Abstract

This paper presents an Intelligent Decision Support System (IDSS) to optimize transport and logistics activities in a set of Portuguese companies currently operating in the freight transport sector. This IDSS comprises three main modules that can be used individually or chained together, dedicated to: a geographic clustering detection of transport services; a transport driver suggestion; and a route and truckload optimization. The IDSS was entirely designed and developed to support real-time data and it consists of an end-to-end solution (E2ES), given that it covers all the main transport and logistics processes since the registration in the database to the optimized transport plan. The entire set of functionalities inserted in the IDSS was designed and validated by freight transport sector experts from the different companies that will use the proposed system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Intelligent decision support system

- Transport and logistics

- Geospatial clustering

- Resource optimization

- Route optimization

- TAM 3

1 Introduction

Due to the global market competition, current world market dynamics (e.g., effect of the COVID-19 pandemic) and other issues (e.g., sustainability), there is an increased pressure to improve the road freight transport sector. Until recently, the planning of transport activities was mainly focused on cost minimization [7]. However, the transport sector represents a substantial source of greenhouse gas (GHG) emissions. As a result, one of the main goals of supply chain management programs is to develop more sustainable transport solutions [9]. Under this context, Intelligent Decision Support Systems (IDSS) [3] represent a potential valuable solution, since they can be used to extract valuable insights from the freight transport data, allowing to address several objectives (e.g., reduce costs and gas emissions).

In this work, we propose an end-to-end solution (E2ES) that consists of an IDSS that targets the main processes and tasks involved in planning freight transport. The IDSS prototype was designed in conjunction with a consultant company that is responsible for the transport management of several Portuguese freight transport companies. Moreover, the business knowledge and data obtained proved crucial throughout the development, testing, and validation of the IDSS. In particular, the IDSS includes: an adaptive distance-constrained geospatial clustering algorithm, for the detection of possible clusters of loading or unloading locations; a tool for ranking drivers in the allocation to a transport service by considering their distance to a loading location; and an overall routing optimization process that considers the rules stipulated by the European Commission (EC) in Regulation No 561/2006 regarding driving time and rest periods, and that includes the truckload and sequencing operations. In order to evaluate the proposed IDSS, the inexistence of a system or set of methods and procedures dedicated to the optimization of the sector in the freight transport companies led us to assemble a questionnaire using the Technology Acceptance Model (TAM) 3 model [13] and perform open interviews.

2 Related Work

Within the freight transport sector, there are several studies and proposed frameworks to enhance the optimization of transport planning. However, most approaches address specific and isolated topics within the transport sector, and within our knowledge there is no complete solution that includes the whole set of tasks and activities required to optimize a full transport plan.

Regarding the use of unsupervised Machine Learning (ML) techniques, clustering has been applied to freight transport and logistics issues to understand the geographic distribution of demand [6] and streamline logistics operations, enabling the use of GPS data to analyze the repetitiveness of commercial vehicle travel [11].

As for the driver management module, the rules stipulated by the European Commission (EC), their strictness, and respective oversight and monitoring by law enforcement agencies, are contributing to the evolving scientific research on this subject. These related works fall mainly under the field of mixed integer linear programming for driver activities scheduling, considering rest periods and breaks [4].

Over the last sixty years, load optimization, sequencing, and vehicle routing issues have been a subject of an intensive and growing research, in which the analyzed task is commonly known as a Vehicle Routing Problem (VRP). Due to the wide range of operating rules and restrictions found across the various industry sectors, diverse variants of the VRP have emerged. Over time, complexities such as travel times, time windows for delivery and collection of goods, and legislation establishing the driver working hours have been assimilated into the problem [5]. For instance, [14] explores current research trends, recent achievements, and new challenges in the topic while providing a short overview of current and emerging VRP variants.

As a result, the existing range of solutions and methodologies in the freight transport sector focus essentially on specific topics without taking into account the complexity and vast scope of the theme and the interdependence of all the variables encountered in the process of planning a transport service from start to finish. Also of note is the lack of adaptation of these solutions to real-world applications and preparation of their deployment in the industry with a continuous integration and continuous deployment (CICD) philosophy. In this paper, in contrast to the related works, an end-to-end solution (E2S2) is proposed, comprising a set of components capable of carrying an adaptive optimized transport plan throughout the whole process.

3 Materials and Methods

3.1 Problem Formulation

The set of Portuguese companies covered in the development of this IDSS is currently operating in the freight transport sector and is primarily composed of the following components: the main logistics center, a fleet of vehicles, and drivers. The main logistics center represents the company headquarters and it is also used as a warehouse and distribution center. The primary role is operationalizing logistics activities and freight transport. We highlight that the transport planning and resource allocation are performed using a software system in which the proposed IDSS will be incorporated. This system works as the cornerstone of the entire transport and logistics business.

Regarding the drivers, these represent the human resources that perform transport activities. In addition to being essential to the execution of the transport services, these resources require a particular organization and management to comply with the requirements set forth by the European Commission (EC) Regulation No 561/2006, which establishes driving and rest periods.

Each business that holds a fleet of vehicles can diverge in their types, models, sizes, capacities, and purposes. The digital transition philosophy in these Portuguese freight transport companies has led to data storage of the mentioned tasks and components. However, data analysis, pattern recognition, and automation are not optimized or even implemented. The range of transport planning activities is managed and arranged based on intuition and human experience of the transport software system users. Often, this manual approach is non optimal. The lack of interoperability and divergent (often ad-hoc) human logistics decisions lead to a misuse of resources and, consequently, to an unsustainable development.

3.2 Proposed IDSS

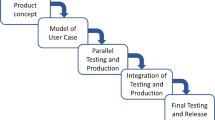

In this work, we propose an IDSS that follows a three-tier architecture that assumes three logical and physical computing elements, as presented in Fig. 1. The Data Layer is accountable for extracting and processing data from the different databases regarding the surrounding factors involved in freight transport planning, including data on freight services to be planned, data associated with the various drivers (relevant to comply with European Union (EU) rules) and data on the physical properties of trailers. In addition, there is a middleware with PTV [8], a mobility software prepared to provide distances and routes that consider the truck dimensions and legal restrictions. Its outputs are sent to the Processing Layer.

The Processing Layer of the IDSS is composed of three modules: Groupage Detection Module (GpDM), Resource Optimization Module (RsOM), and Route Optimization Module (RtOM).

Currently, the company plans routes based on specific Portuguese districts (e.g., Viseu, Coimbra, Castelo Branco), creating long and more expensive routes, thus spending more resources. To tackle this issue, the GpDM assumes an unsupervised ML algorithm in charge of planning clusters of route points to travel based on a maximum distance, thus producing better route planning and cost management (e.g., time and fuel). The developed distance-constrained geospatial clustering (DcGC) algorithm can group geographic locations based on their geographical positional similarities and a maximum adjustable distance between transports inserted in the same cluster. This way, it is possible to improve the current approach implemented with an adaptive method to create dynamic zones according to the reality of each moment of the component execution. This functionality was designed to address the inefficiency of the current grouping of transports that, despite belonging to the same zone, are highly dispersed in the vertical or horizontal geographical spectrum. It is also important to note the particularity of its performance in cross-border areas where the problem of geographic coordinates separation from very close locations is addressed. The DcGC pseudocode is presented in Algorithm 1.

Afterwards, a Time Difference (TD) leaderboard of possible drivers is calculated and provided by the Resource Optimization Module (RsOM) module. The TD leaderboard is calculated using the following equation:

where PID represents the expected start date by the company, and \(AD_{d}\) represents the driver availability date. This ranking is then presented to the driver manager, who will choose the most suitable driver to travel the route provided by the GpDM module.

The last module is the Route Optimization Module (RtOM), which is responsible for creating and optimizing the route to be covered based on two objectives: sequencing the road to be covered in the shortest possible distance; maximizing the load carried by the various vehicles on these routes. Furthermore, this module provides a better selection of vehicles depending on each route created. One of the main advantages lies within the ability of each module to be executed individually, and if requested, the outputs will be returned to the IDSS user.

3.3 Evaluation Methodology

The proposed IDSS was developed by a research team comprising Artificial Intelligence (AI), Software Development (SD), and freight transport experts. Several individual components of the proposed IDSS (e.g., GpDM module) are evaluated by considering specific logistics scenarios. To globally validate the full IDSS, we adopted the Technology Acceptance Model (TAM) 3, which allowed us to develop a questionnaire with ten questions to assess the system acceptance and evaluation. TAM 3 is composed of six constructs: Perceived Usefulness (PU); Perceived Ease of Use (PEOU); Perception of External Control (PEC); Job Relevance (REL); Output Quality (OUT); and Behavioral Intention (BI). Each question included a 5-point Likert scale [10] choice with a range of 1 (strongly disagree) to 5 (strongly agree) for each response. Direct feedback from the consultant company responsible for transport management was also captured. Moreover, we also map the IDSS tool functionalities, comparing them with current logistics practices and procedures (termed here as the AS-IS approach).

4 Results

4.1 Developed IDSS Prototype

The designed IDSS was exclusively developed using the Python language. Prototyping and deployment were accomplished using Flask. Finally, for the set of critical and proposed features in this paper, namely ML and optimization techniques, scikit-learnFootnote 1, ortools, and PTV DeveloperFootnote 2, were the tools used. It is also important to note that, at a preliminary stage of development, to overcome the lack of data derived from General Data Protection Regulation (GDPR) bureaucratic issues, the RanCoordFootnote 3 package was used. The package offers an easy procedure to generate random coordinates within a set of geographic boundaries [12].

Groupage Detection Module (GpDM) is responsible for detecting possible load groupages using zone grouping and clustering techniques. Figure 2 (plot a and plot b) depicts the transition from static to adaptive and dynamic zones, elevating the compactness of the clusters. This illustrates the grouping of 71 transport load zones to be carried out, spread over four districts within the Portuguese territory. The AS-IS approach considers the district borders, thus obtaining four grouping zones. These zones are divided into 26, 23, 22, and 4 loading locations respectively.

Coincidentally, the proposed approach using the DcGC algorithm, executed with a standard maximum distance used by the different transport companies of 55 km, also clustered the data into four clustering zones, consisting of 23,14, 16, and 22 locations. The equal number of clusters makes it possible to compare the efficiency and primacy of DcGC. The enhancement of transport groupage can be verified through each approach’s distance matrix of the different clusters. The AS-IS method obtained an average distance between geographic points of the same cluster of 19.45 km, composed of 23.14, 19.04, 20.21, and 15.44. On the other hand, the DcGC algorithm allowed a remarkable reduction of this distance to 15.42 km, composed of averages of 13.98, 18.76, 15.71, and 13.23 km. The contribution of the algorithm extends to balancing the number of locations grouped in the same cluster. The standard deviation of the number of sites to be grouped in each cluster was reduced from 8.60 to 3.80.

The Resource Optimization Module (RsOM) includes the driver suggestion (DS) and the optimization of truckload allocation (TOpt). Table 2 illustrates how this component behaves, including the set of input attributes in the Transport and Drivers sections. The Leaderboard section represents the result of this micro-framework, assembling qualified drivers to execute a transport arranged by TD. The resulting leaderboard (DLead) relevance lies within the decision-making support throughout the driver selection process, enhancing its efficiency. The information regarding driving hours will allow the manager to comply with European standards. The second component of the module relates to truckload optimization (TOpt) by formulating the problem as a packaging problem. The goal of issues of this nature is to find the best combination to pack a set of items of given sizes or weights into containers with fixed capacities. Using the SCIP for mixed integer programming (MIP) solver [1, 2], we developed an algorithm capable of optimizing the allocation of loads in different vehicles to maximize the occupancy of the vehicle and minimize the number of vehicles needed to pack and transport them, turning it into a multi-objective optimization. Regarding a set of 11 loads stored in a specific warehouse of one of the freight transport companies, it was possible to find the best combination of loads with a minimized solution of 4 vehicles and maximized occupation of the different vehicles of 99.60%, 100.00%, 77.10%, and 98.80% with a capacity established at 25 tons, the standard legal net load value.

The last module of the IDSS focuses on the Route Optimization Module (RtOM). As exemplified in Table 1 and Fig. 2 (plot c), the component takes as input parameters a set of loads to be transported to 13 geographically separated hypermarkets (HM) from the Central Region of Portugal from a logistics center and, as a second input, a set of 7 available vehicles and their respective physical profiles. This component of the IDSS generates a load allocation to the set of vehicles and the sequencing of hypermarkets to be carried out by each one. The solution presented in Table 1 and illustrated in Fig. 2 (plot c) is a multi-objective optimization that takes into account: (i) minimizing the distance traveled by each vehicle; (ii) maximizing the occupancy of each vehicle. Objective (ii) maximizes the occupancy of each vehicle, allowing the usage of only 5 vehicles of the 7 available. Finally, the second component of the module only increases the value of the solution provided by the previous one. Rather than just returning the sequence of locations to cross, it returns the complete route to be taken by each vehicle through a set of waypoints depicted in Fig. 2 (plot c). The user of the IDSS can specify whether to avoid tolls or not.

4.2 Evaluation

The results columns include the average of five freight transport managers’ responses based on a Likert scale and their corresponding standard deviation (SD). It must be underlined that, to avoid bias, these managers correspond to people from the different transport companies who were not in the research, design, or development process of the proposed IDSS. The average responses range from 3.60 to 4.60, and the standard deviation (SD) is between \(\pm 0.16\) and \(\pm 0.40\), revealing a positive evaluation and acceptance of the proposed IDSS and compliance among the various people involved in the questionnaire. The most positive responses are inserted in Job Relevance (REL1 and REL2) and Behavioral Intention (BI1), with an average rating of 4.60. To increase the value of this evaluation, the feedback given during all technical sessions of design, presentation, and enrichment of the IDSS, was also aggregated. The designed TAM 3 questionnaire is presented in Table 3.

Regarding the GpDM, the feedback was unanimously positive. These managers pointed out a remarkable optimization of the clustering process of transport services, evidenced by the examples of comparison between the AS-IS process and the developed DcGC algorithm. Table 4 summarizes the main features introduced by the proposed IDSS, which substantially enhance the current processes and procedures (AS-IS).

Concerning the RsOM module, the truckload optimization component was particularly emphasized because of the transition between intuition and human experience to an optimal combinatorial truckload optimization algorithm. On the other hand, the driver suggestion component, despite its value recognition to the decision-making process and its clear relevance, the suggestion of its improvement regarding increased automation and inclusion of the driving rules and rest times stipulated by the European Union was given by four of the five managers. Lastly, RtOM was the best verbally rated module with a clear satisfaction of the complexity and benefits provided by its sequencing and detailed routing of an optimized transport plan for each required vehicle. Overall, all respondents concluded that the proposed IDSS (including its three modules) is valuable for optimizing transport and logistics activities and represents a possible positive digital disruption for the companies.

5 Conclusions

This paper presents an Intelligent Decision Support System (IDSS) to optimize transport and logistics activities as an end-to-end solution (E2ES) in a set of Portuguese companies currently operating in the freight transport sector. The proposed IDSS follows a three-tier architecture: Data Layer – responsible for extracting and processing data from different data sources accordingly to the respective component to be addressed; Processing Layer – which represents the core of the proposed IDSS, consisting of the set of freight transport crucial procedures and tasks, namely: (a) Groupage Detection Module (GpDM); (b) Resource Optimization Module (RsOM); (c) Route Optimization Module (RtOM); and Output Layer – which includes the results and outputs from the middle layer.

The prototype was evaluated by five managers who were not in the research, design, or development process of the proposed IDSS to avoid bias. The adopted evaluation methodology was TAM 3, comprising questionnaires and feedback gathered throughout technical sessions of the design, presentation, and enrichment of the IDSS. Overall, a very positive evaluation and acceptance were obtained. In future work, we intend to add new modules and components to the IDSS articulated with the suggestions and the expected evolution of the freight transport sector.

Notes

- 1.

- 2.

- 3.

Publicly available https://github.com/hugodscarvalho/rancoord.

References

Achterberg, T.: SCIP: solving constraint integer programs. Math. Program. Comput. 1(1), 1–41 (2009)

Achterberg, T., Berthold, T., Koch, T., Wolter, K.: Constraint integer programming: a new approach to integrate CP and MIP. In: Perron, L., Trick, M.A. (eds.) CPAIOR 2008. LNCS, vol. 5015, pp. 6–20. Springer, Heidelberg (2008). https://doi.org/10.1007/978-3-540-68155-7_4

Arnott, D., Pervan, G.: A Critical Analysis of Decision Support Systems Research, pp. 127–168. Palgrave Macmillan UK, London (2015)

Bernhardt, A., Melo, T., Bousonville, T., Kopfer, H.: Scheduling of driver activities with multiple soft time windows considering European regulations on rest periods and breaks. Schriftenreihe Logistik der Fakultät für Wirtschaftswissenschaften der htw saar 12, econstor, Saarbrücken (2016)

Braekers, K., Ramaekers, K., Van Nieuwenhuyse, I.: The vehicle routing problem: state of the art classification and review. Comput. Ind. Eng. 99, 300–313 (2016)

Cao, B., Glover, F.: Creating balanced and connected clusters to improve service delivery routes in logistics planning. J. Syst. Sci. Syst. Eng. 19(4), 19:453–19:480 (2010 )

Demir, E., Bektaş, T., Laporte, G.: A review of recent research on green road freight transportation. Eur. J. Oper. Res. 237(3), 775–793 (2014)

PTV Group: Mobility and Transportation Software. PTV Route Optimiser

Pan, S., Ballot, E., Fontane, F.: The reduction of greenhouse gas emissions from freight transport by pooling supply chains. Int. J. Prod. Econ. 143(1), 86–94 (2013)

Robinson, J.: Likert scale. In: Michalos, A.C. (ed.) Encyclopedia of Quality of Life and Well-Being Research, pp. 3620–3621. Springer, Dordrecht (2014). https://doi.org/10.1007/978-94-007-0753-5_1654

Sharman, B.W., Roorda, M.J.: Analysis of freight global positioning system data: clustering approach for identifying trip destinations. Transp. Res. Rec. 2246(1), 83–91 (2011)

Carvalho, H.S., Pilastri, A., Cortez, P.: Rancoord (2022)

Venkatesh, V., Bala, H.: Technology acceptance model 3 and a research agenda on interventions. Decis. Sci. 39(2), 273–315 (2008)

Vidal, T., Laporte, G., Matl, P.: A concise guide to existing and emerging vehicle routing problem variants. Eur. J. Oper. Res. 286(2), 401–416 (2020)

Acknowledgment

The authors would like to express the most significant recognition to the project on which this IDSS has arisen, “aDyTrans - Dynamic Transportations Platform” reference NORTE-01-0247-FEDER-045174, supported by Norte Portugal Regional Operational Programme (NORTE 2020), under the PORTUGAL 2020 Partnership Agreement, through the European Regional Development Fund (ERDF).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Carvalho, H.S., Pilastri, A., Matta, A., Matos, L.M., Novais, R., Cortez, P. (2022). An Intelligent Decision Support System for Road Freight Transport. In: Yin, H., Camacho, D., Tino, P. (eds) Intelligent Data Engineering and Automated Learning – IDEAL 2022. IDEAL 2022. Lecture Notes in Computer Science, vol 13756. Springer, Cham. https://doi.org/10.1007/978-3-031-21753-1_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-21753-1_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-21752-4

Online ISBN: 978-3-031-21753-1

eBook Packages: Computer ScienceComputer Science (R0)