Abstract

Fiber Reinforced Polymer (FRP) composites have been widely used in past decades for the seismic upgrading of sub-standard reinforced concrete (RC) members and their effectiveness as a suitable strengthening technique for such kind of structural components has largely been proved. However, some concerns still arise with the effectiveness of such composite materials at high temperature, such as in the case of fire exposure. Furthermore, the use of FRPs requires a minimum quality for the concrete substrate to avoid undesirable premature failure mechanisms. Usually, the replacement of the poor quality or damaged concrete cover of existing members with a new one is needed before the strengthening intervention. Current research is now moving towards the adoption of inorganic composite materials, such as Fiber Reinforced Cementitious Composite (FRCC), for repairing existing RC buildings and infrastructures as a replacement of the original concrete cover, due to its good durability properties and resistance to high temperature. The present study discusses the possibility of adopting such FRCC jacketing also for the seismic upgrading of existing shear critical RC columns. The experimental performance of RC columns strengthened with FRCC jacketing subjected to cyclic lateral loading and different axial load ratios is analyzed herein, and the experimental performance of FRCC and FRP jacketed columns is compared to point out the effectiveness of both retrofit solutions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Short reinforced concrete (RC) columns or shear walls in existing buildings (i.e., stairs, band-type windows) can compromise significantly the capacity of structures to undertake seismic events without severe damage (Koçak 2013). Indeed, short structural members attract higher lateral forces than slender ones, but are not able to sustain such high loading. Thus, to avoid brittle shear failures sometimes followed by the loss of load bearing capacity, short members in existing structures need to be strengthened properly.

It is well known that the seismic performance of RC members can be significantly improved by externally bonded Fibre Reinforced Polymer (FRP) jacketing. A few experimental tests were so far conducted on short RC columns (Ghobarah and Galal 2004, Galal et al. 2005, Colomb et al. 2008, Del Zoppo et al. 2017, Dirikgil and Atas 2019, Kargaran and Kheyroddin 2019, Haji et al. 2019) and short shear walls (Qazi et al. 2019) jacketed with FRP and subjected to cyclic lateral loading. The results showed the reliability of this strengthening technique for avoiding the occurrence of brittle failures in short members.

However, in certain circumstances the use of externally bonded FRP strengthening requires preliminary repair interventions. This happens in the case of poor-quality concrete substrate (CNR-DT 200-R1 2013), or high deterioration of the concrete cover due to ageing and lack of maintenance, or damage already occurred after a preceding seismic event. In such cases, the original concrete cover should be partially or totally removed and replaced with a new one with a good quality before the application of the FRP jacketing. Furthermore, some concerns still arise with the effectiveness of FRPs at high temperatures, such as in the case of fire exposure, and protective measures may be required to obtain the target performance.

To avoid such issues, the use of inorganic composite materials such as Fiber Reinforced Cement Mortar (FRCM) (Ombres and Verre 2015), Steel Reinforced Grout (Thermou et al. 2019), Fiber Reinforced Cementitious Composite (FRCC) (Del Zoppo et al. 2018, Del Zoppo et al. 2019) and High Performance FRCC (HPFRCC) (Cho et al. 2018), for repairing existing RC buildings and infrastructures are currently under investigation. These materials, being cement-based, exhibit a better performance under high temperature and can guarantee a better durability of the intervention. Indeed, the reduced porosity of the cementitious matrix coupled with the polymeric or stainless-steel fibers usually adopted for such composites prevent any corrosion issue. However, the poor-quality concrete substrate can represent an issue also for cement-base composites. To overcome this issue, the authors recently proposed a new repair and strengthening solution consisting in the complete replacement of the original concrete cover with a new thin layer (20–30 mm) of FRCC (Del Zoppo et al. 2019, Del Zoppo et al. 2021). This light FRCC jacketing avoids any significant cross-section enlargement and can reduce time and costs of intervention if compared with the externally bonded FRP technique. Preliminary results on short and slender RC columns retrofitted with the light FRCC jacketing technique show the feasibility of the solution for preventing the brittle failure of short columns and enhancing the ductility of slender ones (Del Zoppo et al. 2021). The study also highlighted that the use of short fibres is not able to prevent the diagonal tensile failure of the jacket for large lateral displacement demand, due to the brittle tensile behaviour of the FRCC material.

In this paper, the experimental performance of two full-scale short RC columns with light FRCC jacketing subjected to constant axial load and cyclic lateral loading is presented. Two axial load ratios (i.e., ν = 0.1 and ν = 0.2) are considered. First, the light FRCC jacketing procedure is illustrated. Then, the experimental response of FRCC jacketed specimens is compared with bare ones under same load conditions. The comparison is made in terms of energy dissipation capacity, lateral stiffness degradation and residual deformation. A comparison between FRCC and FRP jacketed short RC columns is also made for axial load ratio ν = 0.1, to point out the effectiveness of both retrofit techniques.

2 The Use of FRPs for Seismic Strengthening

The L’Aquila earthquake (2009) confirmed the high occurrence of columns brittle failure due to shear, especially in the case of short members (Del Zoppo et al. 2017). Indeed, among 284 heavily damaged RC buildings that were demolished after the earthquake, 56 (i.e., 20%) experienced the shear failure or one or more columns, sometimes followed by the loss of axial load capacity. After the Central Italy earthquake (2016), it was observed that the FRP external jacketing was perfectly able to provide enough resistance to carry on the seismic-induced actions on vertical members without failure, see Fig. 1.

The experimental results presented in (Del Zoppo et al. 2017) and the recent Central Italy earthquake (2016) have proven the effectiveness of FRP techniques for increasing the shear capacity of existing RC members and preventing their brittle failures. The experimental campaign carried by the authors on short RC columns with square cross-section, representative of existing RC members, and strengthened with Carbon FRP provided an in deep knowledge about the effectiveness of such systems to avoid brittle failures. Results from Del Zoppo et al. 2017 show that in the case of short columns characterized by a poor-quality concrete (15 MPa on average), FRP jacketing with axial stiffness, Efρf, lower or equal to 0.31 GPa provides an enhancement of lateral capacity from 56% to 67% with respect to the original shear capacity of the short RC columns. However, the external reinforcement is not able to avoid the shear failure of the member. Conversely, an external reinforcement ratio of 0.34 GPa is able to prevent the brittle failure of the poor-quality concrete members, allowing the development of plastic deformations with ultimate drift ratios greater than 7%. Columns characterized by medium quality concrete (30 MPa on average) and strengthened with two plies of FRP jacket are able to achieve the flexural capacity, developing plastic deformations with ultimate drift ratios equal or greater than 8%. Experimental results also attested that the axial stiffness of FRP jacket affects the reduction of the peak-to-peak secant stiffness during the cyclic loading and the energy dissipation capacity. In particular, for increasing axial stiffness of the external reinforcement, the lateral stiffness reduction is less steep, and the energy dissipation increases.

3 FRCC Jacketing

3.1 Material Mechanical Properties

The FRCC material adopted for this experimental program is characterized by a high-strength cement-based mortar with very small aggregates (maximum size 2.5 mm) and plain short stainless-steel fibres (fibre diameter 0.21 mm, fibre length 13 mm), see Fig. 2. The fibres weight ratio is lower than 2%, in order to allow the workability of the composite system and to reduce the costs. This low volumetric ratio, typical of fibre reinforced cements, provides a strain-softening behaviour in tension after the opening of the first crack in the matrix.

To characterize the mechanical properties of the adopted FRCC material, compressive tests on cylindrical specimens (diameter 100 mm, height 200 mm) and direct tensile tests on dog-bone coupon tests (width 40 mm, length 150 mm, thickness 10 mm) are performed under displacement control. The average mechanical properties derived from experimental tests on FRCC materials are herein summarized: average compressive strength fc,FRCC of 104.3 MPa, elastic modulus of 31.3 GPa, ultimate compressive strain εcu equal to 4% and average tensile strength ft,FRCC of 4.3 MPa. Stress-strain curves for the FRCC material in both compression and tension are depicted in Fig. 3a and b, respectively.

3.2 Retrofit Technique

The FRCC jacketing technique consists in replacing the original concrete cover with a new thin layer of FRCC, avoiding any significant cross-section enlargement for the column.

The jacketing procedure relies on different steps: after the complete removal of the original concrete cover (Fig. 4a), the concrete surface is wetted up to complete saturation; if needed, the specimen is repaired with epoxy-resin injections (see Fig. 4b) to close the eventual flexural and shear cracks in the concrete core. The epoxy-resin injections should be cured for 24 h before casting the FRCC jacket. Then, a wooden formwork is built around the column in order to allow fresh FRCC pouring (see Fig. 4c). Given the highly performing bond properties of FRCC material herein adopted, no bonding agent or primer are needed at the FRCC-inner concrete interface.

4 Experimental Evidences

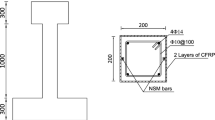

The use of FRCCs is herein investigated for the seismic retrofit of two short RC columns non-conforming to current standards in terms of minimum transverse reinforcement ratio (i.e. 300 mm of spacing) and governed by a brittle failure mode due to shear. The columns had a cross-section original dimension of 300 × 300 mm reinforced with 10ϕ22 deformed steel bars. More details about the specimens’ geometry can be found in Del Zoppo et al. 2017.

The specimens were cast with a poor-quality concrete, with mean compressive strength about 15 MPa. The steel used for the columns had an average yielding strength of 531 MPa for longitudinal reinforcement and of 525 MPa for transverse reinforcement, derived from tensile tests carried out on coupon bars.

The short columns (shear span to depth ratio equal to 3) have been strengthened with the aforementioned FRCC jacketing technique and were tested under two different axial load ratios (i.e., ν = 0.1 and ν = 0.2, with ν = N/(bhfc), N the axial load, b and h the cross-section dimensions) and cyclic lateral loads up to failure. Three repetitions were made for each imposed displacement, in order to statically reproduce the seismic excitation. The experimental results are discussed in terms of failure mode, peak strength, energy dissipation and residual drift in comparison with the behaviour of bare columns.

In the case of axial load ratio ν = 0.1, the test results for FRCC jacketing are also compared with the results obtained by using the FRP jacketing on a specimen with same geometrical and mechanical characteristics (Del Zoppo et al. 2017). The discontinuous FRP jacketing consisted in applying one-ply strips of Carbon FRP (unit weight 600 g/m2), width 100 mm and spacing 165 mm, covering the entire length of the column. Both retrofit configurations are shown in Fig. 5.

4.1 Axial Load Ratio v = 0.1

The bare column subjected to an axial load ratio ν = 0.1 and to cyclic lateral loads exhibited a brittle failure governed by the shear failure before the achievement of the flexural yielding of internal steel reinforcement, as shown in Fig. 6a, where the cyclic force-drift (F−Δ) relationship is reported. Figure 6a also reports the damage pattern at failure for the bare specimen (for a drift ratio of 3.2%), where the development of large diagonal cracks for the entire shear span of the member is clearly visible. Vertical cracks along the longitudinal reinforcement are also detected, due to a probable loss of bond between steel bars and surrounding concrete.

The force-drift relationship derived for the specimen jacketed with FRCC is depicted in Fig. 6b. In this case, the specimen achieved the flexural capacity (with flexural yielding of internal steel reinforcement) and experienced a ductile behaviour up to a drift ratio of 4.2%. During the test, the specimen experienced a very low damage, as visible in Fig. 6b representing the crack pattern at the end of the test. The FRCC jacket showed a few hairline cracks and the major deformation were achieved at the interface between the column base and the foundation block.

A similar performance, in terms of force-drift capacity curve, was experienced by the specimen jacketed with discontinuous CFRP strips (see Fig. 6c). Indeed, also in this case the specimen achieved the flexural capacity, associated with the yielding of longitudinal reinforcement, and experienced a ductile behaviour with ultimate drift ratio greater than 6%. The failure was partly governed by the local rupture of the FRP fibres and partly related to the high deterioration of unconfined concrete between consecutive FRP strips, as visible from Fig. 6c at a drift ratio of 8%.

To further investigate on the potential of FRCC jacketing for the seismic retrofit of existing short RC columns, the behaviour of the specimens has been compared in terms of energy dissipation, Edissipated, peak-to-peak lateral stiffness, Kpeak, and residual drift ratio at the end of each complete cycle (i.e., after the three repetitions for the imposed drift), Δresidual, in Fig. 7.

In terms of energy dissipation (Fig. 7a), the FRCC jacketed specimen experienced a slightly higher energy dissipation capacity with respect to the bare specimen up to a drift ratio of 3.2% and then achieved a quite good energy dissipation, with a cumulative dissipated energy of 2700 kNmm at failure. Conversely, the FRP jacketed specimen showed a greater energy dissipation capacity with respect to bare and FRCC jacketed specimens after a drift ratio of 2.4%. At failure, the FRP jacketed specimen reached an energy dissipation of 3800 kNmm. This is also visible from the comparison between capacity curves in Fig. 6b–c, where the pinching phenomenon is more visible in the FRCC jacketed column (Fig. 7b). This difference is probably related to the global behaviour of the specimens. Indeed, the FRCC jacketed specimen experienced a rocking behaviour, with damage concentrated mainly at the base cross-section. Conversely, the FRP jacketed specimen showed flexural deformations for its entire length.

The peak-to-peak stiffness was measured at the first cycle for each imposed drift ratio. The initial flexural stiffness is almost the same for all specimens, as the cross-section was not enlarged with both the jacketing techniques (Fig. 7b). The lateral stiffness reduction for increasing drift demand was lower in both jacketed specimens with respect to the bare one, up to a drift ratio of 1.8%. Then, a sudden reduction of lateral stiffness was observed for the FRCC jacketed specimen, probably related to the beginning of the rocking behaviour. Conversely, specimen jacketed with FRP showed a softer reduction of lateral stiffness for increasing drift demand.

Finally, in terms of residual drift ratio at the end of each imposed cycle, both FRP and FRCC jacketed specimens experienced a slightly lower residual drift with respect to the bare column. The behaviour of the two jacketed specimens was very similar in terms of residual drift ratio (see Fig. 7c).

4.2 Axial Load Ratio v = 0.2

The force-drift relationship derived for the bare and FRCC jacketed specimens under axial load ratio 0.2 are depicted in Fig. 8 along with the damage pattern at failure.

Also in this case, the bare specimen achieved a brittle failure before the yielding of internal steel bars (Fig. 8a). The failure mode was governed by the loss of bond between steel reinforcement and surrounding concrete associated with the shear resisting mechanism. Conversely, the specimen jacketed with FRCC experienced a ductile behaviour, with the flexural yielding and the ultimate drift ratio greater than 4% (Fig. 7b). The damage pattern at failure of FRCC jacketed specimen was very similar to that observed under axial load ratio 0.1, with very few hairlines cracks of the jacket and major damage located at the interface between the column and the foundation block.

In terms energy dissipation capacity, reduction of peak-to-peak lateral stiffness and residual drift, the same considerations made for the specimens under axial load ratio 0.1 apply to the case of specimens under axial load ratio 0.1. The FRCC jacketed specimen exhibited a higher energy dissipation capacity and a softer lateral stiffness reduction up to an imposed drift ratio of 1.8%. Then, a drop of the lateral stiffness was observed, confirming the beginning of a rocking mechanism. In terms of residual drift ratio, significant differences between bare and jacketed specimens were not clearly visible (Fig. 9).

5 Conclusions

In this paper, the use of the light FRCC jacketing for the seismic retrofit of existing short RC columns non-conforming to current seismic standards has been investigated. The effectiveness of this technique has been analysed by means of experimental tests on two full-scale RC columns under load reversal and different axial load ratios. Then, the performance of columns has been compared with that of bare specimens and specimens retrofitted with CFRP jacketing. The different performance in terms of failure mode, damage pattern, energy dissipation, lateral stiffness degradation and residual drift has been pointed out, based on experimental results.

The main outcomes of this work are summarized as follows:

-

In terms of failure mode, the FRCC jacketing (with 20mm thickness) avoided the shear failure of the columns, that experienced a flexural behaviour with ultimate drift ratios greater than 4%;

-

In terms of damage pattern at failure, the FRCC jacketed specimens experienced a very light damage, consisting of few hairline cracks, with respect to the bare specimens and also to the specimen jacketed with discontinuous FRP strips;

-

Both FRCC jacketed specimens developed a rocking behaviour, with major damage located at the interface between column and foundation. This behaviour affected both the energy dissipation capacity and the lateral stiffness reduction, that were slightly better than the one of bare specimens;

-

In terms of residual drift, a slightly difference was observed between bare and FRCC jacketed specimens;

-

From the comparison between specimens with FRCC and FRP jacketing, both techniques were able to provide the same flexural failure mode. It is also observed that the FRCC jacketed specimen experienced a lower energy dissipation capacity, a faster reduction of lateral stiffness and same residual drift ratio of FRP jacketed specimen. However, the FRP jacketing is able to provide a higher ductility enhancement with respect to the FRCC, due to the difference in length and orientation of the fibres.

More experimental research is needed to fully understand the effectiveness and limitations of this new strengthening technique and to avoid premature failure due to rocking at the foundation level. More research is also needed to investigate the use of long fibres or mesh reinforcement for increasing the ductility of the retrofitted columns (i.e., confinement). Analytical models are also required for the design of such solutions for their application in current engineering and construction practice.

References

Cho CG, Han BC, Lim SC, Morii N, Kim JW (2018) Strengthening of reinforced concrete columns by High-Performance Fiber-Reinforced Cementitious Composite (HPFRC) sprayed mortar with strengthening bars. Compos Struct 202:1078–1086

CNR-DT 200 R1/2013 (2013) Guide for the design and construction of externally bonded FRP systems for strengthening existing structures e materials, RC and PC structures, masonry structures”. Italian National Research Council.

Colomb F, Tobbi H, Ferrier E, Hamelin P (2008) Seismic retrofit of reinforced concrete short columns by CFRP materials. Compos Struct 82(4):475–487

Del Zoppo M, Di Ludovico M, Balsamo A, Prota A, Manfredi G (2017) FRP for seismic strengthening of shear controlled RC columns: experience from earthquakes and experimental analysis. Compos B Eng 129:47–57

Del Zoppo M, Di Ludovico M, Balsamo A, Prota A (2018) Comparative analysis of existing RC columns jacketed with CFRP or FRCC. Polymers 10(4):361

Del Zoppo M, Menna C, Di Ludovico M, Balsamo A (2019) Flexural performance of RC columns with FRCC jacketing. E3S Web Conf 97:03037

Del Zoppo M, Menna C, Di Ludovico M, Asprone D, Prota A (2021) Opportunities of light jacketing with Fibre Reinforced Cementitious Composites for seismic retrofitting of existing RC columns. Compos Struct 263:113717

Dirikgil T, Atas O (2019) Experimental investigation of the performance of diagonal reinforcement and CFRP strengthened RC short columns. Compos Struct 223:110984

Galal K, Arafa A, Ghobarah A (2005) Retrofit of RC square short columns. Eng Struct 27(5):801–813

Ghobarah A, Galal KE (2004) Seismic rehabilitation of short rectangular RC columns. J Earthq Eng 8(01):45–68

Haji M, Naderpour H, Kheyroddin A (2019) Experimental study on influence of proposed FRP-strengthening techniques on RC circular short columns considering different types of damage index. Compos Struct 209:112–128

Kargaran A, Kheyroddin A (2019) Experimental investigation of seismic strengthening of reinforced concrete short columns using externally bonded reinforcement, near surface mounted, and hybrid techniques. J Compos Mater 0021998319874499.

Koçak A (2013) The effect of short columns on the performance of existing buildings. Struct Eng Mech 46(4):505–518

Ombres L, Verre S (2015) Structural behaviour of fabric reinforced cementitious matrix (FRCM) strengthened concrete columns under eccentric loading. Compos B Eng 75:235–249

Qazi S, Michel L, Ferrier E (2019) Seismic behaviour of RC short shear wall strengthened with externally bonded CFRP strips. Compos Struct 211:390–400

Thermou GE, Papanikolaou VK, Lioupis C, Hajirasouliha I (2019) Steel-Reinforced Grout (SRG) strengthening of shear-critical RC beams. Constr Build Mater 216:68–83

Acknowledgements

This study was performed in the framework of PE 2019–2021 joint program DPC Reluis. The materials used for the strengthening of specimens were provided by Mapei SpA, Milan.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Del Zoppo, M., Di Ludovico, M., Balsamo, A., Prota, A., Morandini, G. (2022). RC Columns Upgrade: Opportunities Given by FRP and Potential of FRCC Systems. In: Ilki, A., Ispir, M., Inci, P. (eds) 10th International Conference on FRP Composites in Civil Engineering. CICE 2021. Lecture Notes in Civil Engineering, vol 198. Springer, Cham. https://doi.org/10.1007/978-3-030-88166-5_160

Download citation

DOI: https://doi.org/10.1007/978-3-030-88166-5_160

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-88165-8

Online ISBN: 978-3-030-88166-5

eBook Packages: EngineeringEngineering (R0)