Abstract

Constructed wetlands (CWs) are non-conventional treatment methods that have continuously been developed into a secure wastewater treatment technology for domestic, agricultural and industrial wastewater as well as for runoff and leachate waters. These nature-based systems have some advantages in comparison to conventional wastewater treatment plants. Furthermore, CWs are of special interest when it comes to the reduction of climate change impacts. The main disadvantage of CWs is the comparatively high surface requirement. According to their properties, contaminants get removed via several physical, chemical and biological removal processes. Furthermore, CWs perform sufficient removal of emerging contaminants. CW types can be classified according to the vegetation type and the flow pattern within the wetland. In this paper, basic methods and information about CW design are given. Further, a substantial literature review on CWs used for river water treatment is conducted. Generally, satisfying removal efficiencies of standard parameters and emerging contaminants are reported, and many authors stated that water quality could be improved with feasible use of CW systems. Even though there is comparatively less maintenance required, the most important management activities are assumed. Finally, the case study of a pre-design FWS-CW for river water treatment is briefly described.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Ecological treatment

- Emerging organic contaminants

- Natural and constructed wetlands

- Nutrient removal

- Wetland types

1 Introduction

Sufficient wastewater treatment is important when it comes to hygienic and environmental aspects. Different systems were developed over time to clean up polluted water. Other than the conventional wastewater treatment methods, non-conventional systems have also been set up. A prominent example of non-conventional wastewater treatment methods are constructed wetlands (CWs). In comparison with conventional wastewater treatment systems, CWs generally convince due to their little environmental impact, strong adaptability [1], low sludge generation [2], and good self-purification capacity [3]. In addition, they provide ecosystem services and improve ecosystem health. As CWs are water treatment systems that require low-cost, low-maintenance and low-energy, they are of special interest for implementation in developing countries and rural areas [4]. Moreover, CWs are of special interest when it comes to the reduction of climate change impacts [5]. Due to water regulation, they are able to improve adaption to extreme weather conditions such as local floods and droughts [6], which are more likely to occur with ongoing climate change [7]. When it comes to floods, CWs function as water reservoirs and buffers [8, 9]. In case of droughts, which may lead to water shortage and thus affect water supply and agricultural yields [10], CWs can improve water security and access to water [6], as they can provide water for non-potable purposes such as irrigation. Reusing treated water saves valuable drinking water [10]. Furthermore, CWs capture carbon like natural wetlands, which store the main part of global soil carbon due to low decomposition rates in anaerobic soils [11, 12]. In the context of global warming, CWs have a positive effect on local climate parameters such as precipitation, temperature and humidity [13]. Vegetation in CWs perform evaporative landscape cooling [14], resulting into a decrease of the overall temperature in CWs for about 2 ℃ [15]. Many CWs have the ability to function as temperature buffer [14]. However, in contrast to conventional watewater treatment plants, CWs require a comparatively high surface. A minor disadvantage is that the choice of plant species is geographically limited. Even though it can be prevented by proper management, CWs may support the breeding of disease producing organisms and insects and may generate odours [16]. Furthermore, adjustment of certain conditions as oxygen concentrations is less precise than in conventional treatment systems.

This paper provides an overview about natural and constructed wetlands. Different ways of pollutant removal in CWs are described with particular focus on emerging contaminants. The categorization of the different CW types is further explained and the basic design parameters are demonstrated. The various range of use for CW systems is pointed out and highlights the utilization of CWs for river water treatment.

2 Natural Wetlands

Globally, 12.1 million km2 are covered by inland and coastal wetlands. Wetlands are defined as “areas of land where water covers the soil”. Almost 54% of the world’s wetlands are permanently flooded, while 46% are flooded seasonally. The water covering wetlands can have different properties such as static or flowing as well as fresh, brackish or saline. The term natural wetland includes rivers and streams, natural lakes, peatlands, marshes and swamps for inland wetlands, and estuaries, mangroves seagrass beds, coral reefs, coastal lagoons, kelp forests, coastal karst, and caves for coastal wetlands [11]. Wetlands are highly productive ecosystems that stand out due to their combination of terrestrial and aquatic habitats [17]. Therefore, they support a wide range of biodiversity and are habitat for water birds [17, 18]. Wetlands play a key role for migratory species, as they are used as feeding, breeding and stop-over grounds [17]. With a view to growth of adapted plants and the development of characteristic wetland soils are supported as a result of present water [19]. Typically, emergent aquatic vegetation such as cattails, rushes and reeds can be found in wetlands [16]. Furthermore, wetlands play an important role in the water cycle. Flows are regulated, water is received, stored and released [11], and groundwater gets recharged [17]. These regulatory properties can help protecting against extreme weather conditions such as floods and droughts [17, 20]. Additionally, wetlands serve many ecosystem services, which can be divided into cultural, provisioning and regulating services. Cultural services refer mainly to aesthetical and recreational aspects [20], while provisioning services enclose mainly resourcing of food and energy. Regulating services are mainly provided in the sense of carbon sequestration, water purification and water regulation [11].

3 Constructed Wetlands

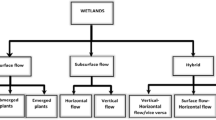

Constructed wetlands are defined by EPA as “engineered or constructed wetlands that utilize natural processes involving wetland vegetation, soils, and their associated microbial assemblages to assist, at least partially, in treating an effluent or other water source” [21]. The vegetation of CWs is similar to the one of natural wetlands and can be divided according to their growth behaviour referring to the water surface into the three main categories of submerged, emergent and floating plants (Fig. 10.1) [14]. Due to the ability of controlling and adjusting hydraulic parameters and conditions in a constructed wetland, the positive qualities of natural wetlands can be adopted and used in an effective way [16]. CWs offer a secure and sustainable opportunity to treat domestic, agricultural, and industrial wastewater as well as runoff and river waters [2, 22].

Classification of CW types according to flow pattern within the wetland and vegetation type [14]

3.1 Pollutant Removal by CWs

Contaminants get removed in CWs via several physical, chemical and biological removal processes according to their properties. Mechanisms that contribute to the removal of pollutants are microbial mediated processes, chemical networks, volatilization, sedimentation, sorption, photo degradation, plant uptake, vertical diffusion in soils and sediments, transpiration flux, seasonal cycles and accretion [14]. On average, wetlands can remove 60–95% of known pollutants from industry and households [23].

Physical removal mechanisms include sedimentation, filtration and adsorption, and take place mainly when water passes through substrate or root masses and in settings, where gravitational settling can take place. Adsorption occurs on substrate and plant surfaces [24], as cited in [16]. Additionally, volatile organic compounds like pesticides can be removed from the water by volatilization [23, 25].

Precipitation and chemical decomposition are the main processes of chemical removal. These are the main processes responsible for removal of nutrients as nitrogen and phosphorus as well as removal of heavy metals and pathogens. Decomposition happens as UV radiation, oxidation and reduction [24], as cited in [16]. Aerobic processes are supported by provision of oxygen through the root-system of the plants [26].

Removal due to biological processes can be categorized into bacterial and plant metabolism, plant adsorption, predation and natural die-off [25]. Plant metabolism and uptake removes refractory organics. Bacteria and viruses may be eliminated by toxic root excretions. Nutrients as nitrogen and phosphorus as well as heavy metals and refractory organics can be taken up by plants [24], as cited in [16]. Predation mainly refers to removal of total suspended solids and pathogens [24, 25]. Removal due to natural die-off is only relevant for pathogens [24], as cited in [16]. Nevertheless, bacterial metabolism is the main factor, when it comes to removal of biodegradable compounds such as colloidal solids, BOD5, nitrogen and refractory organics in CWs [16, 27].

In case of emerging contaminants, such as pesticides or pharmaceuticals, the removal efficiency depends on different factors. Often there is a various set of physical, chemical, and biological processes involved, which can be influenced by the CW design and the selected operational parameters [28]. Generally, oxygen concentration is shown to be one of key factors, since the best performance took place at of aerobic pathways [29]. According to Ding et al. [28] and Kadlec and Wallace [14], possible removal factors of antibiotics in livestock wastewater and pesticides in CWs are adsorption to soil particles and organic matter, sedimentation of particles, photo degradation, plant uptake, and biodegradation as well as physicochemical degradation. Especially “old” pesticides, such as DDT, are very persistent in the environment and partition to a relevant amount to particulate matter. In this case, CWs might rather act as a trap for the particulate matter than provide any very effective mechanisms for degradation. In contrast, modern pesticides degrade faster, and studies have shown that CWs generally reduce concentrations of many of these compounds [14]. As mentioned before, the CW design parameters have a considerable influence on the removal of emerging contaminants. For example, vegetation, primary treatment, loading mode (e.g., batch mode) and specific surface area (m2/Person Equivalent) play an important role. However, a key parameter in the removal of emerging pollutants in CWs is the hydraulic retention time (HRT); the greater the HRT, the higher the removal efficiencies for most of the selected compounds. The HRT has especially an influence on the removal rate of hydrophobic compounds such as hormones [28].

The most relevant removal factors can be differentiated between the different types of emerging contaminants. Non-steroidal anti-inflammatory drugs (NSAID) such as Ibuprofen and Diclofenac, which are the most common drugs used in humans, are negatively charged at environmental pH. Due to that, the process of sorption was found to be negligible. Instead, their removal in CWs can mainly be explained by biodegradation next to photo degradation. Consequentially, oxygen is a key parameter affecting the removal rates next to water depth. For lipid regulator drugs and anti-epileptic agents such as Carbamazepine and Clofibric acid, HRT has the greatest influence on removal efficiencies [29]. Masi et al. [30] found up to 100% removal rates of oestrogens in hybrid systems. Removal mechanisms for these compounds in CWs are mainly associated with sorption by organic matter due to its high hydrophobicity, next to biofilm interaction [29, 30]. According to Matamoros and Bayona [29], removal of oestrogen could be improved by an increase in HRT, since it might increase the interaction time.

3.2 CW Types

The different CW types are divided into surface and subsurface flow CWs [22]. Surface flow CWs can further be grouped due to the vegetation type, while subsurface flow CWs can additionally be classified according to the flow direction into horizontal and vertical subsurface flow CWs (Fig. 10.1). These CW types can be joined with each other in hybrid systems in order to combine the particular advantages of each CW type [31]. In few cases, floating treatment wetlands are used [32].

3.2.1 Free Water Surface CWs

Free water surface CWs (FWS-CWs) are defined as “wetland systems, where the water surface is exposed” [33]. Typically, FWS-CWs are performed as shallow basins or channels with vegetated soil [16, 25]. Implementation for treatment of river water or channels can be operated as off-stream or on-stream system. Subsurface barriers like silty soils prevent seepage and keep water above the soil [6, 16]. The water to be treated flows in a horizontal pattern through the vegetation and top soil from an inlet to an outlet point (Fig. 10.2) [6, 25]. In very few cases, there is no effluent due to evapotranspiration and infiltration within the wetland [25]. Short circuiting is minimized by the shallow water depth, low flow velocity and the presence of plants [16]. FWS-CWs display the CW type that mimics the hydrologic regime of natural wetlands the most [25]. As this treatment system has its highest efficiency during warmer periods [23], FWS-CWs fit best for warm climates [31].

Cross section of a free water surface constructed wetland planted with reed [34]

FWS-CWs are distinguished by their process stability and ability to tolerate fluctuating water levels and nutrient loads. They perform effective treatment with e.g., high reduction of BOD5 and solids and moderate removal of pathogens [31]. Due to the passive treatment, mechanical and technical equipment as well as energy and skilled operator needs can be minimized [33]. Besides, the use of chemicals like coagulants is not needed. Additionally, FWS-CWs can be built with local materials [31] and are less expensive to construct than other CW types. Another advantage is that this wetland technology produces only small quantities of sludge [33]. Therefore, sludge treatment and disposal is not necessary. Furthermore, FWS-CWs stand out due to their possible multiple purpose use. FWS-CWs are flora and fauna habitats. Besides, they can be used as a park and for educational, aesthetical as well as for recreational purposes. Next to that the effluent might be reused e.g., for irrigation [25].

But, land requirements are high for FWS-CWs [25]. Therefore, this CW type is most cost effective in regions, where suitable areas are available for reasonable prices [33]. Next to that, starting time for FWS-CWs is long before they operate at full capacity. The created wetland area may promote mosquito breeding [31], and faecal coliforms are introduced into the area by birds and other wildlife. In contrast to renewable removal of biodegradable contaminants, pollutants like phosphorus and metals are bound in the wetland sediments and accumulate over time [33].

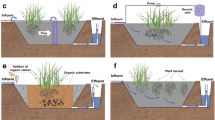

3.2.2 Horizontal Subsurface Flow CWs

A horizontal subsurface flow CW (HSSF-CW) consists of a filter bed, filled with gravel, sand or soil, and is planted with wetland vegetation (Fig. 10.3). From the inlet point, the water to be treated flows horizontally beneath the surface of the bed media passing plant roots and rhizomes to the outlet point [14]. This subsurface flow avoids mosquito problems as they might be found in FWS-CWs [7]. Furthermore, the risk of human or animal exposure to pathogenic organisms is minimized [14]. As the porous filter medium provides a greater contact surface for treatment processes, HSSF-CWs require less land compared to FWS-CWs [31].

Cross section of a horizontal subsurface flow constructed wetland planted with reed [34]

3.2.3 Vertical Subsurface Flow CWs

Vertical subsurface flow constructed Wetlands (VSSF-CWs) are typically sand or gravel beds, planted with wetland vegetation (Fig. 10.4) [14]. The water to be treated is intermittently applied across the surface of the filter medium and then percolates vertically through the root zone of the plants towards a drainage system at the bottom [35]. Due to the intermittently loading, the flow in VSSF-CWs is unsaturated, which leads to higher oxygen transfer to the filter medium compared to HSSF-CWs [32]. This set up results into smaller area requirement but higher construction and operation costs. VSSF-CWs start running quickly and operate better than FWS-CWs under cold weather conditions [36].

Cross section of a vertical subsurface flow constructed wetland planted with reed [34]

3.3 Constructed Wetlands Design

Before starting a calculation for CW design, the following general information should be determined according to Kadlec and Wallace [14]:

-

inlet concentrations and flows,

-

target concentrations (regulatory limits and allowable exceedance factors),

-

allowable inflow and seepage rates,

-

rain, evapotranspiration and temperature ranges for the project site,

-

wetland type (FWS or SSF).

The specific input data necessary for the calculative step of the CW design is shown in Table 10.1. The presented values are differentiated between suggested literature values and site-specific values.

The required area for the wetland system can be calculated in two ways. One option is to identify the area according to the maximum BOD5 loading rate (see Table 10.1). To do so, the BOD5 load of the influent needs to be put in relation to the maximum BOD5 loading rate receiving the minimum CW area required for water treatment:

where:

- \({{\mathrm{A}}_{{\mathrm{CW}}}} \):

-

\(\mathrm{minimum}\;\mathrm{CW}\;\mathrm{area}\;\left[ {\mathrm{ha}} \right]\)

- \({\mathrm{B}_{{{{\mathrm{BO}}{{\mathrm{D}}_5},\,}\mathrm{in}}}}\):

-

\({\mathrm{BO}}{{\mathrm{D}}_5}\;{\mathrm{load}}\;{\mathrm{of}}\;{\mathrm{influent}}\;\left[ {{\mathrm{kg/d}}} \right]\)

- \({{\mathrm{B}}_{{{{\mathrm{BO}}{{\mathrm{D}}_5}}},\,{\mathrm{max}}}}\):

-

\({\mathrm{maximum}}\;{\mathrm{BO}}{{\mathrm{D}}_5}\,{\mathrm{loading}}\;{\mathrm{rate}}\;\left[ {{\mathrm{kg}}/({\mathrm{ha}}*{\mathrm{d}}} \right)]\)

According to EPA [37], a safety factor should be applied for buffers and setbacks. Consequently, the resulting area is calculated by multiplication of the determined CW area with the safety factor.

In an additional step, the corresponding hydraulic parameters should be calculated in order to match them with suggested hydraulic parameters given in the literature. To do so, the hydraulic residence time (HRT), (Eq. 10.1), and the hydraulic loading rate (HLR), (Eq. 10.2) should be determined for the resulting area according to the following formulas [14]:

where:

- HRT:

-

hydraulic residence time [d]

- \({\mathrm{A}}_{\mathrm{CW},\mathrm{s}}\):

-

CW area including safety factor [m2]

- ε:

-

porosity [−]

- h:

-

water depth [m]

- \({\mathrm{Q}}_{\mathrm{ in}}\):

-

daily inflow [m3/d]

where:

- HLR:

-

hydraulic loading rate [m3/(ha * d)]

- \({\mathrm{Q}}_{\mathrm{ in}}\):

-

daily inflow [m3/d]

- \({\mathrm{A}}_{\mathrm{CW},\mathrm{s}}\):

-

CW area including safety factor [ha]

Alternatively, the area can be conducted according to the hydraulic loading rate e.g., in cases when the hydraulic parameters do not match with literature values after CW design according to BOD5 loading rate. To do so, an HLR suggested in the literature can be applied. Afterwards, the safety factor according to EPA [37] should be applied with reference to the minimum CW area (Eq. 10.3).

where:

- \({\mathrm{A}}_{\mathrm{CW}}\):

-

minimum CW area [ha]

- \({\mathrm{Q}}_{\mathrm{ in}}\):

-

daily inflow [m3/d]

Depending on the inlet water quality, a pre-treatment might be considered. The given calculations refer to the design of a single reactor. For better treatment performance, the “sequential model” approach should be used considering three different zones. Furthermore, when conducting the CW design more detailed, attention should be paid to implementation of the system in multiple parallel trains. In the best case, it should consist of three parallel trains in order to have the possibility to remove any single zone of one train from service and transfer its inflow to the same zone kind of a parallel train [37].

3.4 CWs for Wastewater and Leachate Treatment

Nowadays, CWs for municipal wastewater treatment are most often restricted to small communities due to their high land area requirements. Nevertheless, they provide a nature-based solution for wastewater treatment and are often used as “polishing” step after wastewater treatment in a conventional treatment plant. Generally, a pre-treatment with conventional processes is advised in order to avoid potential solids or oxygen demand overload. However, CWs may be used to perform all the functions of secondary treatment and higher [14].

CW systems might also be used for the treatment of industrial wastewater. Especially industries that produce wastewater, which is high in biodegradable organic and nitrogen content, such as potato, wine, olive oil, sugar, starch, alcohol, and meat processing industries, are potential users of CWs [14].

Using sanitary landfills for solid waste disposal entailsx the treatment and disposal of liquid leachates. Modern landfills are lined and thus enable the collection of leachate. The collected water can differ widely in chemical composition due to the various natures of solid waste, age differences as well as differences in decomposition and taken place reactions within the landfill [14]. However, studies have shown sufficient removal efficiencies of leachates with the help of CW systems [43].

3.5 CWs for River Water Treatment

CWs offer a secure and sustainable opportunity to treat raw domestic, agricultural and industrial wastewater. Next to that, they are used for effluent polishing as well as for treatment of runoff and river waters [2, 22]. A literature review on CWs used for river water treatment was conducted (Table 10.2). It revealed that mainly the free water surface type or hybrid systems are used. However, also horizontal subsurface flow CWs as well as vertical subsurface flow CWs were applied. Generally, satisfying removal efficiencies of standard parameters were reported, and many authors stated that the river water quality could be improved with feasible use of a CW system. Next to that, Zheng et al. [44] reached removal rates of approx. 20% for four phthalic acid esters (PAEs).

In CWs used for treatment of river water, free floating, emergent as well as submerged plants have been used. Phragmites australis and Typha latifolia were used most often [44,45,46,47,48,49,50,51,52,53]. In addition, Typha spp., Typha orientalis, Phragmites communis, Sparganium erectum, Juncus effuses, Carex elata, Chrysopogon, Lythrum salicaria L., Iris pseudacorus L., Salix integra and Dactylis glomerata were utilized in some of the studies. Planting densities differ from less than 5% of surface coverage [54] up to 90% surface coverage [55].

3.6 Wetland Operation, Maintenance and Management

One advantage of CW systems is that there is generally only infrequent operational control or maintenance required due to their design and construction. However, there are some activities that should be executed daily, such as the monitoring and adjustment of flows, water levels, inflow and outflow water quality, and biological parameters [14].

Especially for FWS-CWs, skilled operator needs can be minimized, since the systems experience minimal ecological changes due to the conservative design, passive treatment and simple mechanical controls [14, 33]. In contrast, maintenance of HSSF-CWs and VSSF-CWs is more problematic, since HSSF-CWs require regular bed maintenance throughout the lifetime of the system, and VSSF-CWs depend on loading-and-resting regimes to maintain hydraulic conductivity, unless lightly loaded. Operations and maintenance activities that need to be conducted less frequently are, e.g., the repair of pumps and water control structures, vegetation management, pest control and removal of accumulated mineral solids.

To enable maintenance, CWs require access facilities such as dikes and berms, which need maintenance and mowed [14].

4 Case Study “Oued Hamdoun” River

In many countries, rivers are the main sources of pollutant transport to the sea. On the one hand, this is a serious threat to the river and marine ecosystem. On the other hand, it might be a concern for public health and tourism development, in case the sea discharge is located close to beaches, as it is the case at the Hamdoun River. The Hamdoun River is located on the east coast of central Tunisia at the Gulf of Hammamet and in the south of the City of Sousse. The river water quality is affected by the discharge of five wastewater treatment plants, industrial wastewater, untreated wastewater, surface runoff and illegal disposed wastes along river side. During summer months, more than half of the river discharge has its origin in the discharge of the wastewater treatment plants [60]. Because of polluted river water, the beaches near the river mouth had to be closed for bathing in several years resulting into serious economic constraints [61]. A case study was carried out to pre-design a FWS-CW in order to clean up the river water. Since the estimated calculated hydrograph of Hamdoun River shows clear fluctuation over the year, the 85% percentile value of 375,645 m3/d was used according to ATV-DVWK [62] in analogy to the design of conventional WWTPs. Additional positive effects could be the possible reuse of the effluent water for irrigation and the establishment of a green area, which could also be used for educational purposes [63].

5 Conclusions

Because of their wide range of applications, constructed wetlands are very suitable for wastewater, river water and leachate treatment. They are also cost-effective and require hardly any energy. They show sufficient removal rates for standard pollution parameter as well as for emerging contaminants. Furthermore, in comparison with conventional wastewater treatment plants their little environmental impact, strong adaptability, low sludge generation and good self-purification capacity can be highlighted. In addition, CWs require low maintenance with generally mostly infrequent operational control requirements. One major disadvantage is the need for comparatively large land surfaces. The utilized vegetation in CWs is similar to the one of natural wetlands. Generally, pollutants get removed via several physical, chemical, and biological removal processes during their passage through the CW system. With regard to the removal of newly emerging pollutants, the oxygen input and thus the oxygen concentration is often a limiting factor.

CWs are often divided into different types according to their flow characteristics and can be combined to form so-called hybrid systems. FWS-CWs are characterised by their process stability and ability to tolerate fluctuating water levels and nutrient loads. This also leads to the fact that for FWS-CWs less maintenance is needed. But, FWS-CWs require more land. CWs that are used for sufficient river water treatment can be found frequently in China. Here, mostly FWS and hybrid systems are applied.

References

Yang Q, Wu Z, Liu L, Zhang F, Liang S. Treatment of oil wastewater and electricity generation by integrating constructed wetland with microbial fuel cell. Materials. 2016;9.

Gökalp Z, Karaman S, Taş I, Kirnak H. Constructed wetland technology to prevent water resources pollution. Curr Trends Nat Sci. 2016;5(9):125–32.

Liu S, Song H, Li X, Yang F. Power generation enhancement by utilizing plant photosynthate in microbial fuel cell coupled constructed wetland system. Int J Photoenergy. 2013.

Avellan CT, Ardakanian R, Gremillion P. The role of constructed wetlands for biomass production within the water-soil-waste nexus. Water Sci Technol. 2017;75(10):2237–45.

Small-Lorenz S. Wetlands do triple duty in a changing climate; 2014. [30.08.2019].

UNEP-DHI, UNEP-DTU, CTCN. Constructed wetlands for water treatment. Technology Compendium; 2017.

Hoffmann H, Platzer C, Winker M, Muench EV. Technology review of constructed wetlands—subsurface flow constructed wetlands for greywater and domestic wastewater treatment. Deutsche Gesellschaft für Int Zusammenarbeit (GIZ) GmbH; 2011.

Abrahams JC, Coupe SJ, Sañudo-Fontaneda LA, Schmutz U. The Brookside farm wetland ecosystem treatment (WET) system: a low-energy methodology for sewage purification, biomass production (Yield), flood resilience and biodiversity enhancement. Sustainability. 2017;9.

Meerburg BG, Vereijken PH, Visser WD, Verhagen J, Korevaar H, Querner EP, Blaeij ATD, Werf AVD. Surface water sanitation and biomass production in a large constructed wetland in the Netherlands. Wetlands Ecol Manage. 2010;18(4):463–70.

Qomariyah S, Ramelan AH, Setyono P, Sobriya. Linking climate change to water provision: greywater treatment by constructed wetlands. In: IOP conference series: earth and environmental science. 2018;129.

Gardner RC, Finlayson CM. Global wetland outlook: state of the world’s wetlands and their services to people, ed. Dudley N. Gland, Switzerland: Ramsar Convention Secretariat; 2018.

Kanungo P, Kumawat DM, Billore SK. Carbon sequestration potential of constructed wetlands used for wastewater treatment. Int J Appl Pure Sci Agric. 2017;3(4):38–44.

Gokalp Z, Karaman S. Critical design parameters for constructed wetlands natural wastewater treatment systems. Curr Trends Nat Sci. 2017;6(12):156–64.

Kadlec RH, Wallace SD. Treatment wetlands. 2nd ed. Taylor & Francis Group; 2009.

Panrare A, Sohsalam P, Tondee T. Constructed wetland for sewage treatment and thermal transfer reduction. Energy Proc. 2015;79:567–75.

Crites RW, Gunther DC, Kruzic AP, Pelz JD, Tchobanoglous G. Design manual—constructed wetlands and aquatic plant systems for municipal water treatment. United States Environmental Protection Agency, Hydrik Wetlands Consultants; 1998.

Ainsworth D, Hedlund J. Wetlands and ecosystem services, in world wetlands day—wetlands for our future, C.o.B. Diversity, Editor; 2015.

EPA. Why are wetlands important? 2018 [19.08.2019]. https://www.epa.gov/wetlands/why-are-wetlands-important.

EPA. What is a wetland? 2018 [19.08.2019]. https://www.epa.gov/wetlands/what-wetland.

UNEP-DHI, UNEP-DTU, CTCN. Natural wetlands. In Climate change adaptation technologies for water—a practitioner’s guide to adaptation technologies for increased water sector resilience; 2017.

EPA. Guiding principles for constructed treatment wetlands: providing for water quality and wildlife habitat, ed. O.a.W. Office of Wetlands. United States Environmental Protection Agency; 2000.

Vymazal J. Constructed wetlands for wastewater treatment. Water. 2010;2:530–49.

Tousignant E, Fankhauser O, Hurd S. Guidance manual for the design, construction and operations of constructed wetlands for rural applications in Ontario; 1999.

Hayes TD, Isaacson HR, Reddy KR, Chynoweth DP, Biljetina R. Water Hyacinth systems for water treatment. Aquatic plants for water treatment and resource recovery, ed. Reddy KR, Smith WH; 1987.

Gearheart R, Finney B, Lang M, Anderson J, Lagacé S. Free water surface wetlands for wastewater treatment: a technology assessment. Environmental Resources Engineering Department, CH2M-Hill, Wetland Management Services; 1999.

Healy MG, Newell J, Rodgers M. Harvesting effects on biomass and nutrient retention in Phragmites australis in a free-water surface constructed wetland in western Ireland. Biol Environ Proc R Irish Acad. 2007;107B(3):139–45.

Yang Z, Wang Q, Zhang J, Xie H, Feng S. Effect of plant harvesting on the performance of constructed wetlands during summer. Water. 2016;8(24).

Ding H, Ding Y, Bai S. Emerging organic contaminant removal in constructed wetlands. In 6th international conference on energy and environmental protection. Advances in engineering research, vol 143, pp 451–454. Atlantis Press; 2017.

Matamoros V, Bayona JM. Behavior of emerging pollutants in constructed wetlands. In: Hutzinger O, Barceló D, Kostianoy A (eds.) The handbook of environmental chemistry. Volume 5—Water pollution part s/2: emerging contaminants from industrial and municipal waste—removal technologies. Barceló D, Petrovic M (Volume Editors). Springer, Berlin, Heidelberg; 2008. pp. 199–217.

Masi F, Conte G, Lepri L, Martellini T, Bubba MD. Endocrine disrupting chemicals (EDCs) and pathogens removal in an hybrid CW system for a tourist facility wastewater treatment and reuse. ResearchGate; 2004.

EAWAG, B. Stauffer, Free-water surface CW, s.i.g. Swiss Federal Institute of Aquatic Science and Technology, Editor. Sustainable Sanitation and Water Management Toolbox; 2019.

Zhang DQ, Jinadasa KBSN, Gersberg RM, Liu Y, Ng WJ, Tan SK. Application of constructed wetlands for wastewater treatment in developing countries—a review of recent developments (2000–2013). J Environ Manage. 2014;141:116–31.

EPA, Wastewater technology fact sheet—free water surface wetlands. United States Environmental Protection Agency; 2000.

Blumberg-engineers. Constructed wetlands for wastewater treatment. 2021. https://www.blumberg-engineers.com/en/ecotechnologies/constructed-wetlands.

Eawag B Stauffer D Spuhler. Vertical Flow CW. 2019 [30.08.2019]. https://sswm.info/factsheet/vertical-flow-cw.

Maupin AJ Constructed wetlands. In Idaho water reuse conference. Idaho; 2011.

EPA. Constructed wetlands treatment of municipal wastewaters. In: Manual. U.S. Environmental Protection Agency; 1999.

Bendoricchio G, Cin LD, Persson J. Guidelines for free water surface wetland design. EcoSys. 2000;8:51–91.

Economopoulou MA, Tsihrintzis VA. Design methodology of free water surface constructed wetlands. Water Resour Manage. 2004;18:541–65.

Li X, Ding A, Zheng L, Anderson BC, Kong L, Wu A, Xing L. Relationship between design parameters and removal efficiency for constructed wetlands in China. Ecol Eng. 2018;123:135–40.

Rühmland S. Technische Feuchtgebiete zur Nachreinigung von Abwasser—Stickstoff, Abwasserdesinfektion, Spurenstoffe, in Fakultät VI—Planen Bauen Umwelt. Technischen Universität Berlin; 2015.

Novotny V, Ahern J, Brown P. Water centric sustainable communities: planning, retrofitting, and building the next urban environment; 2010.

Bakhshoodeh R, Alavi N, Oldham C, Santos RM, Babaei AA, Vymazal J, Paydary P. Constructed wetlands for landfill leachate treatment: a review. Ecol Eng. 2020;146.

Zheng L, Liu T, Xie E, Liu M, Ding A, Zhang B-T, Li X, Zhang D. Partition and fate of phthalate acid esters (PAEs) in a full-scale horizontal subsurface flow constructed wetland treating polluted river water. Water. 2020;12(3):865.

Chen ZM, Chen B, Zhou JB, Li Z, Zhou Y, Xi XR, Lin C, Chen GQ. A vertical subsurface-flow constructed wetland in Beijing. Commun Nonlinear Sci Numer Simul. 2008;13:1986–97.

Zheng Y, Wang X, Xiong J, Liu Y, Zhao Y. Hybrid constructed wetlands for highly polluted river water treatment and comparison of surface- and subsurface-flow cells. J Environ Sci. 2014;26(4):749–56.

Saeed T, Paul B, Afrin R, Al-Muyeed A, Sun G. Floating constructed wetland for the treatment of polluted river water: a pilot scale study on seasonal variation and shock load. Chem Eng J. 2016;287:62–73.

Kasak K, Kill K, Pärn J, Mander Ü. Efficiency of a newly established in-stream constructed wetland treating diffuse agricultural pollution. Ecol Eng. 2018;119:1–7.

Kill K, Pärn J, Lust R, Mander Ü, Kasak K. Treatment efficiency of diffuse agricultural pollution in a constructed wetland impacted by groundwater seepage. Water. 2018;10(11).

Stefani GD, Tocchetto D, Salvato M, Borin M. Performance of a floating treatment wetland for in-stream water amelioration in NE Italy. Hydrobiologia. 2011;674(1):157–67.

Wu H, Zhang J, Wei R, Liang S, Li C, Xie H. Nitrogen transformations and balance in constructed wetlands for slightly polluted river water treatment using different macrophytes. Environ Sci Pollut Res. 2013;20:443–51.

Bass KL. Evaluation of a small in-stream constructed wetland in North Carolina’s coastal plain. North Carolina State University; 2000.

Saeed T, Majed N, Khan T, Mallika H. Two-stage constructed wetland systems for polluted surface water treatment. J Environ Manage. 2019;249(109379).

Schulz R, Peall SKC. Effectiveness of a constructed wetland for retention of nonpoint-source pesticide pollution in the Lourens river catchment, South Africa. Environ Sci Technol. 2001;35(2):422–6.

Juang DF, Chen PC. Treatment of polluted river water by a new constructed wetland. Int J Environ Sci Technol. 2007;4(4):481–8.

Tang X, Huang S, Scholz M, Li J. Nutrient removal in pilot-scale constructed wetlands treating eutrophic river water: assessment of plants, intermittent artificial aeration and polyhedron hollow polypropylene Balls. Water Air Soil Pollut. 2009;197:61–73.

Zhao J, Zhu W, Lianfang Z. Efficiency and mechanism of treating the polluted river water with constructed wetland. J Lake Sci. 2007;19(1):32–8.

Huang Y-P, Kuo W-C, Lee C-H, Ting C-S, Hsieh H-H. River water quality improvement using a large-scale constructed wetland in southern Taiwan. Environ Eng Manag. 2007;17:277–81.

Bai X, Zhu X, Jiang H, Wang Z, He C, Sheng L, Zhuang J. Purification effect of sequential constructed wetland for the polluted water in urban river. Water. 2020;12(4):1054.

Domscheit E. Contribution to a pre-feasibility study of a constructed wetland system for the treatment of the Hamdoun river water, Tunisia. In Leichtweiß-Institut für Wasserbau, Technical University Braunschweig; 2019.

I2E. Inventaire et caracterisation des sources de pollution, in Etude de depollution de l'Oued Hamdoun (Gouvernorat de Sousse et de Monastir). Societe d'ingenerie de l'environnement et de l'énergie SA; Direction Générale de l'Environnement et de la Qaulité de la Vie. 2008. p. 148.

ATV-DVWK. Vereinheitlichung und Herleitung von Bemessungswerten für Abwasseranlagen. In ATV-DVWK-A 198. 2003.

Domscheit E. Contribution to a pre-feasibility study of a constructed wetland system for the treatment of the Hamdoun River water, Tunisia. In Water perspectives in emerging countries, water resources and climate change—impacts, mitigation and adaptation. Amman, Jordan: Cuvillier, Göttingen; 2019.

Acknowledgements

The author would like to thank DAAD and Exceed Swindon project. Thanks also to Prof. Dr. Müfit Bahadir for his valuable support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Domscheit, E. (2022). Near-Nature Wastewater Treatment Methods. In: Bahadir, M., Haarstrick, A. (eds) Water and Wastewater Management. Water and Wastewater Management. Springer, Cham. https://doi.org/10.1007/978-3-030-95288-4_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-95288-4_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-95287-7

Online ISBN: 978-3-030-95288-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)