Abstract

The present article studies the metrological characteristics of AMV-1006M NMR analyzers obtained during their calibration to determine the mass fraction of oleic acid in sunflower oil. Calibration is of great importance for obtaining repeatable and reproducible measurements of the quality indicators of agricultural raw materials using measuring instruments. Calibration can be carried out in different ways. In this case, the calibration procedure is performed using sunflower seeds and specially developed imitator reference materials (RMs) for the mass fraction of oleic acid in seed oil. The developed imitator RMs are characterized by high long-term stability of their physicochemical parameters and do not require special storage and operating conditions. The obtained data confirm the feasibility of using these imitator RMs for calibration purposes. In the calibration of analyzers, the random error limits of measurement results when using natural seeds exceeded those obtained with the use of imitator RMs by a factor of 3. Furthermore, the study of the temperature effect on calibration results indicates that the standard deviation of measurement results does not exceed 0.8 abs% for the imitator RMs, whereas the use of natural seeds yields 2.5 abs%.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Sunflower seeds

- Oleic acid mass fraction

- Nuclear magnetic relaxation

- Imitator reference materials

- Calibration

- Metrological support

Introduction

Stable development of present-day companies requires the introduction of control systems implementing feedback principles. Such systems improve the quality of end products and guarantee their consistent quality. According to regulatory documents [1], companies engaged in the fat-and-oil industry are to monitor oil and moisture content during sunflower seed harvesting, which directly affects oil yield, as well as storage and processing conditions. Furthermore, the emergence of new raw materials, specifically high-oleic sunflower seeds [2], has set a new challenge for companies to control oleic acid content in seed oil. Currently, this indicator is not regulated by state standards, so it is set by companies instead; the minimum baseline value varies from 78 to 85%, depending on the company’s requirements.

The mass fraction of oleic acid in sunflower oil is significantly influenced by species-specific characteristics, as well as by growing conditions for seeds [3,4,5]. In addition, deliberate seed adulteration is possible due to the higher cost of such raw materials. The above-mentioned factors necessitate companies to exercise prompt control over this indicator.

Presently, the chromatographic method is used as an umpire method to determine the mass fraction of oleic acid in sunflower oil [6, 7]. The disadvantages of this method include its poor performance, high labor intensity, high qualification requirements for staff, as well as the need for consumables. The listed disadvantages do not allow the chromatographic method to be used for prompt control over the mass fraction of oleic acid in sunflower oil.

Literary sources describe rapid methods using refractometry [8] and IR-spectroscopyFootnote 1 [9,10,11] that are difficult to implement at factory laboratories. In addition, these methods exhibit low representativeness, require a lot of time to implement and obtain calibration curves, as well as improve them in the process of operation, with the correlation coefficients not exceeding 85%.

Earlier, we developed an instrumental method for determining the mass fraction of oleic acid in sunflower oil [12] using the pulsed NMRFootnote 2 method. The advantages of this method consist in its rapidness (analysis time of one sample – below 1 min), simple sample preparation, high representativeness, and possible simultaneous determination of several indicators.

Procedures for calibrating analyzers are of great importance in ensuring high repeatability and reproducibility of measurement results via indirect instrumental methods. However, no universal calibration procedures are currently available for measuring instruments, with existing regulatory documents merely serving as guidelines. Moreover, measuring instruments comprise a considerable nomenclature.

An analysis of literary sources has shown that the following basic methods are used for calibrating quantitative analyzers in the fat-and-oil industry:

-

use of natural oilseeds [13, 14]. Since they comprise complex biological entities and their physicochemical parameters change during storage, an obvious disadvantage lies in their low long-term stability;

-

a type of calibration using natural materials that involves producing reference materials (RMs) from such natural components as grist and oil [15]. The advantage of such RMs over natural seeds consists in the possibility of obtaining repeatable characteristics, whereas their disadvantage lies in the fact that they require special storage conditions and are difficult to produce;

-

use of imitator RMs produced from chemically inert substances. They provide metrological characteristics within a given range, require no special storage conditions, and exhibit high long-term stability [16, 17].

For calibrating AMV-1006M NMR analyzers,Footnote 3 we developed a special imitator RM set for the mass fraction of oleic acid in sunflower oil [18].

The present article aims to study the influence of used materials on the calibration results of NMR analyzers when determining the mass fraction of oleic acid in sunflower oil. The obtained results will provide a practical justification for the effectiveness of imitator RMs in calibrating quantitative NMR analyzers.

Materials and Methods

The studies were carried out at the Central Experimental Base (CEB) of VNIIMK (Krasnodar) in 2017–2020. The sample preparation of sunflower seeds was conducted in accordance with GOST 8.597–2010 [19] used to determine the oil and moisture content of oil crops employing the pulsed NMR method [20]. The sample preparation procedure consisted in collecting a portion of sunflower seeds weighing (150 ± 5) g from the material under analysis, as well as 3-mm sieving the sample to remove foreign matter. Prior to performing measurements, each sample was checked for the presence of metal impurities. The prepared samples were stored in tightly closed containers at 23 °C. Oleic acid measurements were performed using a quantitative NMR analyzer AMV-1006M (VNIIMK, Krasnodar). This analyzer is used at most Russian and CIS fat-and-oil companies for promptly determining the oil and moisture content of oil crops and their products. The analyzer was upgraded to determine oleic acid content using special software [20].

The oil of sunflower seeds prepared for the study exhibited a mass fraction of oleic acid ranging from 31 to 86% (Table 1).

Oil was extracted from the prepared seed samples using a laboratory press. Then the resulting oil was filtered to remove impurities and dissolved in hexane, followed by the addition of a fresh solution of sodium ethoxide in methanol, having a concentration of 2 mol/dm3. After intensive stirring followed by settling, the resulting mixture was paper filtered [6].

The fatty acid composition of sunflower oil was determined using a Chromatec-Crystal 5000 chromatograph (JSC SDO Chromatec, Yoshkar-Ola). The instruction manual of the chromatograph was used to prepare the analyzer for operation and analyze the prepared methyl esters.

Imitator RMs for the mass fraction of oleic acid in sunflower oil were developed and patented at VNIIMK to simplify the process of calibrating quantitative AMV-1006M NMR analyzers [21]. These instruments comprise hermetically sealed ceramic ampoules filled with a mixture of organosilicon liquids that imitate different oleic acid contents. The weighted average of the proton spin–spin relaxation time of the used organosilicon liquids ranges from 100 to 200 ms. Table 2 presents the mass fractions of oleic acid in sunflower oil for imitator RMs.

The mass fractions of oleic acid in sunflower oil were certified for the developed imitator RMs using the upgraded AMV-1006M NMR analyzer. This unit is only hypothetically standard as the present procedure is currently being developed and has not been approved yet. The above analyzer was calibrated using natural sunflower seeds, whose mass fractions of oleic acid were determined in accordance with GOST 31,663–2012 Vegetable Oils and Animal Fats. Mass Fraction Determination of Fatty Acid Methyl Esters via Gas Chromatography [7]. According to the specified GOST, the repeatability of measurement results did not exceed 1 abs%. In order to reduce the random component of measurement error, the average mass fraction of oleic acid obtained in ten parallel measurements was used for each seed sample.

In most cases, fat-and-oil companies apply GOST 30,418–96 reducing the accuracy of results due to a greater error of up to 5 abs% [6].

The imitator RMs were used to calibrate the other NMR analyzers specified in the study. This study was conducted to show the advantages of these RMs for the calibration of other (hypothetically working) AMV-1006M NMR analyzers in order to ensure the reproducibility of calibration results, as well as the uniformity of further measurement results, for all working NMR-analyzers. Future certification of all imitator RM sets is expected to be conducted using a single unit (hypothetically standard unit).

When measuring nuclear magnetic relaxation characteristics, the material under analysis was thermostated at the required temperature for 2 h.

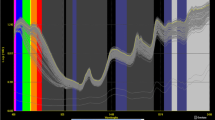

The calibration curve obtained using natural sunflower seed is shown in Fig. 1. The presented data indicate a linear relationship between the nuclear magnetic relaxation characteristics of oleic acid protons and oleic acid content in seed oil, with the correlation coefficient exceeding 0.991. Furthermore, this linear character is observed over the entire considered range of oleic acid content in sunflower oil.

The data obtained during the study were processed using the methods of mathematical and physical modeling, statistical processing, as well as interpolation and correlation analysis from the Mathcad. 8 (Professional) and Mathlab 5.1 Relaxsometr software package.

Results and Discussion

The first stage of the study produced the calibration repeatability results of one AMV-1006M NMR analyzer using imitator RMs and natural seeds. Table 3 shows the measurement results of imitator RMs and sunflower seeds having different certified values of oleic acid mass fraction; these measurements were replicated 12 times using the same NMR analyzer.

The relative standard deviations of the measurement results (\({S}_{\overline{x}}\)), as well as the confidence random error limits of the measurement results (ε), are almost three times lower for the measurement results obtained using the imitator RMs as compared to the use of sunflower seeds.

In order to check the reproducibility of calibration results obtained using the imitator RMs and sunflower seeds, the study employed four AMV-1006M NMR analyzers operating under the same conditions to eliminate the temperature effect on calibration results (Tables 4 and 5).

The prepared seed samples and the imitator RMs for the mass fraction of oleic acid were thermostatted at 23 ± 0.5 ℃ for 2 h prior to each calibration.

It follows from Tables 4 and 5 that the calibration results of NMR analyzers using the imitator RMs exceed those obtained using natural sunflower seed in terms of reproducibility almost by a factor of three.

Our studies indicate that the imitator RMs provide higher metrological characteristics of NMR-analyzer calibration as compared to the use of natural seeds as reference materials.

This factor is attributable to the homogeneous structure of imitator RMs formed in the process of their production. Sunflower seeds constitute a complex heterogeneous system, exhibiting structural heterogeneity even within a single sample under analysis.

In addition, a study of the temperature effect on the calibration results of NMR analyzers was carried out. This study was conducted in the operating room of the AMV-1006M NMR analyzer, where temperature varied within the range of 23 ± 1 ℃. This regime corresponded to ordinary conditions at factory laboratories using split systems. The analyzer was calibrated every 30 min for 12 h at actual room temperature measured using a digital thermometer (Fig. 2). The color of the marker indicates the type of used material: black – imitator RMs for the mass fraction of oleic acid, gray–natural sunflower seeds.

The presented data indicate that the nuclear magnetic relaxation characteristics of oil protons in seeds are affected by temperature to a greater extent than analogous characteristics exhibited by the protons of the imitator RMs for the mass fraction of oleic acid. The standard deviation of measurement results does not exceed 0.8 abs% for the imitator RMs, whereas the use of natural seeds yields 2.5 abs%. Such nature of the temperature effect is attributable to the fact that temperature has a smaller effect on the mobility of protons contained in imitator substances than in natural seeds.

Conclusion

The present study involved a metrological evaluation of materials used in the calibration of quantitative NMR analyzers of oleic acid mass fraction in sunflower oil in terms of their influence on calibration repeatability and reproducibility. A comparison was made between the use of natural sunflower seeds and imitator RMs for the mass fraction of oleic acid in sunflower oil developed by the present authors.

The study indicates that the imitator RMs for the mass fraction of oleic acid in sunflower oil can improve the repeatability and reproducibility of calibration results almost threefold. This enhancement is achieved due to the high homogeneity of these imitator RMs. Such homogeneity results from their production process, as well as from the used substances imitating nuclear magnetic relaxation characteristics.

The developed imitator RMs are less sensitive to temperature effects, as well as exhibiting higher stability of their physicochemical parameters and, hence, their certified values. An essential factor consists in the simplicity of using the imitator RMs as compared to natural seeds. The RM set was developed and patented to imitate oleic acid mass fraction in sunflower oil within the range of 31% to 93% [18].

Since the present work discusses only the calibration repeatability and reproducibility of quantitative NMR analyzers using imitator RMs and natural sunflower seeds, the next step is to examine the validity of measured oleic acid mass fractions in sunflower oil using the pulsed NMR method. These studies have been conducted from 2019 to the present day at Russian fat-and-oil companies: Uryupinsk and Sorochinsk Elevators, Bolsheglushitskoe HPP (Samara Region), Olsam LLC, and Pavlovskagroproduct JSC (Voronezh Region).

Notes

- 1.

IR-spectroscopy – Infrared spectroscopy.

- 2.

NMR – nuclear magnetic resonance.

- 3.

AMV-1006M NMR analyzers, Federal Information Fund for Ensuring the Uniformity of Measurements. Available at: https://fgis.gost.ru/fundmetrology/registry/4/items/325229.

References

GOST 22391–2015 (2020) Sunflower, Specifications. Standartinform, Moscow, 13p (In Russ)

Four types of sunflower oil. https://sunflowernsa.com/oil/Four-Types-of-Sunflower-Oil/

Fadul O (2012) Changes in oil fatty acid composition during seed development of sunflower. Asian J Plant Sci 11:241–245. https://doi.org/10.3923/ajps.2012.241.245

van der Merwe R, Labuschagne MT, Herselman L, Hugo A (2015) Effect of heat stress on seed yield components and oil composition in highand mid-oleic sunflower hybrids. S Afr J Plant Soil 32(3):121–128. https://doi.org/10.1080/02571862.2015.1018354

Akkaya M, Çil A, Yücel H, Kola O (2019) The influence of sowing dates on the oil content and fatty acid composition of standard, mid-oleic and high-oleic types of sunflower (Helianthus annuus L.). Food Sci Technol Int 39:448–453. https://doi.org/10.1590/fst.20118

GOST 30418–96 (2013) Vegetable oils. Method for determination of fatty acid content. Minsk, 7p (In Russ)

GOST 31663-2012 (2019) Vegetable oils and animal fats. Determination of methyl esters of fatty acids by gaz chromatography method. Standartinform, Moscow (In Russ)

GOST 28238–89 (2010) Sunflower. Method for determination of oleic acid mass fraction according to the oil refraction index. Standartinform, Moscow, 6p (In Russ)

Cantarel MA, Funes lG, Marchevsky EJ, Camiña JM (2009) Determination of oleic acid in sunflower seeds by infrared spectroscopy and multivariate calibration method. Talanta 80(2):489–492. https://doi.org/10.1016/j.talanta.2009.07.004

Efimenko SG, Efimenko SK (2018) Express-evaluation of oleic and linoleic fatty acids content in oil in milled sunflower kernels by means of IR-spectrometry. Oil Crops 176(4):58–63 (In Russ.)

Pérez-Vich B, Velasco L, Fernández-Martínez J (1998) Determination of seed oil content and fatty acid composition in sunflower through the analysis of intact seeds, husked seeds, meal and oil by near-infrared reflectance spectroscopy. J Am Oil Chem Soc 75(5):547–555. https://doi.org/10.1007/s11746-998-0064-1

Agafonov OS, Prudnikov SM, Zverev LV, Rusnak GV (2015) Application of the NMR method to determine the content of oleic acid in sunflower seed oil. In: Development of biological and post-genomic technologies for assessing the quality of agricultural raw materials and creating healthy food products: materials of the 18th international scientific and practical conference dedicated to the memory of V. M. Gorbachev. Moscow, pp. 24–27 (In Russ)

The minispec Oil content and moisture in seeds and nuts. http://spectrante.ru/images/pdf_series/Zernovie.pdf

SRM 10899–2017 Reference material of mass fraction of fat (oil content) in sunflower seeds (set). https://fgis.gost.ru/fundmetrology/registry/19/items/389300 (In Russ)

Kharchuk O, Kuznetsov E, Kirilov A, Geru I (2013) On the issue of standardization of determining the oil content in soybean seeds by NMR relaxation. In: Botnari V, Chișinău (eds) Biotehnologii avansate–realizări şi perspective: Simpozionul ştiinţific naţional cu participare internaţională. Republica Moldova, Tipografia Academiei de Ştiinţe a Moldovei, 48p (In Russ)

Prudnikov SM, Agafonov OS, Zverev LV, Vitiuk BI, Gorelikova IA (2001) Oil with the oleinic acid in sunflower seeds various weight fraction protons nuclear magnetic resonance free precession and spin echo signals simulator. Patent RF no 2001610425 (In Russ)

SRM 3107–84 Reference material of oil content and humidity of sunflower seeds (set). https://fgis.gost.ru/fundmetrology/registry/19/items/393823 (In Russ)

Agafonov OS, Prudnikov SM (2019) Development of simulator reference materials of oleic acid mass fraction in sunflower seed oil. Ref Mater 15(4):42–48. https://doi.org/10.20915/2077-1177-2019-15-4-41-48 (In Russ)

GOST 8.597–2010 (2011) State system for ensuring the uniformity of measurements. Oilseeds and oilseeds residues, determination of oil and moisture content using pulsed nuclear magnetic resonance spectrometry. Standartinform, Moscow (In Russ)

Prudnikov SM, Zverev LV, Dzhioev TE (2001) A system for receiving and processing signals from pulsed relaxometers of nuclear magnetic resonance. Certificate of official registration of the computer program no 2001610425. Moscow (In Russ)

Prudnikov SM, Agafonov OS, Zverev LV, Vitiuk BY, Gorelikova IA (2019) Simulator of a free procession of nuclear magnetic resonance and spin echo oil with a different mass fraction of oleic acid in sunflower seeds. Patent RF no. 2677644 (In Russ)

Author information

Authors and Affiliations

Contributions

Both authors have contributed equally to the preparation of this article.

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

Conflict of Interest

The article was prepared on the basis of a report presented at the IV International Scientific Conference “Reference Materials in Measurement and Technology” (St. Petersburg, December 1–3, 2020). The article was admitted for publication after the abstract was revised, the article was formalized and the review procedure was carried out.

The version in the Russian language is published in the journal “Measurement Standards. Reference Materials” 2021;17(1):47–57. https://doi.org/10.20915/2687-0886-2021-17-1-47-57.

Rights and permissions

Copyright information

© 2022 D. I. Mendeleyev Institute for Metrology

About this paper

Cite this paper

Agafonov, O.S., Prudnikov, S.M. (2022). Calibration of AMV-1006M NMR Analyzers Using Natural Seeds and Imitator Reference Materials. In: Medvedevskikh, S.V., Sobina, E.P., Kremleva, O.N., Okrepilov, M.V. (eds) Reference Materials in Measurement and Technology . RMMT 2020. Springer, Cham. https://doi.org/10.1007/978-3-031-06285-8_1

Download citation

DOI: https://doi.org/10.1007/978-3-031-06285-8_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-06284-1

Online ISBN: 978-3-031-06285-8

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)