation

To analyze the statistic to be used, the Kolmogorov-Smirnov normality test is performed, which yields a value lower than the considered significance level of 0.05 (see Table 7), so the null hypothesis is rejected, that is, the innovation data in product and process, don’t have normal behavior.

To analyze the relationship between technological capacity and the results of innovation in product and process, the Spearman correlation is performed, which is a non-parametric statistical method, which aims to examine the intensity of association between two quantitative variables [34].

The first relationship analysis makes it possible to check the following hypotheses:

-

H0: Technological capabilities influence the results of technological innovation in the products of SMEs.

-

H1: Technological capabilities don’t influence the results of technological innovation in the products of SMEs.

The Spearman coefficient analysis is one of the most widely used non-parametric statistical tests that is applied to nominal and ordinal data with non-normal distributions to determine the level of correlation [34]. The results obtained by the Spearman coefficient in the relationship between technological capacity and product innovation (see Table 8).

With a significance value of less than 0.05, a positive correlation between product innovation and technological capabilities is evidenced. On the other hand, the component of the technological capacity that is called investment and learning is the one that shows a positive correlation significant (rho 0.52) with the innovation of the product, as well as the sum of the components of what is called the technological capacity (rho 0.54), indicating that the technological capacity influences the outcomes of innovation in product, on the other hand, the production capacity and the relationship between technology have a positive relationship average, which confirms that there is an association between the variables accepting the null hypothesis.

The correlation does not become very strong or perfect positive, this may be due to the influence of elements that have not been measured, such as other internal resources of the company or macroeconomic agents. These results contrast with the study carried out by Lestari and Ardianti [13], who points out that technological capacity not only has a direct but also an indirect effect on the performance of SMEs, through innovation. Like the postulates made by García, Blázquez, and López [43], who indicate that technological capabilities are a determining factor of innovation, which is subject to the level of development of countries.

Likewise, the level of correlation between technological innovation and each of the components of technological capabilities was determined to identify the deficient components that require efforts by Ecuadorian SMEs (see Table 9). In this context, investment and learning is the component that has the greatest positive correlation it has on the results of innovation in processes, that is, the more this capacity is strengthened, the better the results will be innovation in processes, this is corroborated with a significance value < 0.05.

-

H0: Technological capabilities influence the results of technological innovation in SME processes.

-

H1: Technological capabilities don’t influence the results of technological innovation in SME processes.

Therefore, the null hypothesis is approved, technological capabilities influence the results of technological innovation in processes of SMEs, this means that, as the metalworking SMEs increase their level of technological capabilities, the greater the number of companies that introduce technological innovations in processes.

Thus, in the quantitative analysis by García, Pineda, and Andrade [1] it was found that technological capabilities are a determining factor of innovation, which depends on different elements, such as the type and size of the company, the sector, technological requirements and the type of manufacturing processes implemented in the integration of all its activities, and mainly the level of economic development of the countries.

In this context, a confirmatory analysis is carried out among the categories that make up each of the variables to characterize the situation of SMEs. It was found that the metalworking SMEs that don’t carry out technological product innovation, for the most part, have a low level of technological capacity. In contrast, SMEs that have medium to high levels of technological capacity essentially carry out technological process innovations (see Table 10).

Finally, corroborating the results are presented in the scatter diagrams of each of the correlations of the data, which confirm that there is an influence of the technological capacity and each of its components with the results of innovation in products and processes within SMEs. However, ensuring a perfect correlation requires a deepening of the analysis with new macroeconomic variables and the business environment (Fig. 1).

4 Conclusions

In Ecuador, the SMEs have an important influence on the development of the country, therefore, enhancing its technological capabilities will allow more and better innovation performance, due to its effective application of knowledge in the context in which they unfold, and in this way contribute to the social and economic growth.

The investigated metalworking SMEs are mostly located in innovative and potentially innovative companies, because they make innovation efforts that lead to obtaining innovative results, however the products and processes that are implemented lack novelty before the company and the market, and this may be because they still need to strengthen their technological learning capacity.

In terms of technological capacity, the SMEs in the engineering sector is located at a medium level, since more than half of them have developed their skills of investment and learning, where not only buy equipment and technologies, but it makes effective use of that capital; the relationship between technology each time is better in terms of partnerships with internal and external stakeholders, however, it is necessary to strengthen and expand the actors in support of knowledge, and this can be a trigger in the low production capacity.

Finally, there is evidence of a positive correlation significant between technological capabilities and innovation in products and processes, it denotes that the greater the development of technological literacy in the company, there is the possibility of more and better innovation performance, and this in turn will allow for greater competitiveness and growth in the industry.

References

García, A., Pineda, D., Andrade, M.: Las capacidades tecnológicas para la innovación en empresas de manufactura. Universidad Empresa 17(29), 257–278 (2015)

Dutrénit, G., Vera, A., Arias, A.: Diferencias en el perfil de acumulación de capacidades tecnológicas en tres empresas mexicanas. El Trimestre Económico 70(277), 109–165 (2003)

Figueiredo, P.: Aprendizagem tecnológica e inovação industrial em economias emergentes: uma breve contribuição para o desenho e implementação de estudos empíricos e estratégias no Brasil. Revista Brasileira de Inovação 2(3), 323–361 (2004)

Peña, M., Vega, N.: Estructura de las pymes en la economía ecuatoriana. Revistas de la Universidad Nacional de Loja 30–34 (2017)

Robledo, J.: Introducción a la gestión de la tecnología y la innovación empresarial (Primera ed.). Universidad Nacional de Colombia, Medellín (2020)

Ahmed, P., Shepherd, C., Ramos, L., Ramos, C.: Administración de la innovación. Pearson Educación (2012)

Rincón, É., Rincón, J., Coromoto, C.: La innovación y el cambio tecnológico desde la perspectiva de la mesoeconomía. Económicas CUC 89–108 (2014)

Nonaka, I., Takeuchi, H.: The Knowledge-Creating Company. Oxford University, Oxford (1995)

Grant, R.: Prospering in dynamically-competitive environments: organizational capability as knowledge integration. Organ. Sci. 375–387 (1996)

Teece, D., Pisano, G., Shuen, A.: Dynamic capabilities and strategic management. Strateg. Manag. 509–533 (1997)

Urgal, B., Quintás, M., Arévalo, R.: Conocimiento tecnológico, capacidad de innovación y desempeño innovador: el rol moderador del ambiente interno de la empresa. Cuadernos de Economía y Dirección de la Empresa 53–66 (2011)

González, C., Hurtado, A.: Propuesta de un Indicador de Capacidad de Absorción del Conocimiento: evidencia empírica para el sector servicios en Colombia. Facultad de Ciencias Económicas 29–46 (2014)

Lestari, E., Ardianti, F.: Technological capability and business success: the mediating role of innovation. In: IOP Conference Series: Earth and Environmental Science, vol. 1, no. 250, p. 012039 (2019)

Kim, L.: Imitation to Innovation. The Dynamics of Korea’s Technological Learning. Harvard Business Review Press (1997)

Ruiz, M.: Competitive strategies and firm performance: technological capabilities’ moderating roles. J. Bus. Res. 63(12), 1273–1281 (2010)

Lugones, G., Gutti, P., Le Clech, N.: Indicadores de capacidades tecnológicas en América Latina. Naciones Unidas, México D.F. (2007)

Zhou, K.Z., Wu, F.: Technological capability, strategic flexibility, and product innovation. Strateg. Manag. J. 31(5), 547–561 (2010)

Huang, K.F.: Technology competencies in competitive environment. J. Bus. Res. 64(2), 172–179 (2011)

Hsieh, M.H., Tsai, K.H.: Technological capability, social capital and the launch strategy for innovative products. Ind. Mark. Manag. 36(4), 493–502 (2007)

Nelson, R.: Why do firms differ and how does it matter? Strateg. Manag. J. 61–74 (1991)

Smith, K.: Measuring innovation. Oxford Handb. Innov. 148–177 (2005)

Nelson, R., Winter, S.: An Evolutionaty Theory of Economic Change. Belknap Press, Cambridge (1982)

Mendizábal, G.: Estrategias para la innovación tecnológica en Castillas y León. Tesis doctoral, Universidad de Valladolid, Valladolid (2002)

Berry, M., Taggart, J.: Managing technology and innovation. R & D Manag. 341–353 (1994)

Zawislak, P.A., Alves, A.C., Tello-Gamarra, J.: Innovation capability: from technology development to transaction capability. J. Technol. Manag. Innov. 7(2), 14–26 (2012)

Damanpour, F.: Innovation type, radicalness, and the adoption process. Commun. Res. 15(5), 545–567 (1988)

Ovalle, A., Ocampo, O., Acevedo, M.: Identificación de brechas tecnológicas en automatización industrial de las empresas del sector metalmecánico de Caldas, Colombia. Ingeniería y Competitividad. Revista Científica y Tecnológica 171–182 (2013)

Moreno, S., García, A.: Sistema para la evaluación de capacidades de innovación en PYMES de países en desarrollo: Caso Panamá. Facultad de Ciencias Económicas: Investigación y Reflexión 109–122 (2014)

Domínguez, L., Brown, F.: Measuring technological capabilities in the Mexican industry. CEPAL Rev. 129–144 (2004)

Lall, S.: Technological capabilities and industrialization. World Dev. 20(2), 165–186 (1992)

Arribas, M.: Diseño y validación de cuestionarios. Matronas Profesión 23–29 (2004)

Clemen, R., Winkler, R.: Limits for the precision and value of information from dependent sources. Oper. Res. 427–442 (1985)

Escobar, J., Cuervo, A.: Validez de contenido y juicio de expertos: una aproximación a su utilización. Avances en Medición 27–36 (2008)

Hernández, R., Fernández, C., Baptista, M.: Metodología de investigación. McGraw Hill, México D.F. (2010)

OCDE. Manual de Oslo (Tercera ed.). OCDE, Madrid (2005)

OECD. Proposed Guidelines for Collecting and Interpreting Technological Innovation Data. OECD, París (2018)

Instituto Ecuatoriano de Estadística y Censos. Principales Indicadores de Actividades de Ciencia, Tecnología e Innovación. Ecuador (2015)

Carvache, O., Gutiérrez, G., Frías, C.: Incidencia de la innovación y la tecnología en el desarrollo competitivo de las pequeñas y medianas empresas (PYMES) exportadoras de Guayas-Ecuador. Revista Espacios 39(47) (2018)

Leal, M., Labarca, N., Bracho, O., Vargas, V.: Gestión Tecnológica en pymes del sector textil del municipio Maracaibo-estado Zulia- Venezuela. Revista Venezolana de Gerencia 314–331 (2018)

Ortiz, F.: Medición de la Capacidad de Innovación Tecnológica (Caso de Estudio: Industria Papelera Venezolana). In: II International Conference on Industrial Engineering and Industrial Management. XII Congreso de Ingeniería de Organización, Burgos, Spain, 3–5 Septiembre (2008)

Velásquez, S., Pino, A., Restrepo, E., Vaina, N.: Innovación en empresas: estado del arte considerando tendencias para su implementación. Revista Espacios, 39(48) (2018)

López, A., Molina, R., Gómez, D.: Enfoque estratégico, orientación emprendedora y experiencia: factores que impulsan el desarrollo de capacidades tecnológicas en el sector automotriz. Revista SBIR 43–57 (2018)

García, M., Blázquez, M., López, J.: Uso y aplicación de la técnica de análisis estadístico multivariante de cluster sobre la capacidad de innovación tecnológica en Latinoamérica y España. INNOVAR. Revista de Ciencias Administativas y Sociales 21–39 (2012)

Acknowledgments

We are especially grateful to the companies that were part of this investigation, for their openness and commitment to providing the information.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Maya Carrillo, M., Suntaxi Imbaquingo, C., Ramos, V., Guerrón, E.R. (2023). Influence of Technological Capabilities on Business Innovation in Ecuador. In: Botto-Tobar, M., Zambrano Vizuete, M., Montes León, S., Torres-Carrión, P., Durakovic, B. (eds) Applied Technologies. ICAT 2022. Communications in Computer and Information Science, vol 1757. Springer, Cham. https://doi.org/10.1007/978-3-031-24978-5_31

Download citation

DOI: https://doi.org/10.1007/978-3-031-24978-5_31

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-24977-8

Online ISBN: 978-3-031-24978-5

eBook Packages: Computer ScienceComputer Science (R0)