Abstract

Rigid piles are used to alleviate the detrimental characteristics of soft soil. Recently, the use of piled embankments has increased by many folds, as it facilitates rapid construction without compromising on serviceability. In the piled embankment, soil arching mechanism between adjacent piles improves the load-transfer to the piles and reduces the stress applied to the soft soil. In this study, a two-dimensional plane strain finite element model is adopted to investigate the mechanism of soil arching in a piled embankment. An idealized unit cell model is used to simulate the pile-supported embankment. The effect of different characteristics of piles and embankment soil are assessed. The outcome shows that friction angle, and embankment modulus significantly affects soil arching. Inconsistency among existing design approaches in the literature is highlighted.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The rapid growth in population and associated infrastructure activities all around the world has necessitated to look for suitable methods of construction on soft soil. The embankment plays a crucial role for construction on soft soil. However, the embankment constructed on soft soil can experience post-construction failure. Hence the adoption of pile-supported embankment is usually recommended in practice. In the piled embankment, the majority of the load, including surcharge, is transferred to the rigid piles through a shearing mechanism, known as soil arching (Terzaghi 1943). Several numerical studies (Han and Gabr 2002; Huang and Han 2010; Wu et al. 2019) as well as experimental studies (Jenck et al. 2007; Fagundes et al. 2015) have been performed on the investigation of soil arching. Han and Gabr (2002) found that soil arching is significantly affected by piled embankment parameters. Based on two-dimensional (2D) numerical analysis, Huang and Han (2010) concluded that piled embankment properties and pile geometrical parameters significantly influence the soil arching. Wu et al. (2019) through 2D analysis of high-speed railway embankment reported that surface settlement of piled embankment is significantly decreased with increase in area replacement ratio (as). The area replacement ratio (as) is defined as the ratio of the pile area (Ap) to surrounded soil cell area (Ac). A series of centrifuge tests performed by Fagundes et al. (2015) revealed that the load transfer to pile is enhanced with an increase in embankment height or decrease in pile spacing. In additional, Ghosh et al. (2017) proposed a mechanical model for reinforced load transfer platform (LTP) and reported that settlement of LTP increases with an increase of pile spacing.

This study aims to perform parametric analysis to identify the most influential parameters in the pile supported embankment. Most of earlier studies have approximated the soft subsoil behaviour using Mohr-Coulomb approach. The current finite element (FE) model considers the modified cam-clay model to accurately simulate the soft subsoil. The different design approaches of piled embankment have also been reviewed.

2 Numerical Modeling

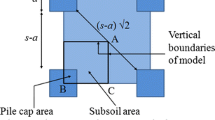

In this study, a unit cell as an idealized case representing the piled embankment is analysed using a finite element method (FEM) based commercial software package ABAQUS version 6.13 (ABAQUS 6.13). The idealized unit cell is assumed to be located at the center of the pile-supported embankment with side boundaries passing through the mid of the pile width on either sides (Meena et al. 2020). An equivalent approach is considered to convert a three-dimensional (3D) piled embankment to 2D plane strain idealization. The past studies (Zhang et al. 2018; Wu et al. 2019) have reported that the equivalent area (EA) approach yields good agreement with field measurements. The equivalent thickness of pile wall is derived as (Wu et al. 2019):

where s = pile spacing in both x and y-direction; d = pile diameter; and teq = equivalent thickness of pile wall.

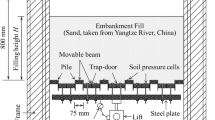

A typical mesh diagram of unit cell is illustrated in Fig. 1. The vertical boundaries of the unit cell are restrained laterally, while the bottom horizontal boundary is fully fixed. The top of the embankment is free from displacement constraints in both vertical and lateral directions. The embankment height is varied from 2.5 to 5 m. The pile diameter (d) is chosen as 1 m, whereas pile spacing (s) is varied from 2 to 3.5 m. Pile length and subsoil depth are assumed as 8 m. The embankment and gravel material are modeled as the Mohr-Coulomb (MC), while the modified cam clay (MCC) model is considered appropriate for subsoil. The pile is modeled as an isotropic linear elastic material with a set of elastic parameters such as Young′s modulus (E) of 30 GPa and Poisson’s ratio (v) of 0.15. The embankment and gravel material properties are assumed, whereas the subsoil is considered as silty clay, and its parameters are derived from Liu et al. (2007). The properties of embankment-fill, gravel layer and subsoil are summarized in Table 1. In this study, drained analysis is performed and dissipation of pore water pressure has not been simulated.

3 Results and Discussion

3.1 Soil Arching

The vertical stress distribution profile in embankment-fill is influenced due to soil arching mechanism. A majority of the vertical stress is transferred to adjacent piles due to the mobilization of soil arching. Figure 2 illustrates the normalized vertical stress (σv/γs) contour in the embankment-fill above the mid of subsoil and pile head (refer points A and B in Fig. 1, respectively). The vertical stress (σv) is normalized with the product of unit weight of embankment-fill and pile spacing (γs), while embankment height (h) is normalized with pile spacing (s). The normalization is used for the sake of general applicability. It is evident that above the normalized embankment height (Nem; h/s) of 0.9, the normalized vertical stress (Nvs; σv/γs) is consistent with geostatic stress for points A and B. The Nvs increases from 0.9 Nem to 0.65 Nem, and then it decreases from 0.65 Nem to 0.1 Nem over the point A. In contrast, Nvs increases with a further decrease in Nem over point B. It is worth noting that most of the vertical stress is transferred to pile head (point B) from 0.65 Nem to 0.1 Nem. This zone is called an arching zone. The trend of vertical stress variation with the embankment height is similar to other studies (Hewlett and Randolph 1988; Meena et al. 2020).

Settlement of embankment-fill between pile heads, especially when located on soft soils, is an important factor governing the serviceability aspect. The minimum settlement of embankment-fill is associated with arching mechanism, as the latter reduces the settlement of embankment-fill and the subsoil. Figure 3 illustrates the normalized settlement (Ns; δ/s) contour in the embankment-fill above points A and B. The embankment height (h) and settlement (δ) both are normalized by pile spacing (s). It is evident that settlement is uniform for points A and B above the 0.9 h/s. This embankment height is referred to as plane of equal settlement (Meena et al. 2020). Underneath this plane, the settlement enhances above point A, whereas it diminutions to nearly zero above point B. This settlement trend is consistent with past study (Jenck et al. 2007). The soil arching is mobilized under this plane as earlier discussed in Fig. 2.

3.2 Influence of Piled Embankment Parameters

The capacity of the embankment and load transfer to the piles is evaluated by stress efficacy (Estr). The efficacy corresponding to different embankment heights (h) is shown in Fig. 4a. Initially, the efficacy increases abruptly (i.e., Estr = 7, 11, and 17.5 for embankment height 2.5, 3.5, and 5 m, respectively) with a slight increase of normalized embankment height. It then decreases to zero at normalized embankment height of 0.9. This is because, there is no stress disturbance after this normalized embankment height, which is also evident from Fig. 3. Thus, it is evident that most of the load is transferred to the piles at smaller normalized embankment height. Figure 4b illustrate the effect of embankment modulus (Eem) on efficacy. The efficacy increases by 97, 103, and 150% for pile spacing 2, 2.5, and 3.5 m, respectively, with an increase of Eem from 1 to 60 MPa. It shows that both embankment modulus and pile spacing are significantly affected efficacy. The influence of friction angle (ϕ΄) on efficacy is illustrated in Fig. 4c. For all considered pile spacing (i.e., 2, 2.5, and 3.5 m), the efficacy increases up to 36% with an increase of ϕ΄ from 25° to 40°. It implies that the effect of friction angle is more pronounced and should be higher for efficient efficacy. In addition, smaller pile spacing shows higher efficacy, as evident in Fig. 4. This is in good agreement with Fagundes et al. (2015).

3.3 Assessment with Different Design Approaches

In the past, several design approaches (Terzaghi 1943; Guido 1987; Hewlett and Randolph 1988; BS8006-1 2010) have been developed for a piled embankment design. These design approaches have demonstrated varied results even for the same piled embankment due to use of different analytical models. Ghosh et al. (2017) stated that the analytical models include frictional models (adopted by Terzaghi 1943), rigid models (Guido 1987), models using mechanical element, and limit-state equilibrium models (Hewlett and Randolph 1988; BS8006-1 2010). Figure 5 illustrates a review of the outcome with these design approaches. None of these approaches gives consistent results with the 2D numerical model results. The Guide (1987); BS8006-1 (2010); and Hewlett and Randolph (1988) approach over-predict, while Terzaghi (1943) approach shows quite similar results for lower embankment height as an agreement with the present study. It is confirmed that these approaches yield inconsistent results. The possible reason for this inconsistency in the results is assumed shape of the soil arch in different analytical models. The shape of soil arch is not convinced in frictional models and the frictional forces follow up vertically along with the pile edges. The rigid models are adopted as a triangular shape of soil arching in 2D and pyramid in 3D. Further, the failure condition is either on the crown of soil arch or the pile head in limit-state equilibrium models. Therefore, it is essential to develop an approach which can be readily adopted for piled embankment design.

4 Conclusions

In the present study, a two-dimensional plane-strain numerical analysis is carried out to investigate soil arching in piled embankment. The influence of piled embankment parameters is evaluated. Following conclusions can be drawn from the present study.

-

The results of finite element analysis reveal two most crucial parameters, (i) soil friction angle and (ii) elastic modulus, both related to the embankment fill. The proper quality control of embankment fill materials is therefore essential in the design of pile supported embankment.

-

The arching zone is significantly influenced with the variation in pile spacing. It is also evident that the arching zone expands in size as the piles are closely spaced.

-

The comparison among different design approaches of piled embankment shows significant variation in the computed results, which demands further investigation in this area.

References

ABAQUS 6.13. [Computer software]. Providence, RI, ABAQUS Inc.

BS8006-1: Code of Practice for Strengthened/reinforced Soils and Other Fills, British Standards Institution (2010). ISBN 978-0-580-53842-1

Fagundes, D.D.F., Almeida, M.D.S.S.D., Girout, R., Blanc, M., Thorel, L.: Behaviour of piled embankment without reinforcement. Proc. Inst. Civ. Eng. Geotech. Eng. 168(6), 514–525 (2015)

Ghosh, B., Fatahi, B., Khabbaz, H., Yin, J.H.: Analytical study for double-layer geosynthetic reinforced load transfer platform on column improved soft soil. Geotext. Geomembr. 45(5), 508–536 (2017)

Guido, V.A., Kneupel, J.D., Sweeny, M.A.: Plate load testing on geogrid reinforced earth slabs. In: Proceedings of Geosynthetics Conference, IGS, Jupiter, FL, pp. 216–225 (1987)

Han, J., Gabr, M.A.: Numerical analysis of geosynthetic-reinforced and pile-supported earth platforms over soft soil. J. Geotech. Geoenviron. Eng. 128(1), 44–53 (2002)

Hewlett, W.J., Randolph, M.F.: Analysis of piled embankments. Ground Eng. 21(3), 12–18 (1988)

Huang, J., Han, J.: Two-dimensional parametric study of geosynthetic-reinforced column-supported embankments by coupled hydraulic and mechanical modeling. Comput. Geotech. 37(5), 638–648 (2010)

Jenck, O., Dias, D., Kastner, R.: Two-dimensional physical and numerical modeling of a pile-supported earth platform over soft soil. J. Geotech. Geoenviron. Eng. 133(3), 295–305 (2007)

Liu, H.L., Ng, C.W., Fei, K.: Performance of a geogrid-reinforced and pile-supported highway embankment over soft clay: case study. J. Geotech. Geoenviron. Eng. 133(12), 1483–1493 (2007)

Meena, N.K., Nimbalkar, S., Fatahi, B.: Finite element modeling of soil arching in pile supported embankment: 2D approach. In: International Congress and Exhibition “Sustainable Civil Infrastructures”, pp. 40–50. Springer, Cham (2020)

Terzaghi, K.: Theoretical Soil Mechanics. Wiley, New York (1943)

Wu, L., Jiang, G., Ju, N.: Behavior and numerical evaluation of cement-fly ash-gravel pile-supported embankments over completely decomposed granite soils. Int. J. Geomech. 19(6), 04019048 (2019)

Zhang, L., Zhou, S., Zhao, H., Deng, Y.: Performance of geosynthetic-reinforced and pile-supported embankment with consideration of soil arching. J. Eng. Mech. 144(12), 06018005 (2018)

Acknowledgements

The work presented in this paper is financially supported by the Government of India under the National Overseas Scholarship, No. 11016/16/2016 Education.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Meena, N.K., Nimbalkar, S., Fatahi, B. (2021). Finite Element Analysis of Soil Arching in Piled Embankment. In: Barla, M., Di Donna, A., Sterpi, D. (eds) Challenges and Innovations in Geomechanics. IACMAG 2021. Lecture Notes in Civil Engineering, vol 126. Springer, Cham. https://doi.org/10.1007/978-3-030-64518-2_97

Download citation

DOI: https://doi.org/10.1007/978-3-030-64518-2_97

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-64517-5

Online ISBN: 978-3-030-64518-2

eBook Packages: EngineeringEngineering (R0)