Abstract

Purpose: This project aims to determine the additive technology parameters for automatic arc surfacing and their impact on the metal structure and properties in a product.

Design /methodology/approach: Automatic gas-shielded arc surfacing was performed with a modified 3D plasma cutting gantry machine controlled by the Mach 3 software. During surfacing, the welding torch weave pattern was generated by the G codes. The shapes obtained by layer-by-layer surfacing were evaluated by geometry and the analysis of microhardness and microstructure in the wall cross section. The coupons were prepared for microstructure testing with the EcoMet 250 Pro grinder and polisher machine. The microstructure was studied using the Nikon MA200 metallographic microscope; Vickers hardness was measured with the Shimadzu HMV-2 microhardness tester at the indentations with a spacing of 0.5 mm, with each one placed at the center of the rollers with a load of 1.961 N ≈ 0.2 kg.

Findings: The article describes the study of metal product fabrication (growth) by the layer-by-layer surfacing technique. The layer-by-layer surfacing technique, various surfacing processes, and selection of the conditions are reviewed. Preparation and analysis of metallographic specimens and the equipment used are described. The main results of metallographic and microhardness tests are listed.

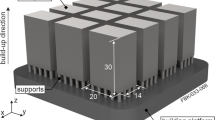

Originality/value: Rectangular shapes are obtained by layer-by-layer growth with automatic arc surfacing on a steel plate using various techniques. The impact of welding torch weave on the geometry, structure, and properties of the welding beads is identified. Recommendations are given on the selection of a specific surfacing technique.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Sviridov, A., Odinokov, V., Dmitriev, E., Evstigneev, A., Bashkov, O.: Numerical simulation of stress-strain state of electrophoretic shell molds. J. Phys: Conf. Ser. 894, 012125 (2017). https://doi.org/10.1088/1742-6596/894/1/012125

Evstigneev, A., Odinokov, V., Sviridov, A., Dmitriev, E., Petrov, V.: Theoretical prediction of crack formation in axisymmetric multilayer shell molds. Mater. Sci. Forum 857, 573–577 (2016). https://doi.org/10.4028/www.scientific.net/MSF.857.573

Zhu, S., Li, C., Shen, C., Liu, J.: Microstructure and micro mechanical property of part formed by GMAW surfacing rapid prototyping. Key Eng. Mater. 419–420, 853–856 (2010)

Zhang, Y., Li, P., Chen, Y., Male, A.: Automated system for welding-based rapid prototyping. Mechatronics 12(1), 37–53 (2002). https://doi.org/10.1016/S0957-4158(00)00064-7

Zhang, Y., Chen, Y., Li, P., Male, A.: Weld deposition-based rapid prototyping: a preliminary study. J. Mater. Process. Technol. 135(2–3), 347–357 (2003). https://doi.org/10.1016/S0924-0136(02)00867-1

Song, Y., Park, S., Choi, D., Jee, H.: 3D welding and milling: Part I-a direct approach for freeform fabrication of metallic prototypes. Int. J. Mach. Tools Manuf. 45(9), 1057–1062 (2005). https://doi.org/10.1016/j.ijmachtools.2004.11.021

Hur, J., Lee, K., Zhu-Hu, K.J.: Hybrid rapid prototyping system using machining and deposition. CAD Comput. Aided Des. 34(10), 741–754 (2002)

Aiyiti, W., Xiang, J., Zhang, L., Chen, R.: Study on the veritable parameters filling method of plasma arc welding based rapid prototyping. Key Eng. Mater. 522, 110–116 (2012). https://doi.org/10.4028/www.scientific.net/KEM.522.110

Huang, J., Shi, Y., Lu, L., Fan, D., Zhang, Y.: High-speed welding based on consumable DE-GMAW. In: 2010 International Conference on Mechanic Automation and Control Engineering, MACE 2010, pp. 5335–5338 (2010)

Xiaomao, H., Chunsheng, Y., Yongjun, H.: Tool path planning based on endpoint build-in optimization in rapid prototyping. J. Mech. Eng. Sci. 225(12), 2919–2926 (2011)

Kulkarni, P., Marsan, A., Dutta, D.: Review of process planning techniques in layered manufacturing. Rapid Prototyp. J. 6(1), 18–35 (2000). https://doi.org/10.1108/13552540010309859

Dutta, D., Prinz, F., Rosen, D., Weiss, L.: Layered manufacturing: current status and future trends. J. Comput. Inf. Sci. Eng. 1(1), 60–71 (2001). https://doi.org/10.1115/1.1355029

Jamieson, R., Hacker, H.: Direct slicing of CAD models for rapid prototyping. Rapid Prototyp. J. 1(2), 4–12 (1995)

Acknowledgments

The research project was performed with the funds of FGBOU VO Komsomolsk-on-Amur State University allocated to the Algorithm Development and Analysis of Programmable Control for Welding/Buildup Bead Welding (Including Application of Additive Technology) With Automatic Gas-Shielded Welders Scientific Project using the equipment of the Welding and Metallurgical Engineering Department and the New Materials and Technology Resource Sharing Center of the Komsomolsk-on-Amur State University.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bakhmatov, P.V., Sviridov, A.V., Khabibov, M.M. (2021). Fabrication Specifics and Study Results for Metal Items Produced by Surfacing. In: Shakirova, O.G., Bashkov, O.V., Khusainov, A.A. (eds) Current Problems and Ways of Industry Development: Equipment and Technologies. Lecture Notes in Networks and Systems, vol 200. Springer, Cham. https://doi.org/10.1007/978-3-030-69421-0_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-69421-0_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-69420-3

Online ISBN: 978-3-030-69421-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)