Abstract

When driven by undrained cyclic shearing, saturated granular soils will experience the increase of excess pore water pressure and the decrease of effective stress. This phenomenon is termed as “cyclic liquefaction” or “cyclic softening”. Revealing the evolution of fabric in accompany with effective stress reduction provides a significant insight into the fundamental mechanism of cyclic liquefaction. In this study, numerical tests were conducted in DEM simulations to explore the cyclic liquefaction of granular packings with different void ratios. With the decrease of mean effective stress p′ during cyclic liquefaction process, the decrease of particle-void descriptor Ed can be observed for all packings. From the micromechanical perspective, large size voids are redistributed and the local void distribution around particle becomes relative uniform. The change of particle-void fabric from consolidated state to initial liquefaction state is irrelevant to density of the packing. A power function is further adopted to describe the negative correlation between Ed and p′.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Cyclic liquefaction of granular soils has attracted considerable interests from researchers and engineers from both geotechnical and seismic fields since 1964 Nigaata Earthquake. After initial liquefaction, granular soils will be transformed between “fluid-like” state and “solid-like” state (Idriss and Boulanger 2008; Shamoto et al. 1997; Wei et al. 2018). Granular packing in the “solid-like” state can resist external load whereas packing in the “fluid-like” state flows under any applied loads. In terms of cyclic liquefaction of a granular system, geotechnical researchers were interested in the liquefaction potential and liquefaction assessment of granular soils (Vaid et al. 2001; Idriss and Boulanger 2008; Yang and Sze 2011), and the consequences of cyclic liquefaction such as lateral spreading and post-liquefaction settlement (Ishihara 1993; Shamoto et al. 1997).

A great number of studies have revealed that cyclic liquefaction of granular soils mainly attributes to the collapse of load bearing structure, which can be reflected by the decrease of coordination number (Wang and Wei 2016; Wang et al. 2016; Sitharam et al. 2009). This is from the contact-based fabric to explain the cyclic liquefaction. However, few studies have probed cyclic liquefaction phenomenon from void-based fabric, partially due to the difficulty to define individual void (Li and Li 2009; Ghedia and O’Sullivan 2012). Wang et al. (2016) proposed a fabric entity termed as mean neighboring particle distance (MNPD) to reflect space arrangement of particles. Wei et al. (2018) proposed fabric descriptors based on Voronoi tessellation to quantify the anisotropy of local void distribution. These studies revealed that the void-based fabric was strongly correlated with large post-liquefaction deformation of granular soils. How the void-based fabric evolves with the effective stress reduction in pre-liquefaction is not well understood.

In this study, comprehensive numerical tests were performed in DEM (discrete element method) simulations to explore the cyclic liquefaction of granular soils from void-based fabric perspective. DEM has been proven to be an excellent tool to study cyclic behaviors of granular soils (Sitharam et al. 2009; O’Sullivan 2011; Huang et al. 2018). Particle-void descriptors proposed by Wei et al. (2018) were adopted to quantify void-based fabric, in terms of particle arrangement and local void distribution within the granular packing. Evolution of particle-void descriptors in accompany with the decrease of mean effective stress in cyclic liquefaction process is further explored for samples with different densities.

2 Methodology and Approach

2.1 Numerical Setups in DEM Simulation

Numerical simulations in this study are carried out in an open-source DEM platform YADE (Smilauer et al. 2015), which has been widely used to perform DEM simulations. Granular packings in the simulation are generated in a 2D square box with the periodic boundaries in all directions. The packing consists of 4,000 frictional disks, with the radii ranges from 0.3 to 0.6 mm. The simplified Hertz-Mindlin model is employed to describe the contact behaviors between contacted particles (Yimsiri and Soga 2010; Wei and Wang 2020). In the contact model, the normal contact force is given by

where \({k}_{n}\) is the normal stiffness and \(\delta \) is the contact overlap. r is the equivalent radius determined by the radii of two contacted particles: \(r=\frac{{r}_{A}{r}_{B}}{{r}_{A}{+r}_{B}}\). E and \(\upnu \) are Young’s modulus and Poisson’s ratio of particles, respectively. In the DEM modellings, E = 67 GPa and \(\upnu =0.3\).

The tangential contact force is given by

where \({k}_{s}\) is the tangential stiffness, \({U}_{s}\) is the tangential displacement of the contact. The tangential contact force satisfies the Coulomb criterion that \({f}_{s}<\mu {f}_{n}\), and \(\mu \) is the frictional coefficient of particle. After generation of particles within a 2D square box, the packing is firstly subjected to an isotropically consolidation process to reach the confining stress \({p}_{0}=10\,\mathrm{kPa}.\mathrm{m}\). Figure 1(a) demonstrates the consolidated packing. In this process, packings with different void ratios can be obtained by assigning different frictional coefficient \(\upmu \) to particles. In the simulation, four samples with different void ratios (i.e. e = 0.206, 0.214, 0.222, 0.231) are prepared, in order to explore the influence of density to the evolution of fabric.

2.2 Quantification of Void-Based Fabric

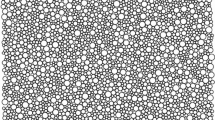

To quantitatively explore the void-based fabric in a granular packing, we follow the approach proposed by Wei et al. (2018). In the approach, the granular packing is firstly partitioned into microscopic particle-void cells using Voronoi tessellation. As shown in Fig. 2, each cell is polygonal shape and consists of one particle and its surrounding voids. Local void distribution in the cell is further described by the function \(r\left(\theta \right)\), which is defined as the ratio between the radial dimension of the cell and the particle:

Using Fourier descriptor analysis (Bowman et al. 2001), \(r\left(\theta \right)\) can be approximated by a concise expression with three parameters:

where \({A}_{r}\) is the enclosed area of\(r\left(\theta \right)\), such that \(\oint {r}^{2}\left(\theta \right)d\theta /2={A}_{r}\). \({e}_{d}\) is the shape factor of \(r\left(\theta \right)\) and it measures the shape elongation of local void distribution. \({\theta }_{d}\) measures the principal orientation of\(r\left(\theta \right)\). Figure 2 presents \(r\left(\theta \right)\) of particle-void cells with different magnitude of\({e}_{d}\), ranging from 0.01 to 0.30 (Wei and Zhang 2020). With the increase of\({e}_{d}\), the cell becomes elongated and local void distribution around the central particle is non-uniform. Furthermore, relative large pores can be observed besides the particle with a higher value of\({e}_{d}\).

\(r\left(\theta \right)\) of particle-void cells with different magnitude of \({e}_{d}\), ranging from 0.01 to 0.3 (from Wei and Zhang 2020).

In the approach, particle-void descriptors (denoted as \({E}_{d}\) and \({A}_{d}\)) are derived from statistical analysis of \({e}_{d}\) and \({\theta }_{d}\) to quantify void-based fabric of the whole packing. \({E}_{d}\) is defined as the mean value of \({e}_{d}\) of all cells, and it measures the shape elongation of the local void distribution throughout the packing. \({A}_{d}\) is defined to quantify the anisotropy degree of particle-void fabric. \({E}_{d}\) and \({A}_{d}\) have a strong correlation with cyclic mobility and jamming transition in post-liquefaction stage of granular soils (Wei et al. 2018).

Figure 3 presents the initial value of \({E}_{d}\) for samples with \({p}_{0}=10\,\mathrm{kPa}.\mathrm{m}\) before any shearing. A linear function can be employed to describe the relationship between \({E}_{d}\) and void ratio e:

where k is scale factor and T is intercept. The scale factor k is determined by particle size distribution of granular packing. In this study, the value of k is around 0.55.

3 Results and Observations

3.1 Cyclic Liquefaction

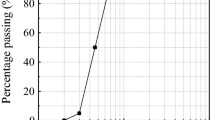

To explore the characteristics of particle-void fabric for granular packing with different confining stresses, all samples are subjected to the undrained cyclic loading tests, in which the volume of the packing is kept constant and the decrease of mean effective stress can be observed. Figure 4 demonstrates representative results from sample with e = 0.214 during the loading test with axial strain amplitude \({\varepsilon }_{a}=0.5\%\). The simulation results are qualitatively similar to laboratory results of medium-dense sands (Figueroa et al. 1994). With the increase of cycle number, both the amplitude of deviatoric stress q and mean effective stress p′ decrease. The loading is terminated when the packing reaches initial liquefaction, in which the mean effective stress p′ is close to zero and coordination number Z is lower than 2. As shown in Fig. 4(c) and (d), sample reaches the initial liquefaction after 25 loading cycles, as p′ decreases from initial value of 10 kPa·m to 10–3 kPa·m and Z decreases from initial value of 3.67 to 1.89.

Responses of sample with e = 0.214 during undrained cyclic loading test with axial strain amplitude \({\varepsilon }_{a}=0.5\%\). (a) Effective stress path; (b) Evolution of deviatoric stress q with axial strain \({\varepsilon }_{a}\); (c) Decrease of mean effective stress p′ with the increase of cycle number; (d) Evolution of Z with the decrease of p′.

We further check the evolution of particle-void descriptors \({E}_{d}\) and \({A}_{d}\) during the cyclic liquefaction process and the results are presented in Fig. 5. To get rid of the influence of shear-induced anisotropy, the data of \({E}_{d}\), \({A}_{d}\) and \(p\mathrm{^{\prime}}\) in Fig. 5 are picked at zero deviatoric stress state (i.e. q = 0) in each loading cycle. With the increase of cycle number, the value of \({A}_{d}\) remains at a relative low range during the whole loading process. It implies that the void-based fabric at zero deviatoric stress state can be regarded to be isotropic. On the other hand, \({E}_{d}\) decreases from the initial value of 0.114 to 0.102. Figure 5(b) demonstrates the evolution of \({E}_{d}\) versus p′ during cyclic liquefaction process. A positive correlation between \(p\mathrm{^{\prime}}\) and \({E}_{d}\) can be observed. Similar behaviors are also found in the monotonic loading tests (Wei and Zhang 2020).

3.2 Ed with P′

The evolution of \({E}_{d}\) in accompany with the decrease of p′ for samples with different particle size distributions and void ratios are presented in Fig. 6(a). For all samples, a positive correlation between \({E}_{d}\) and p′ can be observed, and the slope of the curve gradually increase with the decrease of p′. It is interesting to find that the curves for different samples are almost parallelled with each other. The results imply that the change of particle-void fabric during the entire cyclic liquefaction process may be irrelevant to void ratio of the sample. The insets of the figure further present \({\Delta E}_{d}\) for samples from consolidated state p′ = 10 kPa·m to initial liquefaction state. The value of \({\Delta E}_{d}\) for samples with different void ratios are close to each other, which is −0.0122.

Considering the linear relationship between \({E}_{d}\) and void ratio e at consolidated state with p′ = 10 kPa·m (refers to Eq. 7), the value of \({E}_{d}\) at initial liquefaction state (denoted as \({E}_{d,0}\)) is also linearly related with void ratio:

Note that \({E}_{d,0}\) can be regarded as the minimum value of \({E}_{d}\) for the packing in the pre-liquefaction stage. After initial liquefaction, \({E}_{d}\) will keep decreasing with continued cyclic loading (Wei et al. 2018).

The relationship between \({E}_{d}\) and p′ can be well fitted by a power function:

where a and b are fitting parameters. Combining the linear correlation between \({E}_{d,0}\) and e in Eq. (8), we can get the following equation to predict \({E}_{d}\) from p′ and e of the granular packing:

Figure 6(b) presents the curve fitting by Eq. (10). The parameters in the equation are summaries below: a = 2.44 × 10–3, b = 0.70, k = 0.548 and T0 = −0.015.

4 Conclusions

In summary, the relationship between void-based fabric and mean effective stress p′ during cyclic liquefaction process is explored by DEM simulations. Void-based fabric is quantified by particle-void descriptor \({E}_{d}\), which measures the uniformity of local void distribution around particles. Under the same confining pressure, a linear function can be employed to describe the positive correlation between \({E}_{d}\) and void ratio e. With the decrease of p′ during cyclic liquefaction process, the decrease of \({E}_{d}\) is observed for all samples with different void ratios. From consolidated state (p’ = 10 kPa·m) to initial liquefaction state, the change of \({E}_{d}\) is almost the same for samples with different void ratios, which implies that the change of void-based fabric during cyclic liquefaction process is irrelevant to density of the packing. A power function is further adopted to describe the negative correlation between \({E}_{d}\) and p′.

References

Bowman, E.T., Soga, K., Drummond, W.: Particle shape characterisation using Fourier descriptor analysis. Geotechnique 51(6), 545–554 (2001)

Christoffersen, J., Mehrabadi, M.M., Nemat-Nasser, S.: A micromechanical description of granular material behavior. J. Appl. Mech. 48(2), 339–344 (1981)

Figueroa, J.L., Saada, A.S., Liang, L., Dahisaria, N.M.: Evaluation of soil liquefaction by energy principles. J. Geotech. Eng. 120(9), 1554–1569 (1994)

Gu, X., Yang, J., Huang, M.: DEM simulations of the small strain stiffness of granular soils: effect of stress ratio. Granular Matter 15(3), 287–298 (2013)

Ghedia, R., O’Sullivan, C.: Quantifying void fabric using a scan-line approach. Comput. Geotech. 41, 1–12 (2012)

Huang, X., Kwok, C.-Y., Hanley, K.J., Zhang, Z.: DEM analysis of the onset of flow deformation of sands: linking monotonic and cyclic undrained behaviours. Acta Geotech. 13(5), 1061–1074 (2018). https://doi.org/10.1007/s11440-018-0664-3

Idriss, I., Boulanger, R.: Soil Liquefaction During Earthquakes. Earthquake Engineering Research Institute, Oakland, California (2008)

Li, X., Li, X.S.: Micro-macro quantification of the internal structure of granular materials. J. Eng. Mech. 135(7), 641–656 (2009)

O’Sullivan, C.: Particle-based Discrete Element Modeling: A Geomechanics Perspective. Taylor & Francis, Hoboken (2011)

Seguin, A.: Experimental study of some properties of the strong and weak force networks in a jammed granular medium. Granular Matter 22(2), 1–8 (2020). https://doi.org/10.1007/s10035-020-01015-z

Shamoto, Y., Zhang, J., Goto, S.: Mechanism of large post-liquefaction deformation in saturated sand. Soils Found. 37(2), 71–80 (1997)

Sitharam, T.G., Vinod, J.S., Ravishankar, B.V.: Post-liquefaction undrained monotonic behaviour of sands: experiments and DEM simulations. Géotechnique 59(9), 739–749 (2009)

Šmilauer, V., Catalano, E., Chareyre, B.: Yade Documentation, 2nd edn. The Yade Project (2015)

Vaid, Y., Stedman, J., Sivathayalan, S.: Confining stress and static shear effects in cyclic liquefaction. Can. Geotech. J. 38(3), 580–591 (2001)

Wang, G., Wei, J.: Microstructure evolution of granular soils in cyclic mobility and post-liquefaction process. Granular Matter 18(3), 1–13 (2016). https://doi.org/10.1007/s10035-016-0621-5

Wang, R., Fu, P., Zhang, J.-M., Dafalias, Y.F.: DEM study of fabric features governing undrained post-liquefaction shear deformation of sand. Acta Geotech. 11(6), 1321–1337 (2016). https://doi.org/10.1007/s11440-016-0499-8

Wei, J., Huang, D., Wang, G.: Microscale descriptors for particle-void distribution and jamming transition in pre-and post-liquefaction of granular soils. J. Eng. Mech. 144(8), 04018067 (2018)

Wei, J., Zhang, Y.: The relationship between contact-based and void-based fabrics of granular media. Comput. Geotech. 125, 103677 (2020)

Yang, J., Sze, H.: Cyclic behaviour and resistance of saturated sand under non-symmetrical loading conditions. Géotechnique 61(1), 59–73 (2011)

Yimsiri, S., Soga, K.: DEM analysis of soil fabric effects on behaviour of sand. Géotechnique 60(6), 483–495 (2010)

Zhang, J., Majmudar, T.S., Tordesillas, A., Behringer, R.P.: Statistical properties of a 2D granular material subjected to cyclic shear. Granular Matter 12(2), 159–172 (2010)

Acknowledgements

This research was supported by the National Natural Science Foundation of China (51908471). The financial supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Wei, J., Jiang, M., Zhang, Y. (2022). The Relationship Between Particle-Void Fabric and Pre-liquefaction Behaviors of Granular Soils. In: Wang, L., Zhang, JM., Wang, R. (eds) Proceedings of the 4th International Conference on Performance Based Design in Earthquake Geotechnical Engineering (Beijing 2022). PBD-IV 2022. Geotechnical, Geological and Earthquake Engineering, vol 52. Springer, Cham. https://doi.org/10.1007/978-3-031-11898-2_207

Download citation

DOI: https://doi.org/10.1007/978-3-031-11898-2_207

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-11897-5

Online ISBN: 978-3-031-11898-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)