Abstract

In this paper, a surface Electromyography (sEMG)-based compliant rehabilitation training method for the end traction upper limb rehabilitation robot is proposed. The sEMG signal of the forearm and upper arm on the affected side of the human body is collected by the electromyography sensor, and the sEMG signal is used to perform real-time force recognition through the end force estimation model, and the estimated force is used as the interactive force input in the admittance controller. Linear and circular compliance training trajectories were planned, and impedance parameter characteristics were analyzed to obtain admittance control parameters suitable for upper limb passive rehabilitation training. The results show that the force estimation method based on sEMG, combined with the compliance control strategy, improves the interactive ability of upper limb rehabilitation training, ensures the personal safety of users, and makes the training more scientific and effective.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Stroke is the leading cause of death and disability among Chinese residents, and its morbidity ranks first in the world. It has the characteristics of high morbidity, high mortality and high disability rate [1]. In China, one person has a stroke every 12 s, and one person dies of a stroke every 21 s [2]. Stroke survivors all have different degrees of motor dysfunction, and 80% of them have upper limb dysfunction [3]. Clinical studies have shown that rehabilitation training can effectively promote the functional recovery of patients. The traditional rehabilitation treatment is mainly a one-on-one, hand-in-hand way for therapists to rehabilitate patients, which will inevitably increase the workload of rehabilitation therapists [4, 5]. Rehabilitation equipment is needed to relieve the work pressure of rehabilitation therapists. Most of the traditional rehabilitation equipment adopts passive rehabilitation training and lacks the ability of human-computer interaction.

At present, many studies have been carried out on human-robot interaction methods for rehabilitation robots. Among them, sEMG is used in human-computer interaction in rehabilitation therapy and has achieved good evaluation because it has the characteristics of producing ahead of limb movement, and patients with complete upper limb hemiplegia can also produce EMG signals [6]. The upper limb rehabilitation robotic arm system developed by Harbin Institute of Technology collects the sEMG of the four muscles of the unaffected upper limb of the patient, and establishes the sEMG recognition model through the AR parameter model and the BP neural network [7]. The upper limb rehabilitation device designed by Wu Jun of Huazhong University of Science and Technology uses 4-channel sEMG signal for control, with active mode, passive mode and impedance mode [8]. The power-assisted robot HAL developed by the Cybernics Laboratory of the University of Tsukuba combines the joint torque estimated by sEMG and the lower limb motion reference model to construct a hybrid autonomous control system of HAL. The intention control based on sEMG makes the exoskeleton movement more flexible and natural. With the help of HAL, the subject can not only carry out normal daily life, but also complete more difficult tasks such as standing, walking, climbing, grasping, and lifting heavy objects.

In summary, the use of sEMG to achieve joint continuous force and motion estimation can achieve the safety and compliance of human-computer interaction. At present, there are few related studies and it has not been widely used. In this paper, a passive upper limb training method based on sEMG is proposed. The sEMG signal of the affected side is collected by the electromyography equipment, and the end force of the affected side is estimated in real time through the end force estimation model. Use the estimated force as the external force input to the admittance controller. Finally, the effectiveness of the method is verified by training experiments on straight lines and circles. The main contributions of this paper are as follows:

-

Established a end force estimation model to achieve accurate force estimation for the upper limb end force.

-

By introducing sEMG signals in passive training, the passive training that can only use the healthy side for interaction can be converted into passive interactive training only using the affected side, making the training more scientific and effective.

2 sEMG-Based Compliant Rehabilitation Method

2.1 Experimental Paradigm

For the linear motion and plane motion commonly used in upper limb rehabilitation training, the upper limb sEMG signal and force sensor data are collected during interaction. sEMG signal acquisition was performed using a Myo armband. Considering that the contact force is related to the upper forearm muscles, the Myo armbands are worn at the positions where the forearm muscles are located. The wearing method is shown in Fig. 1.

The force sensor adopts the six-dimensional force sensor of the UR5e robotic arm, which can measure the force and torque of six degrees of freedom, and the sampling frequency can reach up to 500 Hz. The selected sampling frequency is 200 Hz and the 30004 port is used to read the real-time data of the UR5e robotic arm end position and force sensor. Three male subjects (age: 23.7 ± 0.5 years old, mean ± SD) take part in the experiment. Subjects completed 3 linear motion and circular motion experiments. In the experiment, the Myo armband was used to collect the sEMG signal of the subject's right arm, and the sEMG information and the end force information of the robotic arm were recorded at the same time.

2.2 Force Estimation

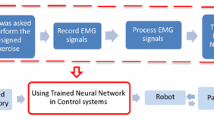

After feature extraction of the collected sEMG signals, the NMF method is used to extract muscle synergy information, and the long-short-term memory neural network model is used to establish a end force estimation model for continuous force estimation during the interaction process (Fig. 2).

After preprocessing the acquired sEMG signals, the EMG features for muscle synergy extraction were selected. It is generally believed that the level of muscle activity and EMG time-domain characteristics are approximately linear. The EMG time-domain features can be selected for muscle synergy extraction, and MAV features can be selected for subsequent muscle synergy extraction.

In this experiment, the non-negative matrix decomposition method was chosen to decompose for force estimation. The muscle activation level E can be expressed by the synergistic element matrix W and the activation coefficient matrix H:

Where m is the number of channels collected by sEMG, n is the number of sampling points, and R is the number of muscle synergy elements, which means that the muscle activation level is decomposed into R synergy elements.

Considering that the force continuous estimation is a time-varying sequence, this study chose to use a long short-term memory neural network model (LSTM) to build the end force estimation model. In this study, the tensor flow framework is used to build a force estimation model. The input of the model is the extracted muscle synergy information, and the dimension is n*5*16, where n is the number of samples. The network consists of five layers. The first layer is the LSTM layer, the second layer is the dropout layer to avoid model over fitting. The third layer is the LSTM layer, the fourth layer is the dropout layer, and the fifth layer is the full connection layer. The number of neurons is 3, which is the force output in the x, y and z directions.

2.3 Impedance Control Strategy

The impedance control of the rehabilitation robot is to adjust the impedance parame-ters to make the force and position of the robot end conform to a certain dynamic relationship. As an auxiliary robot, the rehabilitation robot is in direct contact with the human body and should be safe and flexible. There are two methods to realize im-pedance control. According to the realization method of target impedance, there are two methods, one is the force-based impedance control method, and the other is the position-based impedance control method. Active compliance of the joint with force-based impedance control.

The force-based impedance control strategy detects the force on the end of the ro-bot through the force sensor at the end of the robot, and then feeds the detected force information to the control model, outputs the position deviation, and corrects the desired position Xd. The admittance controller can be described as a spring-damper-mass system:

Among them, Md, Bd, Kd are the inertia parameters, damping parameters and stiffness parameters in the control model, respectively, F is the external environment force of the robot end, X, Xd are the actual motion trajectory and expected motion trajectory of the robot end.

For the linear motion and circular motion of the upper arm, different control strategies such as tracking the given trajectory and dynamically adjusting the power assist are proposed.

In the passive training mode, the end of the rehabilitation robot drives the patient's arm to move along a given trajectory. For patients in the early stage of rehabilitation, the muscle tension of the affected limb is high, which makes it impossible to complete the passive training along the set trajectory, and it is easy to damage the affected limb during exercise. It can be controlled by impedance. When the end is subjected to force in the vertical direction of motion, it will make a compliant motion in the corresponding direction to ensure safety (Fig. 3).

Xd and X represent the expected trajectory and the actual trajectory of the robot. The force F is obtained through the end interactive force estimation model, and it can be converted into the position offset XF after passing through the impedance model, so as to obtain the corrected position signal and input it to After the position control loop, the rehabilitation robot is controlled by the position controller, and the position control of the robot end is realized, thereby achieving the effect of compliant control.

In the assist training mode, it is hoped that the end assist of the rehabilitation robot can be dynamically adjusted. The deviation between the expected force and the force applied by the arm is regarded as the force provided by the end of the manipulator, and is converted into a position offset through impedance control to realize dynamic adjustment of power assistance. The patient can adjust the impedance parameters according to the rehabilitation situation, and select the appropriate interactive force for booster training (Fig. 4).

3 Results and Analysis

For linear motion in the tracking given trajectory strategy, the end of the robot applies a vertical force F during the linear motion along a given direction, and the robot makes an active compliant motion while performing linear motion in the original direction. \(\vec{F}\) is the external force received, \(\vec{l}\) is the vertical motion direction vector, and the vertical direction force is calculated by projection.

Then get the position offset through impedance control:

Decompose into the x, y direction to get the corrected target position:

The target position is then sent to the position controller to achieve compliance control in the corresponding direction. The force, motion position and trajectory diagram of linear motion are shown in Fig. 5. It can be seen that when the applied force is perpendicular to the motion direction, the end of the manipulator will be offset in the corresponding direction. When the force is removed, the end of the robotic arm continues to move in the original direction.

For circular motion, during the movement of the robot end along the circular trajectory, a force F in the direction of the vertical velocity is applied, and the robot makes an active and compliant motion while tracking the trajectory motion (Fig. 6).

Considering the trajectory offset during the movement process, first calculate the corresponding position on the circle through the current position:

Calculate the next target position:

Calculate the radial force through projection, and then obtain the position offset through impedance control:

Decompose to the x, y direction, update the target position:

Then send the target position to the controller. The force, motion position and trajectory diagram of linear motion are shown in Fig. 7. It can be seen that when the applied force deviates from the center of the circle, the end of the robotic arm will deflect in the corresponding direction. When the force is removed, the end of the manipulator continues to complete the circular motion in the original direction.

In the dynamic adjustment assist strategy, the force F is obtained through the terminal interactive force estimation model, and the deviation between the calculated F and the set expected force Fd is as follows

After passing through the impedance model, it can be converted into the position offset \(\Delta X = \left[ {\begin{array}{*{20}c} {\Delta p_{x} } & {\Delta p_{y} } \\ \end{array} } \right]^{T}\), so as to obtain the corrected position signal.

After inputting it into the position control loop, the position controller is used to control the rehabilitation robot, realize the position control of the robot end, and realize the dynamic adjustment of the power assist. Figure 8 shows the force, motion position and trajectory of the dynamic adjustment assist strategy. It can be seen that when the applied force is less than the expected force, the end of the robotic arm will apply corresponding assistance.

4 Conclusion

In this paper, a passive upper limb training method based on sEMG is proposed. The EMG signal of the affected side is collected by the EMG equipment, the end force of the affected side is estimated in real time through the end force estimation model, and the estimated force is used as the external force input of the admittance controller. A compliant control strategy that tracks a given trajectory and dynamically adjusts the power assist is proposed. Finally, through the linear and circular trajectory training experiments, it is verified that the proposed method can realize the compliance control in the upper limb training process.

References

Gao, P.C., Tang, F.: Effect of intelligent rehabilitation training system on upper limb and hand function of patients with stroke. Chin. J. Rehabil. Theor. Pract. 26(10), 1198–1203 (2020). https://doi.org/10.3969/j.issn.1006-9771.2020.10.013

Kim, J.S.: Acute vestibular disorders: stroke or not. J. Neurol. Sci. 429, 117978 (2021). https://doi.org/10.1016/j.jns.2021.117978

Fisher, M., Martins, S.: Update of the world stroke organization activities. Stroke 52(7), e356–e357 (2021). https://doi.org/10.1161/STROKEAHA.121.035357

Xiong, J., Zheng, G.H.: Advance in executive function for post-stroke patients. Chin. J. Rehabil. Theor. Pract. 26(7), 797–801 (2020). https://doi.org/10.3969/j.issn.1006?9771.2020.07.012

Ye, H.L., Chen, Q.Y., Peng, X.M.: Investigation and research on the needs of nursing professional support in rehabilitation patients after stroke. Int. Med. Health Guidance News 27(03), 379–381 (2021). https://doi.org/10.3760/cma.j.issn.1007-1245.2021.03.019

Peng, F., Zhang, C., Xu, B.: Locomotion prediction for lower limb prostheses in complex environments via sEMG and inertial sensors. Complexity 28(7), 1–12 (2020). https://doi.org/10.1155/2020/8810663

Li, Q.L., Kong, M.X., Du, Z.J.: 5-DOF upper limb rehabilitation robotic ARM interactive rehabilitation training control Strategy. J. Mech. Eng. 44(009), 169–176 (2008). https://doi.org/10.3321/j.issn:0577-6686.2008.09.028

Wu, J., Jian, H., Wang, Y.: A wearable rehabilitation robotic hand driven by PM-TS actuators. In: International Conference on Intelligent Robotics and Applications, pp. 1154–1159. ICIRA (2010). https://doi.org/10.1016/j.jns.2021.117978

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Lyu, H., Gu, YL., Lin, G., Zhang, DH., Zhao, XG. (2022). Research on Compliant Rehabilitation Strategy of Upper Limb Rehabilitation Robot Based on sEMG. In: Liu, H., et al. Intelligent Robotics and Applications. ICIRA 2022. Lecture Notes in Computer Science(), vol 13458. Springer, Cham. https://doi.org/10.1007/978-3-031-13841-6_37

Download citation

DOI: https://doi.org/10.1007/978-3-031-13841-6_37

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-13840-9

Online ISBN: 978-3-031-13841-6

eBook Packages: Computer ScienceComputer Science (R0)