Abstract

Today, membrane technologies are emerging techniques as efficient protocols in multiple types of separation, including chemical compounds, solvents, biomolecules, salts, ions, among others. So far, it is likely that standard membrane-based technologies driven by pressure, such as microfiltration (MF), ultrafiltration (UF) and nanofiltration (NF), have been mainly explored in the separation of biologically active compounds and food ingredients from natural products. More emergently, fractionation and concentration of bioactive compounds, such as phenolic compounds from agro-food wastes and by-products, can also be done via membrane technologies. At this point, such technologies have been fully involved within valorization and recycling protocols of various by-products. Thus, the aim of this chapter is to provide a comprehensive overview of the main agro-food by-products processed by membrane technologies for the recovery of phenolic compounds, their derivatives of different molecular weight and some other compounds. An introduction is provided in terms of separation processes, molecule properties, membrane features and other interesting phenomena that occur during their extraction. To finalize, the current challenges of membrane technologies in bioactive separation are elucidated.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

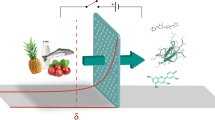

The food industry faces many issues during the production of the crucial ingredients for the fabrication of food products (Gibson et al. 2004). This becomes more challenging when there is a need of satisfying the production of bioactive compounds involved in food products. According to the literature, a bioactive compound comprises any kind of chemical found in small quantities in plants, vegetables and specific natural foods (such as fruits, nuts, oils, grains, among others), which must display any actions in the body that may foster good health in the consumers (Panić et al. 2019), for example, antioxidant (such as polyphenols and carotenoids) and non-antioxidant (such as phytosterols) compounds and dietary fiber have proved a significant role in health (Saura-Calixto and Goni 2009). Thanks to the high amount of bioactive compounds in natural products, scientists and food technicians are continuously exploring several types of sources to extract such bioactives and some other food ingredients (Conidi et al. 2020). To some extent, it is quite possible that the current available natural products may satisfy the current nutritive requirements in the manufacture of food products (Burdock et al. 2006), however, the main issue concerns to the right and suitable extraction protocol towards such molecules. To date, several extraction techniques and methods have been evaluated including hot-water extraction (Rao et al. 2012), solvent extraction, irradiation-assisted extraction, adsorption (Cerón-Montes et al. 2015; Valencia-Arredondo et al. 2020), ultrasound-assisted extraction (Malićanin et al. 2014), enzyme-assisted extraction (Galiano et al. 2019), pulsed-electric field (Gachovska et al. 2010) and supercritical fluid extraction (Chemat et al. 2020; Barba et al. 2015). Most of these methods have not released enough positive results associated to relevant factors, e.g. specific bioactives, such as phenolic compounds, antioxidants carotenoids, to mention just a few of them, tend to be thermolabile that imply their degradation/denaturation related to their low stability at high temperatures, long extraction periods and the necessity of solvents in such mentioned methodologies (Cassano and Conidi 2019; Garcia-Castello et al. 2010; Castro-Muñoz et al. 2016a). Therefore, new protocols and techniques are being proposed by the research community; in which membrane technologies are pointed out as promising methods since they own multiple advantages over conventional and emerging extraction techniques, such as low energy demand, high separation efficiency, possibility of scale-up, simple operating parameters, high productivity (i.e., permeate fluxes), and the absence of phase transition (Castro-Muñoz et al. 2021; Díaz-Montes and Castro-Muñoz 2019). Together with these advantages, the inherent properties of the membranes facilitate the separation of bioactive and food ingredients from natural systems. However, the application of membrane technologies does not only rely on molecule’s extraction from natural sources, their role has also been directed towards the agro-food waste valorization (Castro-Muñoz et al. 2020a; Cassano et al. 2015a; Ochando-Pulido and Martínez-Férez 2017; Roselló-Soto et al. 2015). Food waste generation is a result of raisin global economic development, which collaborates to discard food and by-products that still contain nutritive agents and is most often related to the behavior of retailers, the foodservice sector, and consumers (Ong et al. 2018). Carmona-Cabello et al. (2018) highlighted the importance of new strategies in biorefineries based on food waste nutrients and their interactions to generate new sustainable feedstocks, as illustrated in Fig. 1.1.

General concept of food waste recovery based on its composition in biorefinery (Carmona-Cabello et al. 2018)

In addition to this, it is well-known that the final waste disposal has become a major concern of food industries due its harmful impact on the environment. Until now, various methods have been potentially proposed attending such an issue, including dissolved air flotation, simple decantation, de-emulsification, coagulation and flocculation, enzymatic hydrolysis, fermentations, to mention just a few of them, in which their primary core is targeted to reduce the organic matter from aqueous waste stream (Maroušek et al. 2019; Ale et al. 2020) or to produce extensive valuable components (García-Depraect et al. 2021). At this point, membrane technologies, such as micro- (MF), ultra- (UF) and nano- (NF) filtration, have also assisted the treatment of food wastes (by-products, wastewaters, so on). As an outlook, it can be described that MF has been involved in macroscopic pre-treatment (MF), while UF and NF implementation has been mainly devoted to the selective separation, fractionation and concentration (Cassano and Conidi 2019; Cassano et al. 2015a; Galanakis 2015). Therefore, the main goal of this chapter is to release an overview of the bioactive compounds (mainly phenolic compounds) and some food ingredients that have been recovered from natural sources and food wastes by means of membrane-based technologies. This chapter also describes some basic principles of membrane technologies and their relevant phenomena appearing during the recovery of specific compounds, finalizing with the current challenges of membrane technologies in bioactive extraction.

2 Membrane Technologies: The Emerging Pathway for Recovering Bioactive Compounds

In principle, pressure-driven membrane technologies are generally differentiated by the membrane’s molecular weight cut-off (MWCO), as represented in Fig. 1.2. Initially, the presence of a narrower pore size of the membrane will require a higher pressure demand. MF generally owns the larger pore size allowing to easily remove suspended particles, bacteria, and oil emulsion (Ochando-Pulido and Martínez-Férez 2017; Castro-Muñoz et al. 2015a), while UF is declared as one of the most efficient membrane technologies for the separation of proteins, sub-molecular organic groups, viruses, macromolecules (Russo et al. 2019; Castro-Muñoz and Yañez-Fernandez 2015; Van Der Bruggen et al. 2003a). Evidently, the separation performance of UF becomes more efficient when membranes have tight pore sizes (Galanakis 2015; Cassano et al. 2018), it means, the UF membranes possess a MWCO in the range of 1–3 kDa, being able to effectively extract and thus concentrate low-molecular weight molecules (including anthocyanins, low molecular weight phenols, low molecular weight sugars, and peptides) (Castro-Muñoz et al. 2020a); these particular membranes are categorized in the molecular limit of the NF membranes.

Schematic drawing of pressure-driven membrane technologies and their role in separation (Liang et al. 2019)

Considered as the most selective technology for the fractionation and concentration of bioactives, NF technology (having pore size between 350–400 Da), together with tight UF membranes are the most recommended to achieve the recovery of low molecular weight polyphenols (Liang et al. 2019; Castro-Muñoz et al. 2019a). In the light of recovery bioactives from natural products, Table 1.1 summarizes the most extracted bioactives from natural sources using membrane technologies. It can be proved that these technologies exhibit acceptable recovery rates towards various bioactives; for instance, MF offers a rate from 47 up to ∼100% toward molecules with a molecular weight between 200 and 500 g/mol, such as anthocyanins, glutamine, isoproline, proline, betanin, isobetanin, sugars, and galacturonic acid and some phenolic compounds. Depending on the membrane’s MWCO, UF can display rates between 44 and 99% of similar compounds, which have been mainly contained on the permeate side. It is important to note that some of these bioactives can be initiated to be retained by the membranes, and hence partially recovered on the retentate side. NF in turn collects mostly water on permeate side and concurrently concentrates bioactive molecules on the retentate side from 50 up to 99%. In addition to this, the application of membrane technologies has been extended to the extraction of specific food ingredients. This is the case of steviol glycosides (SGs) generally obtained from the Stevia rebaudiana plant (Žlabur et al. 2015). Such ingredients have recently increased their popularity since they can easily exceed the sweetening power of sucrose. Castro-Muñoz and co-workers (Castro-Muñoz et al. 2020b) have recently reviewed the current advanced in extracting SGs via membrane process. In principle, considering their molecular weight (oscillates about 318 g/mol) (Myint et al. 2020) and physiochemical properties, their extraction has been proposed using specific methods (such as solvent extraction, microwave-assisted extraction, supercritical fluid extraction, chromatographic techniques, etc) (Žlabur et al. 2015; Bursać Kovačević et al. 2018; Jaitak et al. 2009; Carbonell-Capella et al. 2017), however, their purification becomes challenging since they have exhibited specific bioactive properties (against diabetes mellitus, cancer, hypertension, gastroenteritis, cholesterol) (Ceunen and Geuns 2013), therefore, the research community has initiated to look for alternatives to preserve such bioactivity. By analyzing the literature data, Castro-Muñoz et al. stated that membranes can offer recovery yields from 25 to 80%. They also found out that the recovery rate strongly depends on various factors, such as operating parameters (transmembrane pressure, feed flow, temperature, etc.), intrinsic properties of the membranes and pre-treatment steps. However, the highest efficiencies were noticed using integrated membrane processes. For instance, Díaz-Montes et al. (2020a) demonstrated that a two-step UF processes (implying 100/1 kDa membranes) was effective enough to extract rebaudioside A, as depicted in Fig. 1.3.

Integrated ultrafiltration process implemented for the aqueous extraction of SGs (Díaz-Montes et al. 2020a)

More specifically, the authors reported that the UF100 membrane unit worked mostly to remove total solids (ca. 42%) and carbohydrates (ca. 41%) from the crude aqueous extract, while tight UF1 membrane unit recovered about 93% of the initial rebaudioside A.

In the light of integrated membrane processes, Valencia-Arredondo et al. (2020) implemented, for the first time, an integrated membrane-adsorption protocol for anthocyanin extraction from red cabbage. In a first approach, the acidified extract, containing 32 mg cyanidin-3-glucoside per milliliter (mg ECyn-3-glu•L−1), was processed using membrane technologies, such as MF and UF followed by adsorption processes, producing an enriched anthocyanin concentrate with 3221 mg ECyn-3-glu•L−1. Secondly, the pigments were completely fractionated by molecular exclusion chromatography, reverse-phase vacuum liquid chromatography and semi-preparative chromatography, purifying di-acylated cyanidin. The latter is recognized among the most valuable water-soluble pigments. Its importance comprises as food additive for use in manufacturing purple-colored jam, confectionaries, and beverages. It is important to mention that acylated anthocyanins are used in the food industry since they display high stability over nonacylated anthocyanins (Khoo et al. 2017). This approach opened a new window of exploration since more efficient integration processes are needed to satisfy the current demand for natural ingredients and colorants for food formulations (Carunchia et al. 2015). With the aim of extracting another food additive (like dextran) from complex aqueous systems, Díaz-Montes et al. (Díaz-Montes et al. 2020b) developed an integrated microdiafiltration-MF process for dextran extraction from fermentation broth. The usage of dextran regards as stabilizer and moisturizer (Heinze et al. 2006). Its synthesis is primarily performed via facultative bacteria Leuconostoc mesenteroides , cultivated in a sucrose enriched medium (Aman et al. 2012). The typical production of dextran implies separation and extraction stages, such as precipitation with polar solvents (e.g., ethanol and methanol) due to its insoluble properties in such alcohols (Vettori et al. 2011). At this point, Díaz-Montes et al. pointed out this integrated membrane approach can simultaneously extract and recover of dextran from the fermentation broth. Additionally, the authors compared the microfiltration-mediated extraction with a conventional solvent extraction protocol in terms of product yield, and physicochemical properties of the dextran. Interestingly, a successful extraction with a final yield (∼22%) was acquired using the membrane stages and resulted in less ethanol use for the final dextran precipitation, saving about 75% ethanol compared with normal ethanol precipitation.

Apart from recovery of bioactive compounds and food ingredients from natural sources, membrane technologies are contributing to the treatment of the primary by-products and wastes from food industries. Initially, these technologies were implemented for the organic matter elimination from aqueous streams, nevertheless, such a role has shifted to the valorization of agricultural waste enriched in a wide amount of bioactive molecules (Castro et al. 2018). For instance, Table 1.2 enlists the main bioactive compounds reclaimed from food wastes using membrane processes. Hydroxytyrosol, protocatechuic acid, caffeic acid, tyrosol and p-cumaric acid are among the most recovered bioactives, while olive mill wastewaters (OMW) have been found as the most investigated food waste over the last 20 years (Rahmanian et al. 2014; Conidi et al. 2014a; Galanakis et al. 2016; Cassano et al. 2016a). Russo (2007) was most probably the pioneering scientist proposing a membrane steps for the fractionation phenolic compounds from raw OMW extracts. Herein, MF and UF processes were used and produced permeates containing phenolic fractions, such as hydroxytyrosol (134,879–266,679 ppm), tyrosol (7968–11,218 ppm,) oleuropein (7765–26,698 ppm), caffeic acid (10,570–21,982 ppm) and protocatechuic acid (8871–22,601 ppm), among others. Since olive and its derived products are fundamental part of the Mediterranean diet (Bendini et al. 2007), it is obvious that by-products derived from olive processing are among the most produced wastes but also relevant source of nutraceutical molecules. The author also utilized NF and Reverse Osmosis (RO) unit operations for the fractionation and concentration of the phenolics, respectively (Russo 2007).

Unfortunately, most of the researches have concluded that the fouling phenomenon is a critical parameter when dealing with the long-term operation and stable performance of the processes. Therefore, the concept of integrated membrane processes has also been used in these applications to reduced membrane fouling. By prepending UF and NF membranes. Cassano et al. (2013) fractionated OMWs obtaining a concentrated fraction enriched with phenolic substances (ca. 960 mg L−1), which was suggested for food, cosmetic and pharmaceutical applications according to the presence of hydroxytyrosol, tyrosol, caffeic acid, p-cumaric acid, catechol and protocatechuic acid. In this work, the authors proposed a narrow pore size membrane, which in contribution with the nature of the phenolics, reached an excellent recovery. It is documented that phenolic compounds possess aromatic rings and aliphatic chains producing a hydrophobic profile increasing their volume, while concurrently attract water molecules allowing the volume increase of the polyphenols, and thus restricting their permeation due to the “polarity resistance” phenomenon (Galanakis 2015).

The winemaking is another food processing sector that produces large quantities of wastes, including grape seeds, fermented grape pomaces, lees and liquors. Díaz-Reinoso and co-workers (Díaz-Reinoso et al. 2009) recovered antioxidants from liquors. At this point, UF and NF membranes with narrow pore size were able to concentrate phenolic fractions between 0.615–1.09 mg L−1 from initial concentration of 0.173 mg L−1 in extracts. Artichoke wastewaters (AWs) are also important agro-food by-products, which have been a target of study for fractionation via integrated membrane process (Conidi et al. 2014b). In this waste, cynarin, chlorogenic acid and apigenin-7-O-glucoside were the primary molecules obtained with concentrations of 412, 612 and 400 mg L−1, respectively. After evaluating their bioactivity, the complex of polyphenols displayed high antioxidant properties (ca. 40 mM Trolox).

Ultimately, an integrated membrane process was designed to extract bioactive compound compounds from Nixtamalization wastewaters (NWs) (Castro-Muñoz and Yañez-Fernandez 2015), recognized as typical by-product from the tortilla processing in America (Castro-Muñoz et al. 2017). To sum up, MF and tight UF membranes were capable to separate a phenol content of 951 mg L−1. By analyzing the reported development works, this chapter has evidenced that UF and NF technologies can easily recover low molecular weight bioactives (such as phenolic compounds) from various wastewaters (Conidi et al. 2020; Cassano and Conidi 2019; Castro-Muñoz and Ruby-Figueroa 2019). Unfortunately, membrane technologies are still facing specific issues to consolidate their applications. The following section is devoted to the challenges and important factors in the framework of membrane technologies.

3 Challenges in Membrane Technologies for Bioactive Compounds Separation

The challenges of these processes deal with their weakness and limitations during the separation. In this way, it is likely that the “purity restriction” is one of the limitations of membrane technologies since most of the streams do not present pure compounds; in other words, none of the streams usually contain a minor amount of untargeted molecules (Castro-Muñoz et al. 2018b). For instance, the permeate samples can contain a significant amount of molecules aimed to concentrate in the retentate side; this is due to the fact that the membrane selectivity is not infinite. Herein, it is worth noting that the storage and handling of the membranes are crucial to extend the initial physicochemical properties and self-life, for example, if the membrane is treated by the right cleaning procedures without modifying its structure can be reutilized as long as needed. Of course, there is another important matter, like membrane fouling, to maintain the original properties of the membranes. The “fouling” is identified as the key drawback of these technologies and thus the main challenge at obtaining a more feasible and stable process, however, this is an inherent phenomenon since it depends on the types of feed bulk to be treated, basically, it is directly related to the physicochemical composition of feed (Gule et al. 2016). In addition to such factors, the fouling also becomes dependent on the membrane material and configuration, as well as operating and fluid-dynamic parameters. Particularly, the fouling, especially non-reversible fouling, can majorly restrict the permeation rate through the membranes and thus limiting their use towards specific applications.

Conventional protocols to control and regulate membrane fouling involve preliminary treatments of the feed solutions, including particle sedimentation-decantation (Fukuda et al. 2014), centrifugation (Domingues et al. 2014), flocculation (Maroušek et al. 2019), enzymatic hydrolysis (Galiano et al. 2019), screening, along with membrane surface modification (Kucera 2019), hydrodynamic optimization of the membrane module and membrane cleaning with commercial chemical or enzymatic detergents. To date, there are plenty of commercially available enzymatic (such as Ultrasil® 62 and 53, Filzym® 161) and chemical (Ultrasil® 13, OptiClean™ A, Ultrasil® 10A, AMI Chemicals® AM-55) detergents that are usually used to hydrolyze most of the pollutants, including polysaccharides, proteins, polysaccharide-like, protein-like materials and humic substances (Nguyen et al. 2010). In the field of membrane engineering, researchers are strongly working on several developments to prevent the adhesion of organic and inorganic matter that is translated to biofouling on membranes. Here, the core application has been the modification of the physicochemical properties of membranes, such as hydrophilicity, membrane charge, and membrane surface (Pichardo-Romero et al. 2020; Buonomenna 2016). Basically, the manufacture of highly hydrophilic membranes is a promising alternative since they are less prone to matter incrustation. In this regard, the preparation of nanocomposite membranes using inorganic materials and additives seems to be the most advanced way (Castro-Muñoz et al. 2019b; Akar et al. 2013; Vatanpour et al. 2012; Zinadini et al. 2014).

Furthermore, over the course of this chapter, it has been also noted that the use of integrated membrane system can significantly contribute to reduce the early-stage fouling in membranes; a typical integrated membrane process implies the design and arrangement of multiple membrane units in sequence, contributing to mitigate fouling phenomena in the subsequent membrane stages by prepending high pore size membranes (Steeneveldt et al. 2006). Classic cases of mitigation of membrane fouling using membranes have been evidenced in the fractionation of agro-food wastes, such as artichoke wastewaters (Conidi et al. 2014b; Castro-Muñoz et al. 2018c), artichoke brines (Cassano et al. 2016b), OMWs (Russo 2007; Cassano et al. 2013), Nixtamalization (Castro-Muñoz et al. 2015a, c, 2016b; Castro-Muñoz 2019) and cellulose alkaline by-products (Cassano et al. 2016c). It is known that the implementation of integrated membrane system may require more bioseparation steps to meet high recovery rates; nevertheless, the right selection of the membranes and sequence design can give a potential strategy for the fractionation of the food and waste systems.

When dealing with the fabrication of membranes, polymers are among the main materials used in membrane preparation at industrial level. Here, there are thermal, mechanical and chemical limitations in this kind of membranes. Polymeric membrane modules cannot offer an operation at high temperature conditions since polymers do not guarantee their physical integrity at temperatures over 90–100 °C. In addition to this, most of the polymers are susceptible to chemical degradation when treating strong acid and alkaline substances, resulting in a significant reduction in membrane life. Also, specific polymeric membranes have limited mechanical stability leading to a diminish in permeability at high pressures and potential membrane failure. In this sense, it is likely that inorganic membranes, based on alumina (Al2O3), titania (TiO2), silica (SiO2) and zirconia (ZrO2), can overcome such limitations showing greatly improved chemical, mechanical and thermal stability in comparison with polymeric membranes (Majumdar et al. 2020; Castro-Muñoz et al. 2019c). Inorganic membranes are able to operate at temperatures as high as 500 °C, with extreme pH values and they are suitable to be subjected for cleaning with chemicals, organic solvents and hot water.

Finally, as in most of the downstream processes, the energy consumption-cost relationship is a critical factor when regarding the feasibility of processes. Theoretically, pressure-driven membrane processes have been considered as low energy consumption separation techniques (Mirza 2008; Van Der Bruggen et al. 2003b), which in turn can reduce the operating costs, however, membrane modules represent the major direct capital cost of all the unit membrane separation, followed by the devices investment and their maintenance, which indeed contribute greatly to overall process costs.

4 Conclusion

In this chapter, membrane technologies have been demonstrated their ability in separation functional bioactive compounds and food ingredients from natural sources, as well as their derivative products and wastes. At this point, UF and NF membranes can be efficiently used to separate, fractionate and concentrate bioactive compounds that, according to their biological activity, have potential applications in the food and pharmaceutical industries. When compared with conventional recovery processes, these membrane-based processes are economically viable not only in terms of recovery, but also since they do not need the application of external agents. Apart from natural sources, the production of bioactive solutes from wastes is both industrially sustainable and environmentally friendly alternative.

It is quite possible that R&D will pay attention on new implementations of NF technology as the emerging tool for the recovery and concentration of phenolic-based compounds. Importantly, when further purification is required, the implementation of alternative selective methodologies, such as osmotic distillation and adsorption processes, will be needed. To finalize, this chapter also denotes the main challenges of membrane technologies in terms of purity restrictions, chemical, mechanical and thermal stability and energy consumption-cost relationship, which should be analyzed by technicians before applying at any recovery stage. Likewise, such criteria greatly play an important role in the consolidation of such technologies.

Abbreviations

- MF:

-

Microfiltration

- UF:

-

Ultrafiltration

- NF:

-

Nanofiltration

- MWCO:

-

Molecular weight cut-off

- SG:

-

steviol glycosides

References

Akar N, Asar B, Dizge N, Koyuncu I (2013) Investigation of characterization and biofouling properties of PES membrane containing selenium and copper nanoparticles. J Membr Sci 437:216–226. https://doi.org/10.1016/j.memsci.2013.02.012

Ale F, Castro-Muñoz R, Barragán-Huerta BE, Rodriguez-Nava O (2020) Effect of barium addition on hydrolytic enzymatic activities in food waste degradation under anaerobic conditions. PRO 8:1–16

Aman A, Siddiqui NN, Qader SAU (2012) Characterization and potential applications of high molecular weight dextran produced by Leuconostoc mesenteroides AA1. Carbohydr Polym 87:910–915. https://doi.org/10.1016/j.carbpol.2011.08.094

Arend GD, Adorno WT, Rezzadori K, Di Luccio M, Chaves VC, Reginatto FH et al (2017) Concentration of phenolic compounds from strawberry (Fragaria X ananassa Duch) juice by nanofiltration membrane. J Food Eng 201:36–41. https://doi.org/10.1016/j.jfoodeng.2017.01.014

Baklouti S, Ellouze-Ghorbel R, Mokni A, Chaabouni (2012) Clarification of pomegranate juice by ultrafiltration: study of juice quality and of the fouling mechanism. Fruits 67:215–225. https://doi.org/10.1051/fruits/2012010

Barba FJ, Galanakis CM, Esteve MJ, Frigola A, Vorobiev E (2015) Potential use of pulsed electric technologies and ultrasounds to improve the recovery of high-added value compounds from blackberries. J Food Eng 167:38–44. https://doi.org/10.1016/j.jfoodeng.2015.02.001

Bazzarelli F, Piacentini E, Poerio T, Mazzei R, Cassano A, Giorno L (2016) Advances in membrane operations for water purification and biophenols recovery/valorization from OMWWs. J Membr Sci 497:402–409. https://doi.org/10.1016/j.memsci.2015.09.049

Bendini A, Cerretani L, Carrasco-Pancorbo A, Gómez-Caravaca AM, Segura-Carretero A, Fernández-Gutiérrez A et al (2007) Phenolic molecules in virgin olive oils: a survey of their sensory properties, health effects, antioxidant activity and analytical methods. An overview of the last decade. Molecules 12:1679–1719. https://doi.org/10.3390/12081679

Buonomenna MG (2016) Smart composite membranes for advanced wastewater treatments. Elsevier Ltd. https://doi.org/10.1016/B978-1-78242-283-9.00014-2.

Burdock GA, Carabin IG, Griffiths JC (2006) The importance of GRAS to the functional food and nutraceutical industries. Toxicology 221:17–27. https://doi.org/10.1016/j.tox.2006.01.012

Bursać Kovačević D, Maras M, Barba FJ, Granato D, Roohinejad S, Mallikarjunan K et al (2018) Innovative technologies for the recovery of phytochemicals from Stevia rebaudiana Bertoni leaves: a review. Food Chem 268:513–521. https://doi.org/10.1016/j.foodchem.2018.06.091

Carbonell-Capella JM, Šic Žlabur J, Rimac Brnčić S, Barba FJ, Grimi N, Koubaa M et al (2017) Electrotechnologies, microwaves, and ultrasounds combined with binary mixtures of ethanol and water to extract steviol glycosides and antioxidant compounds from Stevia rebaudiana leaves. J Food Process Preserv 41:1–8. https://doi.org/10.1111/jfpp.13179

Carmona-Cabello M, Garcia IL, Leiva-Candia D, Dorado MP (2018) Valorization of food waste based on its composition through the concept of biorefinery. Curr Opin Green Sustain Chem 14:67–79. https://doi.org/10.1016/j.cogsc.2018.06.011

Carunchia M, Wang L, Han JH (2015) The use of antioxidants in the preservation of snack foods. In: Shahidi F (ed) Handbook of antioxidants for food preservation, vol 6. Elsevier Ltd, pp 447–74. https://doi.org/10.1016/B978-1-78242-089-7.00019-1.

Cassano A (2003) Clarification and concentration of citrus and carrot juices by integrated membrane processes. J Food Eng 57:153–163

Cassano A, Conidi C (2019) Castro-Muñoz R. Current and Future Applications of Nanofiltration in Food Processing. https://doi.org/10.1016/b978-0-12-815056-6.00009-7

Cassano A, Jiao B, Drioli E (2004) Production of concentrated kiwifruit juice by integrated membrane process. Food Res Int 37:139–148. https://doi.org/10.1016/j.foodres.2003.08.009

Cassano A, Conidi C, Timpone R, D’Avella M, Drioli E (2007) A membrane-based process for the clarification and the concentration of the cactus pear juice. J Food Eng 80:914–921. https://doi.org/10.1016/j.jfoodeng.2006.08.005

Cassano A, Donato L, Conidi C, Drioli E (2008) Recovery of bioactive compounds in kiwifruit juice by ultrafiltration. Innov Food Sci Emerg Technol 9:556–562. https://doi.org/10.1016/j.ifset.2008.03.004

Cassano A, Tasselli F, Conidi C, Drioli E (2009) Ultrafiltration of clementine mandarin juice by hollow fibre membranes. Desalination 241:302–308. https://doi.org/10.1016/j.desal.2007.10.102

Cassano A, Conidi C, Drioli E (2010) Physico-chemical parameters of cactus pear (Opuntia ficus-indica) juice clarified by microfiltration and ultrafiltration processes. Desalination 250:1101–1104. https://doi.org/10.1016/j.desal.2009.09.117

Cassano A, Conidi C, Drioli E (2011a) Clarification and concentration of pomegranate juice (Punica granatum L.) using membrane processes. J Food Eng 107:366–373. https://doi.org/10.1016/j.jfoodeng.2011.07.002

Cassano A, Conidi C, Drioli E (2011b) Comparison of the performance of UF membranes in olive mill wastewaters treatment. Water Res 45:3197–3204. https://doi.org/10.1016/j.watres.2011.03.041

Cassano A, Conidi C, Giorno L, Drioli E (2013) Fractionation of olive mill wastewaters by membrane separation techniques. J Hazard Mater 248–249:185–193. https://doi.org/10.1016/j.jhazmat.2013.01.006

Cassano A, Conidi C, Ruby-Figueroa R (2014) Recovery of flavonoids from orange press liquor by an integrated membrane process. Membranes (Basel) 4:509–524. https://doi.org/10.3390/membranes4030509

Cassano A, Conidi C, Ruby-Figueroa R, Castro-Muñoz R (2015a) A two-step nanofiltration process for the production of phenolic-rich fractions from artichoke aqueous extracts. Int J Mol Sci 16:8968–8987. https://doi.org/10.3390/ijms16048968

Cassano A, Conidi C, Ruby-Figueroa R, Castro-Muñoz R (2015b) A two-step nanofiltration process for the production of phenolic-rich fractions from artichoke aqueous extracts. Int J of Mol Sci:8968–8987. https://doi.org/10.3390/ijms16048968

Cassano A, Conidi C, Tasselli F (2015c) Clarification of pomegranate juice (Punica Granatum L.) by hollow fibre membranes: analyses of membrane fouling and performance. J Chem Technol Biotechnol 90:859–866. https://doi.org/10.1002/jctb.4381

Cassano A, Conidi C, Galanakis CM, Castro-Muñoz R (2016a) Recovery of polyphenols from olive mill wastewaters by membrane operations. https://doi.org/10.1016/B978-0-08-100451-7.00007-4.

Cassano A, Cabri W, Mombelli G, Peterlongo F, Giorno L (2016b) Recovery of bioactive compounds from artichoke brines by nanofiltration. Food Bioprod Process 98:257–265. https://doi.org/10.1016/j.fbp.2016.02.004

Cassano A, Destani F, Conidi C (2016c) Remediation of spent alkaline solutions in the production of cellulose fibers from Spanish broom by membrane operations. J Water Process Eng 10:48–55. https://doi.org/10.1016/j.jwpe.2016.02.001

Cassano A, Conidi C, Ruby-Figueroa R, Castro-Muñoz R (2018) Nanofiltration and tight ultrafiltration membranes for the recovery of polyphenols from agro-food by-products. Int J Mol Sci 19:351. https://doi.org/10.3390/ijms19020351

Castro R, Blanca M, Huerta EB, Fíla V (2018) Current role of membrane technology: from the treatment of agro-industrial by-products up to the valorization of valuable compounds. Waste Biomass Valoriz 9:513–529. https://doi.org/10.1007/s12649-017-0003-1

Castro-Muñoz R (2019) Retention profile on the physicochemical properties of maize cooking by-product using a tight ultrafiltration membrane. Chem Eng Commun 0:1–9. https://doi.org/10.1080/00986445.2019.1618844

Castro-Muñoz R, Ruby-Figueroa A (2019) Membrane technology for the recovery of high-added value compounds from meat processing coproducts. In: Galanakis CM (ed) Sustainable meat production and processing, 1st edn. Elsevier, London, pp 127–43. https://doi.org/10.1016/B978-0-12-814874-7.00007-9.

Castro-Muñoz R, Yañez-Fernandez J (2015) Valorization of nixtamalization wastewaters (nejayote) by integrated membrane process. Food Bioprod Process 95. https://doi.org/10.1016/j.fbp.2015.03.006

Castro-Muñoz R, Orozco-Álvarez C, Cerón-Montes GI, Yáñez-Fernández J (2015a) Characterization of the microfiltration process for the treatment of nixtamalization wastewaters. Ing Agric y Biosist 7:23–34. https://doi.org/10.5154/r.inagbi.2015.03.001

Castro-Muñoz R, Barragan-Huerta BE, Yañez-Fernandez J (2015b) Use of gelatin-maltodextrin composite as an encapsulation support for clarified juice from purple cactus pear (Opuntia stricta). LWT Food Sci Technol 62. https://doi.org/10.1016/j.lwt.2014.09.042

Castro-Muñoz R, Cerón-Montes GI, Barragán-Huerta BE, Yáñez-Fernández J (2015c) Recovery of carbohydrates from Nixtamalization wastewaters (Nejayote) by ultrafiltration. Rev Mex Ing Química 14:735–744

Castro-Muñoz R, Yáñez-Fernández J, Fíla V (2016a) Phenolic compounds recovered from agro-food by-products using membrane technologies: an overview. Food Chem 213:753–762. https://doi.org/10.1016/j.foodchem.2016.07.030

Castro-Muñoz R, Barragán-Huerta BE, Yáñez-Fernández J (2016b) The use of nixtamalization waste waters clarified by ultrafiltration for production of a fraction rich in phenolic compounds. Waste Biomass Valoriz 7:1167–1176. https://doi.org/10.1007/s12649-016-9512-6

Castro-Muñoz R, Fíla V, Durán-Páramo E (2017) A review of the primary by-product (Nejayote) of the nixtamalization during maize processing: potential reuses. Waste Biomass Valoriz 0:1–10. https://doi.org/10.1007/s12649-017-0029-4

Castro-Muñoz R, Fíla V, Barragán-Huerta BE, Yáñez-Fernández J, Piña-Rosas JA, Arboleda-Mejía J (2018a) Processing of Xoconostle fruit (Opuntia joconostle) juice for improving its commercialization using membrane filtration. J Food Process Preserv. https://doi.org/10.1111/jfpp.13394

Castro-Muñoz R, Conidi C, Cassano A. Membrane-based technologies for meeting the recovery of biologically active compounds from foods and their by-products. Crit Rev Food Sci Nutr 2018b;0:1–22. https://doi.org/10.1080/10408398.2018.1478796.

Castro-Muñoz R, Conidi C, Cassano A (2018c) Recovery of phenolic-based compounds from agro-food wastewaters through pressure-driven membrane technologies. https://doi.org/10.1016/B978-0-12-815056-6.00006-1

Castro-Muñoz R, Conidi C, Cassano A (2019a) Membrane-based technologies for meeting the recovery of biologically active compounds from foods and their by-products. Crit Rev Food Sci Nutr 59:2927–2948. https://doi.org/10.1080/10408398.2018.1478796

Castro-Muñoz R, Fíla V, Ahmad MZ (2019b) Enhancing the CO2 separation performance of matrimid 5218 membranes for CO2/CH4 binary mixtures. Chem Eng Technol 42:645–654. https://doi.org/10.1002/ceat.201800111

Castro-Muñoz R, Buera-González J, de la Iglesia Ó, Galiano F, Fíla V, Malankowska M et al (2019c) Towards the dehydration of ethanol using pervaporation cross-linked poly(vinyl alcohol)/graphene oxide membranes. J Membr Sci 582:423–434. https://doi.org/10.1016/j.memsci.2019.03.076

Castro-Muñoz R, Boczkaj G, Gontarek E, Cassano A, Fíla V (2020a) Membrane technologies assisting plant-based and agro-food by-products processing: a comprehensive review. Trends Food Sci Technol 95:219–232. https://doi.org/10.1016/j.tifs.2019.12.003

Castro-Muñoz R, Díaz-Montes E, Cassano A, Gontarek E (2020b) Membrane separation processes for the extraction and purification of steviol glycosides: an overview. Crit Rev Food Sci Nutr 4:1–23. https://doi.org/10.1080/10408398.2020.1772717

Castro-Muñoz R, González-Melgoza LL, García-Depraect O (2021) Ongoing progress on novel nanocomposite membranes for the separation of heavy metals from contaminated water. Chemosphere 270. https://doi.org/10.1016/j.chemosphere.2020.129421

Cerón-Montes GI, San-Martin-Martinez E, Yañez-Fernández J, Quezada-Cruz M, Castro-Muñoz R (2015) Preliminary purification of anthoncyanins from blue corn by adsorption and electrophoresis. Rev Mex Ing Química 14:99–108

Ceunen S, Geuns JMC (2013) Steviol glycosides: chemical diversity, metabolism, and function. J Nat Prod 76:1201–1228. https://doi.org/10.1021/np400203b

Chemat F, Abert Vian M, Fabiano-Tixier AS, Nutrizio M, Režek Jambrak A, Munekata PES et al (2020) A review of sustainable and intensified techniques for extraction of food and natural products. Green Chem 22:2325–2353. https://doi.org/10.1039/c9gc03878g

Chornomaz PM, Pagliero C, Marchese J, Ochoa NA (2013) Impact of structural and textural membrane properties on lemon juice clarification. Food Bioprod Process 91:67–73. https://doi.org/10.1016/j.fbp.2012.12.001

Cisse M, Vaillant F, Pallet D, Dornier M (2011a) Selecting ultrafiltration and nanofiltration membranes to concentrate anthocyanins from roselle extract (Hibiscus sabdariffa L.). Food Res Int 44:2607–2614. https://doi.org/10.1016/j.foodres.2011.04.046

Cisse M, Vaillant F, Soro D, Reynes M, Dornier M (2011b) Crossflow microfiltration for the cold stabilization of roselle (Hibiscus sabdariffa L.) extract. J Food Eng 106:20–27. https://doi.org/10.1016/j.jfoodeng.2011.04.001

Conidi C, Cassano A, Drioli E (2011) A membrane-based study for the recovery of polyphenols from bergamot juice. J Memb Sci 375:182–190. https://doi.org/10.1016/j.memsci.2011.03.035

Conidi C, Cassano A, Drioli E (2012) Recovery of phenolic compounds from orange press liquor by nanofiltration. Food Bioprod Process 90:867–874. https://doi.org/10.1016/j.fbp.2012.07.005

Conidi C, Mazzei R, Cassano A, Giorno L (2014a) Integrated membrane system for the production of phytotherapics from olive mill wastewaters. J Membr Sci 454:322–329. https://doi.org/10.1016/j.memsci.2013.12.021

Conidi C, Cassano A, Garcia-Castello E (2014b) Valorization of artichoke wastewaters by integrated membrane process. Water Res 48:363–374. https://doi.org/10.1016/j.watres.2013.09.047

Conidi C, Rodriguez-Lopez AD, Garcia-Castello EM, Cassano A (2015) Purification of artichoke polyphenols by using membrane filtration and polymeric resins. Sep Purif Technol 144:153–161. https://doi.org/10.1016/j.seppur.2015.02.025

Conidi C, Cassano A, Caiazzo F, Drioli E (2017) Separation and purification of phenolic compounds from pomegranate juice by ultrafiltration and nanofiltration membranes. J Food Eng 195:1–13. https://doi.org/10.1016/j.jfoodeng.2016.09.017

Conidi C, Castro-Muñoz R, Cassano A (2020) Membrane-based operations in the fruit juice processing industry: a review. Beverages 6:1–39. https://doi.org/10.3390/beverages6010018

Córdova A, Astudillo C, Giorno L, Guerrero C, Conidi C, Illanes A et al (2016) Nanofiltration potential for the purification of highly concentrated enzymatically produced oligosaccharides. Food Bioprod Process 98:50–61. https://doi.org/10.1016/j.fbp.2015.11.005

de Carvalho LMJ, de Castro IM, da Silva CAB (2008) A study of retention of sugars in the process of clarification of pineapple juice (Ananas comosus, L. Merril) by micro- and ultra-filtration. J Food Eng 87:447–454. https://doi.org/10.1016/j.jfoodeng.2007.12.015

De Oliveira RC, Doc?? RC, De Barros STD. Clarification of passion fruit juice by microfiltration: analyses of operating parameters, study of membrane fouling and juice quality. J Food Eng 2012;111:432–439. https://doi.org/10.1016/j.jfoodeng.2012.01.021.

Destani F, Cassano A, Fazio A, Vincken JP, Gabriele B (2013) Recovery and concentration of phenolic compounds in blood orange juice by membrane operations. J Food Eng 117:263–271. https://doi.org/10.1016/j.jfoodeng.2013.03.001

Díaz-Montes E, Castro-Muñoz R (2019) Metabolites recovery from fermentation broths via pressure-driven membrane processes. Asia Pac J Chem Eng 22:e2332. https://doi.org/10.1002/apj.2332.

Díaz-Montes E, Gutiérrez-Macías P, Orozco-Álvarez C, Castro-Muñoz R (2020a) Fractionation of Stevia rebaudiana aqueous extracts via two-step ultrafiltration process: towards rebaudioside a extraction. Food Bioprod Process 123:111–122. https://doi.org/10.1016/j.fbp.2020.06.010

Díaz-Montes E, Yáñez-Fernández J, Castro-Muñoz R (2020b) Microfiltration-mediated extraction of dextran produced by Leuconostoc mesenteroides SF3. Food Bioprod Process 119:317–328. https://doi.org/10.1016/j.fbp.2019.11.017

Díaz-Reinoso B, Moure A, Domínguez H, Parajó JC (2009) Ultra- and nanofiltration of aqueous extracts from distilled fermented grape pomace. J Food Eng 91:587–593. https://doi.org/10.1016/j.jfoodeng.2008.10.007

Díaz-Reinoso B, González-López N, Moure A, Domínguez H, Parajó JC (2010) Recovery of antioxidants from industrial waste liquors using membranes and polymeric resins. J Food Eng 96:127–133. https://doi.org/10.1016/j.jfoodeng.2009.07.007

Díaz-Reinoso B, Moure A, Domínguez H, Parajó JC (2011) Membrane concentration of antioxidants from Castanea sativa leaves aqueous extracts. Chem Eng J 175:95–102. https://doi.org/10.1016/j.cej.2011.09.059

Domingues RCC, Ramos AA, Cardoso VL, Reis MHM (2014) Microfiltration of passion fruit juice using hollow fibre membranes and evaluation of fouling mechanisms. J Food Eng 121:73–79. https://doi.org/10.1016/j.jfoodeng.2013.07.037

Fuenmayor CA, Lemma SM, Mannino S, Mimmo T, Scampicchio M (2014) Filtration of apple juice by nylon nanofibrous membranes. J Food Eng 122:110–116. https://doi.org/10.1016/j.jfoodeng.2013.08.038

Fukuda J, Iwura T, Yanagihara S, Kano K (2014) Separation and quantification of monoclonal-antibody aggregates by hollow-fiber-flow field-flow fractionation. Anal Bioanal Chem 406:6257–6264. https://doi.org/10.1007/s00216-014-8065-4

Gachovska T, Cassada D, Subbiah J, Hanna M, Thippareddi H, Snow D (2010) Enhanced anthocyanin extraction from red cabbage using pulsed electric field processing. J Food Sci 75. https://doi.org/10.1111/j.1750-3841.2010.01699.x

Galanakis CM (2015) Separation of functional macromolecules and micromolecules: from ultrafiltration to the border of nanofiltration. Trends Food Sci Technol 42:44–63. https://doi.org/10.1016/j.tifs.2014.11.005

Galanakis CM, Tornberg E, Gekas V (2010) Clarification of high-added value products from olive mill wastewater. J Food Eng 99:190–197. https://doi.org/10.1016/j.jfoodeng.2010.02.018

Galanakis CM, Markouli E, Gekas V (2013) Recovery and fractionation of different phenolic classes from winery sludge using ultrafiltration. Sep Purif Technol 107:245–251. https://doi.org/10.1016/j.seppur.2013.01.034

Galanakis CM, Castro-Muñoz R, Cassano A (2016) Conidi C. Recovery of high-added-value compounds from food waste by membrane technology. https://doi.org/10.1016/B978-0-08-100451-7.00008-6

Galaverna G, Di Silvestro G, Cassano A, Sforza S, Dossena A, Drioli E et al (2008) A new integrated membrane process for the production of concentrated blood orange juice: effect on bioactive compounds and antioxidant activity. Food Chem 106:1021–1030. https://doi.org/10.1016/j.foodchem.2007.07.018

Galiano F, Mecchia A, Castro-Muñoz R, Tagarelli A, Lavecchia R, Figoli A (2019) Enzyme-mediated extraction of limonene, linalool and linalyl acetate from bergamot peel oil by pervaporation graphical abstract keywords. J Membr Sci Res 5:187–193. https://doi.org/10.22079/JMSR.2018.95080.1221

Garcia-Castello E, Cassano A, Criscuoli A, Conidi C, Drioli E (2010) Recovery and concentration of polyphenols from olive mill wastewaters by integrated membrane system. Water Res 44:3883–3892. https://doi.org/10.1016/j.watres.2010.05.005

García-Depraect O, Castro-Muñoz R, Muñoz R, Rene ER, León-Becerril E, Valdez-Vazquez I et al (2021) A review on the factors influencing biohydrogen production from lactate: the key to unlocking enhanced dark fermentative processes. Bioresour Technol 324. https://doi.org/10.1016/j.biortech.2020.124595

Garcia-Ivars J, Iborra-Clar MI, Alcaina-Miranda MI, Mendoza-Roca JA, Pastor-Alcañiz L (2015) Treatment of table olive processing wastewaters using novel photomodified ultrafiltration membranes as first step for recovering phenolic compounds. J Hazard Mater 290:51–59. https://doi.org/10.1016/j.jhazmat.2015.02.062

Giacobbo A, Do Prado JM, Meneguzzi A, Bernardes AM, De Pinho MN (2015) Microfiltration for the recovery of polyphenols from winery effluents. Sep Purif Technol 143:12–18. https://doi.org/10.1016/j.seppur.2015.01.019

Giacobbo A, Meneguzzi A, Bernardes AM, de Pinho MN (2017) Pressure-driven membrane processes for the recovery of antioxidant compounds from winery effluents. J Clean Prod 155:172–178. https://doi.org/10.1016/j.jclepro.2016.07.033

Gibson GR, Probert HM, Van Loo J, Rastall RA, Roberfroid MB (2004) Dietary modulation of the human colonic microbiota: updating the concept of prebiotics. Nutr Res Rev 17:259–275. https://doi.org/10.1079/nrr200479

Gule NP, Begum NM, Klumperman B (2016) Advances in biofouling mitigation: a review. Crit Rev Environ Sci Technol 46:535–555. https://doi.org/10.1080/10643389.2015.1114444

Gulec HA, Bagci PO, Bagci U (2017) Clarification of apple juice using polymeric ultrafiltration membranes: a comparative evaluation of membrane fouling and juice quality. Food Bioprocess Technol 10:875–885. https://doi.org/10.1007/s11947-017-1871-x

Gulec HA, Bagci PO, Bagci U (2018) Performance enhancement of ultrafiltration in apple juice clarification via low-pressure oxygen plasma: a comparative evaluation versus pre-flocculation treatment. LWT Food Sci Technol 91:511–517. https://doi.org/10.1016/j.lwt.2018.01.082

Heinze T, Liebert T, Heublein B, Hornig S (2006) Functional polymers based on dextran. Polysaccharides II, pp 199–291.

Jaitak V, Bandna SB, Kaul VK (2009) An efficient microwave-assisted extraction process of stevioside and rebaudioside-A from Stevia rebaudiana (Bertoni). Phytochem Anal 20:240–245. https://doi.org/10.1002/pca.1120

Khoo HE, Azlan A, Tang ST, Lim SM (2017) Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr Res 61. https://doi.org/10.1080/16546628.2017.1361779

Kucera J (2019) Biofouling of polyamide membranes: fouling mechanisms, current mitigation and cleaning strategies, and future prospects. Membranes (Basel) 9. https://doi.org/10.3390/membranes9090111

Laorko A, Li Z, Tongchitpakdee S, Chantachum S, Youravong W (2010) Effect of membrane property and operating conditions on phytochemical properties and permeate flux during clarification of pineapple juice. J Food Eng 100:514–521. https://doi.org/10.1016/j.jfoodeng.2010.04.039

Liang CZ, Chung TS, Lai JY (2019) A review of polymeric composite membranes for gas separation and energy production. Prog Polym Sci 97:101141. https://doi.org/10.1016/j.progpolymsci.2019.06.001

Machado MTC, Trevisan S, Pimentel-Souza JDR, Pastore GM, Hubinger MD (2016) Clarification and concentration of oligosaccharides from artichoke extract by a sequential process with microfiltration and nanofiltration membranes. J Food Eng 180:120–128. https://doi.org/10.1016/j.jfoodeng.2016.02.018

Majumdar S, Tokay B, Martin-Gil V, Campbell J, Castro-Muñoz R, Ahmad MZ et al (2020) Mg-MOF-74/polyvinyl acetate (PVAc) mixed matrix membranes for CO2 separation. Sep Purif Technol 238:116411. https://doi.org/10.1016/j.seppur.2019.116411

Malićanin M, Rac V, Antić V, Antić M, Palade LM, Kefalas P et al (2014) Content of antioxidants, antioxidant capacity and oxidative stability of grape seed oil obtained by ultra sound assisted extraction. J Am Oil Chem Soc. https://doi.org/10.1007/s11746-014-2441-2

Maroušek J, Stehel V, Vochozka M, Kolář L, Maroušková A, Strunecký O et al (2019) Ferrous sludge from water clarification: changes in waste management practices advisable. J Clean Prod 218:459–464. https://doi.org/10.1016/j.jclepro.2019.02.037

Mello BCBS, Petrus JCC, Hubinger MD (2010) Concentration of flavonoids and phenolic compounds in aqueous and ethanolic propolis extracts through nanofiltration. J Food Eng 96:533–539. https://doi.org/10.1016/j.jfoodeng.2009.08.040

Mirza S (2008) Reduction of energy consumption in process plants using nanofiltration and reverse osmosis. Desalination 224:132–142. https://doi.org/10.1016/j.desal.2007.04.084

Mondal S, Cassano A, Conidi C, De S (2016) Modeling of gel layer transport during ultrafiltration of fruit juice with non-Newtonian fluid rheology. Food Bioprod Process 100:72–84. https://doi.org/10.1016/j.fbp.2016.06.012

Moßhammer MR, Stintzing FC, Carle R (2006) Evaluation of different methods for the production of juice concentrates and fruit powders from cactus pear. Innov Food Sci Emerg Technol 7:275–287. https://doi.org/10.1016/j.ifset.2006.04.003

Myint KZ, Chen JM, Zhou ZY, Xia YM, Lin J, Zhang J (2020) Structural dependence of antidiabetic effect of steviol glycosides and their metabolites on streptozotocin-induced diabetic mice. J Sci Food Agric 100:3841–3849. https://doi.org/10.1002/jsfa.10421

Nawaz H, Shi J, Mittal GS, Kakuda Y (2006) Extraction of polyphenols from grape seeds and concentration by ultrafiltration. Sep Purif Technol 48:176–181. https://doi.org/10.1016/j.seppur.2005.07.006

Negrão Murakami AN, De Mello Castanho Amboni RD, Prudêncio ES, Amante ER, de Moraes Zanotta L, Maraschin M et al (2011) Concentration of phenolic compounds in aqueous mate (Ilex paraguariensis a. St. Hil) extract through nanofiltration. LWT Food Sci Technol 44:2211–2216. https://doi.org/10.1016/j.lwt.2011.06.002

Nguyen ST, Roddick FA, Harris JL (2010) Membrane foulants and fouling mechanisms in microfiltration and ultrafiltration of an activated sludge effluent. Water Sci Technol 62:1975–1983. https://doi.org/10.2166/wst.2010.505

Ochando-Pulido JM, Martínez-Férez A (2017) About the recovery of the phenolic fraction from olive mill wastewater by micro and ultracentrifugation membranes. Chem Eng Trans 60:271–276. https://doi.org/10.3303/CET1760046

Ong KL, Kaur G, Pensupa N, Uisan K, Lin CSK (2018) Trends in food waste valorization for the production of chemicals, materials and fuels: case study south and southeast Asia. Bioresour Technol 248:100–112. https://doi.org/10.1016/j.biortech.2017.06.076

Onsekizoglu P (2013) Production of high quality clarified pomegranate juice concentrate by membrane processes. J Membr Sci 442:264–271. https://doi.org/10.1016/j.memsci.2013.03.061

Onsekizoglu P, Bahceci KS, Acar MJ (2010) Clarification and the concentration of apple juice using membrane processes: a comparative quality assessment. J Membr Sci 352:160–165. https://doi.org/10.1016/j.memsci.2010.02.004

Panić M, Gunjević V, Cravotto G, Radojčić RI (2019) Enabling technologies for the extraction of grape-pomace anthocyanins using natural deep eutectic solvents in up-to-half-litre batches extraction of grape-pomace anthocyanins using NADES. Food Chem 300:1–8. https://doi.org/10.1016/j.foodchem.2019.125185

Paraskeva CA, Papadakis VG, Tsarouchi E, Kanellopoulou DG, Koutsoukos PG (2007) Membrane processing for olive mill wastewater fractionation. Desalination 213:218–229. https://doi.org/10.1016/j.desal.2006.04.087

Pichardo-Romero D, Garcia-Arce ZP, Zavala-Ramírez A, Castro-Muñoz R (2020) Current advances in biofouling mitigation in membranes for water treatment: an overview. PRO 8:182. https://doi.org/10.3390/pr8020182

Pizzolato S, Andrada M, Rinaldoni AN, Campderros M (2012) Process for integral use of blueberry. Int J Food Eng 8. https://doi.org/10.1515/1556-3758.2415

Prudêncio APA, Prudêncio ES, Amboni RDMC, Murakami ANN, Maraschin M, Petrus JCC et al (2012) Phenolic composition and antioxidant activity of the aqueous extract of bark from residues from mate tree (Ilex paraguariensis St. Hil.) bark harvesting concentrated by nanofiltration. Food Bioprod Process 90:399–405. https://doi.org/10.1016/j.fbp.2011.12.003

Quist-Jensen CA, Macedonio F, Conidi C, Cassano A, Aljlil S, Alharbi OA et al (2016) Direct contact membrane distillation for the concentration of clarified orange juice. J Food Eng 187:37–43. https://doi.org/10.1016/j.jfoodeng.2016.04.021

Rahmanian N, Jafari SM, Galanakis CM (2014) Recovery and removal of phenolic compounds from olive mill wastewater. J Am Oil Chem Soc 91:1–18. https://doi.org/10.1007/s11746-013-2350-9

Rao AB, Prasad E, Sridhar GRS, Ravikumar YVL (2012) Simple extraction and membrane purification process in isolation of steviosides with improved organoleptic activity. Adv Biosci Biotechnol 03:327–335. https://doi.org/10.4236/abb.2012.34048

Reis MHM, Da Silva FV, Andrade CMG, Rezende SL, Wolf MacIel MR, Bergamasco R (2009) Clarification and purification of aqueous stevia extract using membrane separation process. J Food Process Eng 32:338–354. https://doi.org/10.1111/j.1745-4530.2007.00219.x

Roselló-Soto E, Koubaa M, Moubarik A, Lopes RP, Saraiva JA, Boussetta N et al (2015) Emerging opportunities for the effective valorization of wastes and by-products generated during olive oil production process: non-conventional methods for the recovery of high-added value compounds. Trends Food Sci Technol 45:296–310. https://doi.org/10.1016/j.tifs.2015.07.003

Ruby Figueroa RA, Cassano A, Drioli E (2011) Ultrafiltration of orange press liquor: optimization for permeate flux and fouling index by response surface methodology. Sep Purif Technol 80:1–10. https://doi.org/10.1016/j.seppur.2011.03.030

Ruby-Figueroa R, Cassano A, Drioli E (2012) Ultrafiltration of orange press liquor: optimization of operating conditions for the recovery of antioxidant compounds by response surface methodology. Sep Purif Technol 98:255–261. https://doi.org/10.1016/j.seppur.2012.07.022

Russo C (2007) A new membrane process for the selective fractionation and total recovery of polyphenols, water and organic substances from vegetation waters (VW). J Membr Sci 288:239–246. https://doi.org/10.1016/j.memsci.2006.11.020

Russo F, Castro-Muñoz R, Galiano F, Figoli A (2019) Unprecedented preparation of porous Matrimid ® 5218 membranes. J Membr Sci 585:166–174. https://doi.org/10.1016/j.memsci.2019.05.036

Santamaría B, Salazar G, Beltrán S, Cabezas JL (2002) Membrane sequences for fractionation of polyphenolic extracts from defatted milled grape seeds. Desalination 148:103–109. https://doi.org/10.1016/S0011-9164(02)00661-6

Saura-Calixto F, Goni I (2009) Definition of the mediterranean diet based on bioactive compounds. Crit Rev Food Sci Nutr 49:145–152. https://doi.org/10.1080/10408390701764732

Servili M, Esposto S, Veneziani G, Urbani S, Taticchi A, Di Maio I et al (2011) Improvement of bioactive phenol content in virgin olive oil with an olive-vegetation water concentrate produced by membrane treatment. Food Chem 124:1308–1315. https://doi.org/10.1016/j.foodchem.2010.07.042

Steeneveldt R, Berger B, Torp TA (2006) Co2capture and storage: closing the knowing-doing gap. Chem Eng Res Des 84:739–763. https://doi.org/10.1205/cherd05049

Tylkowski B, Tsibranska I, Kochanov R, Peev G, Giamberini M (2011) Concentration of biologically active compounds extracted from Sideritis ssp. L by nanofiltration. Food Bioprod Process 89:307–314. https://doi.org/10.1016/j.fbp.2010.11.003

Valencia-Arredondo JA, Hernández-Bolio GI, Cerón-Montes GI, Castro-Muñoz R, Yáñez-Fernández J (2020) Enhanced process integration for the extraction, concentration and purification of di-acylated cyanidin from red cabbage. Sep Purif Technol 238:116492. https://doi.org/10.1016/j.seppur.2019.116492

Van Der Bruggen B, Vandecasteele C, Van Gestel T, Doyen W, Leysen R (2003a) A review of pressure-driven membrane processes in wastewater treatment and drinking water production. Environ Prog 22:46–56. https://doi.org/10.1002/ep.670220116

Van Der Bruggen B, Lejon L, Vandecasteele C (2003b) Reuse, treatment, and discharge of the concentrate of pressure-driven membrane processes. Environ Sci Technol 37:3733–3738. https://doi.org/10.1021/es0201754

Vatanpour V, Madaeni SS, Khataee AR, Salehi E, Zinadini S, Monfared HA (2012) TiO2 embedded mixed matrix PES nanocomposite membranes: influence of different sizes and types of nanoparticles on antifouling and performance. Desalination 292:19–29. https://doi.org/10.1016/j.desal.2012.02.006

Vettori MHPB, Mukerjea R, Robyt JF (2011) Comparative study of the efficacies of nine assay methods for the dextransucrase synthesis of dextran. Carbohydr Res 346:1077–1082. https://doi.org/10.1016/j.carres.2011.02.015

Vieira GS, Moreira FKV, Matsumoto RLS, Michelon M, Filho FM, Hubinger MD (2018) Influence of nanofiltration membrane features on enrichment of jussara ethanolic extract (Euterpe edulis) in anthocyanins. J Food Eng 226:31–41. https://doi.org/10.1016/j.jfoodeng.2018.01.013

Vladisavljević GT, Vukosavljević P, Veljović MS (2013) Clarification of red raspberry juice using microfiltration with gas backwashing: a viable strategy to maximize permeate flux and minimize a loss of anthocyanins. Food Bioprod Process 91:473–480. https://doi.org/10.1016/j.fbp.2013.05.004

Xu L, Lamb K, Layton L, Kumar A (2004) A membrane-based process for recovering isoflavones from a waste stream of soy processing. Food Res Int 37:867–874. https://doi.org/10.1016/j.foodres.2004.05.004

Zagklis DP, Paraskeva CA (2015) Purification of grape marc phenolic compounds through solvent extraction, membrane filtration and resin adsorption/desorption. Sep Purif Technol 156:328–335. https://doi.org/10.1016/j.seppur.2015.10.019

Zinadini S, Zinatizadeh AA, Rahimi M, Vatanpour V, Zangeneh H, Beygzadeh M (2014) Novel high flux antifouling nanofiltration membranes for dye removal containing carboxymethyl chitosan coated Fe3O4 nanoparticles. Desalination 349:145–154. https://doi.org/10.1016/j.desal.2014.07.007

Žlabur JŠ, Voća S, Dobričević N, Brnčić M, Dujmić F, Brnčić SR (2015) Optimization of ultrasound assisted extraction of functional ingredients from Stevia rebaudiana Bertoni leaves. Int Agrophysics 29:231–237. https://doi.org/10.1515/intag-2015-0017

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Castro-Muñoz, R., Jafari, S.M. (2021). Introduction to Membrane Separation of Bioactive Compounds; Challenges and Opportunities. In: Jafari, S.M., Castro-Muñoz, R. (eds) Membrane Separation of Food Bioactive Ingredients. Food Bioactive Ingredients. Springer, Cham. https://doi.org/10.1007/978-3-030-84643-5_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-84643-5_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-84642-8

Online ISBN: 978-3-030-84643-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)