Abstract

Intermittent physical tasks are prevalent in physical manual operations, and engineers must be provided with effective guidelines for intermittent job design to reduce work-related musculoskeletal disorders (WMSDs) resulting from repetitive intermittent operations. In this paper, we combine a local muscle fatigue and a recovery model to determine the endurance limit under intermittent operations. We preliminarily validated the endurance limit model by comparing the predicted endurance limits and the endurance limits measured in a 50% MVC intermittent task. The endurance limit under intermittent isometric operations could be determined using a muscle fatigue-recovery model and individual fatigue attributes. Estimation of the WMSD risk associated with spectrum loadings in a series of intermittent tasks using the proposed endurance limit model is a promising approach.

Supported by the National Natural Science Foundation of China [grant number 71471095 and 71942005].

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Although technological advancements have reduced the number of heavy manual operations for workers, work-related musculoskeletal disorders (WMSDs) remain a widespread issue leading to increased financial and societal costs [1, 12]. Several risk factors are known to be associated with WMSDs. Among the most commonly accepted physical risk factors are exposure to tasks involving high force demands, tasks involving high rates of repetition, tasks involving awkward postures, and tasks of long duration [2, 11, 25]. A number of researchers have attempted to determine the acceptable limit of workload, repetition and duration to provide occupational guidelines that could effectively lower the risk of WMSDs [6, 7, 13, 14, 23, 24].

The acceptable limit associated with prolonged static tasks has been studied extensively to aid physical task design; the most well-known and developed approach is the maximum endurance time (MET) and its corresponding model [9, 16, 19]. The MET has been used to determine the acceptable duration of maintaining a static muscular contraction and to provide reference for physical task design in international standards [15, 16, 19]. Despite research on the MET over several decades, a large proportion of occupational tasks are more flexible than prolonged static tasks, such as intermittent tasks.

Similar to the MET for static tasks, the maximum endurance duration for intermittent tasks is also critical for guiding operation design. Experimental studies and corresponding modelling have been performed in the literature to quantify the acceptable endurance duration limit and its influencing factors [3, 16, 21]. Based on experimental data, several empirical models predicting the endurance duration have been developed to support repetitive isometric tasks design and its assessment [10, 13, 14, 26]. However, the strong task dependency of the models limits the generalization of those models to other intermittent task designs [13] because task parameters and individual fatigue attributes are not considered as variables in those empirical models.

Different from empirical models, physiology-based muscle fatigue modelling has been found to be a promising approach to account for task parameters and individual fatigue attributes in intermittent operations and to provide generalized mathematical forms to describe muscle fatigue progression. Some muscle physiological models have been developed to predict force decline during repeated contractions [4, 28, 30]. Those models are often used to determine the maximum acceptable effort and then to limit workload in physical operations. However, the true situation is that the workload is fixed and cannot be changed easily, and the acceptable duration is more essential for task design. Moreover, none of these models have been associated with physical operation design to determine the endurance limit under intermittent operations.

Therefore, the aim of this study was to determine endurance limit for intermittent tasks. In Sect. 2, a typical intermittent operation is described, and the endurance limit is defined. The endurance limit is determined based on a combined fatigue-recovery model. In Sect. 3, we carried out an preliminary validation experiment to which compared the predicted endurance limits and the measured one. In Sect. 6, the potential applications of the endurance are discussed.

2 Endurance Limit Under Intermittent Operations

2.1 Endurance Limit Under Intermittent Operations

For a given subject, the endurance duration limit under intermittent physical operations is primarily determined by muscle fatigue and individual voluntary effort in maintaining the physical task. Here, we used muscle physiological behaviour featuring repetitive isometric contractions, or intermittent contractions at the same force level to illustrate the endurance limit under intermittent operations (see Fig. 1). Under intermittent tasks consisting of repetitive isometric contractions, the actual profiles of the external load and internal muscle force are approximately cyclic. The load profile in an intermittent task can be assumed to comprise work-rest cycles. Each cycle with a duration of \(T_{cycle}\) comprises a loading period (E) and rest period (P). The external load (\(F_{load}\)) is assumed to be constant under isometric contractions.

Similar to the MET, the endurance limit(N) is the maximum sustainable number of a cyclic physical operation under given intermittent conditions. According to muscle physiology, the muscle strength declines while outputting power against external loads in a physical operation [29]. Under intermittent circumstances, the force decreases during the loading period and partially recovers during the rest period (see Fig. 1). When the muscle strength falls below a certain level (defined as a threshold value at the \(N^{th}\) cycle here), the intermittent operation could no longer be sustained. Intuitively, this threshold could be considered as a function of the external load \(F_{load}\) weighted by a coefficient \(\alpha \) (\(\alpha >0\)), i.e., the physical operation could not be sustained once the muscle strength F(t) falls below \(\alpha \times F_{load}\).

In summary, the endurance limit (N) is primarily determined by the external intermittent load pattern, which can be described using three parameters: its workload \(F_{load}\), duty cycle \(D_{cycle}=E/T_{cycle}\), and cycle time \(T_{cycle}\). The coefficient \(\alpha \) could represent the individual difference in the voluntary effort. Once a local muscle fatigue-recovery model capable of describing the muscle response under intermittent loadings is established, the endurance limit (N) for definite intermittent exertions can be determined.

2.2 Modelling of the Endurance Limit Under Intermittent Isometric Cyclic Operations

An isometric cyclic intermittent task can be described using three parameters: the workload, cycle time, and duty cycle. The cycle time includes two periods, namely, the loading period (E) and rest period (P) (Fig. 1). Within one cycle, the muscle strength declines during the exertion phase and recovers during the pause phase [8]. A combined muscle fatigue and recovery model should be capable of describing the changing strength within the work cycle.

Ma et al. [17, 18] proposed and validated a general muscle fatigue model (Eq. 1) and a recovery model (Eq. 2), respectively. The fatigue and recovery models include external task parameters and a time course that are suitable for calculating the endurance limit under intermittent operations. The fatigue and recovery models have been applied in some industrial practical projects to estimate fatigue risk [5, 27]. Other models, such as those proposed by [30] and [4] can also predict force decline during repeated contractions; however, these models contain some parameters regarding muscle fibre and neuro activity (activation) that are difficult to identify in practice. Models with fewer parameters may be suitable for industrial applications.

The fatigue-recovery model is based on the assumption that muscle physical behaviour during one cycle can be divided into two different periods: one fatigue period and one recovery period. Each period was described using its specific model. Then we could combine the fatigue and recovery models to describe the force profile in an intermittent cycle (Eq. 3). Detailed explanations on the parameters are given in the Nomenclature.

Here, \(F_{ini}=F(nT_{cycle}+E)\), where n = 0, 1, 2 ..., represents the muscle strength at the end of the loading period.

2.3 Numerical Computation of Endurance Limit

To determine the endurance limit N, we must first determine the cycle at which the muscle strength fails against the load. If the initial muscle strength in each cycle is known, then the cycle for which failure may occur can be determined. In the \(n^{th}\) cycle, we only considered the muscle capacity at two critical points: the strength at the beginning of the loading period denoted as \({F_n^s}\), and the strength at the end of each loading period denoted as \({F_n^e}\) (see Fig. 1).

Using the fatigue-recovery model, given in Sect. 2.2, we derived the recurrence relation with two initial muscle strengths of neighbouring cycles (see Eq. 4) as follows:

where \(A=-k\int _{0}^{E}F_{load}(u)du, B=e^{-R\times P},F_{1}^s=MVC\), and \(n=1,2,3....\)

To maximize the flexibility of this model, we used a relatively unit-less measure of muscle force as a percentage of the maximum voluntary contraction (\(\%MVC\)). Therefore, \(F_{n}^s\) and \(F_{n }^e\) are equivalent to the task-specific muscle force in \(\%MVC\).

An analytical expression of N cannot realistically be derived, as we could not obtain general term forms of \(F_{n}^s\) and \(F_{n}^e\) with a transcendental function in the recurrence relation (\(e^{\frac{A}{F_{n-1}^s}}\)). Therefore, with this recurrence relation, we applied a numerical method to solve N. The corresponding programming pseudo code is given as follows. Because \(F_{n}^e\) is lower than \(F_{n}^s\), we compared \(F_{n}^e\) with \(F_{load}\) to simplify the judgement regarding whether the muscle can still sustain the external load.

3 Preliminary Validation of the Endurance Limit Model

Experimental Set-up. We validated the numerical solution directly by comparing the predicted endurance limits with the measured ones. The endurance limit was predicted by optimizing k and R of a given subject in an intermittent isometric operation (\(\alpha =1\)), and the true endurance limit was measured for the same subject under the same intermittent isometric operation until exhaustion.

Ethical approval for this study was obtained in advance, and a total of 12 subjects participated in the study (all male, age 26.5 ± 1.6 yrs, all right-handed). Each participant was told to be seated with their upper arms and back tight against the chair back. Body movement was mechanically restrained by straps that immobilized the trunk and shoulder to the chair. The testing arm was bared, and the participants were asked to keep their right forearm perpendicular to the upper arm. The biceps brachii, triceps brachii, and brachioradialis muscles generated the force against the lever. All the strengths in the experiment for holding the lever against external load were measured using the BTE PrimusRS®(BTE Technologies, Baltimore, MD, United States). During the entire experiment, we closely observed participants to ensure that they maintained a posture as still as possible (see Fig. 2(a)).

Each subject completed three sessions: a session for measuring MVC, a session for measuring the individual fatigue attributes under intermittent isometric operation, and a session for measuring endurance limit under intermittent isometric operation. A 24-h break was enforced between each session, and the subjects were not allowed to conduct heavy physical operations during the break.

In the MVC session, the MVC was determined as the greatest exerted force upon the posture described in Fig. 2(a). At least three MVC trials (each lasting 3 s) were performed, with a 5-min rest interval in-between. The mean of the three measurements was recorded as the participant’s MVC (denoted as the subject’s initial maximum strength \(F_1^s\)).

In the fatigue attribute measurement session, subjects performed the arm holding intermittent operation (\(F_{load}\) = 50%MVC, \(T_{cycle}\) = 20 s, \(D_{cycle}\) = 0.5) for 5 successive cycles. In each cycle, brief MVC measurements (sub-MVC) were conducted immediately after the loading period and rest period for 2 s (see Fig. 2(b)). For the n\(^{th}\) cycle, the sub-MVCs measured after the loading period were denoted as \(F_n^e\), and the sub-MVCs measured after the rest period were denoted as \(F_{n+1}^s\). Each sub-MVC measurement was paired with a 2-s rest break [28] to diminish the effect of the MVC measurement. The fatigue and recovery rate (k and R) were then determined by minimizing the differences between the experimental sub-MVCs (\(F_n^e\) and \(F_n^s\)) and theoretical curves as functions of k and R (Eq. 5). Once k and R for a given subject are known, the endurance limit (N) could be predicted using Algorithm 1.

In the endurance limit session, each subject performed the same operation as that in the fatigue attribute measurement session until the subject self-reported failure. They received non-threatening verbal encouragement throughout the exercise duration. The cycle number at failure was recorded as N.

Results. The predicted and measured endurance limits are listed in Table 1 and shown in Fig. 3. The mean values of the predicted and measured endurance limit are both 14.8, implying that our endurance limit model performs well at the group level (paired t-test, p = 0.947; ICC = 0.58, p = 0.08).

Furthermore, for each subject, individual errors were more substantial between the predicted endurance limit and measured endurance limit. We calculated the goodness of fit (\(R^2\)) and used the measured endurance limit to calculate \(\alpha \) for each subject. The former \(R^2\) indicates how well the force decline is predicted by using the fatigue and recovery model, and the latter \(\alpha \) indicates the individual threshold in maintaining the intermittent operation. A few subjects (e.g., subject 8) stopped the intermittent operation according to their voluntary willingness, and with the threshold is far away from \(F_{load}\); moreover, the fatigue attributes (k, R) of a few subjects may not have been accurately obtained from the experiment (e.g., subject 10).

A: Seated static posture in the experiment and materials used in the experiment. B: The experimental condition consisted of an effort of 50% MVC intensity being held for 10 s and a rest period for 10 s. Every period was followed by a brief sub-MVC measurement and rest. Each sub-MVC measurement was paired with a rest break of matching duration (in this example, 2 s followed by 2 s).

4 Effects of the Task Parameters on the Endurance Limit

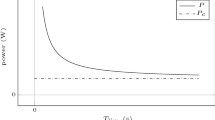

Earlier experimental results provide important details regarding the influences of three task parameters (workload, cycle time, and duty ratio) on the endurance duration or muscle fatigue [6, 7, 13, 14, 23, 24]. Using the proposed model of the endurance limit, we obtained the general derivatives with \(T_{cycle}\), \(D_{cycle}\) and workload, and verified the effects of the two parameters (\(T_{cycle}\) and \(D_{cycle}\)) on the load-number diagrams (or stress-number (S-N) diagram). Figure 4a shows the relationship between the N with loading for different cycle times, and Fig. 4b shows the relationship between N with loading for different duty cycles.

The results show that \(T_{cycle}\), \(D_{cycle}\) and the workload have negative effects on the endurance limit. A higher relative load or duty ratio (longer duty cycle) results in fewer tasks being sustained. This finding is consistent with previous experimental results [13] and [6].

5 Implication: Muscle Fatigue Risk Assessment for Spectrum Loadings

In daily manual operation, a physical task might include several different intermittent tasks, which can be considered as equivalent to spectrum loadings in material science.

The most common method of assessing or predicting damage resulting from spectrum loadings is the linear cumulative damage rule for fatigue life. This rule was proposed by Palmgren and Miner [20, 22] and is shown in Eq. 6 (the parameters are explained in the Nomenclature). For muscle-fatigue risk assessment, Gallagher et al. [10] introduced the Palmgren-Miner rule for ergonomics applications on the basis of material science, and concluded that approach could satisfactorily assess the risk of cumulative damage to muscle.

The Palmgren-Miner rule often provides a useful approximation of the accumulation of fatigue damage in a material; however, it is just an approximation. The results of this study would help in simplifying the job design for spectrum loadings, and the overall fatigue risk could be determined by adding the risks of each intermittent task. Moreover, the effectiveness of rotation between different tasks in reducing muscular fatigue or exposure can be assessed. This finding may refine recommendations of organizational strategies to mitigate musculoskeletal injury risk associated with intermittent work.

6 Discussion

6.1 Endurance Limit Under Intermittent Operations

In this paper, a model to determine the endurance limit for a given intermittent task was developed. Based on the muscle fatigue-recovery model, we could predict the N with satisfying results considering the task parameters and muscle fatigue attributes. With the endurance limit model, engineers can obtain a quantitative measure, that indicates when workers should stop working to avoid WMSD risks. The endurance limit model provides insight into the relationship between the workload (\(F_{load}\)), cycle time (\(T_{cycle}\)), duty ratio (\(D_{cycle}\)) and endurance limit. The objective of the model is to support work design, e.g. selecting an appropriate schedule among different intermittent schedules or selecting the most effective improvement strategy such as increasing the rest time and decreasing the work time. In determining the endurance limit, several assumptions were made to simplify the problem. However, a detailed analysis of the intermittent operation cycle based on a muscle fatigue and recovery model could be an effective approach to obtain a new perspective on intermittent task design and WMSD prevention.

6.2 Limitations

This paper was primarily based on studies featuring repetitive isometric contractions, or intermittent contractions at the same force level. The fatigue-recovery model and the numerical algorithm could consider more dynamic tasks, but we could only derive a simple formula of endurance limit (N) for an external load with simple form, such as repetitive isometric contractions. Thus, we used a muscle physiological behaviour featuring intermittent isometric contractions to illustrate the endurance limit under intermittent operations.

However, these types of simple contraction patterns are not generally reflective of industrial work; as a result, these ergonomic tools may not provide accurate predictions of risk for use in ergonomics. Additional research should aim to improve the model to allow for accurate fatigue predictions during sustained isometric, dynamic and complex contraction patterns.

The fatigue-recovery model is based on the assumption that muscle physical behaviour during one cycle can be divided into two different periods: one fatigue period and one recovery period. Each period was described using its specific model. This assumption helps to simplify the motor unit activity and to derive simple strength decline formula under intermittent isometric operations. However, this assumption may require some adjustment and improvement when generalized to more complex or dynamic tasks.

7 Conclusion

In this study, we proposed a model to determine the endurance limit for an intermittent task. This model could be solved by either numerical solution or by an approximation method with acceptable accuracy. Optimizing the k and R coefficients for the fatigue-recovery model resulted in good predictions of muscle strength during intermittent submaximal force patterns. Along with the Palmgren-Miner rule, this endurance limit model could be applied to evaluate muscle fatigue risk for spectrum loadings.

References

AAOS: The burden of musculoskeletal diseases in the United States: prevalence, societal and economic cost. Rosemont, IL (2008)

Bernard, B.P., Putz-Anderson, V.: Musculoskeletal disorders and workplace factors; a critical review of epidemiologic evidence for work-related musculoskeletal disorders of the neck, upper extremity, and low back (1997)

Björkstn, M., Jonsson, B.: Endurance limit of force in long-term intermittent static contractions. Scand. J. Work Environ. Health 3(1), 23–27 (1977)

Callahan, D.M., Umberger, B.R., Kent, J.A.: Mechanisms of in vivo muscle fatigue in humans: investigating age-related fatigue resistance with a computational model. J. Physiol. 594(12), 3407–3421 (2016)

De Sapio, V., Howard, M., Korchev, D., Green, R., Gardner, R., Bruchal, L.: Demographic specific musculoskeletal models of factory worker performance, fatigue, and injury. In: 2016 IEEE Aerospace Conference, pp. 1–13. IEEE (2016)

Sood, D., Nussbaum, M.A., Hager, K., Nogueira, H.C.: Predicted endurance times during overhead work: influences of duty cycle and tool mass estimated using perceived discomfort. Ergonomics (2017). http://dx.doi.org/10.1080/00140139.2017.1293850

Dickerson, C.R., Meszaros, K.A., Cudlip, A.C., Chopp-Hurley, J.N., Langenderfer, J.E.: The influence of cycle time on shoulder fatigue responses for a fixed total overhead workload. J. Biomech. 48(11), 2911–2918 (2015)

van Dieen, J., Toussaint, H., Thissen, C., Van de Ven, A.: Spectral analysis of erector spinae EMG during intermittent isometric fatiguing exercise. Ergonomics 36(4), 407–414 (1993)

Imbeau, D., Farbos, B., et al.: Percentile values for determining maximum endurance times for static muscular work. Int. J. Ind. Ergon. 36(2), 99–108 (2006)

Gallagher, S., Schall Jr., M.C.: Musculoskeletal disorders as a fatigue failure process: evidence, implications and research needs. Ergonomics 60(2), 255–269 (2017)

Hoogendoorn, W.E., van Poppel, M.N., Bongers, P.M., Koes, B.W., Bouter, L.M.: Physical load during work and leisure time as risk factors for back pain. Scand. J. Work Environ. Health 25, 387–403 (1999)

Horton, R.: GBD 2010: understanding disease, injury, and risk. The Lancet 380(9859), 2053–2054 (2013)

Iridiastadi, H., Nussbaum, M.A.: Muscle fatigue and endurance during repetitive intermittent static efforts: development of prediction models. Ergonomics 49(4), 344–360 (2006)

Iridiastadi, H., Nussbaum, M.A.: Muscular fatigue and endurance during intermittent static efforts: effects of contraction level, duty cycle, and cycle time. Hum. Factors 48(4), 710–720 (2006)

ISO: Ergonomics-Evaluation of static working postures-ISO11226, Geneva (2000)

Kahn, J., Monod, H.: Fatigue induced by static work. Ergonomics 32(7), 839–846 (1989)

Ma, L., Chablat, D., Bennis, F., Zhang, W.: A new simple dynamic muscle fatigue model and its validation. Int. J. Ind. Ergon. 39(1), 211–220 (2009)

Ma, L., Zhang, W., Wu, S., Zhang, Z.: A new simple local muscle recovery model and its theoretical and experimental validation. Int. J. Occup. Saf. Ergon. 21(1), 86–93 (2015)

Miedema, M.C., Douwes, M., Dul, J.: Recommended maximum holding times for prevention of discomfort of static standing postures. Int. J. Ind. Ergon. 19(1), 9–18 (1997)

Miner, M.A.: Cumulative fatigue damage. J. Appl. Mech. 12(3), A159–A164 (1945)

Nussbaum, M.A.: Static and dynamic myoelectric measures of shoulder muscle fatigue during intermittent dynamic exertions of low to moderate intensity. Eur. J. Appl. Physiol. 85(3–4), 299–309 (2001)

Palmgren, A.G.: Die lebensdauer von kugellagern. Zeitschrift des Vereins Deutscher Ingenieure 68(14), 339–341 (1924)

Potvin, J.R., Calder, I.C., Cort, J.A., Agnew, M.J., Stephens, A.: Maximal acceptable forces for manual insertions using a pulp pinch, oblique grasp and finger press. Int. J. Ind. Ergon. 36(9), 779–787 (2006)

Potvin, J.R.: Predicting maximum acceptable efforts for repetitive tasks: an equation based on duty cycle. Hum. Factors 54(2), 175–188 (2012)

Punnett, L., et al.: Estimating the global burden of low back pain attributable to combined occupational exposures. Am. J. Ind. Med. 48(6), 459–469 (2005)

Rose, L.M., Beauchemin, C.A., Neumann, W.P.: Modelling endurance and resumption times for repetitive one-hand pushing. Ergonomics 61, 1–39 (2018)

Seo, J., Lee, S., Seo, J.: Simulation-based assessment of workers muscle fatigue and its impact on construction operations. J. Constr. Eng. Manag. 142(11), 04016063 (2016)

Sonne, M.W., Potvin, J.R.: A modified version of the three-compartment model to predict fatigue during submaximal tasks with complex force-time histories. Ergonomics 59(1), 85–98 (2016)

Vøllestad, N.K.: Measurement of human muscle fatigue. J. Neurosci. Methods 74(2), 219–227 (1997)

Xia, T., Frey Law, L.A.: A theoretical approach for modeling peripheral muscle fatigue and recovery. J. Biomech. 41(14), 3046–3052 (2008)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Fu, J., Ma, L. (2020). Determining Endurance Limit Under Intermittent Physical Operations Based on a Combined Fatigue-Recovery Model. In: Stephanidis, C., Duffy, V.G., Streitz, N., Konomi, S., Krömker, H. (eds) HCI International 2020 – Late Breaking Papers: Digital Human Modeling and Ergonomics, Mobility and Intelligent Environments. HCII 2020. Lecture Notes in Computer Science(), vol 12429. Springer, Cham. https://doi.org/10.1007/978-3-030-59987-4_33

Download citation

DOI: https://doi.org/10.1007/978-3-030-59987-4_33

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-59986-7

Online ISBN: 978-3-030-59987-4

eBook Packages: Computer ScienceComputer Science (R0)