Abstract

In this paper, we propose a two-tier mixed integer linear programming (MILP) model, composed of aggregate production planning (APP) and family disaggregation planning (FDP), to solve the hierarchical production planning (HPP) problem with nontrivial setup times. In addition to disaggregating the aggregate plan in the first period into detailed lot sizing plans as traditional models do, the proposed FDP model optimally adjusts the aggregate plan and eliminates infeasibility arising from the positive setup times. The performance of the proposed model is validated with a case study. Results of the validation show that the proposed model leads to significant cost savings and efficiencies in the supply chain compared to traditional HPP models.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Hierarchical production planning

- Aggregate production planning

- Setup time

- Supply chain management

- Prescriptive analytics

1 Introduction

In the past few decades, companies have increased their product variety to satisfy customized demands and enhance competitiveness. Unfortunately, increases in product variety create negative effects on operations, such as high inventory level, demand forecasting bias [1], buffer capacity, frequent changeover, and workforce fluctuations. To face challenges of a volatile and smart market demand characterized by customization in the era of Industry 4.0 [2], manufacturers have to elaborately plan their production using modern systems such as Seru, Cellular Manufacturing, and Toyota Production System. With higher product variety, shorter product life cycles, and faster responsiveness, mixed-model and small-batch production continue to dominate the production strategy in the supply chain of modern manufacturing companies. Therefore, the production planning problem (PPP) becomes too complex to be solved easily.

Two approaches are traditionally used to model the PPP: monolithic and hierarchical. The monolithic approach produces more accurate results for individual items, but the time-consuming and expensive forecasts for the sporadic demand of thousands of items and the solution of the large-scale monolithic model discourage its wide application. This approach has long been rejected in the literature [3, 4]. On the other hand, the hierarchical approach decomposes PPP into several layers of sub-problems that are easier to solve. Proper product aggregation can reduce the forecast bias and variability for the highly volatile and smart product demands. In most studies on HPP the information flow between two consecutive levels is hierarchical, with the APP model imposing constraints on the FDP model. Traditional HPP systems [4,5,6] employ the rolling horizon procedure to coordinate the interaction between them at the end of current period when the completion condition of the aggregate plan in the period has been determined. However, the feedback information cannot be capitalized on to adjust the APP in the current period, missing an opportunity to globally optimize the production plans in the planning horizon. Furthermore, the aggregate plan becomes infeasible after considering setup times in the FDP model, since the setup times consume some capacity.

In this study, a novel iterative optimization mechanism is proposed to optimally adjust the aggregate plan in the current period with the feedforward information from the FDP model and further optimize the production plan in the planning horizon. The mechanism also eliminates the infeasibility brought about by the non-trivial family setup times, which consume production capacity but are often ignored in the APP.

2 Literature Review

The theoretical and practical benefits of the HPP approach have been documented in the literature [3, 4, 6,7,8,9]. These HPP systems belong to the classical hierarchical class of models since they observe a strict top-down open loop solution procedure without regard to the interaction between the production tiers. However, efficient feedback procedures for anticipating the influence of lower planning levels on higher ones can improve information accuracy and bridge the production asymmetry between the two levels of HPP systems.

In order to optimize the performance of hierarchical systems, Schneeweiss [9] proposes an interaction scheme that considers feedback from and anticipation of the lower-level system. The interaction scheme is widely applied to HPP and other hierarchical systems, such as supply chain [10]. In the HPP system proposed by Qiu et al. [11], the concept of expected setup costs and anticipation of lower-level decision are incorporated into the aggregate planning level resulting in better production decisions than the traditional HPP system [12]. The feedback from lower-level systems is achieved through inaccurate anticipation, and therefore the effectiveness of the iterative optimization is questionable. Moreover, the influence of nontrivial setup times on aggregate plans is not considered in these HPP systems.

Omar and Teo [8] propose a three-level HPP and scheduling approach considering production planning and setup activities for each family, but the solution complexity of the model is large due to the inclusion of setups in all periods of the planning horizon. Jozefowska and Zimniak [13] propose a decision support system for short-term production planning and scheduling. The setup times occupy production capacity in the model, but their effects on the upper-level decision are not considered.

In HPP system [4], the capacity and inventory levels generated in APP impose constraints on the production and inventory in master production scheduling (MPS). In MPS model, setup times are included, but overtime is required to extend the production capacity, losing the opportunity of making the optimal adjustment resulting from setup times in the APP. Alvarez et al. [7] focus on improving the consistency in their hierarchical tactical and operational planning models, and ignores the infeasibility brought about by setup times.

Xue et al. [14] propose a full-space method that optimally integrates APP and FDP, with consideration for sequence-dependent family setup times. Xue et al. [15] also incorporate their integrated model in the dynamic cellular manufacturing setting to generate the optimal production plan and cell formation in each period. However, the solution complexity and customized algorithm for this model may not meet the managers’ need for lower solution efforts, thereby encumbering its efficacy.

Therefore, an iterative optimization of HPP systems which considers the influence of family setup times on the feasibility of aggregate plans, adjusts the aggregate plan in the current period with the feedback information from FDP model for global optima, and considers the need of lower solution efforts in comparison with full-space method, is needed. This paper bridges this gap in the HPP literature.

3 The Proposed HPP System

3.1 The Traditional APP Model

The traditional APP model considers most mid-term decisions, with the objective of minimizing the total cost related to the lower-level decisions. Legend for all notations is summarized as follows:

-

Indices

-

m = 1,…, M type.

-

t = 1,…,T period.

-

i = 1,…,I family.

-

Parameters

-

\(d_{mt}\) net demand of type m in period t.

-

\(ut_{m}\) unit processing time of type m.

-

\(A\) capacity allowance percentage (used for breakdowns, rest, absenteeism, etc.).

-

\(po\) percentage of overtime hours permitted (used to limit maximum overtime hours).

-

\(pu\) percentage of underutilization.

-

\({ua}_{m}\) space occupied by a unit of type m.

-

\(J(m)\) families pertaining to type m.

-

\({st}_{i}\) setup time of family i.

-

\({sl}_{m}\) fill rate (\(\beta\) service level) of type m.

-

\(OS\) total available space for inventory storage.

-

V a large number.

-

sc cost per unit setup time.

-

\({h}_{mt}\) unit inventory holding cost of type m in period t.

-

\({c}_{mt}\) unit production cost (labor cost excluded) of type m in period t.

-

\({cr}_{t}\), \({co}_{t}\) regular time and overtime cost per man hour in period t.

-

\({cs}_{mt}\), \({cb}_{mt}\) unit subcontracting and backordering cost of type m in period t.

-

\({ch}_{t}\), \({cf}_{t}\) cost of hiring and laying off one man hour in period t.

-

\({CAS}_{mt}\) maximum subcontracting capacity of type m in period t.

-

\({\alpha }_{it}\), \({\beta }_{it}\) lower and upper proportions of family i to its type in period t.

-

Decision variables

-

\({X}_{mt}\) production level of type m in period t.

-

\({I}_{mt}\) inventory level of product type m at the end of period t.

-

\({R}_{mt}\), \({O}_{mt}\) regular time and overtime hours consumed for type m in period t.

-

\({S}_{mt}\), \({B}_{mt}\) subcontracting and backordering quantity of type m in period t.

-

\({H}_{t}\), \({F}_{t}\) man hours hired and laid off in period t.

-

\({P}_{it}\) production quantity of family i in period t.

-

\({AR}_{t}\), \({AO}_{t}\) added regular time and overtime hours in period t.

-

\({AS}_{mt}\), \({AB}_{mt}\) added subcontracting and backordering quantity of type m in period t.

-

Auxiliary variables

-

\({TR}_{t}, {TO}_{t}\) total regular time and overtime hours in period t.

The APP model, which is a mixed integer linear programming (MILP) model, can be formulated as follows:

In the model, constraints (2) are the inventory balance equations. Constraints (3) are regular time and overtime capacity limits. In order to balance production in different periods, constraints (4) set lower bounds for the utilization of available capacity. In constraints (5), the total capacity consumed by each type in each period is defined. The consumed total regular time will not exceed the available regular time capacity in constraints (6). Constraints (7) and (8) are subcontracting and backordering limits. Constraints (9) are the balance equations for the relationship between the change in available regular time in two adjacent periods and the fluctuation value arising from hiring or laying off man-hours. Constraints (10) are the inventory limits.

3.2 The FDP Model

In the FDP model proposed in this paper the optimal scheme to adjust the aggregate plan in the first period is integrated. The model (1) determines the optimal production quantity of each family, (2) minimizes the sum of setup costs and extra costs including labor costs, subcontracting and backordering costs, arising from the adjustment of the aggregate plan in the first period, and (3) transforms the infeasible aggregate plan to feasibility. Furthermore, \({X}_{m1}\), \({TR}_{1}\), \({TO}_{1}\), \({R}_{m1}\), \({O}_{m1}\), \({CAS}_{m1}\), \({S}_{m1}\), and \({B}_{m1}\) obtained from the APP model facilitate the solution of the FDP model.

The FDP model can be formulated as follows:

In the model, constraints (14) indicate that the production quantity of a type in the first period is not necessarily disaggregated into that of the families within the type because some may be subcontracted or backordered. Constraints (15) show the options to absorb setup times. Constraints (16) and (17) are the maximum idle regular time and overtime in the first period. Constraints (18) and (19) are the maximum permitted subcontracting and backlogging quantities. Constraints (20) set the lower and upper bounds of the production quantity of each family in the first period. Constraints (21) ensure that when family i is not produced in the first period, binary variable \(Z_{i1}\) is zero; otherwise, \(Z_{i1}\) is 1.

There are four options to absorb the influences of family setup times: idle regular time \(AR_{1}\), idle overtime \(AO_{1}\), or the released capacity resulting from added subcontracting quantities \(AS_{m1}\), and added backordering quantities \(AB_{m1}\). Therefore, the aggregate plan in the first period is adjusted and becomes feasible to implement.

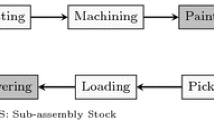

4 Solution Heuristics

The APP model is solved first for types in order to obtain the production plans in the planning horizon and the production plan in the first period is implemented. Then, the proposed FDP model is solved with the adjustment feedback to the obtained production plan in the first period. The inherent adjustment rule heuristics used on the unconsumed capacity for single-type FDP model is summarized in Table 1. The assumption for the heuristics is that the added regular time cost is less than the added overtime cost, which is less than the added subcontracting cost and backlogging cost. These assumptions are is prevalent in practice.

In order to simplify the expression, the consumed total regular time and overtime are denoted as \(TR_{t}^{^{\prime}} = \sum\nolimits_{m = 1}^{M} {R_{mt} }\) and \(TO_{t}^{^{\prime}} = \sum\nolimits_{m = 1}^{M} {O_{mt} }\) respectively, while the total capacity consumed by the production of all types and setups between all families is set to be \(TSP_{t} = \sum\nolimits_{m = 1}^{M} {\left( {ut_{mt} X_{mt} + \sum\nolimits_{i = 1}^{I} {\sum\nolimits_{j \in J\left( m \right)} {\sum\nolimits_{k = 1}^{I} {st_{ij} Y_{ijkt} } } } } \right)}\). The inherent logic of the heuristics is as follows:

Case I: when \(TSP_{t} \le AR_{t} \cdot A\), that is, the idle regular time capacity is enough to absorb the setup times, \(TSP_{t} - TR_{t}^{^{\prime}}\) units of extra regular time and no overtime will result. Since employing idle regular time is the most cost-saving option among the four options, the idle regular time is first used to absorb the setup times.

Case II: when \(TSP_{t}\) is between available regular time and total capacity, all idle regular time capacity \(\left( {AR_{t} \cdot A - TR_{t}^{^{\prime}} } \right)\) and part of overtime capacity \(\left( {TSP_{t} - TR_{t} \cdot A - TO_{t}^{^{\prime}} } \right)\) are employed to absorb the setup times since overtime is the second most cost-saving option except for regular time. Besides setup cost, the added costs include the labor costs of all idle regular time and part of the idle overtime necessary to replenish the capacity occupied by setup times.

Case III: when \(TSP_{t}\) is larger than total capacity, all idle regular time capacity \(\left( {TR_{t} \cdot A - TR_{t}^{^{\prime}} } \right)\) and overtime capacity \(\left( {TO_{t} \cdot A - TO_{t}^{^{\prime}} } \right)\) are not enough to absorb the setup times, and some of the setup times are absorbed by the capacity released by subcontracting or backordering some families scheduled for production. Besides the added labor costs of regular time and overtime, the added subcontracting (backordering) costs are the subcontracting (backordering) quantity multiplied by the difference between unit subcontracting (backordering) cost and unit production cost. Since the unit subcontracting costs are generally less than the unit backordering costs, subcontracting is preferred to backordering for absorbing the family setup times.

Finally, the feedback information from the FDP model is used to adjust the production plan in the first period and obtain the feasible and optimally adjusted production plan for the period. Then the HPP system is implemented on a rolling horizon basis and a new solution cycle starts at the end of the first period when updated information are available to plan production in the following planning horizon.

However, it is nontrivial to solve the FDP model with the above heuristics in a multiple product production environment due to the different cost structures of the product types. Moreover, the disaggregation function of the FDP also hampers its quick solution. Therefore, some other optimizaiton method has to be introduced for the model. In this paper, branch-and-bound approach in LINGO 8 [16] is used to solve the FDP model.

5 Case Study

The manufacturing system for our test plant is a typical multi-product, small-batch and make-to-stock operation. Using data from the mold manufacturing plant, the APP model in the planning horizon of 12 months and the proposed FDP model in the first month are solved on a DELL OptiPlex GX-620 computer with 2.0 GHz RAM, W8400 Processor 80,547, Pentium 4 Prescott Dt 630. The integrated model proposed by Xue et al. [14] contains 3207 variables (3099 integer variables) and 4103 constraints. However, the integrated model could not reach optimality within a reasonable time frame.

In the MILP APP model proposed in this paper, there are 195 variables (96 integer variables), and 170 constraints. Since the APP model only plans the production of two types, its solution scale is drastically reduced and can be solved within 2 s. In the proposed MILP FDP model, only the production plan in the first month is disaggregated. The FDP model only needs 22 variables (14 integer variables) and 31 constraints to optimally adjust the aggregate plan in the first period and can be solved within 1 s.

From the solution, the aggregate plans for Types 1 and 2 in the first period, and the disaggregation and adjustment results are summarized in Table 2. The objective function of FDP model is $28,670, where the total setup cost is $1,220. In the production plan in the first period, the available regular time and overtime that can be used to absorb family setup times are 0 and 1364 h, respectively. Since the total family setup time is 61 h, the 1364-h overtime is enough to absorb the family setup times, which is also the result of the FDP model. Therefore, the production plan in the first period, which is infeasible due to the setup times, can be adjusted by using 61 h more of overtime in the first period.

In traditional HPP systems the extra cost resulting from the setup times is fixed at $53,460, nearly two times that of the results in this paper. Therefore, the proposed FDP model can adjust the aggregate plan in the first period to realize more cost savings.

6 Conclusions and Future Research

This paper presents an iterative optimization approach of traditional HPP systems considering the feedback information from the FDP model. The proposed novel FDP model minimizes the family setup costs and extra costs arising from the adjustment of aggregate plans due to the existence of nontrivial family setup times. As is the case in most FDP models the proposed FDP model disaggregates the aggregate plan of types in the first period into detailed plans of families within the type. However, unlike other FDP models, the proposed FDP model also eliminates the infeasibility of the aggregate plan when setup times are nontrivial, and optimally adjusts the aggregate plan in the first period. Moreover, the proposed iterative optimization mechanism based on HPP system consummates the application of iterative method to the decomposition scenario of HPP problems.

Data from a mold manufacturing plant is used to validate the performance of the proposed FDP model. The results indicate that the proposed FDP model can optimally adjust the corresponding aggregate plan in the first period and eliminate the infeasibility arising from positive family setup times. The higher family setup times result in more cost savings over the traditional HPP systems. Moreover, compared with traditional HPP systems, the iterative optimization mechanism proposed in this paper can save over 37% of its setup and adjustment costs for each problem set.

This paper can be extended in two ways. First, the integration of APP and FDP models can lead to real optimization of the HPP system. Although the FDP model adjusts the aggregate plan optimally, the essence of sequential decisions of the two models impedes the achievement of true optimization. Therefore, an integrated model of APP and family disaggregation problems is worthy of further study. Second, the sequence dependency of family setup times and the lot sizes of each family can be integrated into the FDP model in the first period, since only sequence-independent setup times are considered in this paper.

References

Wan, X., Sanders, N.R.: The negative impact of product variety: forecast bias, inventory levels, and the role of vertical integration. Int. J. Prod. Econ. 186, 123–131 (2017)

Yin, Y., Stecke, K.E., Li, D.: The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 56(1–2), 848–861 (2018)

Sawik, T.: Monolithic versus hierarchical approach to integrated scheduling in a supply chain. Int. J. Prod. Res. 47(21), 5881–5910 (2009)

Vogel, T., Almada-Lobo, B., Almeder, C.: Integrated versus hierarchical approach to aggregate production planning and master production scheduling. OR Spectrum 39(1), 193–229 (2016). https://doi.org/10.1007/s00291-016-0450-2

Bitran, G.R., Haas, E.A., Hax, A.C.: Hierarchical production planning: a single stage system. Oper. Res. 29(4), 717–743 (1981)

Selcuk, B., Fransoo, A.G., De Kok, A.G.: The effect of updating lead times on the performance of hierarchical planning systems. Int. J. Prod. Econ. 104, 427–440 (2006)

Alvarez, P.P., Espinoza, A., Maturana, S., Vera, J.: Improving consistency in hierarchical tactical and operational planning using robust optimization. Comput. Ind. Eng. 139, 106–112 (2020)

Omar, M.K., Teo, S.C.: Hierarchical production planning and scheduling in a multi-product, batch process environment. Int. J. Prod. Res. 45(5), 1029–1047 (2007)

Schneeweiss, C.: Hierarchical planning in organizations: elements of a general theory. Int. J. Prod. Econ. 56–57, 547–556 (1998)

Schneeweiss, C., Zimmer, K.: Hierarchical coordination mechanisms within the supply chain. Eur. J. Oper. Res. 152, 687–703 (2004)

Qiu, M.M., Fredendall, L.D., Zhu, Z.: Application of hierarchical production planning in a multiproduct, multimachine environment. Int. J. Prod. Res. 39(13), 2803–2816 (2001)

Bowers, M.R., Jarvis, J.P.: A hierarchical production planning and scheduling model. Decis. Sci. 23, 144–159 (1992)

Jozefowska, J., Zimniak, A.: Optimization tool for short-term production planning and scheduling. Int. J. Prod. Econ. 112, 109–120 (2008)

Xue, G., Offodile, O.F., Zhou, H., Troutt, M.D.: Integrated production planning with sequence dependent family setup times. Int. J. Prod. Econ. 131, 674–681 (2011)

Xue, G., Offodile, O.F.: Integrated optimization of dynamic cell formation and hierarchical production planning problems. Comput. Ind. Eng. 139, 106155 (2020)

LINDO User's Manual. Lindo Systems Inc., Chicago, IL (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 IFIP International Federation for Information Processing

About this paper

Cite this paper

Xue, G., Offodile, O.F. (2021). Optimization of Hierarchical Production Planning with Setup Time Feasibility for Effective Supply Chain Management. In: Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D. (eds) Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems. APMS 2021. IFIP Advances in Information and Communication Technology, vol 632. Springer, Cham. https://doi.org/10.1007/978-3-030-85906-0_54

Download citation

DOI: https://doi.org/10.1007/978-3-030-85906-0_54

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85905-3

Online ISBN: 978-3-030-85906-0

eBook Packages: Computer ScienceComputer Science (R0)