Abstract

In the modern Russian economy, the level of development of the industrial sector continues to be quite low. A wide range of reasons can be identified for this, one of which is the historical background of the formation of industry in 70–80s. But it is important not only to understand that this area requires certain innovations, but also to evaluate the further creation of its development in order to improve the economic growth of the country as a whole. At the same time, the degree of influence of RandD in industry should not be underestimated. As concerns directly the prospects of the RandD sector of the national industry, it is determined by the following trends: insufficient implementation of RandD potential; - reduction of intellectual potential; increased labor intensity; institutional transformation, changing of the forms and specialization of the subjects performing the work. In this context, there is an objective need for modernizing management mechanisms to streamline complex interactions between production and research structures. This study evaluates the development of the RandD sector of industry in Russia.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The industrial sector has long played a decisive role in the economy of any country, allowing it to increase indicators and economic potential. Since Soviet times, the growth of industry has been a key factor in replenishing the state budget. This was due to regular modernization and development of the technological structure as a whole. But since the 90s, the Russian industrial sector has demonstrated a negative increase in indicators. The growth rate of industrial enterprises has decreased every year, while foreign countries, especially China, Japan and the United States, have showed positive dynamics in industrial production, resulting in stable economic growth.

The potential of the Russian industrial complex has not been fully used. Technologies are insufficiently improved, or lag behind foreign analogues, resulting in import substitution. In our country, when there is a huge scientific and technological potential, the quality and properties of products are not improved, due to which these indicators directly affect the growth of Russia’s GDP. The technological capacity of industrial enterprises in Russia continues to develop at too slow a pace in the innovation sphere: long-established work patterns are used, which is unacceptable in the conditions of regular development of innovative technologies. The market economy dictates its own rules of competition, in which the domestic industrial sector occupies, unfortunately, not the leading position. An objective assessment makes it possible to conclude that equipment is not upgraded at the enterprises with sufficient speed, some technologies have long been outdated and replaced by innovative analogues; production efficiency is not used at full capacity, despite the fact that improving productivity and product quality can be performed without attracting large additional resources.

The authors have worked out a new innovative evaluation strategy that addresses the issues of the duration of production of an innovative model and the RandD cost (planned and actual) of domestic industrial enterprises. The proposed method shows its effectiveness at all stages of development, which will improve the work and, of course, increase productivity in the industrial sector. The impact of contracting work at the RandD planning stages has also been analyzed in the research, since, according to the authors, this approach has not been fully studied or given sufficient importance.

As mentioned above, in recent decades the country’ industrial development has declined, namely the RandD sector, a key sector, according to the authors. It was then that the issue of the development of innovative activity in this area became the most important and attracted the attention of researchers and practitioners. It becomes clear that if global changes in the equipment of modern industrial plants are not made, this could lead to a negative increase and further decline of the main economy-forming segment [4]. But it is important to understand that not only new equipment will help bring industry to a positive increase, but also competent modernization in the mechanism of RandD management and development, not only in particular cases, but also on the whole.

The study of this problem has been conducted, and the reasons that hinder the process have also been identified for a long time. However, all measures to eliminate them have not brought expected results, which makes it possible to assume the need for a deeper reformation, starting with the process of RandD creating. Not only obsolete equipment and the lack of cardinal innovations slows down the development of industry, but the approach and management scheme itself is ineffective.

2 Methodology

The authors studied the possibilities of improving research and development of the national industrial sector. The economic characteristics of RandD developments were worked out and an innovative approach to improving the work of low-tech industrial enterprises was proposed. The processes of RandD, experimental and technological development at low-tech industrial enterprises were analyzed. The key points of the analysis are: stages of RandD implementation and development in Russia’s industry, Russia’s industrial sector modernization assessment, importance of RandD process diversification, planning stage for the implementation of RandD at a low-tech industrial enterprises.

3 Results

In the process of the research, the authors formed an effective technological model that affects the process of developing new approaches in the field of RandD at industrial enterprises, including the dynamics of the duration and cost of stages for low-tech enterprises under the conditions of using the new planning stages proposed by the authors. This area of planning, divided into 13 stages, allows low-tech enterprises to make more accurate RandD forecasts, calculate not only labor costs, but also consider the financial aspect, which undoubtedly plays a key role. As for the duration of the stages, the development often becomes “outdated” at the time of release of the prototype, due to the long time intervals at each level. As a result, the development ceases to be innovative, and its demand drops to zero. The proposed analytics of the duration of the stages from “pilot project” to “operation” gives a clear idea of the possible results obtained with a minimum error.

As mentioned above, the industrial sector is one of the main sources of country’s budget replenishment and a source of economic growth in general. Stable economic growth and the level of Russia’s GDP directly depend on the level of the industrial turnover coefficient. In the industrial sector, the key factor is undoubtedly the level of innovative equipping of production, and directly the research and development work itself. It is this indicator that can be equated to the fundamental one when calculating the development coefficient of the national industrial sector. That, in turn, affects leadership in the competition between the world’s largest industrial powers. Evidence of the above can be provided by statistical data on the development of innovations in the industrial sector, namely in 2016, a negative increase of 1.5 points in terms of investment in research activities in the industrial sector [7]. This was the impetus for innovations and increasing the efficiency of enterprises, starting with the discovery of great potential in scientific field.

The result of this outcome of events could be a number of aspects related to the “boiler” approach in the study and implementation of RandD in industrial production. Most Russian industrial plants, as mentioned above, prefer to operate according to the methodology that has been worked out for years. Often there is a certain consistency in the interaction of intermediate structures, namely, contracts with long-established firms, institutions, research institutes. This is rather a historical trend that is difficult to overcome in the innovation process, since the mechanism for introducing new development is more or less well-established. One way or another, according to the authors, in the event of “leaving the zone of comfortable” cooperation with “old” contracting enterprises, the industry of the Russian Federation can certainly claim higher performance indicators of innovative developments. The effectiveness of the new subcontracting is undeniable. In order for industrial enterprises to reach a new level of RandD development, fundamental changes are needed precisely in the structure, it is also necessary to use absolutely all the existing potential of domestic developments [8]. It is the so-called “pattern” in the implementation of RandD at domestic enterprises that creates a barrier to improving the economic situation. Though this way of implementation is already familiar to our industry, it is not payed due attention by researchers.

4 Discussion

It is necessary to analyze several essential factors that affect the dynamics of industrial enterprises’ production efficiency. The main point is benchmarking. This implementation approach is based on competitive parity. This approach is relatively new for domestic industry, and has been active for the last 40 years, which is relatively short for the industrial sector. Competition has become an important moment in the progress of RandD with the transformation of our economy to a market one [3]. An open database of statistics from competing enterprises is certainly an encouraging element in the process of developing a new product. Sometimes the appearance of a modernized product from a competing company is an impetus for new developments and improvements in production. This is an undeniable advantage of the market system where industrial enterprises operate. But a logical question arises as to how important it is to take into consideration the factor of the economies of scale in planning the development of each stage for small enterprises, since its significance in considering the largest industrial plants is undeniable. Once again, the question arises of how important it is to diversify enterprises by scale in the RandD process to conduct the most accurate forecast of the cost and duration of the stages [2].

The “benchmarking” method, built on planning RandD budgets on the basis of competitive parity, is considered to be most effective for markets with a pronounced innovative competitiveness factor. Largest global industrial holdings operate on this basis today. Apologists of the presented method of dividing the stages of RandD planning can point to its effective applicability for both large and small - medium industrial enterprises. Of course, one should take into account the error associated with individual industries, but on total assessment, and the collection of analytical data, the method demonstrates high correctness. It is important to understand that the coefficient principle of budgeting has a weak side - it does not take into account the “economies of scale”. However, an error of 5–9% will not significantly affect the proposed methodology [5]. 1% of RandD expenses at a large enterprise can bring 7% of gross profit rise, while the same 1% at a small enterprise can bring only 1.2%. The indicators can be affected by both external and internal factors, such as the political situation in the country, indicators of wear resistance and modernization of equipment, purchasing power and demand for manufactured products or raw materials. All these and many other factors can easily affect the increase or decrease in indicators [6]. The situation is rather unstable.

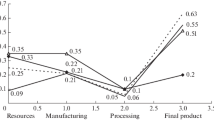

After analyzing, the authors have proposed a method that will help to identify the cost and duration of implementation of an innovative product at the earliest stages of calculations with a minimum error. So, it was proposed to form 13 independent stages from the “task statement” to the “accompanying documentation”, which will help more accurately determine the prospects of an innovative project. If the monitoring base of large enterprises determines the levels of RandD investment of the industry leaders (or the industry average), then for small innovative enterprises it is the budget of competing projects. This model demonstrates the logical way of innovations implementation at industrial enterprises and helps to prioritize the budget distribution at all stages of RandD planning and implementation. Table 1 shows a chart that allows you to evaluate the duration of putting into the production of an innovative project at low-tech industrial enterprises. The most capacious process, as expected, is the production start-up and creation of a prototype. Of course, this stage is the main one, since it will give clear answer on how effective the innovative project is. The methodology also allows making cost assessment of the above stages. The authors’ calculations revealed that the most expensive stages are “prototyping” - 14.5%, “production start-up” - 22.1% and “operation” - 46.3%.

In the industrial sector of the economy, large organizations tend to use the network model of RandD planning. On the basis of this method, calculations of co-financing of each of the proposed stages of innovative development are carried out separately [9]. The scope of RandD application in industry is one of the widest, so along with internal funding, the receipt of financial flow from external sources is essential. External investments are attracted on the assumption of the initial advance project of the innovation model, so calculations correctness of the stages cost and duration is the key point in assessing the effectiveness of an innovation project. This may lead to some inconsistency, because RandD planning budget includes co-financing from some external entities, but the recipients are the external enterprises themselves, whose domestic economic activity is not reflected in the budget. This kind of phenomenon causes many scientists to doubt the quality of the effectiveness of the already finishing model.

5 Conclusion

When using the network distribution model proposed by the authors, a number of contradictions may arise, namely, the possibility of underestimating the cost of RandD development stages in the interests of the customer. When it comes to the contractor, in this case, on the contrary, the cost can be artificially inflated [10]. As for the performers, as a rule, the selection goes through tenders, and the approval of the price is based on the assessment of the lowest and highest cost of the specified work. This sampling policy complicates the contours of network interaction, the task of attracting external investors to RandD, though the largest financial injection often comes from them. In addition, the process of coordinating the work of performers at each of these 13 stages is becoming more complicated. In this planning method, a number of controversial areas of interaction are observed, namely design bureaus, universities, the administration, the RandD departments of industrial enterprises themselves, the Innovation Support Fund, etc., which displaces the network control center [2]. The RandD departments of industrial enterprises and Universities take the first place. With this consideration of the situation, it is the only case when the above entities interact in the process of the development of this separation technique in RandD developing and implementing at an industrial enterprise. The chosen interaction scheme may differ because of various factors. Among them: type of company’s activity, initial assigned budget, subcontracting, the innovative impact of RandD and implementation functionality on production, urgency of the implementation of innovative development, namely the period from “pilot project” to “operation”. Surely, it is important to consider a number of external factors beyond control of the industrial enterprise and even the state [1]. Thus, summarizing the results of the study, we can confidently confirm that the proposed methodology for the development of RandD at industrial enterprises is of high efficiency. It may also contribute to our country’s industry in competition with developed countries.

References

Galimova, M.P., Aymurzin, V.A.: Analysis of existing programs for financing and supporting RandD of young scientists. Youth Herald Ufa State Aviat. Tech. Univ. 1(13), 189–190 (2015)

Glushak, O.V.: The innovation process in the industrial complex as an urgent issue of scientific research of the national sphere of innovations. Bull. Bryansk State Univ. 3, 140–142 (2011)

OECD: Main science and technology indicators (2017). https://www.oecd-ilibrary.org/science-and-technology/main-science-and-technology-indicators/volume-2017/issue-2_msti-v2017-2-en. Accessed 20 June 2020

OECD: Science, technology and industry outlook (2016). https://www.oecd.org/fr/sti/oecd-science-technology-and-innovation-outlook-25186167.htm. Accessed 20 June 2020

Oxley, J.E., Sampson, R.C.: The scope and governance of international RandD alliances. Strateg. Manage. J. 25, 723–749 (2004)

Platonov, V.V., Dyukov, I.I.: An approach to the study of the formation of the intellectual potential of innovative managers in the process of continuing education. Econ. Manage. 8(82), 42–47 (2012)

Rosstat: Russia 2015: Statistical reference book (2016). https://www.gks.ru/bgd/regl/b15_13/Main.htm. Accessed 20 June 2020

Rybakov, F.F.: Genesis and evolution of the RandD economy. In: Sidorova, A.F. (ed.) The Phenomenon of Market Economy: From the Beginnings to the Present Day, pp. 239–244. Saint Petersburg State University, Saint Petersburg (2014)

Schuh, G., Anderl, R., Jürgen, G., ten Hompel, M., Wahlster, W. (eds.) Industrie 4.0. maturity index. Managing the digital transformation of companies (2017). https://www.acatech.de/wp-content/uploads/2018/03/acatech_STUDIE_Maturity_Index_eng_WEB.pdf. Accessed 20 June 2020

World Economic Forum: The global competitiveness report 2016–2017 (2017). https://www.weforum.org/reports/the-global-competitiveness-report-2016-2017-1. Accessed 20 June 2020

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Salkina, A.R., Charikov, V.S. (2021). Key Factors of R and D Process Modernization at Industrial Enterprises of Russia. In: Ashmarina, S.I., Horák, J., Vrbka, J., Šuleř, P. (eds) Economic Systems in the New Era: Stable Systems in an Unstable World. IES 2020. Lecture Notes in Networks and Systems, vol 160. Springer, Cham. https://doi.org/10.1007/978-3-030-60929-0_38

Download citation

DOI: https://doi.org/10.1007/978-3-030-60929-0_38

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-60928-3

Online ISBN: 978-3-030-60929-0

eBook Packages: EngineeringEngineering (R0)