Abstract

The fruit and vegetable sector generates large amounts of waste. This organic waste is mainly generated before consumption during agricultural production and distribution. In Tunisia, fruit and vegetable waste (FVW) started creating enormous waste disposal problems due to the negative effects of improper waste management. The disposal of these wastes in a municipal landfill site represents a loss of valuable biomass and also affects the overall economy of the country. Considering the high moisture and organic content of FVW, the anaerobic digestion can be an attractive option for energy generation as well as for reducing the disposal problem. In this context, the aim of this work was to study the anaerobic co-digestion of FVW and poultry manure. The objectives were to characterize substrates by chemical-fluorescence fractionation method, investigate the performance of FVW co-digestion in a hybrid solid batch bioreactor, and evaluate the fertilization characteristics of digestate. The determination of the methane potential of substrates during mono- and co-digestion tests showed a correlation between the biogas yield and the bio-accessibility as well as the complexity index of organic matter present in FVW. The co-digestion experiment conducted in a bi-phasic reactor with leachate recirculation showed the stability of anaerobic bio-systems and an improvement of biogas yield of (22.5%). The physicochemical characterization and the phytotoxicity test indicated the fertilizing quality of obtained digestate.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In Tunisia, fruits and vegetable waste (FVW) generation is significantly increasing and started creating enormous waste disposal problems. It posed environmental hazard due to its physicochemical characteristics and bad odors’ production. The current management system for FVW is landfilling which leads to the generation of greenhouse gases. As an integrated municipal solid waste (MSW) management system, anaerobic digestion (AD) technology is suggested for the treatment of highly biodegradable wet organic MSW. For example, FVW is considered as a suitable feedstock for AD due to its high biodegradability and water content. However, failure of AD of FVW is usually faced during fermentation with high TS%. Higher concentration of rapidly biodegradable materials can lead to the accumulation of VFAs that causing inhibition of methanogenic phase. Single-step AD can lead to process instability due to the rapid production and slow conversion of VFAs. These negative aspects can be reduced by the use of new reactor configuration with phase separation (solid–liquid). Bi-phasic reactor with leachate recirculation was demonstrated to enhance process stability and biogas production. This new configuration for solid waste treatment was proposed to solve the problems of accumulation of VFAs and to evaluate the state inside the reactor (Massaccesi et al. 2013). In this study, the improvement of methane potential of FVW was suggested by the co-digestion technology using poultry manure (PM) as co-substrate. The first part of this work aims to characterize substrates by physicochemical analyzes and by the combined method of fractionation-fluorescence. The second part consists in determining the methane potential of substrates. In the last part of the study, the suggested co-digestion method was performed in a hybrid reactor with recirculation of percolate, and the performance of the system was demonstrated.

2 Material and Methods

FVW and PM were collected, respectively, from an open market and a poultry farm, located in Sfax, Tunisia. The organic fraction consisting of fruits and vegetables waste was sorted manually and grinded using a MINERVA OMEGA Groul brand chopper. The anaerobic inoculum was taken from a digester treating household waste (pH = 8.31; TSS = 2.59 g/l; VSS = 1.82 g/l). Biogas potential of substrates was determined by conducing BMP tests (Khoufi et al. 2015). Lab-scale mono- and co-digestion experiments were performed by using a hybrid solid batch bioreactor with percolation of leachate. The temperature of bioreactor was maintained around 37 ± 2 ℃ via recirculation of heat water. The bio-accessibility of organic matter of substrates was investigated using the integrated method of fractionation and 3D fluorescence (Jimenez et al. 2015).

Total solids (TS), volatile solids (VS), total suspended solids (TSS), pH, EC, ammonium nitrogen (TAN) were analyzed using standard methods. Soluble COD was determined as described by ALPA 2012. Total Kjeldahl nitrogen (TKN) was measured as described by Kjeldahl-N method. The quantification of volatile fatty acids (VFAs) was carried out by HPLC (Jimenez et al. 2015).

3 Results

3.1 Characterization of Substrates

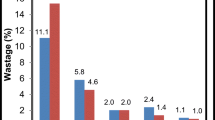

The obtained results show that the FVW is potentially rich in carbon with a high C/N ratio (126.8). However, low C/N ratio was noted for PM. A mixture of FVW and PM was prepared to obtain C/N = 28. Figure 1 gives the percentage of COD, TKN, and complexity index of each fraction (NEOM, PEOM, SEOM, REOM, SPOM).

3.2 Batch Anaerobic Fermentations

BMP tests gave biogas yields of 626.6 and 718.8 ml/g MV, respectively, for FVW and the mixture of FVW and PM. However, a low yield of about 445.01 ml/g MV was registered for PM. The lab-scale mono- and co-digestion carried out in the hybrid (two-phase) reactor was also investigated in batch mode. In comparison to mono-digestion, high biogas production and low VFA concentrations were observed during the co-digestion (Fig. 2).

4 Discussion

For FVW, the highest COD and TKN percentages are observed in the SPOM and SEOM fraction which means a high bio-accessibility of OM of this substrate (Fig. 1a). The 3D fluorescence spectrum indicates that SPOM is rich in biodegradable compounds (proteins, humic acids, and fulvic acids). The % TKN shows that the PM contains almost 75% of extractable nitrogen which can be accessible to microorganisms during biological treatment. However, a higher complexity factor (1.5) was obtained compared to the SPOM fraction of the FVW (0.48). Higher complexity factors have been recorded in the other extractable fraction (REOM, SEOM, PEOM, and NEOM) which shows the complexity of this substrate and consequently its low biodegradability. The improvement of biogas yield in the co-digestion assay is probably due to PM buffer. The results of BMP tests were confirmed at laboratory scale reactor. During mono-digestion, the accumulation of VFAs is an indicator of the inhibition of the biological system. This result clearly explains the cause of the shutdown of biogas production. However, an optimum biogas production was registered during the co-digestion experiment with high stability of reactor noted by the low concentration of VFA. From a technological point of view, the use of PM was considered as a more feasible solution to improve the conversion of many kinds of organic (Rahman et al. 2017) into biogas and reduced the process costs. The enhancement of methane potential of the mixture can be also explained by the correction of the C/N ratio of the substrate. In addition, the co-digestion has improved the fertilizing character of digestate.

5 Conclusion

The performance of co-digestion of FVW and PM was studied. PM was used as a nitrogen source to acquire a stable environment and a C/N ratio balance. The lab-scale experiment has shown an improvement in biogas yield by applying the co-digestion method. The biogas yield increased from 627 to 717.2 ml/g MV. The new configuration of reactor (hybrid reactor with recirculation of the leachate) seems to be a useful technology to monitor semi-dry anaerobic digestion.

References

Jimenez, J., Aemig, Q., Doussiet, N., Steyer, J.-P., Houot, S., Patureau, D.: A new organic matter fractionation methodology for organic wastes: bioaccessibility and complexity characterization for treatment optimization. Bioresour. Technol. 194, 344–353 (Oct 2015). https://doi.org/10.1016/j.biortech.2015.07.037

Khoufi, S., Louhichi, A., Sayadi, S.: Optimization of anaerobic co-digestion of olive mill wastewater and liquid poultry manure in batch condition and semi-continuous jet-loop reactor. Bioresour. Technol. 182, 67–74. (April 2015). https://doi.org/10.1016/j.biortech.2015.01.092

Massaccesi, L., et al.: Chemical characterisation of percolate and digestate during the hybrid solid anaerobic digestion batch process. Process Biochem. 48(9), 1361–1367 (Sept 2013). https://doi.org/10.1016/j.procbio.2013.06.026

Rahman, M.A., Møller, H.B., Saha, C.K., Alam, M.M., Wahid, R., Feng, L.: Optimal ratio for anaerobic co-digestion of poultry droppings and lignocellulosic-rich substrates for enhanced biogas production. Energy Sustain. Dev. 39, 59–66 (août 2017). https://doi.org/10.1016/j.esd.2017.04.004

Acknowledgements

The authors thank the European Union for the financial support of the study under the ENI CBC Mediterranean Sean Basin Program (CEOMED_A_B.4.2_0058) and the financial support of Ministry of Higher Education and Scientific Research of Tunisia under the contract program of the Environmental Bioprocess Laboratory.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Gharsallah, N., Sayadi, S., Feki, F., Jimenez, J., Khoufi, S. (2022). Anaerobic Digestion Engineering Opportunities for Fruit and Vegetable Waste Management in the Water–Energy–Waste Nexus. In: Naddeo, V., Choo, KH., Ksibi, M. (eds) Water-Energy-Nexus in the Ecological Transition. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-031-00808-5_96

Download citation

DOI: https://doi.org/10.1007/978-3-031-00808-5_96

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-00807-8

Online ISBN: 978-3-031-00808-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)