Abstract

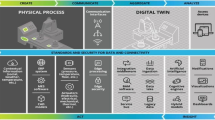

This work analyses methods of digital model development and uses electronics production as an example. It focuses on the analysis of the visual tools of a digital manufacturing system design. The digital model development process is divided into a sequence of tasks, to solve which a number of models, methods and tools is proposed. These procedures can be used to perform simulation modelling, performance prediction, promising option selection, parameters optimisation of both the device itself and its manufacturing mechanisms along with other lifecycle components, without the expensive sample tests, field tests or introduction of any changes to the already established manufacturing, selling, service and other infrastructures. Digitalisation aspects are covered by creating interrelated digital models of the device and the digital manufacturing process model that take all the technical and economic aspects into account. This approach, called Digital Twin (of the actual production), underlies the modern Industry 4.0 concept that suggests the introduction of different cyber-physical systems in the manufacturing systems. The proposed method of the visual system design uses a complex of software tools to produce digital system models of an electronics manufacturing system. The resulting digital twin of the actual manufacturing is representative of both the produced device and its manufacturing process design features. And it can be used for preparation, analysis and manufacturing improvement purposes.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Shakhnov, V.A., Kurnosenko, A.E.: Modelling of the digital electronics manufacturing in the context of Industry 4.0 concept. In: Akberdina, V.V. (ed.) Proceedings of the 1st International Scientific and Practical Conference Digital Transformation of the Industry: Trends, Management, Strategies, pp. 585–594. Ural State University of Economicis, Ekaterinburg, Russia (2019)

Berduygina, O.N., Vlasov, A.I., Kuzmin, E.A.: Investment capacity of the economy during the implementation of projects of public-private partnership. Investment Manag. Financ. Innovations 14(3), 189–198 (2017)

Akberdina, V.V., Kalinina, A.V., Vlasov, A.I.: Transformation stages of the Russian industrial complex in the context of economy digitalization. Probl. Perspect. Manag. 16(4), 201–211 (2018)

Ivanov, Y.V., Kurnosenko, A.E.: Kontur software complex for design of the automated electronics assembly complexes in multiproduct manufacturing. Eng. Bull. 3, 4 (2013)

Kurnosenko, A.E., Arabov, D.I.: Optimization of electronic components mounting sequence for 3D MID assembly process. Breakthrough directions of Scientific Research in NRNU MEPhI: Development Perspectives in the Framework of the Strategic. “KnE-Engineering”, pp. 311–321 (2018)

Demin, A.A., Vlasov, A.I.: Visual methods of formalization of knowledge in the conditions of the synchronous technologies of system engineering. In: Proceedings of the 13th Central & Eastern European Software Engineering Conference in Russia (CEE-SECR’17), art. 4, pp. 1–7. Association for Computing Machinery, New York, NY, US (2017). https://doi.org/10.1145/3166094.3166098

Yudin, A., Kolesnikov, M., Vlasov, A., Salmina, M.: Project oriented approach in educational robotics: from robotic competition to practical appliance. Adv. Intell. Syst. Comput. 457, 83–94 (2017)

Popova, I.N., Vlasov, A.I., Nikitina, N.I.: Optimization of inventory distribution logistics in industrial enterprises. Espacios 39(24), 16 (2018)

Kurnosenko, A.E., Haritonov, K.P.: Use of teamcenter PLM system to control lifecycle of electronics. Inform. Technol. Des. Manuf. 2(170), 56–62 (2018)

Kurnosenko, A.E., Haritonov, K.P.: Use of teamcenter device data control system for manufacturing technology preparation. Inform. Technol. Des. Manuf. 4(172), 42–48 (2018)

Levin, I.V., Kurnosenko, A.E., Mashina, N.A.: Solutions for design, modelling and optimisation of electronics manufacturing. Inform. Technol. Des. Manuf. 1(169), 26–32 (2018)

PiepenbrockGeorg Tecnomatix Plant Simulation. Validation of Plant Performance and Plant Control. Siemens Industry Software. https://www.plm-europe.org/admin/presentations/2017/2013_PLMEurope_24.10.17-13-30_GEORG-PIEPENBROCK_SPLM_validation_of_plant_performance_and_plant_control_with_tecnomatix_plant_simulati.pdf. Accessed 25 June 2020

Adamova, A.A., Adamov, A.P., Vlasov, A.I.: Leading approaches to energy solutions in the 21st century. Adv. Soc. Sci. Educ. Human. Res. 386, 190–196 (2019). https://doi.org/10.2991/assehr.k.191221.197

Berdyugina, O.N., Krivoshein, A.I., Vlasov, A.I.: Technological platform for innovative social infrastructure development on basis of smart machines and principles of internet of things. In: 2018 Global Smart Industry Conference (GloSIC), pp. 1–7. IEEE, Chelyabinsk, Russia (2018)

Ragulina, Y.V., Semenova, E.I., Zueva, I.A., Kletskova, E.V., Belkina, E.N.: Perspectives of solving the problems of regional development with the help of new internet technologies. Entrepreneurship Sustain. Issues 5(4), 890–898 (2018). https://doi.org/10.9770/jesi.2018.5.4(13)

Toomsalu, L., Tolmacheva, S., Vlasov, A., Chernova, V.: Determinants of innovations in small and medium enterprises: a european and international experience. Terra Economicus 17(2), 112–123 (2019)

Prudius, A.A., Karpunin, A.A., Vlasov, A.I.: Analysis of machine learning methods to improve efficiency of big data processing in Industry 4.0. J. Phys. Conf. Ser. 1333, 032065 (2019). https://doi.org/10.1088/1742-6596/1333/3/032065

Kurnosenko, A.E., Levin, I.V., Semeniakina, V.O., Zaharov, E.R., Sherstiuk, A.E.: Methods and means of simulation modelling for studying the technical preparation of electronics manufacturing. In: Collected Scientific Works of International Forum Digital Technologies in Engineers’ Education: New Trends and Implementation Experience, pp. 310–314. Bauman Moscow State Technical University, Moscow, Russia (2020)

Nikolskii, T.V., Lomachenko, A.S., Kurnosenko, A.E.: Use of Jack/Simulate human module for simulation modelling of the electronics assembly operations. Inform. Technol. Des. Manuf. 2(174), 21–25 (2019)

Kurnosenko, A.E., Nikolskii, T.V., Lomachenko, A.S.: Preparation of the equipment model for simulation modelling in a CAD system. Inform. Technol. Des. Manuf. 2(178), 24–30 (2020)

Acknowledgements

Some results were obtained in the framework of the State task #0705-2020-0041 “Component’s digital transformation methods’ fundamental research for micro- and nanosystems”.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Shakhnov, V.A., Kurnosenko, A.E., Demin, A.A., Vlasov, A.I. (2020). Industry 4.0 Visual Tools for Digital Twin System Design. In: Silhavy, R., Silhavy, P., Prokopova, Z. (eds) Software Engineering Perspectives in Intelligent Systems. CoMeSySo 2020. Advances in Intelligent Systems and Computing, vol 1295. Springer, Cham. https://doi.org/10.1007/978-3-030-63319-6_80

Download citation

DOI: https://doi.org/10.1007/978-3-030-63319-6_80

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-63318-9

Online ISBN: 978-3-030-63319-6

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)