Abstract

Efficient and accurate fault diagnosis is essential to ensure the safe operation of rotating machinery. An intelligent fault diagnosis based convolutional neural networks (CNN) and fast independent component analysis (FICA), is proposed to improve the classification and recognition ability of rolling bearings and. Firstly, the intrinsic mode function (IMF) components of the raw vibration signals are obtained by empirical mode decomposition (EMD) preprocessing method. Secondly, FICA method is used to extract additional feature components of IMFs and ICA components are obtained. Finally, a shallow CNN model is constructed to learn feature and diagnosis from different signal-to-noise ratio (SNR) and different working load of rolling bearings. The proposed method can conduct high accuracy of fault recognition and classification, which is more efficient than the IMFs feature. To verify this method, Back propagation neural networks (BPNN), stacked autoencoder (SAE), multilayer perceptron (MLP) are used as comparative models. The results demonstrate that the proposed method can achieve higher accuracy than other comparative methods.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As the key components in rotating machinery, rolling element bearings and gears play an important role in most industrial fields. These components often suffer from wear and pitting or other structural damages due to long time running and harsh working conditions [1]. The research shows that 30% of rotating machinery faults and 40% of motor faults are related to rolling bearings [2]. The failure may result in equipment breakdown, economic loss, or even human casualties [3,4,5]. Therefore, condition monitoring and fault diagnosis are extremely significant.

Due to the vibration signals of rotating machinery are mostly nonlinear and non-stationary, and contain different degrees of noise. How to realize the separation of signal and noise and propose an efficient fault diagnosis method of rolling element bearings has received extensive attention.

Intelligent fault diagnosis methods based on deep learning have received increasing attention in recent years. Convolutional Neural Networks (CNN) is widely used in natural language processing [6, 7], and visual image recognition [8, 9]. Now CNN also has excellent diagnosis performance for its strong feature extraction ability.

Wu [10] and Guo [11] designed a CNN framework as raw vibration signal input matrices directly to diagnose rotating machinery faults. Qiu [12] proposed a Principal Component Analysis (PCA) DCNN for fault diagnosis of a gearbox, where the feature is extracted by time domain, frequency domain, and wavelet packet decomposition, then the dimensionality of feature was reduced by PCA. Islam [13] adopt the wavelet packet transform to preprocess raw acoustic emission signals and designed an adaptive DCNN for multi-fault classification of bearings. To improve fault diagnosis capability, Li [14] used deep statistical feature learning as an integrated feature optimization and classification tool based on Gaussian-Bernoulli restricted Boltzmann machines (GRBMs). Chen [15] extracted several time-frequency domain features from different healthy state gearbox and achieved fault classification by CNN. Gangsar [16] utilized the wavelet packet transform to extract fault features and designed a Support Vector Machine (SVM) for multi-fault classification of asynchronous motor. Hu [17] decomposed the gear vibration signals with EMD and took the IMF components with the largest kurtosis as the input of CNN to realize the fault identification and classification.

Although different feature extraction and classification methods based on CNN have been successfully applied for fault diagnosis, there are still a few questions that should be considered.

-

(1)

The high SNR of the original vibration signal affects the quality of feature extraction and the accuracy of fault recognition and classification. The quality of signal data preprocessing method interferes with the feature learning ability of deep learning model.

-

(2)

CNN model has deep weight layer and complex structure. Although the diagnostic accuracy is improved, the learning efficiency will be reduced, and the model becomes redundant.

To overcome above weakness, a fault diagnosis based on EMDFICA-CNN is proposed. The raw vibration signal is decomposed by EMD and eight IMF components are obtained. To extract fault-sensitive feature, IMFs are analyzed with FICA method and get six ICA components. These ICA components of different fault types signal are trained and tested through shallow CNN with two convolutional layers and one pooling layer. This method simplifies the network model structure and realizes the high efficiency and high accuracy identification and classification of multi-fault bearings.

This paper is organized as follows. Section 2 describes a brief theory of EMDFICA and CNN, and the shallow CNN model is also given in Sect. 2. Experimental setup and diagnostic results are presented in Sect. 3. Some conclusions are extracted in Sect. 4.

2 Methodology

2.1 Empirical Mode Decomposition Fast Independent Component Analysis (EMD-FICA)

EMD is a new adaptive signal time-frequency domain processing method proposed by Huang in 1998 [18]. The traditional EMD can cause the mode aliasing of the raw signal and produce some false components. If it is not selected properly, the fault diagnosis result will be affected.

EMD-FICA method is used to process the raw vibration signals. Firstly, the vibration signals are decomposed by EMD. IMF components should satisfy the following two conditions:

In the whole time range, the number of local extremum points and zero-crossing points must be equal or at most one difference. At any time, the average value of the envelope of local maximum and local minimum should be zero.

When the vibration signal x(t) meets the above conditions, the EMD could be carried out according to the following steps:

When all local extremum points are fixed, all local maximum points and local minimum points are connected by a cubic spline curve to form upper envelope F1 and lower envelope F2. Then calculate the average of upper and lower envelopes m. Judge whether h meets the IMF conditions. If h meets, h1 is one of IMF components. If not, h repeat the process as the original signal. As shown in Fig. 1, when the preset termination conditions are met, the cycle ends. The signal can be expressed as Eq. (1).

where Ci is the decomposed IMF components of x(t). rn is the residual signal, indicating the average trend of the signal. Next, each IMF is assumed to be a mixed-signal, then doing FICA for each IMF.

Through the FICA, each IMF component of SNR is improved further. The equation is described as Eq. (2).

where Sn(t) is the hypothetical independent noise source signal. Cn(t) is composed of ASn(t), A is an unknown full rank mixed coefficient matrix. The separation matrix M is obtained by statistics so that the separation matrix satisfies Eq. (2). Yn(t) is the ICA component, and input samples are composed of six ICA components.

2.2 Convolutional Neural Network

CNN is a typical feed-forward neural network and consists of input layer, convolutional layers, pooling layers, fully-connected layers and output layer generally.

The convolutional layer contains multiple convolutional kernels, which is a matrix, also known as a convolutional filter. Through the convolutional operation, multiple features are obtained from different sizes of convolutional kernels. The convolution is defined as Eq. (3).

where Y l−1j is (l-1)th layer jth element. W li j is convolutional kernel weight matrix. f(*) is an activation function, which Sigmoid is selected as Eq. (4).

The pooling layer is a king of dimension-reduction algorithm and achieved by average pooling. A pooling layer is calculated as Eq. (5).

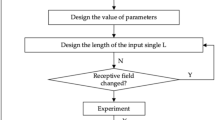

2.3 Fault Diagnosis Framework

The overall fault diagnosis procedure is shown in Fig. 2. In the feature extraction process, the EMD as a data preprocessing method is firstly applied to deal with the input signals to obtain IMF components of different fault types. Then FICA is introduced to analyze each IMF component, obtain ICA components and extract corresponding features of each fault type. After the feature extraction by EMD-FICA, a CNN model is designed and adopted for multi-fault classification and identification.

The proposed CNN contains two convolutional layers, one pooling layer, without a fully-connected layer. Due to the large receptive field through two convolutional layer, the output size of the second convolutional layer is 1 × 1 × 10. It has reduced the overfitting during network training. Therefore the proposed CNN framework is simple and efficient.

The hyper-parameters of CNN are summarized as follows. The first convolutional layer have five feature maps of kernel size 11 × 11. This is followed by a pooling layer of size 2 × 2. The next convolutional layer have ten feature maps of kernel size 5 × 5. Then, all above-learned features form a 10-dimensional feature vector, which is corresponded to different fault states. The output layer contains ten neurons for each sample.

3 Experiment Results and Analysis

3.1 Experiment Setup

The experimental data of fault rolling bearings is from the public bearing data centre of Case Western Reserve University (CWRU) [19]. The fault bearing test rig is shown in Fig. 3, which consists of an induction motor, a torque transducer, and a dynamometer. The vibration data was obtained by an accelerometer mounted on the housing of the driven end of the induction motor. The sampling frequency is 12 kHz. The multi-types bearings include normal condition, inner race faults, ball faults and outer races faults. These three fault types have three levels of severity with fault diameters of 0.007 in., 0.014 in. and 0.021 in.. The experiments were conducted under 1797 rpm, 1772 rpm, 1750 rpm and 1730 rpm, corresponding to loads of 0, 1, 2 and 3 hp respectively.

Each experiment type is conducted in four different operating conditions. 10,000 data points of each operating condition form 40,000 data points as the total data points of each type. 6 IMF components is obtained by EMD method and make up 240,000 data points. In order to improve the SNR of signals, FICA is proposed to process 6 IMF components. Then the same 6 ICA components are obtained, and each ICA component contains 40,000 data points. Next, the total data points are reshaped to 600 samples, and each sample contains 400 points. The details of the dataset description are shown in Table 1. There are 10.

3.2 Experiment Results

The combination of EMD and FICA is applied to preprocess the rolling bearing dataset. The dataset consists of 10 fault types, 6000 samples, and 80% of the samples are used for training and the rest for testing.

The preprocessing results of EMD and FICA of label 2 are presented in Fig. 4. The 6 IMF components are shown in Fig. 4(a), which contain some fault features and different levels of noise. Then FICA is used to extract respective features, and 6 ICA components are obtained shown in Fig. 4(b).

In order to testify the advantages of the proposed FICA processing method, the fault diagnosis results are compared with EMD and EMDFICA used same CNN. The batch size is 5, the number of iterations is 60, the learning rate of model is 0.5, the results are shown in Fig. 5. The training accuracy of EMDFICA-CNN can achieve 100% when the number of iterations is 13, while the accuracy of EMD-CNN method achieves 99.44% when the number of iterations is 60. The maximum testing accuracy 99.73% of EMDFICA-CNN is achieved in 13th iteration. Obviously, the proposed method have high efficiency and accuracy.

In order to better evaluate the performance of the proposed method, the different methods are compared with BPNN, SAE, MLP in different SNR. The results are shown in Table 2.

Add different levels of white Gaussian noise to the original signals to composite signals with different SNR, and the definition of SNR is presented as Eq. (6).

where Psignal and Pnoise are the power of signal and noise respectively.

The proposed method and other models are experimented under SNR ranging from-4 dB to 6 dB. The same preprocessing method and the same input data size are used with these four models. As is shown in Table 2, the training and testing accuracy of proposed the method can achieve 100% in different SNR. The results show that the fault diagnosis performance of the proposed method is better than others.

4 Conclusion

A new fault diagnosis framework based on EDM and FICA preprocess method is proposed in this paper. In order to improve the fault recognition efficiency and performance of bearing, EMDFICA is applied on raw vibration signals to extract fault feature as the preprocessing method. Then a shallow CNN model is proposed for feature learning and classification.

The proposed method is evaluated on the CWRU motor bearing dataset. The results of the experiments have indicated that EMDFICA-CNN has a better performance of feature extraction and diagnosis than other methods.

References

Chen, Z., et al.: A Deep Learning method for bearing fault diagnosis based on cyclic spectral coherence and convolutional neural networks. Mech. Syst. Sign. Process. 140, 106683 (2020)

Jiang, H., Li, C., Li, H.: An improved EEMD with multiwavelet packet for rotating machinery multi-fault diagnosis. Mech. Syst. Sign. Process. 36(2), 225–239 (2013)

Liu, R., et al.: Artificial intelligence for fault diagnosis of rotating machinery: a review. Mech. Syst. Sign. Process. 108, 33–47 (2018)

Zhao, R., et al.: Deep learning and its applications to machine health monitoring. Mech. Syst. Sign. Process. 115, 213–237 (2019)

Shao, H., et al.: Rolling bearing fault feature learning using improved convolutional deep belief network with compressed sensing. Mech. Syst. Sign. Process. 100, 743–765 (2018)

Gimenez, M., Palanca, J., Botti, V.: Semantic-based padding in convolutional neural networks for improving the performance in natural language processing. A case of study in sentiment analysis. Neurocomputing 378, 315–323 (2020)

Sercu, T., Goel, V.: Advances in very deep convolutional neural networks for LVCSR, pp. 3429–3433 (2016)

Lian, J., et al.: Deblurring retinal optical coherence tomography via a convolutional neural network with anisotropic and double convolution layer. Comput. Vis. IET 12(6), 900–907 (2018)

Liu, W.B., Wang, T.: The character recognition of vehicle’s license plate based on BP neural networks. Appl. Mech. Mater. 513–517, 3805–3808 (2014)

Wu, C., et al.: Intelligent fault diagnosis of rotating machinery based on one-dimensional convolutional neural network. Comput. Ind. 108, 53–61 (2019)

Guo, X., Chen, L., Shen, C.: Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 93, 490–502 (2016)

Qiu, G., Gu, Y., Cai, Q.: A deep convolutional neural networks model for intelligent fault diagnosis of a gearbox under different operational conditions. Measurement 145, 94–107 (2019)

Islam, M.M.M., Kim, J.M.: Automated bearing fault diagnosis scheme using 2D representation of wavelet packet transform and deep convolutional neural network. Comput. Ind. 106, 142–153 (2019)

Li, C., et al.: Fault diagnosis for rotating machinery using vibration measurement deep statistical feature learning. Sensors 16(6), 895 (2016)

Chen, Z.Q., Li, C., Sanchez, R.V.: Gearbox fault identification and classification with convolutional neural networks. Shock Vib. 2015(PT.5), 1–10 (2015)

Gangsar, P., Tiwari, R.: Multifault diagnosis of induction motor at intermediate operating conditions using wavelet packet transform and support vector machine. Journal of Dynamic Systems Measurement & Control (2018)

Hu, N., Chen, H., Cheng, Z., et al.: Fault diagnosis for planetary gearbox based on EMD and deep convolutional neural networks. J. Mech. Eng. 55(07), 9–18 (2019)

Huang, N.E., et al.: The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. Math. Phys. Eng. Sci. 454(1971), 903–995 (1998)

Smith, W.A., Randall, R.B.: Rolling element bearing diagnostics using the case western reserve university data: a benchmark study. Mech. Syst. Sign. Process. 64–65, 100–131 (2015)

Acknowledgements

This work is supported by National Key R&D Program of China (NO. 2018YFE0207000), Science and Technology Innovation Strategic Project of Hebei (NO.20180104) and Hebei Province full-time introduction of high-end talent projects (NO. 20181228).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Li, G., Chen, Y., Wang, W., Liu, R., Gu, F. (2021). A Convolutional Neural Network for Rotating Machinery Fault Diagnosis Based on Fast Independent Component Analysis. In: Zhen, D., et al. Proceedings of IncoME-V & CEPE Net-2020. IncoME-V 2020. Mechanisms and Machine Science, vol 105. Springer, Cham. https://doi.org/10.1007/978-3-030-75793-9_67

Download citation

DOI: https://doi.org/10.1007/978-3-030-75793-9_67

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75792-2

Online ISBN: 978-3-030-75793-9

eBook Packages: EngineeringEngineering (R0)