Abstract

This paper presents an experimental study on seismic retrofit of circular reinforced concrete (RC) columns with FRP composites. Three RC columns strengthened with Polythylene Naphthalate (i.e., PEN) FRP composite, which has a much larger rupture strain than conventional FRPs, were tested under combined axial loading and cyclic lateral loading. Three conventional CFRP-confined RC columns and one un-strengthened control column were also tested for comparison. The control column was found to fail due to the buckling of the longitudinal steel reinforcement and be of shortage of ductility, while the major role of FRP confinement in cases of slender circular RC columns is to prevent the spalling of concrete cover and the buckling of longitudinal reinforcement. Use of different FRP jackets and FRP stiffness had a marginal effect on the overall load-deformation responses particularly under a lower axial load ratio. Numerical simulations based on OpenSees, into which a cyclic stress-strain model for longitudinal reinforcement previously developed by the authors was implemented, were conducted to facilitate an in-depth understanding of the test results and the corresponding strengthening mechanisms. The cyclic stress-strain model takes into account the buckling effect of steel reinforcement and the lateral confinement effect of FRP jackets. Further parametric studies revealed that under a high axial load ratio (e.g., 0.4), the consideration of buckling of longitudinal reinforcement is of more significance.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

A new category of FRP composites were used as an alternative to conventional FRP composites for seismic retrofit of RC columns [1, 6]. These FRPs are made of thermoplastic polyester materials such as Polythylene Naphthalate (PEN) or Polyethylene Terephthalate (PET) fibers which possess a large rupture strain (LRS) (usually larger than 5%) but a relatively low elastic modulus. Compared to conventional FRPs (e.g., CFRP, GFRP, AFRP), these LRS FRPs are cheaper and more environmentally friendly because they are usually made from recycled materials (e.g., PET bottles). Therefore, the use of LRS FRPs is expected to lead to a more economical and ductile solution for seismic retrofit applications.

The authors’ group has conducted a series of study on the structural performance of LRS FRP-confined concrete/RC columns. Dai et al. [7] investigated the monotonic compressive behavior of LRS FRP-confined plain concrete cylinders through experiments and proposed an analysis-oriented model, which was a modified version of Jiang and Teng’s model [8], to represent the compressive stress-strain response. The model was further extended to a cyclic one [2] to describe the cyclic compressive behavior of LRS FRP-confined plain concrete columns. Bai et al. [3] also conducted experimental studies on LRS FRP-confined RC columns subjected to both monotonic and cyclic compressive axial loading. Based on the studies, a stress-strain model for reinforcing bars including buckling effects was proposed to present the restraining effects of LRS FRP jacket on the reinforcing bars in LRS FRP-confined RC columns [4, 5]. Anggawidjaja et al. [1] conducted a series of experiments to investigate the seismic behavior of LRS FRP-confined square RC columns subjected to combined constant axial load and cyclic lateral loading. It has been well established that the FRP confining mechanism in circular RC columns differs significantly from that in square/rectangular RC columns: i.e., the uniform confinement in the former is much more effective than the non-uniform confinement in the latter. As a consequence, the restraining effects of FRP jackets on the buckling of longitudinal reinforcing bars in LRS FRP-confined circular and rectangular columns may differ from each other.

This paper is therefore primarily concerned with the seismic behavior of LRS FRP-confined circular RC columns. A total of 7 specimens, 3 LRS FRP-confined RC columns, 3 CFRP-confined RC columns and one control specimen, were tested under combined constant axial load and cyclic lateral load. Numerical simulations based on the fiber element model were also conducted to reproduce the lateral load-lateral displacement responses of the test specimens and to perform parametric studies, based on which the effect of buckling of longitudinal reinforcing bars was discussed.

2 Experimental Program

In this study, a total of 7 specimens with the same geometry were constructed to represent the circular RC column of a regular bridge, with the bottom part imitating the footing. The specimens were flexure-dominated cantilevers with the height of 1250 mm to the loading point (i.e., shear span) and the cross section with a diameter of 238 mm (Fig. 1.a). The 7 specimens were divided into three groups: one control specimen without FRP retrofit, three specimens retrofitted with 1-ply CFRP, 2-ply CFRP, and 3-ply CFRP respectively, and three specimens strengthened with PET FRP of different layers (1-ply, 2-ply and 3-ply). All the column specimens were subjected to combined actions of a constant axial load (i.e., 400 kN) and reversed cyclic lateral load.

3 Test Results

Figure 2 shows the lateral load vs. displacement envelope curves of all test specimens. For the control specimen without any strengthening, the load decreased rapidly with the increase of the lateral displacement after the peak. Flexural cracks were widened and spread after the yielding of steel bars with the increase of lateral displacement. Small pieces of cover concrete began to spall off when the displacement reached approximately 6 δy. The cover concrete was removed after the test, and it was seen clearly that the longitudinal bar buckled within the plastic hinge zone of the column (Fig. 1c), as expected due to the wide spacing of transverse steel ties. One ply CFRP-confined RC columns failed when the lateral displacement reached 83.2 mm (8.3 δy), with a maximum of strain value 0.0062 in the CFRP jacket; 2-ply and 3-ply CFRP wrapped specimens, the tests were terminated until the rolling plate reached its maximum displacement range with a displacement value of 124 mm (approximately 12 δy). The maximum tensile strains of FRP jacket were 0.0070 and 0.0067 for 2-ply CFRP and 3-ply CFRP wrapped specimens respectively. Though the typical explosive rupture failure of FRP was not achieved in the test, the FRP jacket can be regarded as having almost ruptured because the above maximum values were very close to the typical FRP rupture strain 0.0075 [4]. Obvious horizontal cracks in the FRP jacket were observed by the end of the test. The reasons why the typical rupture of FRP jacket was not achieved are that the overall slenderness ratio of the column was relatively high (i.e., 5.25) and that the axial load ratio 0.2 was relatively low. For the three PEN-FRP confined specimen, the maximum strains were 0.0095, 0.0093 and 0.0090, respectively. These values are much lower than the rupture strain of PEN FRP (approximately 5.0%). Thus, the PEN FRP jackets were not fully utilized here, and the advantage of its large rupture strain capability compared to conventional CFRP was not well reflected in this particular test series. Nevertheless, the great displacement potential of LRS FRP-confined RC columns was confirmed and the residual strain capacity of LRS FRP would ensure the structural integrity of the columns even under a much larger deformation level.

4 Numerical Simulation

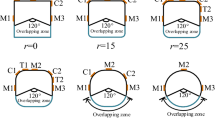

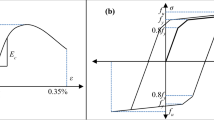

The “NonlinearBeamColumn” element available in OpenSees [9], which is a force-based nonlinear beam-column element and considers the spread of plasticity, was adopted in the present numerical simulations. Three Gauss-Lobatto integration points are defined along each element. In this study, two new cyclic stress-strain models for FRP-confined concrete [2] and laterally-supported reinforcing bar [5], respectively, were implemented into OpenSees to simulate the FRP confining effects and the behaviour of reinforcing bars. Details of the two models can be referred to the original papers. The numerical simulations were conducted with displacement control. The displacement amplitudes of each cycle in the test were input into the analysis program. The analyses were terminated when the final cycle predefined with the tested displacement amplitude was finished. Figure 3 shows that numerical simulations can give fairly close predictions for the test results. It should be noted that in the calculations, for all the six FRP-confined RC columns, the load-displacement curves, especially the descending part, can be well simulated without considering the buckling effects. This indicates that the buckling behaviour of reinforcing bars in this test was not significant, i.e., the buckling was well restrained in all the circular columns regardless of the stiffness of the FRP jackets used. Bai et al. [4] developed a theoretical method to determine the confining stiffness on the reinforcing bar based on the beam-on-elastic foundation (BOEF) model (Fig. 4) and proposed an empirical stress-strain model for the bar considering the buckling effects. However, Bai’s model was only validated for the evaluation of FRP jacket stiffness for the circular RC columns under concentric axial load; for the circular RC columns under combined axial and flexural loading, the reliability of the model is still not clear. In this study, the emphasis is placed on the effect of confining stiffness on the seismic behaviour of FRP-confined RC columns, thus a cyclic stress-strain model proposed by Bai et al. [5] was implemented in the OpenSees. based on Bai et al. [4], the spring stiffnesses provided by external FRP jacket are defined as 251, 405, 522, 120,189, and 250 N/mm per unit height for the test columns confined with 1-ply CFRP, 2-ply CFRP, 3-ply CFRP, 1-ply PEN FRP, 2-ply PEN FRP, 3-ply PEN FRP, respectively. It should be noted that according to Bai et al. [4], when the spring stiffness is beyond 250 N/mm per unit height, the buckling initiation strain tends to be larger than 8%, thus the bar buckling can be regarded to be fully suppressed by the confinement of FRP jacket, Fig. 5 shows the compressive stress-strain of longitudinal reinforcing bars predicted by the model of Bai et al. [4]. It can be seen that one ply of PEN FRP provides the lowest spring stiffness, i.e., 120 N/mm per unit height, and the longitudinal reinforcing bars tend to buckle at the strain value of approximately 6%, which is a relatively high value. This can explain that for all tested circular columns with FRP confinement, the steel buckling did not play a significant role in their seismic performance. On the other hand, it indicates that in cases of circular bridge RC columns and a lower axial load ratio, providing a nominal FRP jacket stiffness may be effective in preventing the longitudinal steel bars from buckling.

5 Further Discussions

Parametric studies were conducted by changing the main parameters to further investigate the influence of buckling of reinforcing bars. The main parameters are the stiffness of the external FRP jacket and axial load ratio. Two types of FRP jacket stiffness (i.e., 1 ply and 0.5 ply of PEN FRP) and two axial load levels 400 kN (axial load ratio = 0.1) and 800 kN (axial load ratio = 0.2) are considered here. The corresponding stress-strain curves of reinforcing bars are illustrated in Fig. 5. Figure 6a shows the numerical results of RC columns with the two different jacket stiffnesses under the axial load of 400 KN, the stress-strain histories of both FRP-confined concrete and longitudinal reinforcing bar can be recorded during the calculation as shown in Figs. 6b and 6c. It can be observed that the lateral peak load of the 0.5-ply PEN FRP wrapped column is slightly lower than that of its counterpart, although Fig. 6c shows that the reinforcing bars have experienced the process of buckling. This is perhaps due to the relatively low axial load ratio of 0.2. Figure 7 shows the results of RC columns with 1-ply PEN FRP jacket under a higher axial load ratio (i.e., 0.4). It is clearly seen that under such high axial load ratio, buckling of reinforcing bars plays a more significant role in the seismic performance of FRP-strengthened RC columns.

6 Conclusions

This paper has presented a combined experimental and analytical study on the behavior of LRS FRP-confined circular RC columns subjected to combined constant axial load and cyclic lateral load. The numerical simulations were conducted based on the OpenSees to reproduce the test results and parametric studies were conducted to investigate the influence of bucking of longitudinal reinforced bars. The following conclusions can be drawn from the research:

-

1)

In case of a bridge circular RC column with a low axial load ratio, LRS FRP is an ideal alternative to conventional FRPs for the seismic retrofit since a nominal FRP stiffness can effectively prevent the buckling of longitudinal reinforcing bars while facilitating large enough concrete ductility.

-

2)

Numerical simulations based on OpenSees generally provide reasonable predictions of the cyclic lateral load-displacement responses of PEN FRP-confined circular columns. Considering the buckling of longitudinal steel bars seems to be less critical in the circular RC columns under a low axial load ratio although the un-strengthened RC column failed due to the buckling of longitudinal bars in the plastic hinge zone, which is a flexure-dominated failure.

-

3)

Provided with a higher axial load ratio of 0.4, the incorporating of the stress-strain model of steel bars considering the buckling effect seems to become important in predicting the hysteretic behavior of the RC columns.

It should be noted that the RC columns used in the present study are slender ones in nature. When the columns become short, the effect of FRP jacket stiffness and steel buckling may become much more complex due to the interaction between the flexure and the shear.

References

Anggawidjaja D, Ueda T, Dai JG, Nakai H (2006) Deformation capacity of RC piers wrapped by new fiber-reinforced polymer with large fracture strain. Cement Concr Compos 28(10):914–927

Bai YL, Dai JG, Teng JG (2014) Cyclic compressive behavior of concrete confined with large rupture strain FRP composites. J Compos Constr 18(1):04013025

Bai YL, Dai JG, Teng JG (2017) Buckling of steel reinforcing bars in FRP-confined RC columns: an experimental study. Constr Build Mater 140:403–415

Bai YL, Dai JG, Teng JG (2017) Monotonic stress-strain behavior of steel rebars embedded in FRP-confined concrete including buckling. J Compos Constr 21(5):04017043

Bai YL, Dai JG, Ozbakkaloglu T (2017) Cyclic stress-strain model incorporating buckling effect for steel reinforcing bars embedded in FRP-confined concrete. Compos Struct 182:54–66

Dai JG, Lam L, Ueda T (2012) seismic retrofit of square rc columns with polyethylene terephthalate (PET) fiber reinforced polymer composites. Constr Build Mater 27(1):206–217

Dai JG, Bai YL, Teng JG (2011) Behavior and modeling of concrete confined with FRP composites of large deformability. J Compos Constr 15(6):963–973

Jiang T, Teng JG (2007) Analysis-oriented stress-strain models for FRP-confined concrete. Eng Struct 29:2968–2986

OpenSess (2009) Open System for Earthquake Engineering Simulation. Pacific Earthquake Engineering Research Center, University of California, Berkeley. California, USA. http://opensees.berkeley.edu/

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Zhang, YF., Bai, YL., Sun, PX., Dai, JG. (2022). Seismic Performance of Large Rupture Strain (LRS) FRP-Wrapped Circular RC Columns. In: Ilki, A., Ispir, M., Inci, P. (eds) 10th International Conference on FRP Composites in Civil Engineering. CICE 2021. Lecture Notes in Civil Engineering, vol 198. Springer, Cham. https://doi.org/10.1007/978-3-030-88166-5_165

Download citation

DOI: https://doi.org/10.1007/978-3-030-88166-5_165

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-88165-8

Online ISBN: 978-3-030-88166-5

eBook Packages: EngineeringEngineering (R0)