Abstract

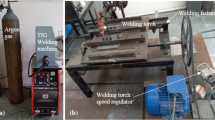

A good-quality weld should have enough penetration, desired microstructure, and bright welding profile without any spatter. Modern welding technology started just before the end of the nineteenth century with the development of methods for generating high temperatures in localized zones. In this study, we have used pulsed TIG (tungsten inert gas) welding. In this work, the weld quality comprises of BW (bead width), DOP (depth of penetration), and its microstructure, which influence the output parameter, i.e., mechanical properties like ultimate tensile strength (UTS) and % elongation. To obtain a good-quality weld, it is, therefore, essential to control the input welding parameters. Traditional one factor at a time method of analysis is time-consuming and does not take into consideration the interaction effects between the input parameters; hence, optimization method with a total of 30 experiments was conducted using CCD of response surface methodology (RSM) to determine the optimum combination of each output process. Experimental data were analyzed by RSM using Design-Expert statistical software version 18. The statistical and analytical steps used in RSM are ANOVA; the second-order polynomial regression equation is used to develop mathematical model and response surface plots of the interaction effects of the factors to evaluate optimum conditions for bead geometry and mechanical properties. The linear, quadratic, and linear interactive effects of the input process variables on the output response were calculated, and their respective significance evaluated by ANOVA test. The p-value was used as the basis for measuring the significance of the regression coefficients, and values of p less than 0.05 signified that the coefficient is significant, otherwise insignificant. The adequacy of the model was tested by the coefficient of determination (R2) value as compared to the adjusted R2 value. The optimal parameter was obtained for BW (170 A, 90 A, 125 Hz, 50%) and DOP (160 A, 80 A, 100 Hz, 45%). After optimization, microstructure characterization has been done on 316 austenite stainless steel weld specimen before and after PWHT (post-weld heat treatment) to see the change in microstructure and to determine the effect of PWHT on tensile strength and on percentage elongation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Website

https://www.sciencedaily.com/releases/2020/04/200403104003.htm

Journal Paper

Ahmad A, Alam S (2018) Grey based Taguchi method for optimization of TIG process parameter in improving tensile strength of S30430 stainless steel. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/404/1/012003

Ahmad A, Alam S (2019) Parametric optimization of TIG welding using response surface methodology. Mater Today Proc 18:3071–3079. https://doi.org/10.1016/j.matpr.2019.07.179

Banerjee P, Sarkar R, Shome M (2016) Effect of nugget size an notch geometry on the high cycle fatigue performance of resistance spot welded DP590 steel sheets. J Mater Process Technol 238:226–243

Box GEP, Draper NR (1987) Empirical model-building and response surfaces. Wiley, New York

Campilho RDSG, Pinto AMG, Banea MD, Silva LFMD (2012) Optimization study of hybrid spot-welded/bonded single-lap joints. Int J Adhes Adhes 37:86–95

Datta S, Bandyopadhyay A, Pal PK (2008) Application of Taguchi philosophy for parametric optimization of bead geometry and HAZ width in submerged arc welding using a mixture of fresh flux and fused flux. Int J Adv Manuf Technol 36(7):689–698. https://doi.org/10.1007/s00170-006-0894-7

Dey V, Pratihar DK, Datta GL, Jha MN, Saha TK, Bapat AV (2009) Optimization of bead geometry in electron beam welding using genetic algorithm. J Mater Process Technol 209:1151–1157

Dhas JER, Kumanan S (2011) Optimization of parameters of submerged arc weld using non-conventional techniques. Appl Soft Comput 11(8):5198–5204. https://doi.org/10.1016/j.asoc.2011.05.041

Dobrota D (2014) Structural modifications which appear in the area of welds of welded structures made of ST 52.3 steel. Metalurgija 53(2):179–182

Eller TK, Greve L, Adnres M, Medricky M, Geiselaers HJM, Meinders VT, van den Boogaard AH (2016) Plasticity and fracture modeling of the heat-affected zone in resistance spot welded tailor hardened boron steel. J Mater Process Technol 234:309–322

Ezekannagha CB, Ude CN, Onukwuli OD (2017) Optimization of the methanolysis of lard oil in the production of biodiesel with response surface methodology. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2016.12.004

Fukuda S, Morita H, Yamauchi Y, Nagasawa I, Tsuji S (1990) Expert system for determine welding condition for a pressure vessel. ISIJ Int 30:150–154. https://doi.org/10.2355/isijinternational.30.150

Gupta V, Parmar R (1989) Fractional factorial technique to predict dimensions of the weld bead in automatic submerged arc welding. J Inst Eng 70:67–75

Kamachi Mudali U, Dayal RK (2000) Pitting corrosion resistance of as welded and thermally aged nitrogen containing type 316 stainless steel weld metal. Mat Sci Tech 16(4):393–398. https://doi.org/10.1179/026708300101507983

Kanigalpula PKC, Pratihar DK, Jha MN, Derose J, Bapat AV, Pal AR (2015) Experimental investigations, input/output modeling and optimization for electron beam welding of Cu-Cr-Zr alloy plates. Int J Adv Manuf Technol 85:711–726

Kim D, Rhee S (2001) Optimization of arc welding process parameters using a genetic algorithm. Weld J 80:184–198

Kim T, Park H, Rhee S (2005) Optimization of welding parameters for resistance spot welding of TRIP steel with response surface methodology. Int J Prod Res 43(21):4643–4657. https://doi.org/10.1080/00207540500137365

Lee J, Rhee S (2000) Prediction of process parameters for gas metal arc welding by multiple regression analysis. Proc IMechE B J Eng Manuf 214:443–449

Lee J, Um KA (2000) Prediction of welding process parameters by prediction of back-bead geometry. J Mater Process Technol 108:106–113

Michaleris P (2011) Minimization of welding distortion and buckling. Woodhead Publishing, Cambridge, UK, p 3

Moi SC, Bandyopadhyay A, Pal PK (2019) Parametric optimization of TIG welding process on mechanical properties of 316L stainless steel using RSM. In: Advances in materials, mechanical and industrial engineering. Springer, Cham, pp 315–336

Moradpour MA, Hashemi SH, Khalili K (2015) Multi-objective optimization of welding parameters in submerged arc welding of API X 65 steel plate. J Iron Steel Res Int 22:870–878

Myers Raymond H, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiment. Wiley, New York

Nielsen CV, Zhang W, Martins PAF, Bay N (2015) 3D numerical simulation of projection welding of square nuts to sheets. J Mater Process Technol 215:171–180

Parida B, Pal S (2015) Fuzzy assisted grey Taguchi approach for optimisation of multiple weld quality properties in friction stir welding process. Sci Technol Weld Join 20:35–41

Peasura P (2015) Application of response surface methodology for modeling of postweld heat treatment process in a pressure vessel steel ASTM A516 grade 70. Sci World J 2015:Article ID: 318475, 8 pages. https://doi.org/10.1155/2015/318475

Qin GL, Meng XM, Fu B (2015) High speed tandem gas tungsten arc welding process of thin stainless-steel plate. J Mater Process Technol 220:58–64. https://doi.org/10.1016/j.jmatprotec.2015.01.011

Raghavendra N, Kumar D (2015) An experimental study and optimization of shielded metal arc welding parameters for welding of pipes by using Taguchi approach. Eur J Adv Eng Technol 21:42–45

Rao RV, Rai DP (2017) Optimization of welding processes using quasi-oppositional-based Jaya algorithm. J Exp Theor Artif Intell 29(5):1099–1117. https://doi.org/10.1080/0952813X.2017

Sharma N, Siddiquee AN, Khan ZA, Mohsin T (2018) Material stirring during FSW of Al-Cu: effect of pin profile. J Mater Manuf Process 33:786–794

Sireesha M, Albert SK, Sundaresan S (2003) Metallurgical changes and mechanical behavior during high temperature aging of welds between Alloy 800 and 316LN austenitic stainless-steel. Mat Sci Tech 19:1411–1417 http://dx.doi.org/10.1179/026708303225006042

Sun TZ, Roy MJ, Strong D, Withers PJ, Prangnell PB (2017) Comparison of residual stress distributions in conventional and stationary shoulder high-strength aluminum alloy friction stir welds. J Mater Process Technol 242:92–100

Tarng Y, Yang W (1998) Optimization of the weld bead geometry in gas tungsten arc welding by the Taguchi method. Int J Adv Manuf Technol 14:549–554

Xu WH, Lin SB, Fan CL, Yang CL (2015) Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 79:183–196

Zhang W, Sun D, Han L, Li Y (2015) Optimised design of electrode morphology for novel dissimilar resistance spot welding of aluminium alloy and galvanised high strength steel. Mater Des 85:461–470

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this entry

Cite this entry

Ahmad, A. (2022). Microstructure Analysis and Multi-objective Optimization of Pulsed TIG Welding of 316/316L Austenite Stainless Steel. In: Hussain, C.M., Di Sia, P. (eds) Handbook of Smart Materials, Technologies, and Devices. Springer, Cham. https://doi.org/10.1007/978-3-030-84205-5_127

Download citation

DOI: https://doi.org/10.1007/978-3-030-84205-5_127

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-84204-8

Online ISBN: 978-3-030-84205-5

eBook Packages: EngineeringReference Module Computer Science and Engineering