Abstract

Today, smart manufacturing is differentiated from many other initiatives by its emphasis on human ingenuity. Human capabilities must be enhanced by intelligently designing a customized solution for a specific domain. For example, Industry 4.0 is based on collaborative robots that digitize and simplify manufacturing processes. In fact, Automatic Guided Vehicles (AGVs) are widely used in intelligent industries due to their productivity, flexibility, and versatility. They are widely considered as one of the most important tools for flexible logistics in workshops. They can move materials and products without a predefined route. Many commercially available AGVs provide a self-guided navigation system to find their way to target workstations. However, many developers and producers of industrial robots face several challenges in designing AGV systems, such as the difficulty of defining a decentralized system decision as well as the discontinuity and complexity of the design process. In this article, we propose a new design approach based on multi-agent technology and the Model-based systems engineering method (MBSE) to meet the challenges of functional, physical, and software integration. It is a top-down approach from requirements specification, functional and structural modeling using the systems modeling language (SysML) to model simulation with the multi-agent tool (Anylogic). Our design approach was applied on an Automated Guided Vehicle (AGV) system to serve items and deliver parts and supplies to stations in a smart factory.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Thanks to rapid advances in technology and manual billing applications, industry productivity is increasing. So, manufacturing companies are becoming more compatible, flexible and scalable (Zhong et al. 2017). Indeed, size of a manufacturing system is increasingly large, its complexity is increasingly high. Nowadays, the new manufacturing mode requires the application system to have agility and flexibility. Recently, the agent concept has been used in many application areas, especially in the field of industrial logistics (Yao et al. 2000). The application of multi-agent system in industrial logistics provides new challenges for multi-agent system technique such as multi-agent system architecture and agent collaborative decision prediction (Lasi et al. 2014).

Thanks to its advantages, the agent system is widely used in many areas such as distribution. Indeed, when the problem domain is related to many different objects that are physically or logically distributed, the agent technique is becomes one of the best options (Guizani et al. 2014a, 2014b). These objects need to collaborate with each other for the same goal (Guizani 2016). Collaborative robotics has been identified as one of the multi-agent technologies of Industry 4.0 (Ferraguti et al. 2019). Nowadays, the use of AGVs in industrial logistics is not yet widely used in manufacturing plants. Many manufacturers and developers of industrial robots have ventured into the AGV industry to reduce the problems of transporting raw materials and finished goods by manual forklifts (Sabattini et al. 2013), but they have faced many integration challenges.

The major difficulty in integrating AGVs in the production industry is the limitation of the operating environment. Indeed, flatness and horizontality are mandatory for the safe and efficient operation of AGVs, e.g., floors should not be too uneven and each transition from one surface to another should be taken into account (Ferreira and Gorlach 2016). The second challenge is related to the limited flexibility of AGVs compared to driver-controlled vehicles, as the human operator can react and change tasks quickly. This makes AGVs less suitable for non-repetitive tasks. Different AGV systems don’t really speak the same language. Thus, the third challenge to integrating AGVs into smart factories is the problem of making AGVs built by different manufacturers work together. We will see later in this paper that the right choice of AGV design methodology could facilitate the collaboration of AGV systems from different manufacturers. Another challenge to the integration of AGVs in the manufacturing industry is the high initial investment cost of the AGV system. However, AGVs are becoming increasingly feasible while increasing the number of working hours, which increases overall efficiency and productivity and creates economic benefits (Saputra and Rijanto 2021).

All of the above issues need to be addressed using the right development tools and methodology for successful AGV development. For example, complexity and discontinuity in the design process are key issues that slow down the integration of AGVs in smart industries. The designer must verify physical and software integrations to ensure design consistency. In other words, to avoid the risk of error and rework, there must be continuity between the data and models used throughout the design process.

In this paper, we introduce a design philosophy to bridge the gap between the various design phases of an AGV system. In particular, our design process improves the traceability between the design specifications, the behavioral modeling, the architectural modeling and the validation phases with the multi-agent simulation, and minimizes the discontinuity between the various design phases.

In general, this paper will be structured as follows: in the next section, we present the various methods proposed in the literature for the design of AGV systems. In the third section, we will describe our approach to the design of AGV systems based on multi-agent concepts. We will also describe the implementation of the proposed design method using the system modeling language SysML and the multi-agent tool Anylogic. In the fourth section, a case study of the design of an AGV system in a production industry is taken into account in order to confirm our method. Finally, we end the article with a conclusion.

2 Related Works

Logistics is very important in the smart industry. Recent advances in computing power and wireless Internet technologies have opened up new opportunities in the field of automated guided vehicles (AGVs) (Zaheer et al. 2013). Many researchers are confronted with several challenges to develop AGVs that meet more specific and customized needs. Mahadevan and Narendran (1990) concentrate on designing a vehicle-guided automated material handling system for a flexible manufacturing system. Aloui et al. (2021a, 2021b) suggested a new integrated design methodology based on swarm robotics to address the challenges of integrating functional, physical and software engineering. This methodology consists of two phases: a top-down phase from requirements specification to functional and structural modeling using the system modeling language (SysML); with a bottom-up phase for model integration and implementation in the robot operating system (ROS). In addition, (Stouten and Graaf 2004) describe the use of AGV systems for collaborative transport of heavy loads. In another research, (Luna and Bekris 2010) proposed partially decentralized solutions to decrease the complexity of the tuning process and address the problem of planning the trajectory of multiple robots through a set of network nodes. Indeed, AGVs need to be equipped with an appropriate detection system, in order to identify obstacles when moving in cluttered environments.

Another major challenge in the design of AGV systems is modeling. For example, (Sharma et al. 2017) modeled an AGV system with a nonlinear kinetic model that describes the robot’s velocity, position, orientation, and the angular velocity of its links. (Caruntu et al. 2020) introduce the concept of application of bio-inspired control and coordination technologies to the development of freight transportation and future manufacturing. On the other hand, task optimization and scheduling is another issue to be addressed in the design phases of AGV systems. For this reason, many researchers are currently working on swarm approaches to develop AGV systems. The study (Aloui et al. 2021a, 2021b) proposes a top-down approach to ensure consistency and continuity of the requirement level at the behavioral level to the functional and structural levels of a swarm system that can be used for the AGV system. Even though we have complete knowledge of the robot’s interior, the analysis and design of self-organizing systems such as swarm robotics remains a challenging task (Aloui et al. 2020). To this end, (Lategahn et al. 2012) proposed an integrated methodology based on the principles of swarm robotics to design an automated guided vehicle (AGV) swarm.

In this paper, we propose a new approach based on multi-agent technology that combines the capabilities of SysML and Anylogic. SysML will be used to specify the system requirements and model the AGV architecture from different points of view (behavioral, functional and structural). Anylogic, on the other hand, will be used to adapt the existing basic robots with the SysML information model and to verify the design with multi-agent simulation. In the following section, we detail the different SysML diagrams used to model the AGVs system which can then be simulated on Anylogic to ensure compliance with the system requirements.

3 Top-Down Approach for Designing an AGVs System

The current need for AGV development is a closer integration that encompasses various factors related to design methods, design practices and tools, design team members, and their interactions. this study is to develop a design approach allowing specialists from different engineering fields to combine their expertise to ensure functional, physical, and software integration using SysML and Anylogic.

The AGV design approach proposed in this article is a top-down approach from the specification of requirements to functional and structural modeling using SysML to the integration of models on the multi-agent tool (Anylogic) and their implementation on real robots (Prototype).

The designer of the AGVs system begins by specifying design requirements using SysML diagrams to describe the various system needs. From these requirements, the designer identifies the different functions that build the collective behavior of AGVs. SysML activity diagrams and state machine diagrams are therefore used to model swarm behavior. Indeed, the designer uses the allocation matrices (Requirement-Behavior, Behavior-Function) to ensure high-level traceability between requirements, behaviors, and functions. These matrices plot the specified requirements with the functions that the AGV system must perform while respecting the collective behavior. Once the collective behaviors of the AGVs are modeled, the designer details the structure of the AGV by specifying the components capable of performing the previously modeled functions that the AGV must perform using the block definition diagram (BDD) and the internal block diagram (IBD). To ensure software integration, the designer uses the SysML model developed in the previous steps to implement the collective behavior of AGVs on Anylogic. The final simulation of the behavior of AGVs is performed with Anylogic to meet the requirements described with the SysML requirements diagrams. Figure 1 shows the steps in the proposed top-down design approach.

3.1 Design Requirements of AGVs

The design requirements are the necessities, the needs, and expectations that the developed AGVs system must meet, or the constraints that it must satisfy (Schranz et al. 2018). AGVs are deployed in many different application areas. They are used in the manufacturing, warehousing, automotive, food, and healthcare industries. This variety of applications specifies general system requirements. The requirements diagram shown in Fig. 2 is used to specify the design requirements for an AGVs system. As illustrated in this figure, a traceability relation “satisfy” is added to ensure traceability between the different design views.

The AGVs navigate facility floors without being guided by predefined paths. There are two different AGVs fleets in this model: one serves items that are processed at the workshops 1, 2, and 3, and the other delivers parts and supplies to stations at workshop 3. The AGVs move between conveyors, racks and station buffers, they automatically find shortest paths and avoid collisions with other transporters and obstacles, like conveyors, pillars and walls.

3.2 Behavioral Modeling of AGVs

An AGV usually transfers a pallet from an automated production line. The pallet must be brought to the shipping area. Sometimes pallets have to be stored in a warehouse that is composed of a set of block storage areas. There are two different AGVs fleets in this model: one serves items that are processed at workshops 1, 2, and 3, and the other delivers parts and supplies to stations at workshop 3. Figure 3 shows the distribution of this two AGV fleets.

3.3 Functional Modeling of AGVs

For the AGVs system, the functions offered by the system are the functions performed by each AGV. A set of functions forms a collective behavior of AGVs. On the other hand, this behavior satisfies a requirement of the system. To apply the collective aspect, each AGV performs its functions in parallel with the other AGVs (that is, throughout the mission, each AGV performs a set of individual functions). The state machine diagram shown in Fig. 4 represents all the functions of the first fleets of AGVs serving the items processed in workshops 1, 2 and 3.

Additionally, the functional modeling of the other AGV fleets that deliver parts and supplies to workshop 3 stations is shown in the state machine diagram shown in Fig. 5.

3.4 Structural Modeling of AGVs

In this step, the general structure of the AGV system should be defined. The AGV swarm consists of a group of AGV individuals. So, the block definition diagram shown in Fig. 6 describe the general AGV structure.

The next step is to identify the different alternative solutions that can meet the functional architecture of the AGV system. In fact, the final structure of the AGV is broken down into subsystems and components. Figure 7 represents the different elements of an AGV.

The structure of the automatic guided vehicle depends on the functions required. In fact, AGV consist of a motion system such as motors to operate and wheels to provide movement. In addition, the AGV contain batteries to provide energy. Other components are specified according to the appropriate behavior such as position sensors to provide localization and laser sensors to explore the environment.

Finally, an allocation matrix is created to link the hardware components of the AGVs system with the individual functions provided by each AGV to ensure the design continuity and consistency of this approach. Figure 8 represents a component function allocation matrix.

3.5 Multi-agents Simulation

In this step, a multi-agent software tool called AnyLogic is used to implement the AGV simulation model (AnyLogicSimulation Software 2016).

Generally, the AGVs move on the floors of the installations without being guided by predefined paths. In fact, our model is made up of two different AGV fleets. Using the models developed with the MBSE method above, the simulation presented in Fig. 9 shows that the AGVs move between conveyors, racks, and station buffers, they automatically find the shortest paths and avoid collisions. with other carriers and obstacles.

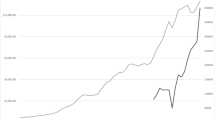

In this simulated model, the following two performance criteria are evaluated: Item wait time for AGV and Number of items moved. Figure 10 shows the evolution of these two criteria over time.

3.6 Prototype: Real Robots’ Implementation

In this phase, manufacturers and developers of industrial robots design the final AGVs system. Indeed, using the models developed and the simulation performed, manufacturers and developers of industrial robots can use already found robots or create new robots to perform given tasks. In this paper, we have not yet implemented real robots. This task is undergoing and it could be a subject of a future paper.

4 Conclusion

Differently from bottom-up approaches, our top-down design approach, which is based on the MBSE method and multi-agents’ technology, offers a systematic methodology towards the development of AGVs systems. With our approach, we can specify the AGV requirements to avoid the risk of developing the “wrong” system, that is, a system that does not satisfy the requirements. Our approach facilitates also the development of a set of simulation and hardware-independent models that can be easily reused in future applications.

In the future, we plan to validate our approach with a real implementation of an AGVs system. After that we can apply our design approach to more complex applications.

Abbreviations

- AGV: :

-

Automatic Guided Vehicle

- BDD: :

-

Block definition diagram

- IBD: :

-

Internal block definition

- ROS: :

-

Robot operating system

- SysML: :

-

Systems modeling language

- MBSE: :

-

Model-based systems engineering

References

Aloui, K., Hammadi, M., Soriano, T., Guizani, A., Haddar, M.: On the continuity of the swarm robot design using MBSE method and simulation. In: 13ème CONFERENCE INTERNATIONALE DE MODELISATION, OPTIMISATION ET SIMULATION (MOSIM2020), 12–14 Nov 2020, AGADIR, Maroc

Aloui, K., Guizani, A., Hammadi, M., Haddar, M., Soriano, T.: A top-down approach to ensure the continuity of the different design levels of swarm robots. In: 2021a 18th International Multi-Conference on Systems, Signals & Devices (SSD), pp. 1438–1445. IEEE (2021a)

Aloui, K., Guizani, A., Hammadi, M., Soriano, T., Haddar, M.: Integrated design methodology of automated guided vehicles based on swarm robotics. Appl. Sci. 11(13), 6187 (2021)

Caruntu, C.F., Pascal, C.M., Maxim, A., Pauca, O.: Bio-inspired coordination and control of autonomous vehicles in future manufacturing and goods transportation. IFAC-PapersOnLine 53(2), 10861–10866 (2020)

Editions Comparison — AnyLogic Simulation Software in www.anylogic.com (consulté le 8 juin 2016)

Ferreira, T., Gorlach, I.A.: Development of an automated guided vehicle controller using a model-based systems engineering approach. South Afr. J. Ind. Eng. 27(2), 206–217 (2016)

Ferraguti, F., Pertosa, A., Secchi, C., Fantuzzi, C., Bonfè, M.: A methodology for comparative analysis of collaborative robots for industry 4.0. In: 2019 Design, Automation & Test in Europe Conference & Exhibition (DATE), pp. 1070–1075). IEEE (2019)

Guizani, A., Hammadi, M., Choley, J. Y., Soriano, T., Abbes, M. S., Haddar, M.: Multidisciplinary approach for optimizing mechatronic systems: application to the optimal design of an electric vehicle. In: 2014a IEEE/ASME International Conference on Advanced Intelligent Mechatronics, pp. 56–61. IEEE (2014a)

Guizani, A., Hammadi, M., Choley, J.Y., Soriano, T., Abbes, M.S., Haddar, M.: Agent-based approach for collaborative distributed mechatronic design. In: 2014b 10th France-Japan/8th Europe-Asia Congress on Mecatronics (MECATRONICS2014b-Tokyo), pp. 156–161). IEEE (2014b)

Guizani, A.: Approche multi-agents pour la conception optimale des systèmes mécatroniques (Doctoral dissertation, Université Paris-Saclay; Laboratoire de recherche de Mécanique, Modélisation et Production (Sfax, Tunisie)) (2016)

Lategahn, J., Müller, M., Röhrig, C.: Global localization of automated guided vehicles in wireless networks. In: 2012 IEEE 1st International Symposium on Wireless Systems (IDAACS-SWS), pp. 7–12. IEEE (2012)

Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., Hoffmann, M.: Industry 4.0. Bus. Inf. Syst. Eng. 6(4), 239–242 (2014). https://doi.org/10.1007/s12599-014-0334-4

Luna, R., Bekris, K. E.: Network-guided multi-robot path planning in discrete representations. In: 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, pp. 4596–4602. IEEE (2010)

Mahadevan, B., Narendran, T.T.: Design of an automated guided vehicle-based material handling system for a flexible manufacturing system. Int. J. Prod. Res. 28(9), 1611–1622 (1990)

Sabattini, L., et al.: Technological roadmap to boost the introduction of AGVS in industrial applications. In: 2013 IEEE 9th International Conference on Intelligent Computer Communication and Processing (ICCP), pp. 203–208. IEEE (2013, Sept.)

Saputra, R.P., Rijanto, E.: Automatic guided vehicles system and its coordination control for containers terminal logistics application. arXiv preprint arXiv:2104.08331 (2021)

Schranz, M., Bagnato, A., Brosse, E., Elmenreich, W:. Modelling a CPS swarm system: a simple case study. In: MODELSWARD, pp. 615–624 (2018)

Sharma, B., Vanualailai, J., Prasad, A.: A dø-strategy: facilitating dual-formation control of a virtually connected team. J. Adv. Transport. (2017)

Stouten, B., de Graaf, A.J.: Cooperative transportation of a large object-development of an industrial application. In: IEEE International Conference on Robotics and Automation, 2004. Proceedings ICRA’04, 2004, vol. 3, pp. 2450–2455. IEEE (2004)

Yao, S., Geng, S., Liu, Y.: Application of development method based on multi-agents. In: Proceedings 36th International Conference on Technology of Object-Oriented Languages and Systems. TOOLS-Asia 2000, pp. 158–161. IEEE (2000)

Zaheer, A., Covic, G.A., Kacprzak, D.: A bipolar pad in a 10-kHz 300-W distributed IPT system for AGV applications. IEEE Trans. Industr. Electron. 61(7), 3288–3301 (2013)

Zhong, R.Y., Xu, C., Chen, C., Huang, G.Q.: Big data analytics for physical internet-based intelligent manufacturing shop floors. Int. J. Prod. Res. 55(9), 2610–2621 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Aloui, K., Hammadi, M., Guizani, A., Soriano, T., Haddar, M. (2023). Development of an AGV System Using MBSE Method and Multi-agents’ Technology. In: Walha, L., et al. Design and Modeling of Mechanical Systems - V. CMSM 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-14615-2_13

Download citation

DOI: https://doi.org/10.1007/978-3-031-14615-2_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-14614-5

Online ISBN: 978-3-031-14615-2

eBook Packages: EngineeringEngineering (R0)