Abstract

Recent advancements in technologies such as in Big data and Internet of Things have made Predictive Maintenance (PdM) a key strategy to reduce unnecessary maintenance costs and improve product quality in the manufacturing sector. The premise of this paper is to implement and explore some of the most promising machine learning models for PdM, a Gradient Boosting (GB) model, and a Support Vector Machine (SVM) model. An innovative methodology for model training is proposed that aims to improve model performance while also allowing for continuous training. Furthermore, it is proposed an automatic hyperparameter tunning approach for the GB and SVM models. A synthetic dataset that reflects industrial machine data was used to validate the proposed methodology. The implemented models can achieve up to 0.92 recall and 94.55% accuracy, highlighting the effectiveness of the proposed methodology.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

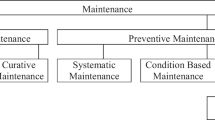

Sharma, A., Yadava, G.S., Deshmukh, S.G.: A literature review and future perspectives on maintenance optimization. J. Qual. Maintenance Eng. 17(1), 5–25 (2011). https://doi.org/10.1108/13552511111116222

Faccio, M., Persona, A., Sgarbossa, F., Zanin, G.: Industrial maintenance policy development: a quantitative framework. Int. J. Prod. Econ. 147, 85–93 (2014). https://doi.org/10.1016/j.ijpe.2012.08.018

Mota, B., Gomes, L., Faria, P., Ramos, C., Vale, Z., Correia, R.: Production line optimization to minimize energy cost and participate in demand response events. Energies 14(2), 462 (2021). https://doi.org/10.3390/en14020462

Ramos, C., Barreto, R., Mota, B., Gomes, L., Faria, P., Vale, Z.: Scheduling of a textile production line integrating PV generation using a genetic algorithm. Energy Rep. 6, 148–154 (2020). https://doi.org/10.1016/j.egyr.2020.11.093

Garg, A., Deshmukh, S.G.: Maintenance management: literature review and directions. J. Qual. Maintenance Eng. 12(3), 205–238 (2006). https://doi.org/10.1108/13552510610685075

Shin, J.H., Jun, H.B.: On condition based maintenance policy. J. Comput. Des. Eng. 2(2), 119–127 (2015). https://doi.org/10.1016/j.jcde.2014.12.006

Matzka, S.: Explainable artificial intelligence for predictive maintenance applications. In: Proceedings - 2020 3rd International Conference on Artificial Intelligence for Industries, AI4I 2020, pp. 69–74 (2020). https://doi.org/10.1109/AI4I49448.2020.00023

Carvalho, T.P., Soares, F.A.A.M.N., Vita, R., da Francisco, R.P., Basto, J.P., Alcalá, S.G.S.: A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 137, 106024 (2019). https://doi.org/10.1016/j.cie.2019.106024

Udo, W., Muhammad, Y.: Data-driven predictive maintenance of wind turbine based on SCADA Data. IEEE Access 9, 162370–162388 (2021). https://doi.org/10.1109/ACCESS.2021.3132684

Calabrese, M., et al.: SOPHIA: An event-based IoT and machine learning architecture for predictive maintenance in industry 4.0. Information 11(4), 202 (2020). https://doi.org/10.3390/info11040202

Chaudhuri, A.: Predictive Maintenance for Industrial IoT of Vehicle Fleets using Hierarchical Modified Fuzzy Support Vector Machine. https://arxiv.org/abs/1806.09612v1 (2018). Accessed 28 Dec 2021

Mathew, J., Luo, M., Pang, C.K.: Regression kernel for prognostics with support vector machines. In: IEEE International Conference on Emerging Technologies and Factory Automation, pp. 1–5. ETFA (2017). https://doi.org/10.1109/ETFA.2017.8247740

Zonta, T., da Costa, C.A., da Rosa Righi, R., de Lima, M.J., da Trindade, E.S., Li, G.P.: Predictive maintenance in the Industry 4.0: a systematic literature review. Comput. Ind. Eng. 150, 106889 (2020). https://doi.org/10.1016/j.cie.2020.106889

Frank, A., Asuncion, A.: {UCI} Machine Learning Repository. https://archive.ics.uci.edu/ml/index.php (2010)

Matzka, S.: UCI Machine Learning Repository: AI4I 2020 Predictive Maintenance Dataset Data Set. https://archive.ics.uci.edu/ml/datasets/AI4I+2020+Predictive+Maintenance+Dataset (2020)

imbalanced-learn documentation — Version 0.9.0 (2022). https://imbalanced-learn.org/stable/. Accessed 20 Apr 2022

sklearn.model_selection.RandomizedSearchCV — scikit-learn 1.0.2 documentation (2011). https://scikit-learn.org/stable/modules/generated/sklearn.model_selection.RandomizedSearchCV.html. Accessed 20 Apr 2022

scikit-learn: machine learning in Python — scikit-learn 1.0.2 documentation (2011). https://scikit-learn.org/stable/index.html. Accessed 20 Apr 2022

sklearn.ensemble.GradientBoostingClassifier — scikit-learn 1.0.2 documentation (2011). https://scikit-learn.org/stable/modules/generated/sklearn.ensemble.GradientBoostingClassifier.html. Accessed 29 Apr 2022

sklearn.svm.SVC — scikit-learn 1.0.2 documentation (2011). https://scikit-learn.org/stable/modules/generated/sklearn.svm.SVC.html. Accessed 29 Apr 2022

Acknowledgments

The present work has received funding from European Regional Development Fund through COMPETE 2020 - Operational Programme for Competitiveness and Internationalisation through the P2020 Project MUWO (ANI|P2020 POCI-01-0247-FEDER-069417), and has been developed under the EUREKA - ITEA3 Project MUWO (ITEA-19022). We also acknowledge the work facilities and equipment provided by GECAD research center (UIDB/00760/2020) to the project team.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Mota, B., Faria, P., Ramos, C. (2023). Predictive Maintenance for Maintenance-Effective Manufacturing Using Machine Learning Approaches. In: García Bringas, P., et al. 17th International Conference on Soft Computing Models in Industrial and Environmental Applications (SOCO 2022). SOCO 2022. Lecture Notes in Networks and Systems, vol 531. Springer, Cham. https://doi.org/10.1007/978-3-031-18050-7_2

Download citation

DOI: https://doi.org/10.1007/978-3-031-18050-7_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18049-1

Online ISBN: 978-3-031-18050-7

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)