Abstract

Magnetic iron oxide nanoparticles have been used by human mankind since ancient times and have had the capacity to adapt to the demanding technologies in each period. Ancient applications used iron oxides from nature, since iron is one of the most abundant elements on the Earth and their oxides are easy to obtain. More recently, the rapid development of the different technologies required iron oxide particles with better properties which was fulfilled with the possibility to design artificially magnetic iron oxide nanoparticles by different synthetic routes, reaching with time an exquisite control of their size, shape and crystallinity. At the end of the last century, spherical particles were used for most of the applications except for flexible recording media. However, the number of synthetic approaches leading to anisotropic nanoparticles with appealing properties has exponentially grown in the last two decades. This chapter describes the most common synthetic routes in liquid media (colloidal synthesis) to prepare magnetic iron oxide nanoparticles with different morphologies. Then, the different applications where these anisotropic nanoparticles have been tested are described, from biomedicine to magnetic recording media, spintronics or environmental remediation.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Iron oxides

- Magnetic nanoparticles

- Particle shape

- Anisometric

- Cubes

- Octahedrons

- Rods

- Magnetite

- Maghemite

- Biomedicine

- Magnetic recording

- Water treatment

- Spintronics

- Microwave absorption

- Li-ion batteries

1 Introduction

Magnetic iron oxide nanocrystals, i.e. magnetite (Fe3O4), maghemite (γ-Fe2O3) or any of its intermediate stoichiometries (Fe3-xO4), have been applied in widespread applications since ancient times due to their appealing properties [1]. Being the only iron oxide with Fe ions in two oxidation states (+2, +3), magnetite is an abundant material that can be found in the nature (rocks) together with titanomagnetite [2]. Magnetite nanocrystals can also be found inside some bacteria (magnetotactic bacteria) where it is mineralized in intracellular vesicles, generally 30–100 nm nanocubes surrounded by a membrane and displayed in chains (magnetosomes) [3]. Finally, these nanocrystals can be “artificially” synthesized by top-down methods like high-energy ball milling, crushing or grinding, [4] or “bottom-up” approaches involving colloidal methods like coprecipitation, hydro−/solvothermal and thermal decomposition, rendering better structural properties in terms of crystallinity, purity and solvent solubility [5]. Moreover, magnetite particles in the nanometre range size can be synthesized breaking down the limit of superparamagnetism (random alignment of the magnetic moment in the absence of a magnetic field) leading to very interesting reversible magnetic behaviour that paves the way for new applications.

Magnetite nanocrystals have been used along human history for a wide spectrum of applications. They were used as pigments for ceramics in terracotta pottery since ancient times (ancient Greece) [6] and more recently as pigment for inks, dyes or any other material that required black colour, being the favourite one as magnetite absorbed light much better than other black candidates, and thus, it was more reliable [7]. Then, other application where magnetite nanocrystals were well-established was their use in water purification processes, e.g. heavy metal removal [8]. In the latest decades of the twentieth century, their applicability boosted due to magnetite electronic and magnetic properties at the microscale and nanoscale. Magnetite exhibited a great performance for magnetic recording media, spintronics and biomedicine, in both diagnosis (contrast agents in MRI, magnetic resonance imaging) and therapy (drug delivery vehicles and nanoheaters in magnetic and optical hyperthermia) [9]. For each application, scientists have designed and optimized the material in terms of particle size, shape, aggregation state and internal crystal structure to maximize their performance (Fig. 1).

However, magnetite is not the most stable iron oxide phase and tends to oxidize to maghemite. [10] The oxidation kinetics is faster as the temperature increases, as the atmosphere is richer in oxygen, when particle size drops or the crystallinity is poorer. Magnetic properties, in terms of saturation magnetization and coercivity, decrease after this phase transformation, but not dramatically [11]. Regarding the electrical properties, magnetite is a semimetal due to the electron hoping between the Fe ions of the octahedral sublattice of its structure, while maghemite is an insulator.

The aim of this chapter is to present an overview on anisotropic magnetic nanoparticles and their applications in several areas. These nanostructures, with different morphology from the spherical one, have anisotropic properties that depend on the direction of the atoms within the nanostructure and a larger specific surface area. Anisotropic magnetic iron oxide nanoparticles could bring several advantages such as their higher surface-to-volume ratio, enhanced magnetic properties and selected reactivity due to the different facet exposure to the solvent. However, the synthesis of these nanostructures requires the use of different protocols or modification of the established ones. [1]The first section will be focused on the most feasible and successful routes for the preparation of magnetic nanoparticles with a specific morphology. Then, in a second part, we will report the most striking results on the use of these morphologies on diverse applications, ranging from environmental ones to most technological ones, like spintronics or biomedicine. As a summary, magnetite can be considered as an old friend that never gets old fashion and evolves adapting every time to new and more technological applications. This transformation can be understood by its multiple structural, electrical, and magnetic properties and also biodegradability. Thus, with more advanced synthetic techniques, it is possible to tailor the structural properties of magnetite nanocrystals making them an attractive material for the intended application.

2 Preparation of Anisotropic Iron Oxide Nanoparticles

For each application, the concept of “ideal” nanoparticles , i.e. the ones that exhibit the best performance, is different. Therefore, the ideal nanoparticle needs to be tailored mainly by their size and shape. In general, a synthetic route that leads to nanoparticles with an accurate control on their size and shape, low size distribution, aggregation state, high crystallinity and chemical purity is the main goal. The resulting particles would be ideal candidates for the intended applications since all of them will contribute to the desire effect. In this sense, colloidal routes developed in liquid media render nanoparticles accomplishing these properties, with low-cost production and large scalability. Moreover, the obtention of particles in liquid media enables an easier manipulation and postprocessing procedures (e.g. surface modification, deposition forming self-assembly, dispersion in different media).

Magnetite has a cubic cell with an inverse spinel structure (Fd3m) with a cell parameter of 8.394 Å [12]. Fe(II) ions are located in octahedral sites, and Fe(III) ions are located in both octahedral and tetrahedral sites (Fig. 2). The complete oxidation to maghemite keeps the same inverse spinel structure, but all Fe(II) ions are oxidized to Fe(III) and vacancies are created in octahedral positions, distributed coherently [13, 14]. After such transformation, due to the oxidation of the Fe ions, the cell parameter decreases to 8.33–8.35 Å depending on the vacancy order.

Crystal structure of magnetite and maghemite. (Adapted with permission from Ref. [15]. © 2015 National Institute for Materials Science)

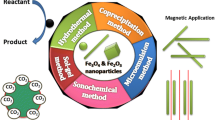

The synthesis of anisotropic , i.e. nonspherical, magnetic iron oxide nanoparticles is not trivial (Fig. 3). Thus, structures with hexagonal, orthorhombic or monoclinic crystal symmetry whose facets are perpendicular to the long axis have higher energy and lead to elongated structures [16]. However, for cubic crystals, like magnetite, the isotropic growth is favoured. Then, there are two main strategies to induce the growth of anisotropic magnetic iron oxide magnetic nanostructures. The first approach is based on the use of an iron oxide/oxohydroxide as shape template. This strategy consists of two stages where first, an iron oxyhydroxide with the target shape is synthesized (i.e. goethite or akaganeite in elongated nanoparticles) and, in a second step, the oxyhydroxide is reduced to magnetite keeping the desired morphology. The second strategy consists on modifying the reaction kinetics to favour a kinetic regime. In this strategy, there is an essential role played by ligands (molecules or polymers) which bind to metal cations to form intermediate species prior nucleation or to regulate the particle growth through specific adsorption on certain facets of the particle surface. Other key parameters to control the reaction regime are the reaction temperature, the heating rate and the monomer concentration [17, 18].

TEM image of magnetic iron oxide nanoparticles with different morphology: (a) nanocubes, (b) elongated nanoparticles, (c) octahedrons, (d) hollow nanoparticles, reprinted with permission from Ref. [31]. Copyright 2007 American Chemical Society; (e) nanoflower, reprinted with permission from [32]. Copyright 2017 American Chemical Society. (f) SEM image of magnetite nanodiscs. (Adapted with permission from Ref. [33], © 2015, by Wiley)

Magnetite nanocubes could be synthesized in a wide range of sizes, in organic and aqueous media. Using the thermal decomposition in organic media, iron(III) acetylacetonate seems to be the best iron precursor (Fig. 3a). Well-defined ferrimagnetic magnetite nanocubes up to 170 nm can be synthesized using iron (III) acetylacetonate as precursor and oleic acid as surfactant in dibenzyl ether [19]. In this synthesis, the particle size can be modified by changing the iron precursor concentration and reflux time. The addition of a second ligand changes the reaction kinetics and thus decreases the particle size down to 20 nm. Ligands of different nature like decanoic acid , [20] tryoctylphosphine oxide [21], chloride ions [22] or sodium oleate [23] modify the decomposition kinetic and control particles growth by adhering to selective facets of the initial nuclei. Interestingly, a novel strategy using a solvent mixture composed by dibenzyl ether, 1-octadecene and 1-tetradecene with oleic acid and sodium oleate has been reported for the synthesis of more stable and reproducible particles than just using dibenzyl ether [24]. Using this synthesis approach , by increasing the temperature at which the reaction mixture is degassed, Fe3O4 nanocubes of 10 nm could be grown. Using an aqueous route, the hydrolysis of iron (II) sulphate in alkaline media mixed with ethanol in the presence of a mild oxidant renders magnetite nanocubes from 30 to 170 nm [25]. This synthesis has been recently scaled up to grams per hour in a continuous flow approach [26].

Magnetite octahedrons exposing the {111} facets are grown through the decomposition of iron (III) oleate in noncoordinating high-boiling point solvents in the presence of an amine or ammonium quaternary salts (Fig. 3c). For example, the decomposition of iron (III) oleate in tetracosane in the presence of oleylamine leads to 21 nm Fe3O4 octahedrons [27]. Using trioctylammonium bromide in conjunction with oleic acid as surfactants and squalene as solvent leads to 50 nm Fe3O4 octahedrons. [28, 29] Interestingly, the decomposition of iron (0) pentacarbonyl in the presence of a mixture of surfactants and oleylamine/oleic acid 10:1 leads to 50 nm octahedral particles [30].

Elongated or rod-like Fe3O4 nanoparticles have been traditionally synthesized using a shape template as intermediate, but nowadays they can also be prepared directly in organic media (Fig. 3b). Due to its crystal structure, hexagonal hematite (α-Fe2O3) [34], orthorhombic goethite (α-Fe2O3) [35] or monoclinic akaganeite (β- Fe2O3) [36] have been ideal candidates for magnetite templating. In the case of direct synthesis of hematite, the synthesis is very slow (it takes several days) and large nanoparticles (hundreds of nm) are obtained [37]. The concentration of the iron salt, the ageing time and the presence of phosphate ions [37] and urea [38] affect their final length. Interestingly, using akaganeite for templating, the reaction time is reduced and also the particle dimensions [39]. This synthesis could be controlled by modifying the pH but also with the presence of polymers with amine groups, such as polyethylenimine [40, 41]. During the last years, a solvothermal method to grow magnetite nanorods in one step has been developed [42, 43]. This method uses iron (0) pentacarbonyl as precursor in the presence of hexadecylamine and oleic acid, using 1-octanol as solvent. The resulting magnetite rods have lengths from 25 to hundreds of nm and aspect ratios from 5 to 10.

Magnetite discs/plates need the use of an intermediate step for their final synthesis (Fig. 3f). By performing a synthesis where the growth through the long axis is inhibited, it is possible to synthesize hematite disk/plate like nanoparticles that serve as templates. Thus, the use of sodium acetate as inhibitor in the hydrolysis of iron (III) chloride in a mixture of water/ethanol is a robust synthesis route [33, 44, 45]. Then, the reduction could be performed by annealing under inert/reducing atmosphere or in organic media with oleic acid. By this route, it is possible to synthesize discs from 400 x 8 nm to structures of 40 x 40 nm.

Hollow magnetite nanoparticles are obtained through different strategies (Fig. 3d). The sodium resulting from the decomposition of sodium oleate at 380 °C is able to carve iron oxide nanocubes synthesized using iron (III) oleate as precursor [46]. Starting from Fe nanospheres, by passing or generating an oxygen flow through the reaction at high temperatures, the hollowing effect is achieved due to the inward diffusion of oxygen and outward diffusion of the iron cations [31, 47].

Flower-like magnetite nanoparticles, i.e. clusters of magnetite nanoparticles of a controlled size, are mainly synthesized by the polyol method using ethylene glycol as solvent (Fig. 3e). For the cluster formation it is critical the addition of N-methyl diethanolamine, which is used to control the aggregation of the primary cores (5–20 nm) in larger particles of around 30–50 nm [48, 49].

3 Applications

The control of the nanoparticle morphology could bring different benefits such as the enhancement of the magnetic properties due to the shape anisotropy and specific surface area increase in comparison to the spherical morphology. In addition, each morphology exposes different facets of the nanoparticle which determine the final activity of the nanoparticles [50]. All these tuneable properties postulate the anisotropic magnetic iron oxide nanoparticles for widespread applications.

3.1 Biomedicine

Magnetic iron oxide nanoparticles have been widely studied in the biomedical field due to their appealing magnetic properties which can be finely controlled by their size, shape and aggregation state [5, 9]. These particles are biocompatible and biodegradable, since iron is a nutrient and can be metabolized by the organisms [51]. Indeed, iron oxide nanoparticles are the only magnetic material approved by the Food and Drug Administration (FDA) for biomedical applications [52]. Although iron oxide nanoparticles can be biofunctionalized with proteins for specific cell targeting, remarkably, due to their magnetic character, this type of particles can be driven to and accumulated at the desired organ/tissue by magnetic actuation (active targeting) [53]. Magnetic iron oxide nanoparticles can be active agents in both diagnosis and therapy.

3.1.1 Diagnosis

In diagnosis, magnetic iron oxide nanoparticles can be used as T2 contrast agents in magnetic resonance imaging. This imaging technique is characterized by a high spatial resolution and high soft-tissue contrast. Iron oxide magnetic nanoparticles have a high magnetic moment that produces inhomogeneities in the local magnetic field of the water protons leading to a reduction of the MRI signal intensity on T2 (transverse relaxation time) weighted images [52]. There were different formulations based on superparamagnetic iron oxide nanoparticles approved by the Food and Drug Administration, but most of them (Feridex, Endorem or Resovist) were removed from the market due to the lack of clinical use [54]. Only Ferumoxytol remains in market due to its low hydrodynamic size (< 40 nm) and its long circulating half-life (15 hours) [55]. To study the capacity of magnetic nanoparticles as contrast agents, one of the variables to study is the longitudinal or transversal relaxivity (r1 or r2, respectively), which is a direct measurement of how the magnetic nanoparticles decrease the relaxation time of the water protons due to the perturbation of their magnetic local field.

In general, faceted magnetic iron oxide nanoparticles present better magnetic properties [36, 56] and are more suitable for MRI than their spherical counterparts. Moreover, it seems that a higher specific surface area favours larger r2 values (Fig. 4). Therefore, elongated nanoparticles are particularly a good morphology to be used as MRI contrast agents. Magnetite rods of 25 and 50 nm length (both with 5 nm in diameter) have r2 values of 670 and 905 mM−1·s−1, respectively [57]. Thicker magnetite nanorods (70x12 nm), that possess a transversal relaxivity of 608 mM−1·s−1 and nanorods (30x4 nm) with a r2 of 312 mM−1·s−1 [58], also exhibit better performances than the commercial MRI contrast agents (Ferumoxytol; r2 = 68 mM−1·s−1).

The exchange interactions given by the clustering of the maghemite particles when they are displayed in flower-shaped morphology also brings benefits to their relaxometric properties. 30 nm clusters made of primary units of 10 nm exhibit a r2 of 365 mM−1·s−1, near 2 times higher than 10 nm single-core particles made by the same method (polyol). This improvement is due to the cooperative behaviour of the magnetic moment, which increases the intensity of the local magnetic field.

Single 23 nm magnetite nanocubes reach a transversal relaxivity value of 398 mM−1·s−1 [59]. However, it should be noted that the configuration of the nanocubes in solution affects their relaxometric properties as when they are clustered in 200 nm beads, their r2 decays down to 161 mM−1·s−1. Magnetite octopods of around 30 nm present a considerable high transversal relaxivity value of 679 mM−1·s−1 (measured at 7 T) much larger than their spherical equivalent (126 mM−1·s−1) [60].

During the last decade, the research on the use the iron oxides as T1 contrast agents (positive contrast) has been intensified [61, 62]. Magnetic iron oxide nanoparticles with a relatively small size and/or a large surface area increase the exposure of Fe ions to water interface and are ideal candidates for T1 contrast agents (Fig. 4). Due to its small size, particles tend to be “more paramagnetic” than superparamagnetic exposing their five unpaired Fe3+/Fe2+ electrons [62]. Moreover, their longer circulation time and better biocompatibility than gadolinium complexes (the main commercial T1 contrast agent) postulates iron oxides as a promising material for this application [63]. Also, ultrathin iron oxide nanowhiskers (20x2 nm) have shown interesting properties as T1 contrast agent with a high r1 (6.3 mM−1·s−1) and low r2 (11.15 mM−1·s−1) [64], slightly better than 3 nm spherical ultrasmall iron oxide nanoparticles (r1 = 5.2 mM−1·s−1; r2 = 10.4 mM−1·s−1) [63].

3.2 Therapy

One of the main problems of cancer and other diseases is the difficulty of achieving enough drug concentration at the action site to produce the desired therapeutic effect. Magnetic iron oxide nanoparticles, through two different approaches, magnetothermia and photothermia, are valuable tools for the design of new and/or more efficient therapies (Fig. 5).

In magnetic hyperthermia, magnetic iron oxide nanoparticles can release heat under the application of an alternating magnetic field (50–700 kHz) [65,66,67]. Since the generated heat affects the tumour locally, it would cause minimal damage to healthy tissues. Therefore, magnetic hyperthermia is an alternative to reduce the side effects of chemotherapy. There are several mechanisms (susceptibility loss, hysteresis losses and viscous heating) by which the magnetic nanoparticles can dissipate heat [68,69,70]. The particles structural and colloidal properties (i.e. particle size, shape, aggregation state, interactions), the media (viscosity) and the AC field (frequency and amplitude) will determine which of the aforementioned mechanisms is the main one to produce heat. The capability of magnetic nanoparticles to release heat is evaluated by the specific absorption rate (SAR), which can be defined as the power dissipated per unit mass [71].

In the latest years, an intense research has been performed regarding the properties of magnetite nanocubes for magnetic hyperthermia . The comparison of nanocubes (19.5 nm) and spheres with the same volume (24 nm) leads to SAR values favourable to the nanocubes. [72] However, comparing heating properties of 53 nm spheres and 43 nm cubes, it was found better heating properties for the spherical ones because the cubes were forming strong and isometric aggregates [73]. Cubes of different sizes (13–38 nm) have been studied finding the best SAR for 19 nm particles 2277 W·g−1 (700 kHz, 300 Oe) [74]. Interestingly, the configuration of possible aggregates deeply affects the SAR values. 3D aggregates of 38 nm nanocubes have a SAR of less than 300 W·g−1; however, when they were isolated, the SAR increased up to 1400 W·g−1 [75]. Nevertheless, it has been demonstrated that the formation of chain-like aggregates aligned in the magnetic field boosts the SAR value by five times compared to 3D aggregates [73]. The measurement of SAR evaluates the possible performance of the nanoparticles; however, when hyperthermia is performed in vivo, it suffers from low heating efficiency due to the high viscosity of the tumour site and particle aggregation upon intracellular internalization [76]. Thus, the confinement of magnetic nanoparticles in cavities of hundreds of nanometres would enable a certain degree of nanoparticle rotation and minimize aggregation effects, so the heating power would be better preserved intracellularly [77].

Octahedral magnetite nanoparticles have also an optimum morphology to work as nanoheaters in magnetic hyperthermia. Small octahedrons of 6 and 12 nm exhibit SAR values of 163 and 275 W·g−1 (247 kHz, 310 Oe) [78]., 40 nm octahedrons reach up to 2483 W·g−1 (358 kHz, 800 Oe) and finally 98 nm octahedrons, around the monodomain limit of magnetite, have been reported to reach 2629 W·g−1 [79].

Elongated magnetite nanoparticles display moderate heating release properties when compared to other morphologies. The drawback is the high field amplitude needed to obtain a proper heating release due to the high switching field needed to reverse the magnetic moment. Magnetite nanorods grown from the reduction of akaganeite with dimensions of 45x10 nm exhibit a SAR of 1072 W·g−1 (390 kHz, 415 Oe), whereas longer rods (400x40 nm) displayed lower SAR values. High crystalline rods made by solvothermal approach exhibit SAR values of 1300 W·g−1 (310 kHz, 800 Oe). In contrast, smaller rods of 41x7nm only reached 540 W·g−1 [43].

Magnetite nanoplates of certain dimensions have the advantage of the formation of magnetic vortex configurations where spins are arranged circularly and oriented parallel to the field [80]. As a consequence, these particles display negligible coercivity and remanent magnetization which results in extraordinary SAR values, up to 4400 W·g−1 for nanoplates of 225 nm in diameter and 26 nm in thickness [81]. However, for nanodiscs without vortex configuration (150–200x10–15 nm), only values of 245 W·g−1 (180 kHz, 12 Oe) have been described [44].

Superparamagnetic γ-Fe2O3 nanoflowers of 50 nm containing spherical 11 nm particles grown by the polyol method can reach a SAR value of 1790 W·g−1, much larger than SAR of single 11 nm (48 W·g−1) [49]. Controlled aggregation seems to boost the increase of SAR; however, a compromise between colloidal stability and heating performance should be achieved. In addition to that, nanoparticle cell affinity needs to be maximized through conjugation with biological targeting molecules to increase nanoparticle concentration inside the cells [82].

During the last 5 years, magnetic iron oxides, especially magnetite, have also shown good photothermal properties allowing their use in photothermal therapy . Magnetite presents some absorption in the near-infrared range (NIR), especially in the first biological window where water or other biomolecules do not present absorption. The combination of magnetic hyperthermia (900 kHz, 250 Oe) with phototherapy (λlas = 808 nm, 2.5 W·cm−2) using 20 nm aggregated magnetite nanocubes resulted in a combined SAR value of 4850 W·g−1. Interestingly, by doing just magnetic hyperthermia, a much smaller SAR value (1000 W·g−1) was achieved [83,84,85].

Interestingly, some anisotropic structures could lead to magnetomechanical actuation by applying an AC magnetic field of low frequency, just to promote the rotation of the particles. It has been reported that Fe3O4 nanorods (200x50 nm) [86] induce cancer cell death on HeLa cells through mechanical oscillations under the exposure of a 35 kHz field, associated with the Brownian motion of the nanorods [87]. Nanodiscs could also induce cell death through magnetomechanical effects. Nanodiscs made of Permalloy coated with gold (1000x60 nm) were able to exert mechanical forces to N10 glioma cells leading to apoptosis. The AC field of low frequency (60 Hz) induced a shift of the vortex structure, creating an oscillation which was then transmitted to a mechanical force applied to the cell [88]. This strategy opens a new pathway where magnetic iron oxide nanodiscs could be applied.

3.3 Magnetic Recording Media

In the second half of the twentieth century, magnetic recording media were based on acicular iron oxide magnetic nanoparticles (γ-Fe2O3) with a length size between 100 and 500 nm and aspect ratios from 6 to 10. They were used as magnetic recording material because of their chemical stability, high magnetic moment aligned with the largest dimension of the particle and high Curie temperature (590–675 °C) to keep moderate coercivity (not too high to allow successful writing and not too small to resist changes or degradation of signals) (Fig. 6) [89, 90]. Elongated morphology was preferred as shape anisotropy is the main contributor to the effective anisotropy, being up to two orders of magnitude higher than the magnetocrystalline one for particles with axial ratio larger than 6. On the other side, the microstructure of the particles, including defects, pores and inhomogeneities, were shown to decrease the effective anisotropy [91, 92]. These problems were inherent to the synthetic routes employed for the growth the magnetic iron oxides using lepidocrocite (γ-FeOOH) or goethite (α-FeOOH) as shape templates, as the subsequent dehydration was the main cause of pore and defects formation [93, 94]. An alternative route was based on the hydrothermal treatment of Fe(OH)3 which leads to hematite (α-Fe2O3) bypassing the formation of iron oxyhydroxides and the formation of pores [34, 95]. In the last decade of the twentieth century, iron oxides, as well as chromium dioxide particles, were replaced by metal particulate materials, which possess twice the magnetization of iron oxides and higher coercivity [96,97,98].

3.4 Water Treatment

One of the major challenges in the environmental field is water treatment for the removal of heavy metal ions like As, Pb, Hg, Cr, Cd and Ni, which cause harmful effects on humans and animals [8]. Moreover, organic pollutants such as detergents and pesticides, all of them from human source, can also be found in water and represent another type of environmental threats. They mainly consist in chlorinated and nonchlorinated aliphatic and aromatic molecules [99]. Traditional methods for water treatment include centrifugation, coagulation, filtration and reverse osmosis. The use of iron oxide nanoparticles for water remediation as absorbents of metal ions presents several advantages such as their relatively low cost, the efficient recovery of the material by a simple magnetic separation procedure and also its high specific surface area (Fig. 7) [100]. It has been demonstrated that the absorption capacity of As(III) and As(V) increases from 0.6 to 59.5 mg As·g−1 as the magnetite particle size decreases from 300 to 11 nm. These differences were explained by the distinct exposed surface area and the different reactivity of the surfaces (decrease of tetrahedral site occupancy) [101,102,103]. The main mechanism related to the absorption of pollutants at the particles surface is the complexation and/or electrostatic interaction , followed by ion exchange between the iron surface and the toxic ions [104, 105]. The performance of the iron oxide nanoparticles depends on the crystalline structure (Fe3O4 or γ-Fe2O3), the particle concentration, the surface coating and the presence of interfering ions (especially nitrate and phosphate ions) [106, 107].

Due to its porous 3D morphology and high specific surface area , micron-sized nanoflowers have shown great potential in the absorption of As(V) and Cr(VI). Depending on the phase, values for the absorption of As(V) of 4.65 and 4.75 mg·g−1 have been found for Fe3O4 and γ-Fe2O3, respectively, while smaller differences have been found for the absorption of Cr(VI) (4.38 and 3.86 mg·g−1 for Fe3O4 and γ-Fe2O3) [108]. These nanoflowers have been also tested for the absorption of Orange II reaching absorption values around 43.5 mg·g−1. Hollow iron oxide nanocubes with a length of 7 nm and a shell thickness of around 2 nm have shown a powerful capacity for the absorption of As(V) (326 mg·g−1) and As(III) (190 mg·g−1) [109]. Hollow spheres between 200 and 300 nm in diameter and 20 nm shell thickness were tested for the absorption and removal of Neutral Red dye reaching values up to 90 mg·g−1 [110].

Despite these encouraging results, magnetic nanoparticles have important limitations in their use for water remediation, mainly related to the large quantities required for this application and the difficulties to fulfil the regulations for obtaining drinking water [8, 111].

3.5 Spintronics

Magnetite is a high-valuable material for application in spintronics because it is classified as a half-metallic ferromagnet (bandgap of 0.1–0.15 eV) with high values of spin polarization but also favourable Curie temperature (TC = 850 K) [112]. Density functional theory (DFT) has predicted a value of −100% spin polarization at the Fermi level for the bulk material [113].

Recently, if has been observed that 8 nm magnetite octahedrons capped with oleylamine exhibit interesting results in tunnelling magnetoresistance (TMR). [114] The oleylamine surface layer between the particles acts as insulating barrier providing multiple tunnel injection junctions where intergranular tunnelling is possible. TMR at room temperature reaches 38% increasing up to 69% at 180 K, much higher than those measured for spherical 8 nm particles coated with oleylamine (24% at room temperature and 41% at 180 K). The better performance of octahedral particles is a consequence of their better stoichiometry at the surface, presenting less defects that increase the spin polarization of the material and so the TMR. Moreover, the fact that (111) facets are exposed facilitates the strong coupling of oleylamine molecules on them (Fig. 8). Magnetite nanorods (75 × 9 nm, aspect ratio 8.3) were also tested as potential material for spintronics, and it was measured a TMR of 14% at room temperature when they were randomly oriented [115]. However, once they were oriented, they could increase its TMR up to 19% and to 31% at 130 K (close to the Verwey transition) because the relative magnetization is maximized due to the parallel orientation of the nanorods. The study of the particle dimensions with the TMR leads to a TMR decreases with the nanorod dimension, mainly for the diameter. Thus, the spin polarization of the 75 x 9 nm magnetite rods was 46%.

3.6 Microwave Absorption

In recent years, there has been an upsurge of electronic devices and communications (i.e. smartphones, satellite broadcasting, local area network (LAN), radars, etc.) operating in the gigahertz range (GHz) whose main drawback is the electromagnetic noise leading to poorer communications. Moreover, microwave radiation induces a considerable amount of health threats to organisms causing the breakdown of DNA strands, increasing heart rate, weakening the immune response and inducing cancer [116]. In this regard, iron oxide magnetic nanoparticles have shown high microwave absorption and low reflection over a broad frequency range. Tuning the particles microwave absorption properties is possible by controlling their size and shape and consequently their magnetic properties, that is high saturation magnetization values and low coercivity that favour larger permeability (Fig. 9) [117]. The development of Fe3O4 composites with large anisotropy may exceed the Snoeck limit, having high permittivity and reaching better MW absorption properties [118, 119].

Fe3O4 nanodiscs with a thickness of 30 nm have shown an increase of the permittivity with the diameter (from 80 to 500 nm) and resonance frequency [120]. However, the permeability shows an opposite trend (2.0 for the 80 nm and 1.8 for 500 nm discs at 0.1 GHz) due to the increase in shape anisotropy as the diameter grows. The smallest nanodiscs (30x 80 nm) exhibit a high microwave absorption as a consequence of its lower permittivity (RL < -10 dB) with a wide frequency bandwidth of about 2–18 GHz, with a sheet thickness of around 2.1 mm. In the same way, nanorods of Fe3O4/Fe/SiO2 of 1 μm x 80 nm present properties as microwave absorbers since the reflection loss below −10 dB is up to 6.96 GHz with a sheet thickness of 2 mm [121]. Porous magnetite flowers with a diameter of 2.5 μm composed of cores of 50 nm present a bandwidth with a RL < -10 dB of 3.8 GHz with a minimum of −28.31 dB at 13.26 GHz. Magnetite nanorings coated by carbon of 160 x 70 nm exhibit a strong reflection loss value of 61.54 dB at 16.9 GHz with a thickness of 1.5 mm and a low filling ratio of 25%. Authors attribute this attenuation ability to the eddy current loss enhanced by combination of confinement vortex and train-driven vortex [122].

It can be concluded that the performance of Fe3O4 for microwave absorption may require a high anisotropic material that also contains certain porosity in its structure increasing the interfacial area throughout the composite [123].

3.7 Li-Ion Batteries

The use of Fe3O4 as material for the design of Li-ion batteries (LIBs) is due to its high theoretical capacity (900–1000 mA·h·g−1), low cost, environmental-friendly and high rate performance [124, 125]. The current generation of LIBs are based on electrode materials in which Li+ ions are stored by insertion between structural layers during charging and extracted from the layers during discharging without significant structural change, which gives excellent cycling performance. The electrochemical reaction between Li and magnetite occurs as follows:

Fe3O4 presents several drawbacks for their application as LIBs such as stress due to volume changes after lithium ions charge and discharge and the high surface area of nanomaterials which causes aggregation of the iron oxide nanoparticles and electrolyte decomposition forming a thick solid electrolyte interphase on the electrode surface [126, 127]. Fortunately, the use of high porous and/or hollow nanostructures with high surface area has shown good properties as LIBs materials because they shorten the diffusion pathway of Li ions and electrons and increase the electrochemical reaction area leading to an improvement penetration of the electrolyte and accommodating the strain caused by the lithium inclusion/removal (Fig. 10).

For example, high porous Fe3O4 nanorods with lengths within 400 and 700 nm and diameters between 20 and 80 nm coming from the reduction of goethite nanorods exhibit a high reversible capacity of 843.5 mA·h·g-1 after the 50th cycle at 0.1 C (10 h discharge time) due to the high dense porous structure and the elongated morphology [128]. A composite of Fe3O4 nanoflowers in carbon with a diameter of 2 μm and sheets of 50 nm in thickness exhibits high capacities up to 1030 mA·h·g−1 at a density rate of 0.2 C (5 h discharge time) up to 150 cycles [129]. Noteworthy, it has been observed a different electrochemical activity in the facets exposed to the media by the Fe3O4 nanostructures. Thus, (220) facets which can be found in nanoprisms are more electroactive than (111) which are characteristic of octahedrons. [130] Moreover, comparing nanorods, nanoplates and spherical particles, the nanorods present a higher electrochemical activity and larger working capacities [42].

Hollow γ-Fe2O3 nanoparticles with a void around 15 nm and a shell thickness near 4 nm can host lithium ions serving as cathode material reaching a capacity of 219 mA·h·g−1 with a Coulombic efficiency of 99.7% [131]. In the case of smaller hollow particles (5.7 nm in void with less than 2 nm in shell thickness) capacities up to 132 mA·h·g−1 were displayed, being the high concentration of vacancies and chemical stability of γ-Fe2O3 during the voltage window the reasons for these high capacity values. On the other hand, 16 nm Fe3O4 nanocubes synthesized by a L-serine-assisted solvothermal approach presents a high specific capacitance of 695 mA·h·g−1 at 0.2 C and an excellent Coulombic efficiency of above 95% after the 11th cycle [132]. Rhombic dodecahedral Fe3O4 nanocrystals (NCs) exposing {110} facets exhibit a high initial discharge capacity of 1147 mA·h·g−1 at 0.2 C and a good cycle performance (362 mA·h·g−1 at 0.2 C after 100 cycles and 191 mA·h·g−1 at 1 C up to 130 cycles) [133].

4 Conclusions and Perspectives

Since ancient times, magnetic iron oxide nanoparticles have been present in people’s daily life being remarkable the feasibility of this material to adapt thank to their appealing properties. The possibility of synthesizing these particles using versatile synthetic routes boosted the interest of researchers to establish a clear relation between the electrical, magnetic and optical properties and their particle size, shape and internal structure. It can be concluded that their performance is intimately related to the followed synthetic pathway.

During the latest years, the synthesis of anisotropic magnetic iron oxide nanoparticles, i.e. nanoparticles with nonspherical shape, has received a great attention. The anisometry leads to new functionalities such as enhanced magnetic properties due to the increase in the magnetic effective anisotropy, a higher surface to volume ratio and different particle facets exposed modulating the reactivity with molecules, particles or other entities. These properties are very advantageous in widespread applications such as biomedicine as theranostic agents (MRI and magnetic/optical hyperthermia) and others such as magnetic recording media, environmental remediation, Li-ion batteries, spintronics or microwave absorption.

This chapter summarizes the most reproducible and successful synthetic routes that lead to iron oxide magnetic nanoparticles with nonspherical morphology and also their applications related to the actual societal challenges. Most of the morphologies considered can be synthesized by thermal decomposition and solvothermal synthesis. Although thermal decomposition produces monodisperse and highly crystalline nanoparticles, this strategy also uses organic solvents which are not environmentally friendly, and for some applications, a further step to transfer them to water is needed. On the other side, solvothermal synthesis produces nanoparticles stable in aqueous media, with less sophisticated protocols and more environmentally friendly solvents. However, this synthesis route is more difficult of scaling up and requires longer time and in many cases a final step for the reduction of the resulting nanoparticles, from hematite to magnetite. Summing up, among the different synthesis routes described here, factors like time, cost, energy consumption, environmental issues and scalability should be considered when translating these processes to the industry.

The applications reviewed in this chapter are very broad, from environmental remediation and biomedicine to spintronics and energy (Li-ion batteries). Most of the research on magnetic nanoparticles for these applications (except magnetic recording media) has been carried out with spherical particles, whose properties depend on particle size, aggregation, crystallinity and coating. However, during the latest decades of the twentieth century, iron oxide and iron metal particles with elongated morphology were the ideal structure for magnetic recording media due to the enhancement of the anisotropy constant. In the latest years, the literature regarding anisometric iron oxides nanoparticles has boosted, demonstrating the interest in them with other areas respect to their spherical equivalents. For example, the use of magnetic nanocubes and nanodiscs in magnetic hyperthermia leads to an increment in the SAR values, also showing a great performance in in vitro studies. Interestingly, the performance of these particles as heating agents can be increased if magnetic hyperthermia is combined with photothermal therapy. On the other hand, nanostructures with high specific surface area that exhibits porosity are very advantageous for Li-ion batteries because they shorten the pathway of Li ions and electrons leading to an improvement penetration of the electrolyte.

In general, the excellent properties of magnetite and maghemite confer these materials of a unique adaptability setting this material far away of being “old fashion” for practical applications. In the case of magnetite, these properties are based on its structure of inverse spinel with an interesting electron hoping between Fe2+ and Fe3+ ions at octahedral sites. This material has been subject of interest in diverse fields such as magnetism, optics and electronics. Interestingly, most of its properties abruptly change when crossing the Verwey transition. Enabling more degrees of freedom by shaping the morphology of the nanoparticles different from the spherical one has brought advantageous benefits in different applications. For most of the applications, only a few morphologies have been tested yet. There are still morphologies with enormous potential such as plates, rings and nanotubes due to their magnetic structure (vortex) or specific surface area that have not been tested properly in a variety of applications. Moreover, for some morphologies, there is room to improve the synthetic routes. These routes should be more robust, reproducible and scalable in order to make monodispersed particles with tuneable properties. Moreover, for the demanding application, there should exist more protocols about how to process the material to exhibit the best performance without losing any of its inherent properties.

References

A.G. Roca, L. Gutiérrez, H. Gavilán, et al., Design strategies for shape-controlled magnetic iron oxide nanoparticles. Adv. Drug Deliv. Rev. 138, 68–104 (2019). https://doi.org/10.1016/j.addr.2018.12.008

D.J. Dunlop, Ö. Özdemir, Rock Magnetism: Fundamentals and Frontiers (Cambridge University Press, Cambridge, 1997)

D. Faivre, D. Schüler, Magnetotactic Bacteria and Magnetosomes. Chem. Rev. 108, 4875–4898 (2008). https://doi.org/10.1021/cr078258w

G. Priyadarshana, N. Kottegoda, A. Senaratne, et al., Synthesis of magnetite nanoparticles by top-down approach from a high purity ore. J. Nanomater. 2015, 1–8 (2015). https://doi.org/10.1155/2015/317312

A.G. Roca, R. Costo, A.F. Rebolledo, et al., Progress in the preparation of magnetic nanoparticles for applications in biomedicine. J Phys D-Applied Phys 42, 224002 (2009). https://doi.org/10.1088/0022-3727/42/22/224002

J. Van Klinken, Magnetization of ancient ceramics. Archaeometry 43, 49–57 (2001). https://doi.org/10.1111/1475-4754.00004

K.J. Sreeram, R. Indumathy, A. Rajaram, et al., Template synthesis of highly crystalline and monodisperse iron oxide pigments of nanosize. Mater. Res. Bull. 41, 1875–1881 (2006). https://doi.org/10.1016/j.materresbull.2006.03.017

K. Simeonidis, S. Mourdikoudis, E. Kaprara, et al., Inorganic engineered nanoparticles in drinking water treatment: A critical review. Environ Sci Water Res Technol 2, 43–70 (2016). https://doi.org/10.1039/C5EW00152H

M. Colombo, S. Carregal-Romero, M.F. Casula, et al., Biological applications of magnetic nanoparticles. Chem. Soc. Rev. 41, 4306 (2012). https://doi.org/10.1039/c2cs15337h

A.G. Roca, J.F. Marco, M.P. Morales, C.J. Serna, Effect of nature and particle size on properties of uniform magnetite and Maghemite nanoparticles. J. Phys. Chem. C 111, 18577–18584 (2007). https://doi.org/10.1021/jp075133m

B.D. Cullity, C.D. Graham, Introduction to Magnetic Materials (Wiley, Hoboken, 2008)

M.E. Fleet, The structure of magnetite. Acta Crystallogr Sect B Struct Crystallogr Cryst Chem 37, 917–920 (1981). https://doi.org/10.1107/S0567740881004597

M.P. Morales, C. de Julián, J.M. González, C.J. Serna, The effect of the distribution of vacancies on the magnetic properties of γ – Fe2O3 particles. J. Mater. Res. 9, 135–141 (1994). https://doi.org/10.1557/JMR.1994.0135

K.V.P.M. Shafi, A. Ulman, A. Dyal, et al., Magnetic enhancement of γ-Fe2O3 nanoparticles by Sonochemical coating. Chem. Mater. 14, 1778 (2002). https://doi.org/10.1021/cm011535+

W. Wu, Z. Wu, T. Yu, et al., Recent progress on magnetic iron oxide nanoparticles: Synthesis, surface functional strategies and biomedical applications. Sci. Technol. Adv. Mater. 16, 023501 (2015). https://doi.org/10.1088/1468-6996/16/2/023501

S.G. Kwon, T. Hyeon, Colloidal chemical synthesis and formation kinetics of uniformly sized Nanocrystals of metals, oxides, and Chalcogenides. Acc. Chem. Res. 41, 1696–1709 (2008). https://doi.org/10.1021/ar8000537

L. Manna, E.C. Scher, A.P. Alivisatos, Synthesis of soluble and processable rod-, arrow-, teardrop-, and tetrapod-shaped CdSe nanocrystals. J. Am. Chem. Soc. 122, 12700–12706 (2000). https://doi.org/10.1021/ja003055+

Z.A. Peng, X. Peng, Mechanisms of the shape evolution of CdSe Nanocrystals. J. Am. Chem. Soc. 123, 1389–1395 (2001). https://doi.org/10.1021/ja0027766

D. Kim, N. Lee, M. Park, et al., Synthesis of uniform Ferrimagnetic magnetite Nanocubes. J. Am. Chem. Soc. 131, 454–455 (2009). https://doi.org/10.1021/ja8086906

P. Guardia, J. Pérez-Juste, A. Labarta, et al., Heating rate influence on the synthesis of iron oxide nanoparticles : The case of decanoic acid. Chem. Commun. 46, 6108–6110 (2010). https://doi.org/10.1039/c0cc01179g

G. Gao, X. Liu, R. Shi, et al., Shape-controlled synthesis and magnetic properties of Monodisperse Fe 3 O 4 Nanocubes. Cryst. Growth Des. 10, 2888–2894 (2010). https://doi.org/10.1021/cg900920q

Z. Xu, C. Shen, Y. Tian, et al., Organic phase synthesis of monodisperse iron oxide nanocrystals using iron chloride as precursor. Nanoscale 2, 1027 (2010). https://doi.org/10.1039/b9nr00400a

M.V. Kovalenko, M.I. Bodnarchuk, R.T. Lechner, et al., Fatty acid salts as stabilizers in size- and shape-controlled Nanocrystal synthesis: The case of inverse spinel Iron oxide. J. Am. Chem. Soc. 129, 6352–6353 (2007). https://doi.org/10.1021/ja0692478

J. Muro-Cruces, A.G. Roca, A. López-Ortega, et al., Precise size control of the growth of Fe 3 O 4 Nanocubes over a wide size range using a rationally designed one-pot synthesis. ACS Nano 13, 7716–7728 (2019). https://doi.org/10.1021/acsnano.9b01281

M. Andrés Vergés, R. Costo, A.G. Roca, et al., Uniform and water stable magnetite nanoparticles with diameters around the monodomain–multidomain limit. J. Phys. D. Appl. Phys. 41, 134003 (2008). https://doi.org/10.1088/0022-3727/41/13/134003

T. Asimakidou, A. Makridis, S. Veintemillas-Verdaguer, et al., Continuous production of magnetic iron oxide nanocrystals by oxidative precipitation. Chem. Eng. J. 393, 124593 (2020). https://doi.org/10.1016/j.cej.2020.124593

L. Zhang, J. Wu, H. Liao, et al., Octahedral Fe3O4 nanoparticles and their assembled structures. Chem Commun 4378. (2009). https://doi.org/10.1039/b906636e

Shavel A, Rodri B, Pacifico J, et al (2009) Shape Control in Iron Oxide Nanocrystal Synthesis , Induced by Trioctylammonium Ions Shape Control in Iron Oxide Nanocrystal Synthesis , Induced by Trioctylammonium Ions. 5843–5849. https://doi.org/10.1021/cm803201p

A. Shavel, L.M. Liz-Marzán, Shape control of iron oxide nanoparticles. Phys. Chem. Chem. Phys. 11, 3762–3763 (2009). https://doi.org/10.1039/b822733k

J. Cheon, N.-J. Kang, S.-M. Lee, et al., Shape evolution of single-crystalline Iron oxide Nanocrystals. J. Am. Chem. Soc. 126, 1950–1951 (2004). https://doi.org/10.1021/ja038722o

A. Cabot, V.F. Puntes, E. Shevchenko, et al., Vacancy coalescence during oxidation of Iron nanoparticles. J. Am. Chem. Soc. 129, 10358–10360 (2007). https://doi.org/10.1021/ja072574a

G. Hemery, A.C. Keyes, E. Garaio, et al., Tuning sizes, morphologies, and magnetic properties of Monocore versus multicore Iron oxide nanoparticles through the controlled addition of water in the Polyol synthesis. Inorg. Chem. 56, 8232–8243 (2017). https://doi.org/10.1021/acs.inorgchem.7b00956

Y. Yang, X. Liu, Y. Lv, et al., Orientation mediated enhancement on magnetic hyperthermia of Fe 3 O 4 Nanodisc. Adv. Funct. Mater. 25, 812–820 (2015). https://doi.org/10.1002/adfm.201402764

M.P. Morales, C. Pecharroman, T. Gonzalez-Carreño, C.J. Serna, Structural characteristics of uniform γ-Fe2O3 particles with different axial (length/width) ratios. J. Solid State Chem. 108, 158–163 (1994)

A.F. Rebolledo, O. Bomatí-Miguel, J.F. Marco, P. Tartaj, A facile synthetic route for the preparation of superparamagnetic iron oxide nanorods and nanorices with tunable surface functionality. Adv. Mater. 20, 1760–1765 (2008). https://doi.org/10.1002/adma.200701782

M.A. Blesa, M. Mijalchik, M. Villegas, G. Rigotti, Transformation of akaganeite into magnetite in aqueous hydrazine suspensions. React Solids 2, 85–94 (1986). https://doi.org/10.1016/0168-7336(86)80066-3

M.P. Morales, T. González-Carreño, C.J. Serna, The formation of alpha-Fe2O 3 monodispersed particles in solution. J. Mater. Res. 7, 2538–2545 (1992). https://doi.org/10.1557/JMR.1992.2538

M. Ocaña, M.P. Morales, C.J. Serna, Homogeneous precipitation of uniform α-Fe2O3 particles from Iron salts solutions in the presence of urea. J. Colloid Interface Sci. 212, 317–323 (1999). https://doi.org/10.1006/jcis.1998.6042

O. Bomati-Miguel, A.F. Rebolledo, P. Tartaj, Controlled formation of porous magnetic nanorods via a liquid/liquid solvothermal method. Chem Commun (Camb), 4168–4170 (2008). https://doi.org/10.1039/b805239e

S. Lentijo Mozo, E. Zuddas, A. Casu, A. Falqui, Synthesizing Iron oxide nanostructures: The Polyethylenenemine (PEI) role. Crystals 7, 22 (2017). https://doi.org/10.3390/cryst7010022

M. Mohapatra, S. Anand, Synthesis and applications of nano-structured iron oxides / hydroxides – A review. Int. J. Eng. Sci. Technol. 2, 127–146 (2010). https://doi.org/10.4314/ijest.v2i8.63846

H. Sun, B. Chen, X. Jiao, et al., Solvothermal synthesis of Tunable Electroactive magnetite Nanorods by controlling the side reaction. J. Phys. Chem. C 116, 5476–5481 (2012). https://doi.org/10.1021/jp211986a

R. Das, J. Alonso, Z. Nemati Porshokouh, et al., Tunable high aspect ratio Iron oxide Nanorods for enhanced hyperthermia. J. Phys. Chem. C 120, 10086–10093 (2016). https://doi.org/10.1021/acs.jpcc.6b02006

X.-L. Liu, Y. Yang, J.-P. Wu, et al., Novel magnetic vortex nanorings/nanodiscs: Synthesis and theranostic applications. Chinese Phys B 24, 127505 (2015). https://doi.org/10.1088/1674-1056/24/12/127505

Y. Huang, D. Ding, M. Zhu, et al., Facile synthesis of α-Fe 2 O 3 nanodisk with superior photocatalytic performance and mechanism insight. Sci. Technol. Adv. Mater. 16, 014801 (2015). https://doi.org/10.1088/1468-6996/16/1/014801

K. An, T. Hyeon, Synthesis and biomedical applications of hollow nanostructures. Nano Today 4, 359–373 (2009). https://doi.org/10.1016/j.nantod.2009.06.013

A. Cabot, A.P. Alivisatos, V.F. Puntes, et al., Magnetic domains and surface effects in hollow maghemite nanoparticles. Phys. Rev. B 79, 094419 (2009). https://doi.org/10.1103/PhysRevB.79.094419

L. Lartigue, P. Hugounenq, D. Alloyeau, et al., Cooperative Organization in Iron Oxide Multi-Core Nanoparticles Potentiates Their Efficiency as heating mediators and MRI contrast agents. ACS Nano 6, 10935–10949 (2012). https://doi.org/10.1021/nn304477s

P. Hugounenq, M. Levy, D. Alloyeau, et al., Iron oxide Monocrystalline Nanoflowers for highly efficient magnetic hyperthermia. J. Phys. Chem. C 116, 15702–15712 (2012). https://doi.org/10.1021/jp3025478

J. Liu, Z. Wu, Q. Tian, et al., Shape-controlled iron oxide nanocrystals: Synthesis, magnetic properties and energy conversion applications. CrystEngComm 18, 6303–6326 (2016). https://doi.org/10.1039/C6CE01307D

R. Crichton, Inorganic Biochemistry of Iron Metabolism (Wiley, Chichester, 2001)

A.S. Thakor, J.V. Jokerst, P. Ghanouni, et al., Clinically approved nanoparticle imaging agents. J. Nucl. Med. 57, 1833–1837 (2016). https://doi.org/10.2967/jnumed.116.181362

M. Angelakeris, Magnetic nanoparticles: A multifunctional vehicle for modern theranostics. Biochim Biophys Acta - Gen Subj 1861, 1642–1651 (2017). https://doi.org/10.1016/j.bbagen.2017.02.022

R. Weissleder, M. Nahrendorf, M.J. Pittet, Imaging macrophages with nanoparticles. Nat. Mater. 13, 125–138 (2014). https://doi.org/10.1038/nmat3780

G.B. Toth, C.G. Varallyay, A. Horvath, et al., Current and potential imaging applications of ferumoxytol for magnetic resonance imaging. Kidney Int. 92, 47–66 (2017). https://doi.org/10.1016/j.kint.2016.12.037

E.D. Smolensky, H.-Y.E. Park, Y. Zhou, et al., Scaling laws at the nanosize: The effect of particle size and shape on the magnetism and relaxivity of iron oxide nanoparticle contrast agents. J. Mater. Chem. B 1, 2818 (2013). https://doi.org/10.1039/c3tb00369h

A. Orza, H. Wu, Y. Xu, et al., One-step facile synthesis of highly magnetic and surface functionalized Iron oxide Nanorods for biomarker-targeted applications. ACS Appl. Mater. Interfaces 9, 20719–20727 (2017). https://doi.org/10.1021/acsami.7b02575

J. Mohapatra, A. Mitra, H. Tyagi, et al., Iron oxide nanorods as high-performance magnetic resonance imaging contrast agents. Nanoscale 7, 9174–9184 (2015). https://doi.org/10.1039/C5NR00055F

M.E. Materia, P. Guardia, A. Sathya, et al., Mesoscale assemblies of Iron oxide Nanocubes as heat mediators and image contrast agents. Langmuir 31, 808–816 (2015). https://doi.org/10.1021/la503930s

Z. Zhao, Z. Zhou, J. Bao, et al., Octapod iron oxide nanoparticles as high-performance T2 contrast agents for magnetic resonance imaging. Nat. Commun. 4, 2266 (2013). https://doi.org/10.1038/ncomms3266

Y. Bao, J.A. Sherwood, Z. Sun, Magnetic iron oxide nanoparticles as T1 contrast agents for magnetic resonance imaging. J. Mater. Chem. C 6, 1280–1290 (2018). https://doi.org/10.1039/C7TC05854C

I. Fernández-Barahona, M. Muñoz-Hernando, J. Ruiz-Cabello, et al., Iron oxide nanoparticles: An alternative for positive contrast in magnetic resonance imaging. Inorganics 8, 28 (2020). https://doi.org/10.3390/inorganics8040028

H. Wei, O.T. Bruns, M.G. Kaul, et al., Exceedingly small iron oxide nanoparticles as positive MRI contrast agents. Proc. Natl. Acad. Sci. 114, 2325–2330 (2017). https://doi.org/10.1073/pnas.1620145114

T. Macher, J. Totenhagen, J. Sherwood, et al., Ultrathin Iron oxide Nanowhiskers as positive contrast agents for magnetic resonance imaging. Adv. Funct. Mater. 25, 490–494 (2015). https://doi.org/10.1002/adfm.201403436

W. Yue, A.H. Hill, A. Harrison, W. Zhou, Mesoporous single-crystal Co3O4 templated by cage-containing mesoporous silica. Chem. Commun. (Camb.) 1, 2518–2520 (2007). https://doi.org/10.1039/b700185a

Y. Yue, X. Wang, Nanoscale thermal probing. Nano Rev 3, 11586 (2012). https://doi.org/10.3402/nano.v3i0.11586

Z. Zhou, D. Huang, J. Bao, et al., A synergistically enhanced T1-T2 dual-modal contrast agent. Adv. Mater. 24, 6223–6228 (2012). https://doi.org/10.1002/adma.201203169

G. Vallejo-Fernandez, O. Whear, A.G. Roca, et al., Mechanisms of hyperthermia in magnetic nanoparticles. J. Phys. D. Appl. Phys. 46, 312001 (2013). https://doi.org/10.1088/0022-3727/46/31/312001

S. Dutz, R. Hergt, Magnetic nanoparticle heating and heat transfer on a microscale: Basic principles, realities and physical limitations of hyperthermia for tumour therapy. Int. J. Hyperth. 29, 790–800 (2013). https://doi.org/10.3109/02656736.2013.822993

A.E. Deatsch, B.A. Evans, Heating efficiency in magnetic nanoparticle hyperthermia. J. Magn. Magn. Mater. 354, 163–172 (2014). https://doi.org/10.1016/j.jmmm.2013.11.006

M. Ma, Y. Wu, J. Zhou, et al., Size dependence of specific power absorption of Fe3O4 particles in AC magnetic field. J. Magn. Magn. Mater. 268, 33–39 (2004). https://doi.org/10.1016/S0304-8853(03)00426-8

Z. Nemati, R. Das, J. Alonso, et al., Iron oxide Nanospheres and Nanocubes for magnetic hyperthermia therapy: A comparative study. J. Electron. Mater. 46, 3764–3769 (2017). https://doi.org/10.1007/s11664-017-5347-6

D. Serantes, K. Simeonidis, M. Angelakeris, et al., Multiplying magnetic hyperthermia response by nanoparticle assembling. J. Phys. Chem. C 118, 5927–5934 (2014). https://doi.org/10.1021/jp410717m

P. Guardia, R. Di Corato, L. Lartigue, et al., Water-soluble Iron oxide Nanocubes with high values of specific absorption rate for Cancer cell hyperthermia treatment. ACS Nano 6, 3080–3091 (2012). https://doi.org/10.1021/nn2048137

P. Guardia, A. Riedinger, S. Nitti, et al., One pot synthesis of monodisperse water soluble iron oxide nanocrystals with high values of the specific absorption rate. J. Mater. Chem. B 2, 4426 (2014). https://doi.org/10.1039/c4tb00061g

K. Mahmoudi, A. Bouras, D. Bozec, et al., Magnetic hyperthermia therapy for the treatment of glioblastoma: A review of the therapy’s history, efficacy and application in humans. Int. J. Hyperth. 34, 1316–1328 (2018). https://doi.org/10.1080/02656736.2018.1430867

M.V. Zyuzin, M. Cassani, M.J. Barthel, et al., Confining Iron oxide Nanocubes inside submicrometric cavities as a key strategy to preserve magnetic heat losses in an intracellular environment. ACS Appl. Mater. Interfaces 11, 41957–41971 (2019). https://doi.org/10.1021/acsami.9b15501

J. Mohapatra, A. Mitra, M. Aslam, D. Bahadur, Octahedral-shaped Fe3O4 nanoparticles with enhanced specific absorption rate and R2 Relaxivity. IEEE Trans. Magn. 51, 1–3 (2015). https://doi.org/10.1109/TMAG.2015.2439213

Y. Lv, Y. Yang, J. Fang, et al., Size dependent magnetic hyperthermia of octahedral Fe 3 O 4 nanoparticles. RSC Adv. 5, 76764–76771 (2015). https://doi.org/10.1039/C5RA12558H

A. Wachowiak, Direct observation of internal spin structure of magnetic vortex cores. Science (80- ) 298, 577–580 (2002). https://doi.org/10.1126/science.1075302

M. Ma, Y. Zhang, Z. Guo, N. Gu, Facile synthesis of ultrathin magnetic iron oxide nanoplates by Schikorr reaction. Nanoscale Res. Lett. 8, 16 (2013). https://doi.org/10.1186/1556-276X-8-16

S. Del Sol-Fernández, Y. Portilla-Tundidor, L. Gutiérrez, et al., Flower-like Mn-doped magnetic nanoparticles functionalized with α v β 3 -integrin-ligand to efficiently induce intracellular heat after alternating magnetic field exposition, triggering Glioma cell death. ACS Appl. Mater. Interfaces 11, 26648–26663 (2019). https://doi.org/10.1021/acsami.9b08318

J. Estelrich, M. Busquets, Iron oxide nanoparticles in Photothermal therapy. Molecules 23, 1567 (2018). https://doi.org/10.3390/molecules23071567

A. Espinosa, R. Di Corato, J. Kolosnjaj-Tabi, et al., Duality of Iron oxide nanoparticles in Cancer therapy: Amplification of heating efficiency by magnetic hyperthermia and Photothermal bimodal treatment. ACS Nano 10, 2436–2446 (2016). https://doi.org/10.1021/acsnano.5b07249

A. Espinosa, J. Kolosnjaj-Tabi, A. Abou-Hassan, et al., Magnetic (hyper)Thermia or Photothermia? Progressive comparison of Iron oxide and gold nanoparticles heating in water, in cells, and in vivo. Adv. Funct. Mater. 28, 1803660 (2018). https://doi.org/10.1002/adfm.201803660

D. Cheng, X. Li, G. Zhang, H. Shi, Morphological effect of oscillating magnetic nanoparticles in killing tumor cells. Nanoscale Res. Lett. 9, 195 (2014). https://doi.org/10.1186/1556-276X-9-195

X. Yao, K. Sabyrov, T. Klein, et al., Evaluation of magnetic heating of asymmetric magnetite particles. J. Magn. Magn. Mater. 381, 21–27 (2015). https://doi.org/10.1016/j.jmmm.2014.12.035

D.-H. Kim, E.A. Rozhkova, I.V. Ulasov, et al., Biofunctionalized magnetic-vortex microdiscs for targeted cancer-cell destruction. Nat. Mater. 9, 165–171 (2010). https://doi.org/10.1038/nmat2591

M.P. Sharrock, Recent advances in metal particulate recording media: Toward the ultimate particle. IEEE Trans. Magn. 36, 2420–2425 (2000). https://doi.org/10.1109/20.908453

M.P. Sharrock, Particulate magnetic recording media: A review. IEEE Trans. Magn. 25, 4374–4389 (1989). https://doi.org/10.1109/20.45317

A. Berkowitz, Some materials considerations in particulate media. IEEE Trans. Magn. 22, 466–471 (1986). https://doi.org/10.1109/TMAG.1986.1064462

A.E. Berkowitz, R.P. Goehner, E.L. Hall, P.J. Flanders, Microstructure, relaxation, and print-through in γ-Fe 2 O 3 particles. J. Appl. Phys. 57, 3928–3930 (1985). https://doi.org/10.1063/1.334919

M. Stachen, M.P. Morales, M. Ocaña, C.J. Serna, Effect of precursor impurities on the magnetic properties of uniform γ-Fe2O3 ellipsoidal particles. Phys. Chem. Chem. Phys. 1, 4465–4471 (1999). https://doi.org/10.1039/a904606b

H. Naono, R. Fujiwara, Micropore formation due to thermal decomposition of acicular microcrystals of α-FeOOH. J. Colloid Interface Sci. 73, 406–415 (1980). https://doi.org/10.1016/0021-9797(80)90086-7

A. Corradi, S. Andress, J. French, et al., Magnetic properties of new (NP) hydrothermal particles. IEEE Trans. Magn. 20, 33–38 (1984). https://doi.org/10.1109/TMAG.1984.1063007

M.P. Morales, S.A. Walton, L.S. Prichard, et al., Characterisation of advanced metal particle recording media pigments. J. Magn. Magn. Mater. 190, 357–370 (1998). https://doi.org/10.1016/S0304-8853(98)00249-2

N.O. Nuñez, M.P. Morales, P. Tartaj, C.J. Serna, Preparation of high acicular and uniform goethite particles by a modified-carbonate route. J. Mater. Chem. 10, 2561–2565 (2000). https://doi.org/10.1039/b005014h

R. Mendoza-Reséndez, M.P. Morales, C.J. Serna, Reduction mechanism of uniform iron oxide nanoparticles to metal used as recording media. Mater. Sci. Eng. C 23, 1139–1142 (2003). https://doi.org/10.1016/j.msec.2003.09.126

T. Pradeep, Anshup, Noble metal nanoparticles for water purification: A critical review. Thin Solid Films 517, 6441–6478 (2009). https://doi.org/10.1016/j.tsf.2009.03.195

A.S. Helal, E. Mazario, A. Mayoral, et al., Highly efficient and selective extraction of uranium from aqueous solution using a magnetic device: Succinyl-β-cyclodextrin-APTES@maghemite nanoparticles. Environ. Sci. Nano 5, 158–168 (2018). https://doi.org/10.1039/C7EN00902J

M. Auffan, J. Rose, J.-Y. Bottero, et al., Towards a definition of inorganic nanoparticles from an environmental, health and safety perspective. Nat. Nanotechnol. 4, 634–641 (2009). https://doi.org/10.1038/nnano.2009.242

M. Auffan, J. Rose, O. Proux, et al., Enhanced adsorption of arsenic onto Maghemites nanoparticles: As(III) as a probe of the surface structure and heterogeneity. Langmuir 24, 3215–3222 (2008). https://doi.org/10.1021/la702998x

S. Brice-Profeta, M.-A. Arrio, E. Tronc, et al., Magnetic order in - nanoparticles: A XMCD study. J. Magn. Magn. Mater. 288, 354–365 (2005). https://doi.org/10.1016/j.jmmm.2004.09.120

G.A. Waychunas, C.S. Kim, J.F. Banfield, Nanoparticulate Iron oxide minerals in soils and sediments: Unique properties and contaminant scavenging mechanisms. J. Nanopart. Res. 7, 409–433 (2005). https://doi.org/10.1007/s11051-005-6931-x

M.S. Onyango, Y. Kojima, H. Matsuda, A. Ochieng, Adsorption kinetics of arsenic removal from groundwater by Iron-modified zeolite. J Chem Engineering Japan 36, 1516–1522 (2003). https://doi.org/10.1252/jcej.36.1516

S.R. Chowdhury, E.K. Yanful, Arsenic and chromium removal by mixed magnetite–maghemite nanoparticles and the effect of phosphate on removal. J. Environ. Manag. 91, 2238–2247 (2010). https://doi.org/10.1016/j.jenvman.2010.06.003

A. Khodabakhshi, M.M. Amin, M. Mozaffari, Synthesis of magnetite nanoparticles and evaluation of its efficiency for arsenic removal from simulated industrial waste water. Iran J Environ Heal Sci Eng 8, 189–200 (2011)

L.-S. Zhong, J.-S. Hu, H.-P. Liang, et al., Self-assembled 3D flowerlike Iron oxide nanostructures and their application in water treatment. Adv. Mater. 18, 2426–2431 (2006). https://doi.org/10.1002/adma.200600504

L. Balcells, C. Martínez-Boubeta, J. Cisneros-Fernández, et al., One-step route to Iron oxide hollow Nanocuboids by cluster condensation: Implementation in water remediation technology. ACS Appl. Mater. Interfaces 8, 28599–28606 (2016). https://doi.org/10.1021/acsami.6b08709

M. Iram, C. Guo, Y. Guan, et al., Adsorption and magnetic removal of neutral red dye from aqueous solution using Fe3O4 hollow nanospheres. J. Hazard. Mater. 181, 1039–1050 (2010). https://doi.org/10.1016/j.jhazmat.2010.05.119

C. Martinez-Boubeta, K. Simeonidis, Magnetic Nanoparticles for Water Purification (Nanoscale Materials in Water Purification. Elsevier, In, 2019), pp. 521–552

G.S. Parkinson, U. Diebold, J. Tang, L. Malkinski, Tailoring the Interface properties of magnetite for Spintronics. Adv Magn Mater, 61–88 (2012). https://doi.org/10.5772/39101

Z. Zhang, S. Satpathy, Electron states, magnetism, and the Verwey transition in magnetite. Phys. Rev. B 44, 13319–13331 (1991). https://doi.org/10.1103/PhysRevB.44.13319

A. Mitra, B. Barick, J. Mohapatra, et al., Large tunneling magnetoresistance in octahedral Fe3O4 nanoparticles. AIP Adv. 6, 055007 (2016). https://doi.org/10.1063/1.4948798

A. Mitra, J. Mohapatra, H. Sharma, et al., Controlled synthesis and enhanced tunnelling magnetoresistance in oriented Fe3O4 nanorod assemblies. J. Phys. D. Appl. Phys. 51, 085002 (2018). https://doi.org/10.1088/1361-6463/aaa697

G. Sun, B. Dong, M. Cao, et al., Hierarchical dendrite-like magnetic materials of Fe 3 O 4 , γ-Fe 2 O 3 , and Fe with high performance of microwave absorption. Chem. Mater. 23, 1587–1593 (2011). https://doi.org/10.1021/cm103441u

C.-L. Zhu, M.-L. Zhang, Y.-J. Qiao, et al., Fe 3 O 4 /TiO 2 Core/Shell nanotubes: Synthesis and magnetic and electromagnetic wave absorption characteristics. J. Phys. Chem. C 114, 16229–16235 (2010). https://doi.org/10.1021/jp104445m

R.K. Walser, W. Win, P.M. Valanju, Shape-optimized ferromagnetic particles with maximum theoretical microwave susceptibility. IEEE Trans. Magn. 34, 1390–1392 (1998). https://doi.org/10.1109/20.706558

L.L. Adebayo, H. Soleimani, N. Yahya, et al., Recent advances in the development OF Fe3O4-BASED microwave absorbing materials. Ceram. Int. 46, 1249–1268 (2020). https://doi.org/10.1016/j.ceramint.2019.09.209

Y. Yang, M. Li, Y. Wu, et al., Size-dependent microwave absorption properties of Fe 3 O 4 nanodiscs. RSC Adv. 6, 25444–25448 (2016). https://doi.org/10.1039/C5RA28035D

Y.J. Chen, P. Gao, C.L. Zhu, et al., Synthesis, magnetic and electromagnetic wave absorption properties of porous Fe3O4/Fe/SiO2 core/shell nanorods. J. Appl. Phys. 106, 054303 (2009). https://doi.org/10.1063/1.3204958

X. Wang, F. Pan, Z. Xiang, et al., Magnetic vortex core-shell Fe3O4@C nanorings with enhanced microwave absorption performance. Carbon N Y 157, 130–139 (2020). https://doi.org/10.1016/j.carbon.2019.10.030

X. Li, B. Zhang, C. Ju, et al., Morphology-controlled synthesis and electromagnetic properties of porous Fe 3 O 4 nanostructures from Iron Alkoxide precursors. J. Phys. Chem. C 115, 12350–12357 (2011). https://doi.org/10.1021/jp203147q

X. Liu, Z. Zhong, Y. Tang, B. Liang, Review on the synthesis and applications of Fe3O4 Nanomaterials. J. Nanomater. 2013, 1–7 (2013). https://doi.org/10.1155/2013/902538

J. Liu, Z. Wu, Q. Tian, et al., Shape-controlled iron oxide nanocrystals: Synthesis, magnetic properties and energy conversion applications. CrystEngComm 18, 6303–6326 (2014). https://doi.org/10.1039/c6ce01307d

O. Delmer, P. Balaya, L. Kienle, J. Maier, Enhanced potential of amorphous electrode materials: Case study of RuO2. Adv. Mater. 20, 501–505 (2008). https://doi.org/10.1002/adma.200701349

J. Ma, X. Guo, Y. Yan, et al., FeO x -based materials for electrochemical energy storage. Adv. Sci. 5, 1700986 (2018). https://doi.org/10.1002/advs.201700986

Z. Xiao, Y. Xia, Z. Ren, et al., Facile synthesis of single-crystalline mesoporous α-Fe2O3 and Fe3O4 nanorods as anode materials for lithium-ion batteries. J. Mater. Chem. 22, 20566 (2012). https://doi.org/10.1039/c2jm34083f

S. Jin, H. Deng, D. Long, et al., Facile synthesis of hierarchically structured Fe3O4/carbon micro-flowers and their application to lithium-ion battery anodes. J. Power Sources 196, 3887–3893 (2011). https://doi.org/10.1016/j.jpowsour.2010.12.078

Y. Zeng, R. Hao, B. Xing, et al., One-pot synthesis of Fe3O4 nanoprisms with controlled electrochemical properties. Chem. Commun. 46, 3920 (2010). https://doi.org/10.1039/c0cc00246a

B. Koo, H. Xiong, M.D. Slater, et al., Hollow Iron oxide nanoparticles for application in Lithium ion batteries. Nano Lett. 12, 2429–2435 (2012). https://doi.org/10.1021/nl3004286

H. Cao, R. Liang, D. Qian, et al., Serine-assisted synthesis of Superparamagnetic Fe3O4 Nanocubes for Lithium ion batteries. J. Phys. Chem. C 115, 24688–24695 (2011). https://doi.org/10.1021/jp2096482

X.-L. Cheng, J.-S. Jiang, D.-M. Jiang, Z.-J. Zhao, Synthesis of rhombic dodecahedral Fe 3 O 4 Nanocrystals with exposed high-energy {110} facets and their peroxidase-like activity and Lithium storage properties. J. Phys. Chem. C 118, 12588–12598 (2014). https://doi.org/10.1021/jp412661e

Acknowledgements

This work was supported by the European Commission Framework Programme 7 (NanoMag project, No. 604448). We acknowledge the Spanish Ministry of Economy and Competitiveness through MAT2016-77391, MAT2017-88148-R, RTI2018-095495-J-I00 and PGC2018-096016-B-I00 grants, and Consejo Superior de Investigaciones Científicas through PIE201960E062 project. L.G. acknowledges financial support from the Ramón y Cajal subprogramme (RYC-2014-15512). A.G.R. thanks the Generalitat de Catalunya through 2017-SGR-292 project and the financial support of Ramon Areces Foundation through project CIVP19A5922. The ICN2 is funded by the CERCA programme/Generalitat de Catalunya. The ICN2 is supported by the Severo Ochoa Centres of Excellence programme, funded by the Spanish Research Agency (AEI, grant no. SEV-2017-0706).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Gutiérrez, L., Morales, M., Roca, A.G. (2021). Synthesis and Applications of Anisotropic Magnetic Iron Oxide Nanoparticles. In: Roca, A.G., et al. Surfaces and Interfaces of Metal Oxide Thin Films, Multilayers, Nanoparticles and Nano-composites. Springer, Cham. https://doi.org/10.1007/978-3-030-74073-3_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-74073-3_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-74072-6

Online ISBN: 978-3-030-74073-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)