Abstract

In this study, some modelling and process control approaches used in Wastewater Treatment Plants (WWTP) are recalled. Two principal kinds of WWTP are used as frameworks: continuous anaerobic and aerobic. The highly nonlinear nature of the system models representing such processes is highlighted. In addition, parametric uncertainties that characterize them, and disturbances to which they are subject and that affect their performance are also underlined. Thus, mention is made of how various modelling and process control techniques have been used to face such issues in different ways. Typical deterministic models proposed by the International Water Association (IWA) are recalled, but some useful simpler models and even knowledge-based ones, like neural networks and fuzzy approaches, are also mentioned for specific applications. Particular emphasis is placed on the main parameters and variables to be monitored and controlled in order to ensure the optimal performance of WWTP: In the case of anaerobic digestion, alkalinity, and in the case of aerobic processes oxygen transfer efficiency. Thus, unlike classical Proportional Integral Derivative (PID) controllers, two kinds of nonlinear control approaches, namely adaptive and predictive, which are robust against uncertainties, nonlinearities, and perturbations are cited as the most used in this kind of process. Finally, some implications are highlighted in terms of energy consumption and cost optimization, and how different control strategies in the frame of benchmarking are used to minimize their impact.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Automatic control

- Operating conditions

- Operational difficulties

- Process control

- Process optimization

- Wastewater treatment simulation

1 Introduction

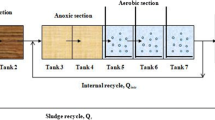

Wastewater Treatment Plants (WWTP) commonly involve a series of biological transformation processes that are usually very complex in terms of biochemical and biokinetics understanding [1], and therefore, also in terms of everything related to its modelling, optimization, and automatic control [2, 3]. The type of waste treated is mostly organic, including urban sewage and agricultural effluents with a multi-variety of organic compounds like carbohydrates, lipids, and proteins. These compounds are typically expressed as Chemical Oxygen Demand (COD) and are the main substrate for a wide variety of microorganisms working in a symbiotic relationship. WWTP may be classified into two large groups: Aerobic (in the presence of oxygen), and Anaerobic (in the absence of oxygen), although Anoxic units [4] (anaerobic, but oxygen is available from nitrates, nitrites, or NO) are also included in industrial and municipal WWTP. The most representative aerobic WWTP include Activated Sludge (AS) [2] and Aerated Lagoons [5], while Anaerobic Digestion (like Upflow Anaerobic Sludge Blanket (UASB) [6]) and Dark Fermentation [7] are among the most common anaerobic WWTP [8]. Other WWTP configurations also combine anaerobic and aerobic units [9]. In these processes, organic matter is degraded and converted into microbial biomass, residual organic matter, and eventually in biogas in the case of Anaerobic Digestion (AD) processes [10, 11], being this last the only biological WWT process capable of treating directly wastewater with an organic load higher than 15–20 gCOD/L [9]. In the following in this contribution, in order not to disperse the information too much, efforts will be concentrated mainly on AS and AD continuous processes.

Whether in industry, in the countryside, or in cities, WWTP technologies are undoubtedly indispensable elements to ensure the conditions of industrialization, urbanization, and sustainability of modern society. Thus, their good enough functioning is necessary to meet all kinds of required standards. However, talking about proper operation involves more than just periodic monitoring and maintenance. In reality, WWTP are subject to several disturbances and uncertainties that make difficult to meet such objectives. Effluents that reach the WWTP have a varying and changing composition affecting their physical, chemical, and physicochemical characteristics. Variations in flow, temperature, pH, organic compounds concentration and even the presence of inhibitors affect the biological performance of microbial communities, which are very sensitive to all these parameters, and therefore, also impact their efficiency. Changes in these parameters represent serious disturbances of different nature. The most typical example is seasonal abrupt flow rate step changes (e.g., in the rainy season), but important steps in all these parameters can also occur weekly or even daily simply by changes in environmental conditions and even by the effect of human activity. Most of these disturbances are difficult to foresee or are of a relatively high monitoring cost.

Taking into account these issues, it is clear that current WWTP operate under important uncertainty conditions from a process control point of view, which may cause serious problems in their industrial, agro-industrial or urban implementation. These features, together with the ecological norms requirements, make evident the importance to implement Instrumentation, Control, and Automation (ICA) systems in WWTP [3].

In order to show the benefits of the application of modern control approaches to WWTP, this paper is intended to present different approaches that have proved their usefulness in the modelling, parameter estimation, and regulation of WWTP. These approaches certainly have demonstrated to be robust against process input disturbances, and uncertainties, and have a strong potential for optimizing the performance of WWTP. Actual application examples and successful cases are also shown and demonstrate that they are a useful and efficient alternative that may be implemented at a relatively low cost.

2 Modelling

Modelling WWTP can become a difficult task mainly because their growth kinetics exhibit a highly nonlinear behavior [12], which in turn is due to the involved microbial consortia being among the most diverse ecosystems in nature [13]. An additional disadvantage is that the high complexity in the microbial populations leads also to high uncertainty in the kinetic parameters of current WWTP models.

Certainly, the attempt to adapt microbial communities to different operating conditions, and to the abovementioned disturbances makes them very changeable. The constant distribution of the different species in the consortium causes that their kinetic parameters are also uncertain and change over time. For these reasons, the first step to control and to optimize WWTP is to have models as closely as possible to reality in such a way that the sources of uncertainty are reduced, but at the same time, a relative simplicity is preserved to facilitate the application of control techniques.

Nowadays, one of the most complete and ambitious AD model is the ADM1 (Anaerobic Digestion Model) [14], while concerning AS, the most used models are the series ASM (Activated Sludge Model) [2]. Both models have been developed by the International Water Association (IWA). Several updates and reviews have been developed until now and still remain an active research field. For instance, in [15, 16] seven variants of the ASM series are exhaustively analyzed, verified and evaluated concerning aspects like stoichiometric and kinetic rate expressions, fermentation features, autotrophic and heterotrophic microbial growth, phosphorus removal, nitrification and denitrification, alkalinity, and others. Model parameter estimation and recalibration are also carried out frequently as in [17,18,19], where stochastic parameter estimation approaches together with Monte Carlo simulations and sensitivity analysis are used to fit ASM models to industrial actual data. Theoretical advances have been also further developed recently in [20].

Regarding AD, an additional issue in comparison to aerobic WWTP is its high sensibility to pH variations, and more exactly to alkalinity. Certainly, inlet concentration disturbances may affect partially or even completely the so-called System Operational Stability (SOS) [21, 22]. Such disturbances may compromise the physicochemical equilibrium that is directly related to the SOS preservation [23]. Furthermore, it is known that the presence of strong ions provokes a physicochemical unbalancing that affects directly microbial activity [24, 25]. Even when ADM1 consider anion-cation balancing, pH is not explicit in their equations [14, 26]. In this concern, some efforts have been developed for taking into account a more physicochemical framework [27, 28]. However, even with these modifications, the ADM1 model remains very large to be useful for control purposes, but it is still used rather for state variables estimation [29], experimental validation [30], and monitoring. Thus, in order to obtain greater applicability, reduced order AD models have been also proposed [31, 32]. Particularly, the so-called AM2 Model [33] has taken on great importance not only for being easier to handle from a mathematical point of view, but for taking into account specifically the strong ions concentration, which at pH 7 is very close to alkalinity [34, 35]. Without demerit of any other model described in the literature, and only for illustrating one of them in this contribution, AM2 model is depicted as follows [33]:

with

where \(x_1\) (g/L) and \(x_2\) (g/L) represent the acidogenic and methanogenic biomass concentrations respectively, \(S_1\) (g/L) is the organic matter concentration expressed as COD, and \(S_2\) (mmol/L) is the volatile fatty acids concentration. \(C\) (mmol/L) is the total inorganic carbon and \(Z\) (mEq/L) is the strong ions concentration. The superscript \(in\) represents “input concentration” for these variables. \(k_L\) (1/d) is the liquid–gas transfer coefficient, \(P_{CO_2 }\) is the CO2 partial pressure, while \(k_H\) is the Henry’s constant. \(\mu_1\) (1/d) (Monod type) and \(\mu_2\) (1/d) (Haldane type) are the microbial specific growth rates for acidogenic bacteria and methanogenic archea, respectively, where \({\mu }_{max1}\) and \({\mu }_{max2}\) (1/d) are the maximum growth rates, \({k}_{S1}\) (g/L), and \({k}_{S2}\) (mmol/L) represent the half saturation constants, while \({k}_{I}\) [(mmol/L)]1/2 represents the inhibition constant. The parameters \(k_1\) to \(k_5\) are yield coefficients in the corresponding units. \(D\) (1/d) is the dilution rate, which usually is used as manipulable control input in several control approaches. The parameter \(\alpha\) (dimensionless) denotes the biomass fraction that is retained for the reactor bed, i.e., \(\alpha = 0\) stands for an ideal fixed-bed reactor, while \(\alpha = 1\) stands for an ideal continuous stirred reactor tank [33].

This model has been also used for optimization, state and parameter estimation, and process control purposes (see for instance [36,37,38,39]), and for modeling the alkalinity spatial distribution in an up-flow fixed bed anaerobic digester [40].

3 Control and Optimisation

It is important to remark that the application of modern control approaches (i.e., those developed from the 60s) to WWTP is relatively recent. Control algorithms used in the past in the field of WWTP were basically on/off type, Proportional Integral (PI) or Proportional Integral Derivative (PID) [41]. However, this situation is changing very quickly. Even when classical control methods may offer satisfactory results in relatively simple systems, more recent approaches nowadays do take into account specifically the nonlinear features of biological WWT systems. For instance, adaptive control or predictive control, which are better adapted to face nonlinear behavior, are finding more and more applications in this field. Furthermore, as it has been mentioned before, the main “SOS” lack indicator in AD is alkalinity, because it involves all the physical–chemical equilibria, and therefore, several studies have been developed for regulating it [42].

One of the most typical control variables in WWTP is the COD, since its reduction is certainly the ultimate goal in these processes. However, due to the uncertainties and disturbances, to which treatment plants are exposed in terms of process inputs, it has become necessary to include control approaches being robust against such disturbances and lack of knowledge [22]. In [43], for example, interval observers have been included to estimate ranges of values in biomass concentrations, as these cannot be measured, and then they were combined with an adaptive control approach for regulating COD, also within a preset control interval. But, uncertainties in the growth kinetics of microbial populations in WWTP often lead researchers to propose different nonlinear type control techniques, see for instance [44, 45]. Moreover, some types of nonlinear tracking controls have been proposed. For instance in [46], an adaptive nonlinear tracking control was proposed for regulating the concentration of biomass in an AS-type WWTP based on the input flow, and thus, proportional to it, using a simplified model.

Furthermore, in particular in relation to aerobic processes such as AS-type WWTP, it is well known that in order to maintain adequate oxygen levels, the main parameter to be controlled is oxygen transfer efficiency, and therefore, the main unit operation is aeration. This demands high levels of energy consumption and other costs that need to be optimized [47,48,49]. Different adaptive and predictive control strategies have been proposed in the past for this purpose [50, 51]. In addition to COD reduction, and not less important, the removal of nitrogen and phosphorus from wastewater is also one of the main targets in WWTP [52]. Several classical and advanced control techniques proposed in this sense have been used and applied successfully [53]. However, as the efficiency of the operation is closely related to the aeration energy, which is a costly process, control objectives are compromised at the same time with concentration set-points and minimal use of energy, and thus, with cost reduction. For instance in [54], adaptive control techniques were used to improve the removal of these nutrients, while reduced the aeration energy required in three WWTP in Switzerland. Nevertheless, Model Predictive Control and other optimization approaches seem to be preferred [55, 56]. However, it is important to note that a common feature in many of the strategies used today, both for AS and AD WWTP is the use of benchmarking [57,58,59]. In such strategies, accumulated knowledge in monitoring, modeling, and control is used to provide a framework for assessing both well-known techniques to be industrially implemented and new approaches to evaluate its correct performance. Certainly, it is in the systematic current form more efficient to simulate WWTP and to take profit from models representing them.

Many modern applications include artificial networks as well lagged regression models, among other methods, that have been used for preventing indirectly the failure of the system due to alkalinity mismatches [60, 61]. These approaches has been also used in cases, when bioreactors have been stopped and then launched after a long time of starvation for bacterial communities in order to recover their correct functioning [62]. Fuzzy logic approaches have also seen a growing interest in the last three decades. For instance in [63], it is depicted how fuzzy logic based modules are used to assess the state of an up-flow fixed bed AD bioreactor, while in [64] similar approaches together with expert systems are proposed and experimentally validated as a methodology for assessing and improving the efficiency of agricultural biogas plants. Neural network and fuzzy approaches have been also used for optimizing energy consumption [65] and regulating the dissolved oxygen concentration [66] in AS processes. Finally, it is important to mention an important current trend in nonlinear control of WWTP, consisting of Sliding Mode approaches that have been used together with models both classical deterministic type [30], and those described by neural networks and fuzzy logic as well [67,68,69]. Finally, it is important to underline that modern control and optimization approaches are currently possible thanks to the existence of Supervisory Control and Data Acquisition (SCADA) systems that play a preponderant role in real-time ICA approaches implementation.

4 Conclusions

The use of Instrumentation Control and Automation (ICA) approaches in WWTP has allowed a greater development of these technologies for wide-scale implementation. The modeling, which is complemented and fed back with monitoring, as well as parameter and state estimation techniques have allowed for a greater understanding of the chemical, physicochemical and biological processes that are carried out in WWTP. The most widely disseminated models, e.g., the ADM1 models and the ASM series of the International Water Association (IWA), are of deterministic type, but models developed from other approaches such as neural networks and diffuse logic have also had extensive development.

As these models are highly nonlinear, the great majority of researchers have developed robust and nonlinear predictive adaptive control approaches. Such approaches allow capturing this nonlinear nature and admitting variations in kinetics and other parameters as well as in operating conditions, which make them robust in the face of these variations as well as in the face of uncertainties and disturbances. This paper has underlined the most important variables to consider in anaerobic and aerobic processes, being alkalinity and oxygen transfer efficiency, respectively, and examples of the main approaches developed for modeling and controlling such variables have been cited.

Advances made in these approaches and technologies over the last 3 decades have enabled good practice reference frameworks in modeling, monitoring, and control of WWTP, which have been validated in different scenarios and have given way to the development of benchmarking strategies that are widely used nowadays. Thus, the use of these techniques has allowed both biological technologies to remove contaminants increasingly efficiently as well as to achieve continuous optimization and improvement of WWTP.

References

Sari T, Wade MJ. Generalised approach to modelling a three-tiered microbial food-web. Math Biosci. Epub ahead of print 2017. https://doi.org/10.1016/j.mbs.2017.07.005.

Henze M, Gujer W, Mino T, et al. Activated sludge models ASM1, ASM2, ASM2d and ASM3. 1st ed. London: IWA Publishing; 2000.

Jimenez J, Latrille E, Harmand J, et al. Instrumentation and control of anaerobic digestion processes: a review and some research challenges. Rev Environ Sci Biotechnol. 2015;14:615–48.

Jetten MSM, Strous M, Van De Pas-Schoonen KT et al. The anaerobic oxidation of ammonium. FEMS Microbiol Rev. Epub ahead of print 1998. https://doi.org/10.1016/S0168-6445(98)00023-0.

Marais GR, Ekama GA, Wentzel MC. Application of the activated sludge model to aerated lagoons. Water SA. 2017;43:238–57.

Chong S, Sen TK, Kayaalp A, et al. The performance enhancements of upflow anaerobic sludge blanket (UASB) reactors for domestic sludge treatment—a state-of-the-art review. Water Res. 2012;46:3434–70.

Guo XM, Trably E, Latrille E et al Hydrogen production from agricultural waste by dark fermentation: a review. Int J Hydrogen Energy. Epub ahead of print 2010. https://doi.org/10.1016/j.ijhydene.2010.03.008.

Zhang R, El-Mashad HM, Hartman K et al. Characterization of food waste as feedstock for anaerobic digestion. Bioresour Technol. Epub ahead of print 2007. https://doi.org/10.1016/j.biortech.2006.02.039.

Chan YJ, Chong MF, Law CL et al. A review on anaerobic-aerobic treatment of industrial and municipal wastewater. Chem Eng J. 2009;1–18.

Holm-Nielsen JB, Al Seadi T, Oleskowicz-Popiel P. The future of anaerobic digestion and biogas utilization. Bioresour Technol. 2009;100:5478–84.

Mao C, Feng Y, Wang X, et al. Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev. Epub ahead of print 2015. https://doi.org/10.1016/j.rser.2015.02.032.

Donoso-Bravo A, Mailier J, Martin C, et al. Model selection, identification and validation in anaerobic digestion: a review. Water Res. 2011;45:5347–64.

Delbès C, Moletta R, Godon JJ. Bacterial and archaeal 16S rDNA and 16S rRNA dynamics during an acetate crisis in an anaerobic digestor ecosystem. FEMS Microbiol Ecol. 2001;35:19–26.

Batstone DJ, Keller J, Angelidaki I, et al. The IWA anaerobic digestion model no 1 (ADM1). Water Sci Technol. 2002;45:65–73.

Hauduc H, Rieger L, Takács I, et al. A systematic approach for model verification: application on seven published activated sludge models. Water Sci Technol. 2010;61:825–39.

Hauduc H, Rieger L, Oehmen A, et al. Critical review of activated sludge modeling: State of process knowledge, modeling concepts, and limitations. Biotechnol Bioeng. 2013;110:24–46.

Sin G, De Pauw DJW, Weijers S, et al. An efficient approach to automate the manual trial and error calibration of activated sludge models. Biotechnol Bioeng. 2008;100:516–28.

Keskitalo J, Leiviskä K. Application of evolutionary optimisers in data-based calibration of activated sludge models. Expert Syst Appl. 2012;39:6609–17.

Alikhani J, Takacs I, Al-Omari A, et al. Evaluation of the information content of long-term wastewater characteristics data in relation to activated sludge model parameters. Water Sci Technol. 2017;75:1370–89.

Fortela DLB, Farmer K, Zappi A et al. A methodology for global sensitivity analysis of activated sludge models: case study with activated sludge model no. 3 (ASM3). Water Environ Res. 2019;91:865–876.

Angelidaki I, Boe K, Ellegaard L. Effect of operating conditions and reactor configuration on efficiency of full-scale biogas plants. Water Sci Technol. 2005;52:189–94.

Méndez-Acosta HO, Palacios-Ruiz B, Alcaraz-González V, et al. A robust control scheme to improve the stability of anaerobic digestion processes. J Process Control. 2010;20:375–83.

Batstone DJ, Amerlinck Y, Ekama G, et al. Towards a generalized physicochemical framework. Water Sci Technol. 2012;66:1147–61.

Chen Y, Cheng JJ, Creamer KS. Inhibition of anaerobic digestion process: a review. Bioresour Technol. 2008;99:4044–64.

Chen S, Zhang J, Wang X. Effects of alkalinity sources on the stability of anaerobic digestion from food waste. Waste Manag Res. 2015;33:1033–40.

Patón M, González-Cabaleiro R, Rodríguez J. Activity corrections are required for accurate anaerobic digestion modelling. Water Sci Technol. 2018;77:2057–67.

Zhang Y, Piccard S, Zhou W. Improved ADM1 model for anaerobic digestion process considering physico-chemical reactions. Bioresour Technol. 2015;196:279–89.

Shi E, Li J, Leu SY, et al. Modeling the dynamic volatile fatty acids profiles with pH and hydraulic retention time in an anaerobic baffled reactor during the startup period. Bioresour Technol. 2016;222:49–58.

Montiel-Escobar JL, Alcaraz-González V, Méndez-Acosta HO et al. ADM1-based robust interval observer for anaerobic digestion processes. Clean Soil Air Water. 40. Epub ahead of print 2012. https://doi.org/10.1002/clen.201100718.

Torres Zúñiga I, Villa-Leyva A, Vargas A et al. Experimental validation of online monitoring and optimization strategies applied to a biohydrogen production dark fermenter. Chem Eng Sci. Epub ahead of print 2018. https://doi.org/10.1016/j.ces.2018.05.039.

Xue L, Li D, Xi Y. Nonlinear model predictive control of anaerobic digestion process based on reduced ADM1. In: 2015 10th Asian control conference emerging control techniques for a sustainable world, ASCC 2015. https://doi.org/10.1109/ASCC.2015.7244539.

Hassam S, Ficara E, Leva A et al. A generic and systematic procedure to derive a simplified model from the anaerobic digestion model no. 1 (ADM1). Biochem Eng J. 2015;99. https://doi.org/10.1016/j.bej.2015.03.007.

Bernard O, Hadj-Sadok Z, Dochain D, et al. Dynamical model development and parameter identification for an anaerobic wastewater treatment process. Biotechnol Bioeng. 2001;75:424–38.

Hassam S, Ficara E, Leva A et al. A generic and systematic procedure to derive a simplified model from the anaerobic digestion model no. 1 (ADM1). Biochem Eng J. 2015;99:193–203.

Attar S, Haugen FA. Model-based optimal recovery of methane production in an anaerobic digestion reactor. Model Identif Control. 2020;41:121–8.

Bernard O, Chachuat B, Hélias A, et al. An integrated system to remote monitor and control anaerobic wastewater treatment plants through the internet. Water Sci Technol. 2005;52:457–64.

Didi I, Dib H, Cherki B. A Luenberger-type observer for the AM2 model. J Process Control. 2015;32:117–26.

Rodríguez A, Quiroz G, Femat R, et al. An adaptive observer for operation monitoring of anaerobic digestion wastewater treatment. Chem Eng J. 2015;269:186–93.

Vargas A, Sepúlveda-Gálvez A, Barrios-Pérez JD. A fast extremum-seeking approach for the methanisation of organic waste in an anaerobic bioreactor. IFAC-PapersOnLine. 2019;52:269–74.

Hmissi M, Harmand J, Alcaraz-Gonzalez V et al. Evaluation of alkalinity spatial distribution in an up-flow fixed bed anaerobic digester. Water Sci Technol. 77. Epub ahead of print 2018. https://doi.org/10.2166/wst.2017.612.

García-Sandoval JP, Méndez-Acosta HO, González-Alvarez V et al. VFA robust control of an anaerobic digestion pilot plant: experimental implementation. IFAC-PapersOnLine. 49. Epub ahead of print 2016. https://doi.org/10.1016/j.ifacol.2016.07.328.

Alcaraz-González V, Fregoso-Sanchez FA, Mendez-Acosta HO, et al. Robust regulation of alkalinity in highly uncertain continuous anaerobic digestion processes. Clean: Soil, Air, Water. 2013;41:1157–64.

Alcaraz-González V, Harmand J, Rapaport A, et al. Robust interval-based regulation for anaerobic digestion processes. Water Sci Technol. 2005;52:449–56.

Méndez-Acosta HO, Palacios-Ruiz B, Alcaraz-González V, et al. Robust control of volatile fatty acids in anaerobic digestion processes. Ind Eng Chem Res. 2008;47:7715–20.

Flores-Estrella RA, Alcaraz-González V, García-Sandoval JP et al. Robust output disturbance rejection control for anaerobic digestion processes. J Process Control. 75. Epub ahead of print 2019. https://doi.org/10.1016/j.jprocont.2018.12.012.

Georgieva P, Ilchmann A. Adaptive λ-tracking control of activated sludge processes. Int J Control. 2001;74:1247–59.

Leu S-Y, Rosso D, Larson LE, et al. Real-time aeration efficiency monitoring in the activated sludge process and methods to reduce energy consumption and operating costs. Water Environ Res. 2009;81:2471–81.

Åmand L, Carlsson B. Optimal aeration control in a nitrifying activated sludge process. Water Res. 2012;46:2101–10.

Füreder K, Svardal K, Frey W, et al. Energy consumption of agitators in activated sludge tanks—actual state and optimization potential. Water Sci Technol. 2018;77:800–8.

Shen W, Chen X, Corriou JP. Application of model predictive control to the BSM1 benchmark of wastewater treatment process. Comput Chem Eng. 2008;32:2849–56.

Belchior CAC, Araújo RAM, Landeck JAC. Dissolved oxygen control of the activated sludge wastewater treatment process using stable adaptive fuzzy control. Comput Chem Eng. 2012;37:152–62.

Sedlak RI. Phosphorus and nitrogen removal from municipal wastewater. Principles and practice, 2nd ed. CRC Press, Taylor & Francis Group; 1991.

Stare A, Vrečko D, Hvala N, et al. Control of nutrient removing activated sludge system. IFAC Proc. 2007;40:61–6.

Rieger L, Takács I, Siegrist H. Improving nutrient removal while reducing energy use at three Swiss WWTPs using advanced control. Water Environ Res. 2012;84:170–88.

Steffens MA, Lant PA. Multivariable control of nutrient-removing activated sludge systems. Water Res. 1999;33:2864–78.

Zhang M, Peng Y, Wang C, et al. Optimization denitrifying phosphorus removal at different hydraulic retention times in a novel anaerobic anoxic oxic-biological contact oxidation process. Biochem Eng J. 2016;106:26–36.

Samuelsson P, Halvarsson B, Carlsson B. Cost-efficient operation of a denitrifying activated sludge process. Water Res. 2007;41:2325–32.

Chen W, Yao C, Lu X. Optimal design activated sludge process by means of multi-objective optimization: case study in benchmark simulation model 1 (BSM1). Water Sci Technol. 2014;69:2052–8.

Gernaey KV, Jeppsson U, Vanrolleghem PA et al. Benchmarking of control strategies for wastewater treatment plants IWA task group on benchmarking of control strategies for wastewater treatment plants.

Wang X, Bai X, Li Z, et al. Evaluation of artificial neural network models for online monitoring of alkalinity in anaerobic co-digestion system. Biochem Eng J. 2018;140:85–92.

Barampouti EMP, Mai ST, Vlyssides AG. Dynamic modeling of the ratio volatile fatty acids: bicarbonate alkalinity in a UASB reactor for potato processing wastewater treatment. Environ Monit Assess. 2005;110:121–8.

Holubar P, Zani L, Hager M, et al. Advanced controlling of anaerobic digestion by means of hierarchical neural networks. Water Res. 2002;36:2582–8.

Lardon L, Punal A, Steyer JP. On-line diagnosis and uncertainty management using evidence theory—experimental illustration to anaerobic digestion processes. J Process Control. 2004;14:747–63.

Djatkov D, Effenberger M, Martinov M. Method for assessing and improving the efficiency of agricultural biogas plants based on fuzzy logic and expert systems. Appl Energy. 2014;134:163–75.

Kusiak A, Wei X. Optimization of the activated sludge process. J Energy Eng. 2013;139:12–7.

Du X, Wang J, Jegatheesan V et al. Dissolved oxygen control in activated sludge process using a neural network-based adaptive PID algorithm. Appl Sci (Switzerland). 8. Epub ahead of print 2018. https://doi.org/10.3390/app8020261.

Jaramillo-Morán MA, Peguero-chamizo JC. Sliding mode control of a wastewater plant with. 2007;120–129.

Han H, Wu X, Qiao J. A self-organizing sliding-mode controller for wastewater treatment processes. IEEE Trans Control Syst Technol. 2019;27:1480–91.

Zlateva P. Sliding mode control of wastewater treatment process with activated sludge under extreme weather events. IOP Conf Ser Earth Environ Sci. 2021;776:012001.

Acknowledgements

This publication is an output of the global collaborative project “EXCEED—Swindon—Sustainable Water Management in Developing Countries”. The author highly acknowledge the support of German Academic Exchange Service DAAD for taking part.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Alcaraz-Gonzalez, V. (2022). Modelling and Control of Wastewater Treatment Processes: An Overview and Recent Trends. In: Bahadir, M., Haarstrick, A. (eds) Water and Wastewater Management. Water and Wastewater Management. Springer, Cham. https://doi.org/10.1007/978-3-030-95288-4_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-95288-4_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-95287-7

Online ISBN: 978-3-030-95288-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)