Abstract

The objective of the paper is to discuss the upcoming challenges in the wastewater treatment of dairy Industry effluent. It is estimated that about 0.2–10 L of wastewater with an average value of 2.5 L is generated per liter of milk processed, therefore, wastewater treatment is of huge concern in these industries. The study shall review the literature available on wastewater treatment technologies used in dairy industry and predict areas for future studies. One of the areas studied is the removal of antibiotic resistant bacteria from the wastewater effluent. Removal of antibiotic resistant bacteria from wastewater is of concern since it may pass onto food chain and ultimately reach humans thereby leading to antibiotic inefficacy in humans. The use of antibiotics in cattle is widespread for treating clinical diseases, enhancing milk production and growth. These antibiotics result into generation of antibiotic-resistant bacteria in the gut of cattle which then pass onto wastewater streams.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In the food industry, milk and its constituted products are one of the most demanded. Due to its demand and highly perishable nature, high quality standard needs to be maintained in the supply of milk and its products to the consumers. To maintain the quality standards, quality control operations need to be performed which require proper washing and sanitization of places and utensils used in the whole process. Also, proper sanitary conditions need to be maintained during the storage, handling, processing, and packaging of milk. All these quality and hygiene requirements results in use of enormous amount of water. It is estimated that about 0.2–10 L of wastewater with an average value of 2.5 L is generated per liter of milk processed (Shete and Shinkar 2013a, b). Hence, the generation of wastewater from milk processing industries is huge which then finds its way to natural bodies. The dairy wastewater contains fats, nutrients, lactose, detergents, and sanitizing chemicals and is characterized by high BOD, COD and TS contents (Zhao et al. 2020). The use of antibiotics in cattle feed has been also reported in various studies as growth promoters and performance enhancement (Koch et al. 2021). It is anticipated that it may lead to development of antibiotic resistant bacteria in the gut of cattle which may pass into dairy effluents. The treatment of antibiotic resistant bacteria in dairy effluent if present shall also be an issue of major concern since it will ultimately affect humans through food chain.

2 Methodology

The literature available on different treatment technologies used in dairy industry was studied and reviewed in the current study. Different treatment technologies were analyzed for the efficiencies and percentage removal of contaminants to estimate the effectiveness of the technology. The study was done with an objective to list down the challenges faced by the dairy industry in the treatment of wastewater and explore the areas for future study.

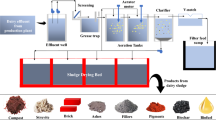

2.1 Sources of Wastewater in Dairy Industry

Dairy industry is a huge market and hence the quantity of wastewater generated form this industry is also extensive. The major sources of wastewater generation from this industry can be categorized into three kinds: Processing water, Cleaning wastewater, Sanitary wastewater (Kolev Slavov 2017). Processing water is generally formed during the cooling of milk. When the milk is evaporated and then condensed, it results in the formation of condensates. The condensate so formed is the cleanest effluent since it contains trace amounts of milk or whey droplets. This process water requires minimal treatment and can be reused in processes where it does not come in direct contact with the milk products such as hot water and steam production or membrane cleaning. The process water can also be discharged directly along with stormwater since it requires only minimal treatment to reach the discharge standards.

The other source of wastewater generation is cleaning requirements. To maintain the high quality of milk and its products, proper hygiene conditions need to be maintained which requires good amount of fresh water. This water comes in direct contact with the milk and its products; therefore, this wastewater is composed of considerable quantities of milk, whey, salt, and sanitization chemicals. This type of wastewater which is generated is highly polluted and requires extensive treatment before discharging.

Another considerable source of wastewater is sanitary requirements. It is similar to municipal wastewater and is either piped directly to sewerage lines or treated separately to meet the discharge standards.

In the current study, we are going to focus mainly on wastewater generated from cleaning requirements within the industry which is highly polluted consisting of high proportion of organic solids and cannot be discharged as it is.

2.2 Literature Review

The COD range of the influent dairy wastewater varies widely from 1000 to 60,000 mg/L as can be seen in Table 15.2. If it is left untreated and directed to the natural streams, it is going to impact the natural water bodies in extreme way posing the threat to aquatic life and ultimately human beings. It may also lead to eutrophication in natural bodies. To prevent all this damage to the environment, the wastewater effluent from the dairy industries shall undergo effective treatment processes to meet the desired discharge standards. The discharge standards for the dairy industries effluent is as mentioned below in Table 15.1.

Many studies were found during the literature review including aerobic as well as anaerobic treatment technologies for effective treatment of dairy wastewater effluents. Both the processes have their own advantages and disadvantages over one another. Aerobic processes are characterized by suspended or attached growth processes with the supply of oxygen which leads to increased energy consumption and production of large amount of sludge, but the rate of reaction is fast, and wastewater can be treated within short HRTs. On the other hand, in Anaerobic processes, there is no requirement of oxygen supply; therefore, less energy consumption is required, and sludge production is also quite less as compared to aerobic processes. But the rate of reaction is slow resulting in longer HRT durations. The stability of process is also low for anaerobic processes. The combined processes were also studied in few of the literature to take the advantage of both type of processes and result in effective treatment of dairy wastewater.

The commonly used anaerobic process for the treatment of dairy wastewater is Upflow Anaerobic Sludge Bioreactor (UASB) and Upflow Anaerobic Packed Bed Bioreactor (UAPB). These are two hybrid systems which overcomes one of the major limitations of anaerobic processes which is slow reaction rate. It was observed in a study that UAPB reactor exhibited maximum COD removal rate of 94.51% at 16 h HRT duration. When the HRT was increased to 24 h, removal efficiency dipped to 83.24% and when the HRT was decreased to 6 h, again the removal efficiency rate came out to be 56.58%. This depicted that 16 h is the most appropriate HRT duration for the process. Decrease in lactose conversion and COD removal was seen with increase in organic loading. Since the influent COD form the dairy wastewater is quite high, UASB/UAPB becomes an effective treatment technology for achieving the desired removal (Najafpour et al. 2008).

Another study focused on comparison of activated sludge process with Sequential Batch Reactor for treatment of dairy industry wastewater. In their study, they also studied the two modified systems which were developed after adding plastic media in both the systems which were then referred to as biofilm conventional activated sludge (BAS) and biofilm sequential batch reactor (BSBR). So, in all, four different systems were analyzed for performance at different temperature conditions of 20, 35 and 45 °C. The basic and the modified processes were analyzed for their treatment capabilities like AS v/s BAS and SBR v/s BSBR. Also, the performance of AS and SBR was compared at different scenarios using GPS-X simulation. Synthetic Wastewater was used for the analysis with 5000 mg/l COD, 250 mg/l NH3–N and 50 mg/l TP. The activated sludge (AS) and biofilm activated sludge (BAS) consisted of two units: aeration tank and the Settling tank. Sequential Batch reactor (SBR) and Biofilm Sequential Batch reactor (BSBR) consisted of only single unit which acted as aeration as well as settling unit. The results from the study concluded that the modified systems performed better in terms of removal efficiencies and reduced acclimatization period of the system. All the systems performed best at temperature of 35 °C compared to 20 and 45 °C. SVI results showed that settling was found to best at 20 °C in all the systems. Nitrification was found to be best at 35 °C which reduced significantly at 45 °C. Also, comparing ASP and SBR, SBR was found to be performing best in terms of removal efficiencies, therefore it can be concluded from the study that SBR performs better than ASP and the best temperature for functioning of biological systems is 35 °C (Khalaf et al. 2021).

A study on one of the aerobic process Sequential Batch Reactor was conducted for dairy wastewater treatment. This study was conducted based on the fact that SBR performs better than ASP for the treatment of dairy wastewater due to its major advantages such as better acclimatization to variation in COD and BOD loading, lesser area required for installation, lesser equipment’s and clarifiers required since the whole cycle is done in single reactor. Apart from all these advantages, the SBR is better performance wise also in terms of removal efficiencies.

In this study also, simulated dairy wastewater was prepared to be fed to an experimental set-up consisting of cylindrical glass reactor with volume 10 L. The SBR reactor was operated at cycle time of 12 h where settling time was 1 h, decanting time was 0.5 h and idle time was 0.5 h. Reaction time was 10 h but it was varied at different experimental steps. The system was operated at different HRT values: 15, 17.14, 20, 24 and 30 h. It was observed that best removal efficiencies were obtained at 24 h HRT period with 96.5% COD and 64.61% TKN values. Increasing the HRT above 24 h did not increase the removal efficiencies. Therefore, for further analysis in the experiments 24 h HRT was used for the reactor.

Different durations of fill phase were analyzed with variations of 0.5–2.0 h. It was observed that increasing the duration of fill phase resulted in increase of COD removal efficiencies at the end of filling phase but there was no significant increase in removal efficiencies after the reaction phase. It was concluded that increase in fill phase reduces the time of reaction phase. Also, no difference was observed in TKN removal efficiency values with varying fill durations. Therefore. Optimum duration for fill phase was considered as 1 h (Kushwaha et al. 2013).

To increase the nitrogen removal, anoxic phase was introduced after the filling phase and reaction phase of varying lengths from 0.5 to 2 h. But no significant difference was observed in the 1 h and 2 h durations. Therefore, anoxic phase duration was best at 1 h interval. Introduction of anoxic phase did not how any effects on nitrogen removal.

Moving Bed Biofilm Reactor (MBBR) system is also used as an advanced wastewater treatment for dairy wastewater. The process combines the properties of both activated sludge process and biofilter process where activated and attached biomass both are used. The study analyzed the performance of the MBBR reactor at different organic load, filling ratio and hydraulic retention time. It was found that MBBR performed more stable at filling ratio of 40% and HRT of 4 h with COD removal efficiency of 95% (Santos et al. 2020).

Another study was done with a purpose to check the effectiveness of combined UASB and MBR system for dairy wastewater treatment. This combined UASB and MBR system proved to be quite effective in COD removal with more than 95% efficiency reaching up to 99% even with higher organic load in the influent. The system was robust in term of acclimatizing to loading changes upto 4.85 kg COD m−3d−1 and varied temperature values from 17 to 25 °C. The study demonstrated yield of biogas up to 150 L kg−1 of total COD having an average methane content of 73% (Buntner et al. 2013).

One study was done to assess the performance of integrated system consisting of anaerobic baffled reactor (ABR) and an Upflow anaerobic sludge blanket (UASB) for the treatment of dairy wastewater. The first stage consisted of ABR where proteins are denatured and coagulated into solids with adsorption of fats and their decomposition. ABR treatment is followed by UASB sludge is retained in the sludge bed. The result of the integrated process is extensive reduction in sludge generation which reduced from 3 to 5 tons per day to 3 tons per month and effective COD removal efficiency of 98%. Also, the energy consumption of the integrated system reduced as compared to conventional systems (Ji et al. 2020).

3 Results

Many technologies have the potential to treat the dairy wastewater which include aerobic as well as anaerobic processes. Aerobic processes are characterized by providing sufficient time for the heterotrophic microorganisms to act on the organics present in the incoming wastewater in the presence of oxygen and nutrients thereby producing biomass and ultimately sludge which needs further treatment and disposal. Aerobic process can be categorized into attached or suspended growth processes. Both types of aerobic processes have their own advantages and disadvantages. Aerobic processes specially suspended growth processes require large land requirement and exhibit energy consumption, but these processes are fast and produce stable compounds. Also, these processes result in effective BOD removal which can solely achieve the discharge standard requirements.

Compared to aerobic processes, anaerobic process requires less energy, lesser sludge is produced, a smaller number of nutrients are required, methane is produced which is a potential source of energy, and smaller land area is required. Certain disadvantages of the anaerobic processes include longer start-up required for the whole process to develop, sometimes it may require addition of alkalinity compounds which increases the cost. These processes may require additional treatments to meet the discharge standards. Anaerobic processes also result in production of odorous and corrosive gases (Metcalf Eddy).

The following lists some of the major technologies which are dominantly used for treatment of dairy wastewater.

3.1 Upflow Anaerobic Sludge Bioreactor (UASB)/Upflow Anaerobic Packed Bed Bioreactor (UAPB)

UASB is one of the most prominent anaerobic treatment technologies and it came into existence in late 1970s in Netherlands by Lettinga and his coworkers.

In UASB, the screened influent comes from the bottom and is distributed at the bottom and travels upward through the sludge blanket. The typical layout of UASB can be modified as per requirements to convert into modified processes like sludge blanket when replaced by packed media forms UAPB reactor. The benefit of UASB/ UAPB reactors is that it allows the use of high volumetric COD loadings and results in development of granulated sludge. Due to the granulated nature of the sludge it has good settling properties with less SVI values (Metcalf and Eddy et al. 2003).

Anaerobic Baffled Reactor (ABR)

This process came into existence in early 1980s and was developed by McCarty and his coworkers at Stanford University. In ABR, baffles are employed which direct the movement of wastewater in the reactor through sludge blankets. The wastewater moves slowly through the reactor resulting in rise and fall of sludge blanket with gas production. Many modifications can be done to the typical reactor in which baffle design can be modified, hybrid reactors can be designed or packing material may be used instead of sludge blanket. It is one of the simple anaerobic treatment processes since no special gas separation technique need to be employed, no mechanical mixing is required, ng SRT is possible with low HRT. These advantages enable treatment of different kinds of wastewater with ABR (Metcalf and Eddy et al. 2003).

Activated Sludge Process (ASP)

The concept of aeration in wastewater was first introduced by Dr. Angus Smith in early 1880s. In the following studies, many researches were conducted with aeration in wastewater as the basic technology. Activated Sludge Process consists of basic 3 components: primary settling tank, aeration tank and secondary settling tank. In primary settling tank, Inorganic solids settle down and suspended solids concentration decreases in the wastewater. In the aeration tank, oxygen is supplied to the microorganisms thriving within the reactor so that they grow and act on organics present in the wastewater and oxidize them to stable compounds. In the third reactor which is secondary settling unit, the reduced compounds settle down at the bottom which are highly stable in nature and forms the composition of secondary sludge which is flocculent in nature and needs further degradation, disposal, and proper management. A small portion of secondary sludge is recirculated back to the line entering the aeration tank to maintain the proper F/M ratio in the aeration tank for proper treatment of wastewater. ASP process can exhibit biological nitrification, denitrification, and phosphorus removal with higher HRT values. Many modifications and researches have been conducted on activated sludge process since it is one of the most widely used aerobic treatment processes. This process is most efficient in terms of producing good quality of effluent which can easily meet the discharge standards with lower HRT values. Only disadvantage with the process is the requirement of land for aeration tanks to provide sufficient contact time between the microorganisms and oxygen. Also, sludge handling gets complex in some scenarios (Metcalf and Eddy et al. 2003).

Moving Bed Biofilm Reactor (MBBR)

This process was first explained by Prof. Hallvard Odengard at Norwegian University of Science and Technology in late 1980s. MBBR is characterized by a submerged biofilm reactor and a separation unit for liquid–solid components. The reactor is filled with special plastic carriers which act as a surface for biomass growth. These carriers are made mainly of high-density polyethylene (HDPE) (Bina et al. 2017) because it has a density close to that of water and it can easily float in water through aeration. In this system both kinds of processes occur; attached film growth and suspended biomass growth due to which the concentration of biomass production increases in a smaller area of bioreactor. This is the advantage of this system over traditional activated sludge approach. Nitrification and Denitrification can also take place in MBBR at low HRTs due to the high biomass concentration in the reactor (McQuarrie and Boltz 2011).

Sequential Batch Reactor (SBR)

This process is very similar to activated sludge process. Only difference is that in this process, all the steps are carried out in a single reactor batchwise. It works on a fill and draw cycle principle. The different phases such as wastewater filling, reaction phase, settling phase, and decantation of effluent are done in single unit in batchwise operation. Therefore, the total cost is reduced in this process due to lesser land area requirement and elimination of construction of different units. One of the major advantages is that SBR process can be exhibited under aerobic as well as anaerobic conditions (Kushwaha et al. 2013).

The summary of percentage removal of contaminants using different technologies is present in Table 15.2. It is analyzed that UAPB is one of the best technologies in terms of COD removal percentage with 94.5 removal. SBR technology also gives promising results with 96.5% COD removal efficiency. It is studied that the integration of two technologies gives the best results. The integration of UASB with MBBR or ABR with UASB gives best removal efficiencies (Buntner et al. 2013, Ji et al. 2020). No data on cost analysis of different treatment technologies was found. But cost implications of different technologies shall also be studied before investing huge cost into the infrastructure for treatment.

3.2 Use of Antibiotics in Animals and Its Impact on Human Health

Antibiotics are chemical therapeutic agents widely used in developing countries to reduce the number of deaths which is caused due to pathogenic infections. A good ratio of antibiotics is used for promoting growth and not for treating infections. In animal feed, antibiotics are used with a purpose to improve the performance and production of livestock. Mixed antibiotic in cattle feed has improved their heath substantially. Different drugs used are tertracyclines, penicillins, streptomycin and bacitracin which act as growth promoters in cattles. Other antibiotics used are sulphacetamide, tetracycline, oxytetracycline, chloramphenicol, lincomycin, virginiamycin, tylosine, etc. (Koch et al. 2021).

The ample use of antibiotics in large-scale animal farms results in generation of antibiotic resistant bacteria which have been found in these farms. Use of antibiotics result in development of antibiotic resistant genes which is carried by the bacteria in the environment. The presence of antibiotic resistant genes in bacteria has been proven to be dangerous for human population and other life forms (Koch et al. 2021).

When treatment happens, microflora in the gastrointestinal tract is exposed to high antibiotic concentrations. Due to the constant exposure of bacteria to antibiotics they develop a resistance towards the same before being discharged into aquatic environment. Antibiotics are extensively used for treatment these days leading to accumulation of antibiotic resistant bacteria in the wastewater streams. This is a matter of concern since they may pass onto food chain and ultimately reach humans thereby leading to antibiotic inefficacy in humans (Abdel-Mohsein et al. 2020). The presence of antibiotic resistant bacteria in animal waste enters the food chain and significantly affects humans and other life forms (Landers et al. 2012).

It was found in a study that antibiotic resistant bacteria are present in the effluent coming out of the anaerobic digester plants. These drug-resistant bacteria showed resistance against penicillin, levofloxacin, ampicillin, and chloramphenicol (Resende et al. 2014). It is also found in a study that many drugs or antibiotics cannot be fully extracted out from the wastewater treatment plants using current technologies (Koch et al. 2021).

4 Discussion

The industrial wastewater generation from the dairy industry was studied. The need for treatment of dairy wastewater is imperative since it is one of the largest industries in food sector. It is estimated that the amount of wastewater being generated from dairy industries is huge. Several aerobic and anaerobic processes can be used for the treatment of dairy wastewater but it was examined after going through the literature that modified or combination of two approaches are most beneficial in production of high-quality effluent after the treatment. Among aerobic processes, SBR was found to be more appropriate technology in terms of operation, maintenance, land requirement, and COD removal efficiency. Among anaerobic processes, UASB/UAPB technologies were found to be most effective technology in treatment of high COD influent from Dairy industries. But lack of literature on cost analysis of different technologies was there due to which it was difficult to assess the cost implications of different types of technologies available. Also, presence of antibiotic resistance bacteria may be found in the influent and effluent wastewater from the treatment plants. The research shall also be done on the presence and removal of antibiotic resistant strains of bacteria since this may lead to a major problem in coming future for humans and other life forms.

5 Conclusion

SBR, UASB and other combined processes which are the most efficient in treating dairy wastewater must also be studied for cost implications so that life cycle assessment can be done for the two technologies and most efficient technology can be explored further.

The treatment technologies shall be explored for presence and efficiency in removal of antibiotic-resistant bacteria. In current practices, antibiotics have found its wide application in human and veterinary medicines. They are widely used in treating infections and act as growth promoters too. If the antibiotic resistance microflora is stopped or eliminated during wastewater treatment processes, it will not lead to harmful consequences in the coming era. Therefore, any wastewater treatment process which has a potential source of antibiotic resistant bacteria in the influent shall consider the removal of these strains during the studies (Abdel-Mohsein. et al. 2020).

Scientists have predicted that the presence of antibiotic resistant bacteria will become an extensive problem by the next 50 years and if the problem remains untouched, number of deaths would increase up to 300 million. As per WHO studies, antibiotic resistance is one of the biggest threats among the public health threats which shall be addressed in twenty-first century (Koch et al. 2021).

References

Abdel-Mohsein HS, Feng M, Fukuda Y, Tada C (2020) Remarkable removal of antibiotic-resistant bacteria during dairy wastewater treatment using hybrid full-scale constructed wetland. Water Air Soil Pollut 231(8):1–12

Alratos CS, Van Oirschot D, Tekerlekopoulou AG, Vayenas DV, Stefanakis AI (2018) Dairy wastewater treatment with constructed wetlands: experiences from Belgium, the Netherlands and Greece. In: Constructed wetlands for industrial wastewater treatment, pp 175–202

Bina B, Mohammadi F, Amin MM, Pourzamani HR, Yavari Z (2017) Evaluation of the effects of alkylphenolic compounds on kinetic coefficients and biomass activity in MBBR by means of respirometric techniques. Chin J Chem Eng 26(4):822–829

Buntner D, Sánchez A, Garrido JM (2013) Feasibility of combined UASB and MBR system in dairy wastewater treatment at ambient temperatures. Chem Eng J 230:475–481

El-Battrawy OA, El-Sonbati MA, El-Awadly EM, Hegazy TA Study on ferric chloride coagulation process and Fenton’s reaction for pretreatment of dairy wastewater

Ji S, Ma W, Wei Q, Zhang W, Jiang F, Chen J (2020) Integrated ABR and UASB system for dairy wastewater treatment: engineering design and practice. Sci Total Environ 749:142267

Khalaf AH, Ibrahim WA, Fayed M, Eloffy MG (2021) Comparison between the performance of activated sludge and sequence batch reactor systems for dairy wastewater treatment under different operating conditions. Alex Eng J 60(1):1433–1445

Koch N, Islam NF, Sonowal S, Prasad R, Sarma H (2021) Environmental antibiotics and resistance genes as emerging contaminants: methods of detection and bioremediation. Curr Res Microb Sci 100027

Kolev Slavov A (2017) General characteristics and treatment possibilities of dairy wastewater–a review. Food Technol Biotechnol 55(1):14–28

Kushwaha JP, Srivastava VC, Mall ID (2013) Sequential batch reactor for dairy wastewater treatment: parametric optimization; kinetics and waste sludge disposal. J Environ Chem Eng 1(4):1036–1043

Landers TF, Cohen B, Wittum TE, Larson EL (2012) A review of antibiotic use in food animals: perspective, policy, and potential. Public Health Rep 127(1):4–22

McQuarrie JP, Boltz JP (2011) Moving bed biofilm reactor technology: process applications, design, and performance. Water Environ Res 83(6):560–575

Metcalf & Eddy, Burton FL, Stensel HD, Tchobanoglous G (2003) Wastewater engineering: treatment and reuse. McGraw Hill

Minakshi D, Sharma PK, Rani A, Malaviya P (2018) Treatment of dairy farm effluent using recirculating constructed wetland units. In: Advances in health and environment safety. Springer, Singapore, pp 57–66

Najafpour GD, Hashemiyeh BA, Asadi M, Ghasemi MB (2008) Biological treatment of dairy wastewater in an upflow anaerobic sludge-fixed film bioreactor. Am Eurasian J Agric Environ Sci 4(2):251–257

Resende JA, Silva VL, de Oliveira TLR, de Oliveira Fortunato S, da Costa Carneiro J, Otenio MH, Diniz CG (2014) Prevalence and persistence of potentially pathogenic and antibiotic resistant bacteria during anaerobic digestion treatment of cattle manure. Biores Technol 153:284–291

Santos AD, Martins RC, Quinta-Ferreira RM, Castro LM (2020) Moving bed biofilm reactor (MBBR) for dairy wastewater treatment. Energy Rep 6:340–344

Shete BS, Shinkar NP (2013a) Comparative study of various treatments for dairy industry wastewater. IOSR J Eng 3:42–47

Shete BS, Shinkar NP (2013b) Dairy industry wastewater sources, characteristics & its effects on environment. Int J Curr Eng Technol 3(5):1611–1615

Sutar AS, Mulla RK, Ranveer AC (2015) Effluent treatment plant of dairy wastewater–a performance evaluation. Int Res J Eng Technol 2(8):837–840

Zhao K, Wu YW, Young S, Chen XJ (2020) Biological treatment of dairy wastewater: a mini review. J Environ Inf Lett 4(1):22–31

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Bansal, A., Kumar, A. (2022). Exploring Challenges in Effective Wastewater Treatment for Dairy Industries. In: Yadav, B., Mohanty, M.P., Pandey, A., Singh, V.P., Singh, R.D. (eds) Sustainability of Water Resources. Water Science and Technology Library, vol 116. Springer, Cham. https://doi.org/10.1007/978-3-031-13467-8_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-13467-8_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-13466-1

Online ISBN: 978-3-031-13467-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)