Abstract

The primary goal of this study is to simulate finite transformation elasto-plasticity problems using the Asymptotic Numerical Method (ANM). Elastoplastic behavior combines two unilateral conditions; the first concerns the transition from the elastic domain to the elastoplastic domain and the second concerns the elastic discharge. In the context of the Asymptotic Numerical Method (ANM), the elastoplastic behaviour law has to be changed to a regular one in order to obtain an analytical representation of every variable. The main point is to find an appropriate relationship between the plastic multiplier and the threshold function of plasticity. The linear problems found are solved using the Finite Element Method (FEM). An example of a 2D plate subjected to a time dependent monotonic loading is considered, and a study on the different regularization parameters is presented. The obtained results by the proposed algorithm are compared to the reference solution (Abaqus code). The comparison shows that this algorithm is effective for solving such problems.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

To numerically simulate the metal forming process such as lamination, stamping…. we must consider the major changes the metal go through both geometrical and/or material. These changes are usually permanent inelastic deformation, which means that the standard elastic behavior lows are no longer valid, which bring us to use plasticity behavior lows combined with the large strain theory. In previous work that exist in the literature (Assidi et al., 2009), (Hamdaoui et al., 2016) and (Yoshida et al. 2002), the majority of researchers have been showing an interest in developing elasto-plastic models to simulate this type of behaviors. As a matter of fact, the past decades have seen a great upsurge in research in modeling elasto-plastic materials. The first research considers that the plastic deformation is small compared to the elastic strain and there, one uses the elastoplastic theory in small deformation (Assidi et al., 2009), (Hamdaoui et al., 2016). The second considers that plastic deformations are important, which is the case in shaping structures (Yoshida et al. 2002), (El Kihal et al., 2022). In order to correctly resolve large deformation plasticity problems, one must take into consideration the objective stress rate, meaning that the mechanical response of a material should not depend on the frame of reference.

In this paper, we propose to solve the large deformation elasto-plastic problems using the Asymptotic Numerical Method (Cochelin et al. 1994) and (Cochelin et al., 2007). The ANM associates three techniques, a perturbation technic, a continuation procedure and a discretization method. In this context, the solution of every step is represented by a power series and forms a family of linear problems. These problems are solved by decomposing only one tangent matrix per step. The length of every step is determined using properties of convergence of the Taylor series which result in naturally adapted step length.

We introduce first the general problem of elasto-plastic structure in large deformation theory, and then we try to regularized the four equations that prevents us from applying the perturbation technic (El Kihal et al., 2022). The elasto-plastic behavior with the elastic unloading exhibits three states, the elastic state, the plastic state and the elastic unloading state. So, to identify a unique regularized constitutive relation, one must regularize the two corresponding unilateral conditions (El Kihal et al., 2022) and (Assidi et al., 2009). The key point to establish this regular problem has already been discussed in previous works of elasto-plasticity in small deformations (Hamdaoui et al., 2016), we take the same regularization technics as in (Assidi et al., 2009), and adopt it to our problem. In other words, determine a regularized relation between the plastic multiplier and the yield function, and add a regularization parameter to the equivalent stress to avoid the singularity point, then add another regularization parameter to the load function for the same reason.

2 Large Deformation Regularized Problem

The variational problem translating the equilibrium of solid in the case of large deformation plasticity is written in the matrix form:

where \(\Omega_{0}\) is the undeformed configuration and \(F^{d}\) is the force applied to the structure, \(\left[ {A\left( f \right)} \right]\) is the matrix of the inverse of the deformation gradient, \(\left\{ \tau \right\}\) represents the stress Kirchhoff tensor, \(\left\{ L \right\}\) represent the vector of the velocity gradient, and \(v\) is the velocity vector. We consider that the strain rate tensor is unambiguously divided into two parts (elastic and plastic) additively as \(\left\{ D \right\} = \left\{ {D^{p} } \right\} + \left\{ {D^{e} } \right\}\). The behavior low that describes such problem is written in the following matrix form:

where \(\left\{ {\tau^{J} } \right\}\) is the Jaumann stress tensor, \(\left[ {C^{elas} } \right]\) is the representing matrix of the material elasticity tensor. The plastic behavior part is written as:

where \(\dot{\lambda }\) is the plastic multiplier, \(\left\{ n \right\}\) is the vector of direction flow and \(f_{y}\) is the yield function. The normal vector \(\left\{ n \right\}\) can be written as:

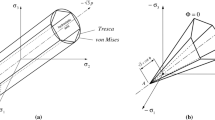

and the yield function is defined as:

where \(\tau_{e}\) represents the effective stress, \(\tau_{y}\) is the yield stress, \(h\) is the plastic modulus, \(\overline{ \in }^{p}\) is the equivalent plastic strain, \(q\) is the equivalent stress and \(\tau^{d}\) is the deviator of the Kirchhoff stress tensor. The condition of the yield function and the plastic multiplier can be reformulated from the Kuhn-Tucker’s condition:

Combining the previous relations with the unilateral relation, one gets the consistency relation:

The unilateral relation is presented by two non-regularized functions \(g\left( {f_{y} } \right)\) and \(\left\langle . \right\rangle\), which are written as:

μ represents the shear modulus. The two functions are going to be replaced by:

With

The Von Mises equivalent stress, which isn’t an analytic equation when the stress tends to zero. So, we add a regularization parameter \(\eta_{1}\) to avoid the zero in the square root, and the new expression of the equivalent stress is given by the following formula: \(q^{2} = \frac{3}{2}\tau^{d} :\tau^{d} + \eta_{1}^{2} \tau_{y}^{2}\). Furthermore, two additional \(\hat{F}\) and \(Den\) variables are introduced to simplify the lettering of \(G\left( {f_{y} } \right)\), that will be split into three elementary equations:

To reproduce a typical behavior of the elastoplastic law (elastic, plastic, elastic unloading), C(t) is defined by the following hyperbolic equation:

where \(C_{m}\) and \(T_{m}\) are the load parameters and \(\eta_{4}\) is a regularization parameter.

In structural mechanics problems involving elasto-plastic constitutive law, the equations are given by:

where \(R\) represents the residual vector and \(U\left( t \right)\) is the vector of unknowns with the following components:

\(\left( {v,\tau , \tau^{j} , D, D^{p} ,G,H,\omega ,f,F,L,l,R,q,n,\xi ,Den, f_{y} , \hat{F},\tau_{e} ,\dot{\lambda }} \right)\), and \(C\left( t \right)\) is a loading parameter.

3 Numerical Resolution

The vector unknown \(U\) and the loading \(C\) are expressed as a Taylor series expansion truncated at order N as:

where \(\left( {U^{j} ,C^{j} } \right)\) are a known and a given regular solutions corresponding to \(a = 0\), \(a_{max}\) is the convergence radius of the series. For this study, we chose to work with the parameterization equation used in (El Kihal et al., 2022), written as:

where \(t\) is the time, \(C\) is the load and \(u\) represents the displacement. The coefficients \(\alpha_{i} , for i = 1, 3\) are equals to \(0\) or \(1\). By injecting the Taylor series representations (14) into the nonlinear problem (13) we obtain, the linear problems verified by each term of the series:

where

The terms \(\left\{ {P_{k}^{nl} } \right\},\left\{ {\tau_{k}^{nl} } \right\}, \left\{ {f_{k}^{nl} } \right\} \) are known and calculated previously. Once the problem is discretized, we apply the finite element method to solve the linear problems (16) and (17). The tangent matrix is given by:

The solution of the problem (13) is computed using a path-following method proposed by (Cochelin et al, 2007), where the solution is obtained branch-by-branch and the final solution point of a branch is the new beginning point of the next branch. The range of validity \(a_{\max }\) of the parameter \(a\) is evaluated as follow:

where \(\in\) represents the tolerance parameter and \(U^{\left( i \right)}\) represents the components of the unknown vector \(U\). For this study, we define the validity range \(a_{\max } \) as in (El Kihal et al., 2022) and (Assidi et al. 2009). We chose \(a_{\max } \) as the smallest of all the components of the vector \(U^{\left( i \right)}\):

Once \(a_{\max }\) calculated, the starting solution \(\left( {U^{j} ,C^{j} } \right)\) in (13) to the next branch is evaluated by \(U^{j} = U\left( {a_{\max } } \right)\) and \(C^{j} = C\left( {a_{\max } } \right)\).

4 Numerical Example

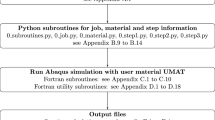

We consider a \(2D\) plate of length \(L = 100\;{\text{mm}}\) and width \(l = 40\). The plate is submitted to a monotonic loading in pressure \(C\left( t \right)P\) on the right edge until reaching an elastoplastic deformation of \(35\% .\) The loading function parameters are chosen as \(C_{m} = 55\) and \(T_{m} = 55\). For symmetry reasons, we work only with the plate quarter as indicated in Fig. 1.

The Taylor series truncation order and the tolerance parameter are \(N = 15\) and \(\in = 10^{ - 3}\). The regularization parameters are \(\eta_{1} = 10^{ - 2}\), \(\eta_{2} = 10^{ - 4}\), \(\eta_{3} = 9.10^{ - 5}\) and \(\eta_{4} = 5.10^{ - 3}\). We chose for this comparison to work with the parametrization based on the load parameter and time (PCT). In Fig. 2, we compare our response curve to the one obtained by the industrial code ABAQUS (Abaqus, 2014) at the Pt1 indicated in Fig. 1; we see clearly that the response curve found by the Asymptotic Numerical Method approach the reference curve. The ANM completed the whole curve in 116 steps where ABAQUS needed 110 increments and 140 iterations which means 250 steps. We will discuss later on how to optimize more our algorithm in order to obtain the whole response curve with less steps.

To justify the choice of the parameters of regularization, we present a full study on the four parameters \(\eta_{1} ,\eta_{2} ,\eta_{3}\) and \(\eta_{4}\), in which we discuss the influence of every parameter on the solution obtained and number of steps. To do so, we are going to fix the order at \(15\) and the tolerance parameter at \(10^{ - 3}\), and to simplify the task we vary each parameter while keeping the others fixed to describe the domain validity of each one with respect to the others. To avoid division by zero, the first parameter \(\eta_{1}\) is added to the equation of the equivalent stress \(q\) given previously. We vary it in an interval of \(\eta_{1} \in \left[ {10^{ - 6} , 10^{ - 1} } \right]\). The response curve starts to converge from a value \(\eta_{1} = 10^{ - 2}\) where we get the whole response curve in 116 ANM steps, and in 118, 127 steps for the values \(\eta_{1} = 10^{ - 3}\) and \(\eta_{1} = 10^{ - 4}\) respectively. And it diverges again for the value of \(\eta_{1} = 10^{ - 5}\) and \(\eta_{1} = 10^{ - 6}\). So, the interval for the first parameter \(\eta_{1}\) will be from \(10^{ - 2}\) until \(10^{ - 4}\). Secondly, we discuss the influence of the \(\eta_{2}\) which influences on the \(H\) function that describe the elastic discharge (10), and it appears also in the equation of \(\zeta\) that completes the \(H\) function. After testing it in the interval of \(\eta_{2} \in \left[ {10^{ - 6} , 10^{ - 1} } \right]\), the solution start to converge from the value \(\eta_{2} = 10^{ - 3} \) with more accurate results at \(\eta_{2} = 10^{ - 4}\), where we obtain the whole response curve in \(116\) ANM steps, and the more it’s value decreases the more steps are needed, for \(\eta_{2} = 10^{ - 6}\) it needs 128 ANM steps. So, the interval is \(\eta_{2} \le 10^{ - 3}\). The third parameter is used to regularize the function \(G\left( {f_{y} } \right)\) (10). We do the same test that was previously conducted on the two other parameters, we vary it in the interval \(\eta_{3} \in \left[ {10^{ - 6} ,10^{ - 1} } \right]\), and the solution starts to converge from the value \(\eta_{3} = 9.10^{ - 4}\). Therefore, the domain of validity is \(\eta_{3} \le 9.10^{ - 4}\).

For the final regularization parameter \(\eta_{4}\) which is linked to the loading equation, which is described by a triangle and as previously done, we fix the other parameters and we vary \(\eta_{4}\). The parameter \(\eta_{4}\) converges for the values \(\eta_{4} \le 5.10^{ - 3}\).

Table 1 indicates the influence of the number of the order for two given tolerance parameters \(CRIT1 = 10^{ - 3}\) and \(CRIT2 = 10^{ - 4}\) for the time parameterization (PT) and the parametrization based on loading and time (PCT). It is shown that, if the number of the series order increases the number of the ANM steps decreases considerably for both parametrization and for the two of the tolerance criteria. In exact numbers, we find that for PT-CRIT1 we get \(42.77\%\) decrease in the number of steps from the order \(10\) to \(30\), and \(57.32\%\) decrease for PT-CRIT2.

5 Conclusion

We propose in this study a high order algorithm based on the Asymptotic Numerical Method technics to simulate large deformation elasto-plasticity problems. We adopted the regularization used in (El Kihal et al., 2022) for the elasto-plastic behavior in order to obtain an analytical representation in the form of a Taylor series. Next, we presented the resolution strategy using the ANM for the regularized problem, and used the parametrization equation based on time, loading and displacement. Finally, the model was practically tested in a tensile numerical simulation of a 2D plate. A comparison was conducted between the obtained results using the proposed algorithm and the ones found by ABAQUS code. Also, an investigation of the influence of the parameterization was presented. The obtained result demonstrates that the algorithm proposed is capable of computing elasto-plasticity problems in finite transformation.

References

El Kihal, C., et al.: Simulation of a 2D Large Transformation Elastoplasticity Problem Using the ANM. In: Abdel Wahab, M. (ed.) NME 2021. LNME, pp. 185–193. Springer, Singapore (2022). https://doi.org/10.1007/978-981-16-8806-5_13

El Kihal, C., et al.: Asymptotic numerical method for finite plasticity. Finite Elem. Anal. Des. 206, 103759 (2022)

Assidi, M., Zahrouni, H., Damil, N., Potier-Ferry, M.: Regularization and perturbation technique to solve plasticity problems. Int.J. Mater. Form. 2(1), 1–14 (2009)

Cochelin, B., Damil, N., Potier-Ferry, M.: Méthode asymptotique numérique. Hermes Lavoissier (2007)

Abaqus.: Version. 6.14 Documentation. Dassault Systemes Simulia Corporation 651, 6.2 (2014)

Cochelin, B.: A path-following technique via an asymptotic-numerical method. Comput. Struct. 53(5), 1181–1192 (1994)

Crishield, M.A.: A faster modified newton-raphson iteration. Comput. Methods Appl. Mech. Eng. 20(3), 267–278 (1979)

Hamdaoui, A., Braikat, B., Damil, N.: Solving elastoplasticity problems by the asymptotic numerical method: Influence of the parameterizations. Finite Elem. Anal. Des. 115, 33–42 (2016)

Yoshida, F., Uemori, T.: A model of large-strain cyclic plasticity describing the Bauschinger effect and workhardening stagnation. Int. J. Plast. 18(5–6), 661–686 (2002)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Chafik, E.K. et al. (2023). Numerical Computation of Plasticity in Large Deformations Using the Asymptotic Numerical Method. In: Azrar, L., et al. Advances in Integrated Design and Production II. CIP 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-23615-0_20

Download citation

DOI: https://doi.org/10.1007/978-3-031-23615-0_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-23614-3

Online ISBN: 978-3-031-23615-0

eBook Packages: EngineeringEngineering (R0)