Abstract

In this chapter, the sustainability, advanced exergy, and exergo-economic aspects of the biomass-assisted solar-based multi-generation plant for producing power load, heating load, cooling load, hydrogen, and freshwater are considered and investigated. To have more extensive knowledge of the recommended multi-generation plant operation, the examinations are undertaken to expand and to envision the simulations in Engineering Equation Solver software. The sustainability index of the plant has been estimated at 1.042. The advanced analyses of the multi-generation plant are examined under unavoidable, and ideal conditions. The advanced inquiries outcomes signify that in most elements, the destructed exergy has endogenous characters, and the parabolic trough solar collector, double-effect absorption chiller, and biomass combustor are holding the most potential to diminish destructed exergy. Additionally, advanced exergetic study shows that by changing the configuration variables of biomass combustor and turbine, 6240 and 4398 KW of these elements' destructed exergy can be avoided, sequentially. Trusted by the advanced exergo-economic investigation outcomes, the PEM electrolyzer holds the highest avoidable and endogenous cost rates and it is probable to avoid destruction near 33$/h internally. In conclusion, some recommendations for augmenting the performance of this multi-generation plant are made.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Advanced exergy analysis

- Multi-generation system

- Solar energy

- Hydrogen

- Desalination

- Advanced exergo-economic analysis

1 Introduction

Now an exergy study stands as a very powerful way for deciding the energy carriers' quality, and the intelligent management of energy conversion. This aforementioned investigation may be involved in every energy-conversion operation. Exergy theory can be applied to improve operations that use energy reserves efficiently [1, 2]. The exergo-economic study implies an exergy-based approach that recognizes the position, quantity, objects, and expenses of thermodynamic inabilities into an energy-conversion operation. The exergo-economic study is carried out at the element of an energy-transformation plant and exposes the inclusive cost-efficacy [3]. The intensities and conditions of the conventional exergy and exergo-economic analyses have previously been considered in other studies [4,5,6,7,8,9]. As can be understood in the earlier researches, alone conventional exergy/exergo-economic approach has been implemented to increase energy conversion in multi-generation plants [10, 11]. Nevertheless, conventional exergy/exero-economic examinations cannot expose inefficiencies of the plant elements and extra developments. The advanced exergy-based study, submitted by Tsatsaronis et al. [12,13,14], enables the communications between elements and the ability to repair them. By the advanced exergy-based study, the conventional destructed exergy is divided toward endogenous/exogenous and unavoidable/avoidable pieces. Throughout this kind of study, the exactness of the general exergy-based investigation can be updated and expedite the advancement of any energy-conversion plants. Besides, advanced exergetic study has been implemented strongly in multiple multi-generation plants. Tan et al. [15] had investigated advanced exergetic aspects of the renewable-based system for producing district heating load. They probed a neighborhood heating plant by adopting an advanced exergetic approach toward recognizing the ability to repair and the ability for managing energy. Dai et al. [16] studied a complete assessment of advanced exergy and economic of a system for power generation. The outcomes revealed that the exergetic efficiency was increased by nearly 20% by the advanced exergy investigation. The cost of endogenous avoidable was comparatively receptive to the temperature of the heat reservoir. Ebrahimi et al. [17] carried advanced exergetic examination of a grid-connected system with compressed air energy storage. The advanced exergetic examination sequences showed that 76.4% of the destructed exergy was avoidable. In another inquiry [18] a unit of separation of the air by a carbon dioxide power system was reviewed by advanced exergo-economic investigation. The report pointed that the destroyed exergy and cost rates of investment held endogenous characters, and the arrangement of the system had an important influence on costs. Kabiri et al. [19] introduced a system based on solar energy to repower steam power plants and conducted the advanced exerg and advanced exergo-economic inquiries to discover the augmentation in cycle operation throughout the repowering. A hydrogen liquefaction process was analyzed by employing advanced exergetic and exergo-economic investigations by Ansarinasab et al. [20]. Considering avoidable endogenous destroyed exergy cost rates, heat exchangers must be controlled via alterations. In another research [21], for examining the organic Rankine cycle-based combined plant, diagnosing the specific communications between elements of the plant, and developing the validity of exergy and exergo-economic investigations, the advanced exergy method was practiced. Based on the model developed by Li et al. [22], advanced exergy inquiry was carried on the hydrogen and power generation plant. Dividing the destructed exergy into avoidable and unavoidable sections in the mentioned work, showed that the betterment in the auxiliary elements would be an adequate way for the plant operation enhancement. To assess the operation of a cogeneration plant integrated with a desalination unit, advanced exergy, and exergo-economic investigations were conducted by You et al. [23]. The advanced study outcomes revealed that the significant share of plant destructed exergy had internal characters. In another work, advanced exergy and advanced exergo-economic inquiries respecting unavoidable and avoidable destructed exergy and rates of cost were carried in the research designated by Moharamian et al. [24]. According to revealed outcomes of advanced exergetic inquiry conducted by Caglayan et al. [25], chemical reactions happening in the combustion chamber make an increment in endogenous destructed exergy rate. Moreover, the unavoidable destructed exergy rates of the combustion chamber were more than its avoidable destructed exergy rates. Colorado [26] conducted an advanced exergetic study on a single-stage absorption unit, working with a solution of lithium bromide/water. The total avoidable portion of the destructed exergy was calculated at 14.78%. Mohammadi et al. [27] estimated the possibility of improving a system operation by determining the advanced exergo-economic study. They showed that the results concerned by the conventional exergetic study were varied from those obtained by the advanced exergetic study. Galindo et al. [28] made advanced exergetic investigation on a bottoming organic Rankine cycle system. Based on the obtained results from the advanced study, 36.5% of destructed exergy could be reduced by improvement in expander and pump.

According to the above-elaborated publications, some other researchers employed advanced exergetic-based investigation and described the importance of this approach for various energy conversion plants. Nevertheless, facing the best of the authors' information, none of those previous publications concerned results for advanced exergy and advanced exergo-economic aspects for a biomass-assisted solar-based multi-generation plant with power, heating, cooling, hydrogen, and freshwater production purposes. This is the first time that advanced analyses of such a recommended multi-generation plant are conducted and in the following chapter, the divided destructed exergy plus the destructed exergy cost toward avoidable and unavoidable, endogenous and exogenous were evaluated as well as the multi-generation plant sustainability, which can satisfy the research gap in the aforementioned area. The next parts of this chapter are classified as follows: The description of the recommended multi-generation plant is addressed in Sect. 5.2. A conceptual description of the three different approaches for advanced studies, the supervising equations, and the hypothesis to develop the model are addressed in Sect. 5.3. By accurate plant simulation, the sustainability, advanced thermodynamic, and advanced thermo-economic aspects could be assessed, therefore, Sect. 5.4 gives numerical outcomes and associated discussions. The concluding points of this chapter are arranged in Sect. 5.5.

2 Description of the System

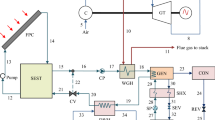

The arrangement of the recommended multi-generation plant has depicted in the following figure that is conceived up of parabolic trough solar collectors (PTC), biomass combustor (BC), steam Rankine cycle (SRC), double-effect absorption chiller (DEAC), proton exchange membrane (PEM) electrolyzer and multi-effect desalination (MED) unit. The main energy reservoir of this plant is solar power that is collected via PTC (state 1) and carries the heat of working fluid to the steam inside a single SRC. Under the BC unit, bagasse roles fuel-assisted, furthermore surplus air penetrated inside the bagasse combustor and fired. This process provides energy as an assisted fuel to fix the variation of periodic solar light. Under the SRC unit, the heat delivered by the BC unit provides superheated vapor (state 4) and generating electric power by the turbine (state 25). To accommodate the heating power of the plant, lost energy exodus from the turbine is utilized by HX1. Into the DEAC unit, via the heat of the exited steam from HX1, the refrigerant (water) is desorbed from the absorbent (lithium bromide). The water vapor catches in the low-temperature generator (LTG) and dense into the condenser to arrive at the cooling temperature. Consequently, the cooled water produces the cooling power inside evaporator2. The light water/lithium bromide solution moves in the high-temperature heat exchanger (HHX), low-temperature generator (LTG), and low-temperature heat exchanger (LHX), and the vapor originating from evaporator 2 is absorbed by the absorber. Heated exodus gasses of biomass burner insert HX2 (state10) to fulfill the demanded energy for the MED unit. Seawater penetrates the first effect of desalination (state12) and the preheater provides the distillation temperature of the feed water (state 23). Lastly, a share of produced power load by the plant and heated water (state 6) is used by the PEM electrolyzer to decay the water toward hydrogen (state 29) and oxygen (state 28) during an electrolysis reaction. Figure 5.1 is displayed the multi-generation plant layout.

3 Process Assessment and Performance of Criteria

In this section, the description of sustainability, advanced exergy, and exergy-economic concepts as a stalwart means to the extra evaluation of the plant and their related equations will be described. To explain the developed model and make sustainability, advanced thermodynamic, and thermo-economic examination available, some right hypotheses are presented [29]:

-

The temperature and pressure of ambient are T0 = 25 °C, P0 = 100 kPa.

-

The inlet pressure of the turbine (TIP) is assumed to be 6000 kPa.

-

The salinity of seawater is 40 g/kg.

-

The plant works in a steady-state condition.

-

This plant owns insignificant variations of kinetic, and potential energy, and exergy.

-

All pumps and the turbine have isentropic efficiencies.

-

Heat and pressure losses of piping and other auxiliary elements are insignificant.

Engineering Equation Solver (EES) software [30] as an applicable software is decided to make the developed modeling of the multi-generation plant. It should be noted that founded upon the first and second laws of thermodynamics, an in-depth conventional energy, exergy, exergo-economic, and exergo-environmental investigations and parametric study of the recommended multi-generation plant were presented in the previous work [29] and all obtained results from conventional analyses and input data are employed in the present work for the sustainability/advanced examinations of the plant.

3.1 Sustainability Index Analysis

Before handling the sustainability report, it could be important to know that sustainable development has been described in many styles, however, the common and generally applied description quotes to “a development that satisfies the requirements of the now without hazarding the capacity of coming generations to satisfy their own demands” [31]. Actuality, sustainability evaluation holds an indication of sustainable development [32] that highlights the effective application of energy origins with the minimum energy loss. On the other hand, sustainability, and exergetic study are deeply associated with each other that aid to determine the sustainability criterion as below [33, 34]:

Here \(D_{plant}\) is a number of depletion, which is described as:

\(E_{D,tot}\) is the plant's total destructed exergy and \(E_{in,tot}\) is the total input exergy of the whole multi-generation plant.

3.2 Advanced Exergy Method

An advanced exergetic approach signifies an inherent method for extra appraising energy-conversion process and operation such as studying the rate of the destructed exergy below deeper circumstances wherever the general exergy study requires. Toward an advanced exergetic study, the rate of the destructed exergy of all elements has been classified into two subdivisions: The prime piece evaluates the irreversibility of the element itself so-called endogenous rate of destructed exergy (\(\dot{E}_{D,k}^{EN}\)). The second is the exogenous rate of destructed exergy (\(\dot{E}_{D,k}^{EX}\)) that exposes the irreversibilities that stay in the care of other elements. Unavoidable rate of destructed exergy (\(\dot{E}_{D,k}^{UN}\)) involves mechanical, technical, and financial boundaries of each plant and the avoidable piece of the destructed exergy rate (\(\dot{E}_{D,k}^{AV}\)) could be described as the growth possibility or deficiency of each element. There are several different approaches for advanced studies like the thermodynamic cycle approach, the equivalent element approach, and the engineering approach [35]. The thermodynamic cycle approach remains relying on dividing the destructed exergy toward endogenous and exogenous sections considering the complete analysis of a thermodynamic cycle. In the equivalent element approach, the elements are drawn equivalent to each other, i.e., an ideal combustor is similar to a beau-ideal heat exchanger and amounts of the pressure and temperature in each state have been kept and the applied operating fluid through the system is alike. Applying different working fluids during inquiring about the real and the ideal operations is the chief problem of this approach. The engineering approach (also known as a graphical method) is applied to estimate endogenous exergy destruction by drawing a graph. For this purpose, Fig. 5.2 is illustrated based on the next equations:

Here \(\dot{E}_{F,tot}\), \(\dot{E}_{P,tot}\), and \(\dot{E}_{L,tot}\) are the total fuel exergy, product exergy, and exergy loss of the plant, individually. Considering the endogenous destructed exergy holds the element exergy efficiency function (\(\varepsilon_{k}\)), the exergy efficiency of each element is required to be retained consistently while \(\dot{E}_{D,others}\) is changing. While other elements of the system are close to the ideal performance, \(\dot{E}_{D,others}\) leads to 0, and their corresponding exergy yields progress to 100%. Direct lines happen since \(\dot{E}_{D,others}\) is diverse, as displayed in Fig. 5.2. This figure depicts the plant's total destructed exergy versus other elements' destructed exergy.

To study in this chapter, the thermodynamic cycle approach as the most common approach with believable accuracy has been adopted. A fundamental pattern for advanced study in this work is illuminated in Fig. 5.3.

Complete governing equations linked to advanced exergetic study are arranged in Table 5.1.

3.3 Advanced Exergo-Economic Method

The central opinion in the advanced exergo-economic study is to ascertain and link the parameters obtained from advanced exergy inquiry to economics. This method helps to make decisions on picking the most suitable procedure for decreasing total cost. In this study, cost rates linked to destructed exergy and the real possibility to economically enhance the operation are revealed within four divisions including their roots and capacity to evade: avoidable endogenous, avoidable exogenous, unavoidable endogenous, and unavoidable exogenous. Mentioned parameters aimed to understand the multi-generation plant behavior deeply. An unavoidable division of cost rates could not be evaded owing to technical and economical restrictions. The avoidable division of cost rates gives the ability to an element and whole multi-generation plant to increase efficiency. Avoidable endogenous division of element cost rates could be diminished by growing the thermodynamic efficiency of the element itself. Avoidable exogenous division of the element cost rates could be defeated by improving the efficiency of the other elements. The associated equations correspond to advanced exergo-economic study are given in Table 5.2.

Presumptions for ideal, and unavoidable conditions for the multi-generation plant elements are tabulated in Table 5.3.

3.4 Verification of the Developed Model

Facing the best of the authors' information, the recommended configuration of the biomass-assisted solar-driven multi-generation plant providing electricity, heating power, cooling power, hydrogen, plus freshwater is firstly investigated in the advanced study area, due to the loss of data recorded for the same whole plant, and considering that the results of the advanced exergetic-based study for each element are carried out according to its unavoidable conditions and the ideal conditions of other elements of the plant, therefore, it is not a scientific decision to validate advanced studies results for subsystems individually except in the same plant cases. Unlike the advanced studies, the results of conventional analyses are suitable to validate individually and had been verified in the previous work [29].

4 Results and Discussion

Antecedent to the advanced analyses, the sustainability index for the biomass-assisted solar-based multi-generation plant has been calculated at 1.042. Figure 5.4 accompanies the trend of sustainability index of the multi-generation plant by accretion of evaporator1 temperature difference, TIP, and the HTG quality. From Fig. 5.4a, it can be understood that by increasing the evaporator1 temperature difference, obeyed by the biomass combustor input temperature, SRC running by more working fluid and producing more valuable products. Therefore, the sustainability of the plant increases following the total destructed exergy of the plant diminished. As implies in Fig. 5.4b, by enhancing the TIP, the sustainability of the plant increases. More TIP needs a more mass flow rate of the operating fluid and consequences to an increment in the amounts of valuable outputs of the plant and points to a decrement in the total quantity of destructed exergy of the plant. Relating to Fig. 5.4c, by the change of HTG inlet quality from 0.2 to 0.9, the quantity of cooling power production diminished. Owing to this decrement, the amount of the total destructed exergy generated by the plant improved, and the sustainability index of the plant drops about 15%.

The consequences of the divisions of destructed exergy of the multi-generation plant elements by advanced exergy are tabulated in Table 5.4. It can be detected that the rate of the internal destructed exergy stands more powerful than the rate of the exogenous destructed exergy for all the plant elements. In other words, the largest destructed exergy has belonged to the internal inefficiencies of the plant element itself. The endogenous destructed exergy holds the prevailing place for all the plant elements and indicates weak interactive interdependencies between plant elements. The rate of the exogenous destructed exergy of parabolic trough solar collector is considerably higher than other elements in the plant. Hence, a change in the other element efficiencies can point to a decrease in the rate of the destructed exergy of this element and enhance the plant efficiency. To assess the real potential of advancement for each plant element, the destructed exergy is divided into avoidable and unavoidable pieces, as noted in the fourth and fifth columns in Table 5.4. The outcomes reveal the heat exchanger 1, proton exchange membrane electrolyzer, turbine, and pump have larger avoidable destructed exergy than the unavoidable. The unavoidable part of the destructed exergy of the biomass combustor is higher than the avoidable part, due to the irreversibility of the combustion process. Also, the greatest share of the internal rate of destructed exergy amount is related to the parabolic trough solar collector, and this is owing to the large temperature difference among the receivers and the operating fluid. The negative value for parabolic trough solar collector avoidable destructed exergy means that its unavoidable destructed exergy is greater than the real value. During applying the unavoidable conditions in the plant, following the increment in mass flow rate entering the parabolic trough solar collector, the difference among fuel and product exergies increases, and raises the destructed exergy. Negative values of exogenous, unavoidable exogenous, and avoidable exogenous destructed exergies for some elements mean that for the decrement in these element exergy destructions, it is necessary to increase the exergy efficiency of other components. According to Table 5.4, it can be stated that the double effect absorption chiller, biomass combustor, turbine, proton exchange membrane electrolyzer, and heat exchanger1 with the most avoidable destructed exergy values, respectively, have the powerful possibility for the plant thermodynamic operation improvement.

Figure 5.5a, b, c, d, e, f manifests the percentages of the endogenous/exogenous and avoidable/unavoidable destructed exergy for each subsystem of the plant.

According to the results achieved from advanced exergo-economic study and conforming to Table 5.5, all of the costs of destructed exergy in the elements comprise endogenously; Therefore, the destructed exergy cost cannot be affected by the element’s interplays remarkably. The trends of the cost rates of destructed exergy for the SRC, PEM, and DEAC subsystem are alike to the trend of the rates of destructed exergy and remain avoidable. The outcomes show that the PEM electrolyzer has higher endogenous rates of destructed exergy than the other components. It is clear that the destructed exergy cost rates for PTC, BC, and MED subsystems are zero, owing to the zero exergy costs per unit for plant fuels.

The internal/exogenous and avoidable/unavoidable share of the cost rate of destructed exergy for the subsystems of the multi-generation plant is designated in Fig. 5.6. Acknowledging that the advanced exergo-economic study is a great means to recognize the possibility of cost decrement owing to inefficiencies inside the multi-generation plant, it can be understood, the subsystem that offers a vaster chance to a decrease of costs of the destructed exergy is the PEM electrolyzer followed by the DEAC and the SRC. In the case of the PEM electrolyzer, it is probable to avoid destruction near 33 $/h internally by cooperating with the other multi-generation plant elements. In the case of non-cooperating by other elements, the destructed exergy cost of 720 $/h can continue avoided and the cost of 324 $/h cannot be avoided.

Figure 5.7 displays the whole plant exergy division cost rates to endogenous, exogenous, avoidable, and unavoidable. As can be detected in this figure, the significantly destructed exergy cost rates of the plant have endogenous and avoidable character.

5 Conclusions

In this chapter, the biomass-assisted solar-based multi-generation plant considering power, heating, cooling, hydrogen, and freshwater production was modeled in the EES software environment to accomplish sustainability, advanced exergetic, and advanced exergo-economic analyses. According to the obtained results, the concluding points are as follows:

-

1.

The sustainability index of the plant has been estimated at 1.042. Matching to the outcomes acquired of the sensitivity assessment, the trends of sustainability index of the multi-generation plant by accretion of evaporator1 temperature difference, and TIP are ascending, and by the increment of HTG quality is descending.

-

2.

Based on the advanced exergetic study the destructed exergy of most elements has endogenous characters and the PTC, DEAC, and BC are holding the most potentials to diminish destructed exergy. Additionally, advanced exergetic study shows that 6240 kW of destructed exergy inside the BC and 4298 kW of destructed exergy inside the turbine can continue avoided by changing the configuration variables of these elements.

-

3.

Trusting on the advanced exergo-economic investigation, amongst whole elements, the PEM electrolyzer holds the highest avoidable and internal rates of cost and it is probable to avoid destruction near 33$/h internally with cooperating with the other multi-generation plant elements. By non-cooperating with other elements, 34% of the cost of destructed exergy can continue avoided and 16% of the cost cannot be avoided.

To diagnose the individual cooperation between elements, to develop the exactness of the conventional exergetic investigations, and to better understand the thermodynamic irreversibility of the overall plant, the advanced study was employed. In this regard, The PTC has notable amounts of exogenous destructed exergy rates. Therefore, improvement in the other elements' efficiencies points to a decrease in the destructed exergy rate of PTC and makes an increase in the plant efficiency. DEAC has the most avoidable destructed exergy, therefore, has high potential and a significant role to improve the efficiency of the plant by increasing its performance. Also, it is important to mention that even technical improvement cannot prevent endogenous exergy destruction, completely.

Abbreviations

- ABS:

-

Absorber

- BC:

-

Biomass Combustor

- BPE:

-

Boiling Point Elevation

- c:

-

Exergy cost per unit, $/J

- \({\dot{C}} \) :

-

Rate of cost, $/s

- Cond:

-

Condenser

- DEAC:

-

Double Effect Absorption Chiller

- Eco:

-

Economizer

- Eva:

-

Evaporator

- \(\dot{E}\) :

-

Exergy rate, kW

- HX:

-

Heat exchanger

- multi:

-

Multi-generation

- P:

-

Pressure, kPa

- PEM:

-

Proton Exchange Membrane

- TIP:

-

Turbine Inlet Pressure

- PTC:

-

Parabolic Trough Collector

- SRC:

-

Steam Rankine Cycle

- T:

-

Temperature, K

- Turb:

-

Turbine

- X:

-

Steam quality

- \(\eta\) :

-

Efficiency

- \(\Delta\) :

-

Difference

- AV:

-

Avoidable

- EN:

-

Endogenous

- EX:

-

Exogenous

- UN:

-

Unavoidable

- 0:

-

Ambient condition

- D:

-

Destruction

- f:

-

Fuel

- L:

-

Loss

- p:

-

Product

- tot:

-

Total

References

J. Szargut, D.R. Morris, F.R. Steward, Exergy Analysis of Thermal, Chemical, and Metallurgical Processes (1987)

M.J. Moran et al., Principles of Engineering Thermodynamics. Wiley Global Education (2015)

A. Lazzaretto, G. Tsatsaronis, SPECO: a systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy 31(8–9), 1257–1289 (2006)

A. Noorpoor, D. Hamedi, N. Hashemian, Optimization of parabolic trough solar collectors integrated with two stage rankine cycle. J. Solar Energy Res. 2(2), 61–66 (2017)

S.M. Parsa et al., Energy-matrices, exergy, economic, environmental, exergoeconomic, enviroeconomic, and heat transfer (6E/HT) analysis of two passive/active solar still water desalination nearly 4000m: Altitude concept. J. Clean. Prod. 261, 121243 (2020)

A. Pirmohamadi et al., Exergoeconomic analysis of a novel hybrid system by integrating the kalina and heat pump cycles with a nitrogen closed brayton system. Energy Rep. 7, 546–564 (2021)

B. Ghorbani, M. Amidpour, Energy, exergy, and sensitivity analyses of a new integrated system for generation of liquid methanol, liquefied natural gas, and crude helium using organic Rankine cycle, and solar collectors. J. Thermal Anal. Calorimetry 1–24 (2021)

P. Heidarnejad, Exergy based optimization of a biomass and solar fuelled CCHP hybrid seawater desalination plant. J. Thermal Eng. 3(1), 1034–1043 (2017)

Y. Cao et al., A novel multi-objective spiral optimization algorithm for an innovative solar/biomass-based multi-generation energy system: 3E analyses, and optimization algorithms comparison. Energy Convers. Manag. 219, 112961 (2020)

N. Hashemian, A. Noorpoor, P. Heidarnejad, Thermodynamic diagnosis of a novel solar-biomass based multi-generation system including potable water and hydrogen production. Energy Equip. Syst. 7(1), 81–98 (2019)

A. Noorpoor et al., A thermodynamic model for exergetic performance and optimization of a solar and biomass-fuelled multigeneration system. Energy Equip. Syst. 4(2), 281–289 (2016)

T. Morosuk, G. Tsatsaronis, Advanced exergy analysis for chemically reacting systems–application to a simple open gas-turbine system. Int. J. Thermodyn. 12(3), 105–111 (2009)

T. Morosuk, G. Tsatsaronis, Advanced exergy-based methods used to understand and improve energy-conversion systems. Energy 169, 238–246 (2019)

F. Petrakopoulou et al., Advanced exergoeconomic analysis applied to a complex energy conversion system. J. Eng. Gas Turbines Power 134(3) (2012)

M. Tan, A. Keçebaş, Thermodynamic and economic evaluations of a geothermal district heating system using advanced exergy-based methods. Energy Convers. Manage. 77, 504–513 (2014)

B. Dai et al., Evaluation of organic Rankine cycle by using hydrocarbons as working fluids: Advanced exergy and advanced exergoeconomic analyses. Energy Convers. Manag. 197, 111876 (2019)

M. Ebrahimi et al., Conventional and advanced exergy analysis of a grid connected underwater compressed air energy storage facility. Appl. Energy 242, 1198–1208 (2019)

M. Mehrpooya et al., Conventional and advanced exergoeconomic assessments of a new air separation unit integrated with a carbon dioxide electrical power cycle and a liquefied natural gas regasification unit. Energy Convers. Manage. 163, 151–168 (2018)

S. Kabiri et al., New procedure for optimal solar repowering of thermal power plants and integration with MSF desalination based on environmental friendliness and economic benefit. Energy Convers. Manag. 240, 114247 (2021)

H. Ansarinasab, M. Mehrpooya, A. Mohammadi, Advanced exergy and exergoeconomic analyses of a hydrogen liquefaction plant equipped with mixed refrigerant system. J. Clean. Prod. 144, 248–259 (2017)

G. Liao et al., Advanced exergy analysis for organic rankine cycle-based layout to recover waste heat of flue gas. Appl. Energy 266, 114891 (2020)

L. Li, et al., Conventional and advanced exergy analyses of a vehicular proton exchange membrane fuel cell power system. Energy 222, 119939 (2021)

H. You, J. Han, Y. Liu, Conventional and advanced exergoeconomic assessments of a CCHP and MED system based on solid oxide fuel cell and micro gas turbine. Int. J. Hydrogen Energy 45(21), 12143–12160 (2020)

A. Moharamian et al., A comparative thermoeconomic evaluation of three biomass and biomass-natural gas fired combined cycles using organic Rankine cycles. J. Clean. Prod. 161, 524–544 (2017)

H. Caglayan, H. Caliskan, Advanced exergy analyses and optimization of a cogeneration system for ceramic industry by considering endogenous, exogenous, avoidable and unavoidable exergies under different environmental conditions. Renew. Sustain. Energy Rev. 140, 110730 (2021)

D. Colorado, Advanced exergy analysis applied to a single-stage heat transformer. Appl. Therm. Eng. 116, 584–596 (2017)

Z. Mohammadi, M. Fallah, S.S. Mahmoudi, Advanced exergy analysis of recompression supercritical CO2 cycle. Energy 178, 631–643 (2019)

J. Galindo et al., Advanced exergy analysis for a bottoming organic rankine cycle coupled to an internal combustion engine. Energy Convers. Manage. 126, 217–227 (2016)

N. Hashemian, A. Noorpoor, Assessment and multi-criteria optimization of a solar and biomass-based multi-generation system: Thermodynamic, exergoeconomic and exergoenvironmental aspects. Energy Convers. Manage. 195, 788–797 (2019)

S. Klein, Engineering Equation Solver (EES) V9, F-Chart Software. Madison, USA (2015)

H. Nami, A. Anvari-Moghaddam, Geothermal driven micro-CCHP for domestic application–Exergy, economic and sustainability analysis. Energy 207, 118195 (2020)

P. Ahmadi, I. Dincer, M.A. Rosen, Development and assessment of an integrated biomass-based multi-generation energy system. Energy 56, 155–166 (2013)

P. Ahmadi, I. Dincer, M.A. Rosen, Energy and exergy analyses of hydrogen production via solar-boosted ocean thermal energy conversion and PEM electrolysis. Int. J. Hydrogen Energy 38(4), 1795–1805 (2013)

P. Ahmadi, I. Dincer, M.A. Rosen, Exergo-environmental analysis of an integrated organic Rankine cycle for trigeneration. Energy Convers. Manage. 64, 447–453 (2012)

S. Kelly, G. Tsatsaronis, T. Morosuk, Advanced exergetic analysis: Approaches for splitting the exergy destruction into endogenous and exogenous parts. Energy 34(3), 384–391 (2009)

H. Nami, A. Nemati, F.J. Fard, Conventional and advanced exergy analyses of a geothermal driven dual fluid organic Rankine cycle (ORC). Appl. Therm. Eng. 122, 59–70 (2017)

F. Petrakopoulou, G. Tsatsaronis, T. Morosuk, Evaluation of a power plant with chemical looping combustion using an advanced exergoeconomic analysis. Sustain. Energy Technol. Assess. 3, 9–16 (2013)

A. Moharamian et al., Advanced exergy and advanced exergoeconomic analyses of biomass and natural gas fired combined cycles with hydrogen production. Appl. Therm. Eng. 134, 1–11 (2018)

H.V. Modabber, M.H.K. Manesh, Optimal exergetic, exergoeconomic and exergoenvironmental design of polygeneration system based on gas Turbine-Absorption Chiller-Solar parabolic trough collector units integrated with multi-effect desalination-thermal vapor compressor-reverse osmosis desalination systems. Renew. Energy 165, 533–552 (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Hashemian, N., Noorpoor, A., Amidpour, M. (2022). A Biomass Assisted Solar-Based Multi-generation Plant with Hydrogen and Freshwater Production: Sustainability, Advanced Exergy and Advanced Exergo-Economic Assessments. In: Amidpour, M., Ebadollahi, M., Jabari, F., Kolahi, MR., Ghaebi, H. (eds) Synergy Development in Renewables Assisted Multi-carrier Systems. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-030-90720-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-90720-4_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-90719-8

Online ISBN: 978-3-030-90720-4

eBook Packages: EnergyEnergy (R0)