Abstract

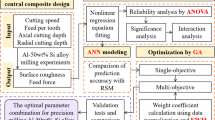

In this work, drilling experiments are performed on an aluminum alloy following the L27 orthogonal array of response surface methodology (RSM) to find out suitable drilling parameters to minimize burr height and thickness. Drilling is done using backup support. Two types of predictive models namely, artificial neural networks (ANN), and a combination of ANN with flower pollination algorithm (ANN-FPA) are constructed using the experimental data to predict burr height and burr thickness. The developed ANN-FPA predictive model is found to be more accurate than the only ANN model. Mathematical model of burr height and burr thickness are developed using this experimental input data and ANN-FPA based output data and it is optimized using Genetic Algorithm (GA) and RSM desirability function optimization techniques. Burr height observed is found minimum at a cutting velocity of 10 m/min, feed of 0.08 mm/rev, and depth of hole within backup support of 0.2 mm, whereas burr thickness is the lowest in this work at a cutting velocity of 3.9 m/min, a feed rate of 0.095 mm/rev and depth of hole inside backup support of 0.56 mm. The validation tests are performed at these optimized process conditions and the prediction error is found to be 6.53% using GA and 6.68% using RSM desirability function for measurement of burr height, and 4.70% using GA a well as RSM desirability function in burr thickness measurement. Finally, developed multi-objective functions of burr height and thickness are optimized through GA. These results are useful to implement in manufacturing practice.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Koelsch, J.: Divining edge quality by reading the burrs. Qual. Mag. 24–28, 343–348 (2001)

Gaitonde, V.N., Karnik, S.R., Achyutha, B.T.: Methodology of Taguchi optimization for multi-objective drilling problem to minimize burr size. Int. J. Adv. Manuf. Technol. 34, 1–8 (2006)

LaRoux, G.K.: Deburring precision miniature parts. Prec. Eng. 1, 189–198 (1979)

Prasanna, J., Karunamoorthy, L., Raman, V.M., Prashanth, S., Chordia, R.D.: Optimization of process parameters of small hole dry drilling in Ti-6Al-4V using Taguchi and grey relational analysis. Measurement 48, 346–354 (2014)

Pandey, R.K., Panda, K.K.: Multi-performance optimization of bone drilling using Taguchi method based on membership function. Measurement 59, 9–13 (2015)

Pandey, R.K., Panda, S.S.: Optimization of bone drilling parameters using grey-based fuzzy algorithm. Measurement 47, 386–392 (2014)

Mia, M.: Mathematical modeling and optimization of MQL assisted end milling characteristics based on RSM and Taguchi method. Measurement 121, 249–260 (2018)

Saha, P.P., Das, S.: Burr minimization in face milling: an edge beveling approach. Proc. IMech Eng. Part B: J. Eng. Manuf. 225, 1528–1534 (2011)

Kundu, S., Das, S., Partha, P.D.: Optimization of drilling parameters to minimize burr by providing back-up support on aluminium alloy. Procedia Eng. 97, 230–240 (2014)

Mondal, N., Sardar, B.S., Halder, R.N., Das, S.: Observation of drilling burr and finding out the condition for minimum burr formation. Int. J. Manuf. Eng. 2014, 1–12 (2014)

Dey, B., Mondal, N., Mondal, S.: Experimental study to minimize the burr formation in drilling process with artificial neural network analysis. IOP Conf. Ser. Mater. Sci. Eng. 377, 1–6 (2018)

Gaitonde, V.N., Karnik, S.R., Achyutha, B.T., Siddeswarappa, B.: Genetic algorithm-based burr size minimization in drilling of AISI 316L stainless steel. J. Mater. Process. Technol. 197, 225–236 (2008)

Mondal, N., Mandal, C.M., Dey, B., Das, S.: Genetic algorithm based drilling burr minimization using ANFIS and SVR. Proc. IMechE. Part B: J. Eng. Manuf. 221(12), 1–13 (2019)

Kilickap, E., Huseyinoglu, M., Yardimeden, A.: Optimization of drilling parameters on surface roughness in drilling of AISI 1045 using response surface methodology and genetic algorithm. Int. J. Adv. Manuf. Technol. 52(1–4), 79–88 (2011)

Warsi, S.S., Agha, M.H., Ahmad, R., Jaffery, S.H.I., Khan, M.: Sustainable turning using multi-objective optimization: a study of Al 6061 T6 at high cutting speeds. Int. J. Adv. Manuf. Technol. 100(1–4), 843–855 (2018). https://doi.org/10.1007/s00170-018-2759-2

Saidi, R., Fathallah, B.B., Mabrouki, T., Belhadi, S., Yallese, A.M.: Modelling and optimization of the turning parameters of cobalt alloy (Stellite 6) based on RSM and desirability function. Int. J. Adv. Manuf. Technol. 100(9–12), 2945–2968 (2019)

Shaomin, L., Deyuan, Z., Daxi, G., Zhenyu, S., Hui, T.: Modeling and drilling parameters optimization onburr height using harmony search algorithm in low-frequency vibration-assisted drilling. Int. J. Adv. Manuf. Technol. 101(9–12), 2313–2325 (2018)

Hassanpour, H., Sadeghi, H.M., Rezaei, H., Rasti, A.: Experimental study of cutting force, microhardness, surface roughness and burr size on micromilling of Ti6AL4V in minimum quantity lubrication. Mater. Manuf. Process. 31(13), 1654–1662 (2016)

Gupta, K.M., Sood, K.P., Sharma, S.V.: Machining parameters optimization of titanium alloy using response surface methodology and particle swarm optimization under minimum quantity lubrication environment. Mater. Manuf. Process. 31(13), 1671–1682 (2015)

Sen, B., Mia, M., Mandal, K.U., Mondal, P.S.: GEP-and ANN-based tool wear monitoring: a virtually sensing predictive platform for MQL-assisted milling of Inconel 690. Int. J. Adv. Manuf. Technol. 105(1–4), 395–410 (2019)

Meral, G., Sarikaya, M., Mia, M., Dilipak, H., Seker, U.: Optimization of hole quality produced by novel drill geometries using the Taguchi S/N approach. Int. J. Adv. Manuf. Technol. 101(1–4), 339–355 (2019)

Ghosh, G., Mandal, P., Mondal, S.C.: Modeling and optimization of surface roughness in keyway milling using ANN, genetic algorithm, and particle swarm optimization. Int. J. Adv. Manuf. Technol. 100(5–8), 1223–1242 (2017). https://doi.org/10.1007/s00170-017-1417-4

Kalita, K., Shivakoti, I., Ghadai, K.R.: Optimizing process parameters for laser beam micro-marking using a genetic algorithm and particle swarm optimization. Mater. Manuf. Process. 32, 1101–1108 (2017)

Nandi, K.A., Davim, P.J.: A study of drilling performances with minimum quantity of lubricant using fuzzy logic rules. Mechatronics 19, 218–232 (2009)

Min, S., Dornfed, D., Kim, J., Shyu, B.: Finite element modelling of burr formation in metal cutting. Mach. Sci. Technol. 5, 307–322 (2001)

Tandon, P., Khan, M.R.: Three dimensional modeling and finite element simulation of a generic end mill. Comput. Aided Des. 41, 106–114 (2009)

Zhang, Z., Babitsky, I.V.: Finite element modelling of a micro-drill and experiments on high speed ultrasonically assisted micro-drilling. J. Sound Vibrat. 330, 2124–2137 (2011)

Gaitonde, V.N., Karnik, S.R., Siddeswarappa, B., Achyutha, B.T.: Integrating Box-Behnken design with genetic algorithm to determine the optimal parametric combination for minimizing burr size in drilling of AISI 316L stainless steel. Int. J. Adv. Manuf. Technol. 37, 230–240 (2008)

Asadi, R., Yeganefar, A., Niknam, A.S.: Optimization and prediction of surface quality and cutting forces in the milling of the aluminium alloys using ANFIS and interval type 2 neuro fuzzy network couple with population-based meta-heuristic learning methods. Int. J. Adv. Manuf. Technol. 105, 2271–2287 (2019)

Gaitonde, V.N., Karnik, S.R.: Minimizing burr size in drilling using artificial neural network (ANN)-particle swarm optimization (PSO) approach. Int. J. Adv. Manuf. Technol. 23, 1783–1793 (2012)

Mondal, N., Mandal, S., Mandal, C.M.: FPA based optimization of drilling burr using regression analysis and ANN model. Measurement 152, 107327 (2020)

More, J.J.: The Levenberg-Marquardt algorithm: implementation and theory. Num. Anal. Lect. Notes Math. 630, 105–116 (1987)

Yang, X.-S.: Flower pollination algorithm for global optimization. In: Durand-Lose, J., Jonoska, N. (eds.) UCNC 2012. LNCS, vol. 7445, pp. 240–249. Springer, Heidelberg (2012). https://doi.org/10.1007/978-3-642-32894-7_27

Yang, X.S., Karamanoglu, M., He, X.S.: Flower pollination algorithm: a novel approach for multiobjective optimization. Eng. Optim. 46(9), 1222–1237 (2014)

Ghosh, A., Mandal, S., Nandi, G., Pal, P.K.: Metaheuristic based parametric optimization of TIG Welded joint. Trans. Indian Inst. Met. 2018, 1–11 (2018)

Hashmi, K.H., Zakria, G., Raza, M.B., Khalil, S.: Optimization of process parameters for high speed machining of Ti-6Al-4V using response surface methodology. Int. J. Adv. Manuf. Technol. 85(5–8), 1847–1856 (2015). https://doi.org/10.1007/s00170-015-8057-3

Padke, M.S.: Quality Engineering Using Robust Design. Prentice Hall, Englewood Cliffs (1989)

Acknowledgments

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. There is no conflict of interest related to this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Mondal, N., Mandal, S., Mandal, M.C., Das, S., Haldar, B. (2022). ANN-FPA Based Modelling and Optimization of Drilling Burrs Using RSM and GA. In: Batako, A., Burduk, A., Karyono, K., Chen, X., Wyczółkowski, R. (eds) Advances in Manufacturing Processes, Intelligent Methods and Systems in Production Engineering. GCMM 2021. Lecture Notes in Networks and Systems, vol 335. Springer, Cham. https://doi.org/10.1007/978-3-030-90532-3_15

Download citation

DOI: https://doi.org/10.1007/978-3-030-90532-3_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-90531-6

Online ISBN: 978-3-030-90532-3

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)