Abstract

3D Concrete Printing (3DCP) is a novel automation construction technique, which interested many researchers extensively in the past few years. Among the major research interests in the specific area, the rheology of 3DCP material attracted more researchers recently. Due to the significantly different rheological requirements in extrusion and layer-wise construction stages, proper understanding and characterization of the rheology of 3D printable concrete are required. Extrudability criteria of the material highly depend on the extrusion geometry, extrusion parameters, and the flow type occurring while extruding (i.e. plug flow or highly sheared flow). Hence, numerical simulation tools may be important to understand the flow behavior and extrudability criteria of 3DCP. Therefore, in the current study, the Discrete Element Method (DEM) was used to model the flow behaviour of 3D printing concrete and to characterize the extrudability. A user-defined two-phase hardcore-softshell contact model was developed for particle interactions and the model was calibrated using the experimental orifice extrusion test results. The developed model was then used to simulate the flow inside a hopper with rotating augur. The extrusion pressure in the simulation was compared with the experimental relative power consumption to discharge ratio (pressure) for different rotational speeds. The results for the simulation show good agreements with the experimental pressure values. Based on the results, suggestions were provided to improve the numerical model predictions and the developed numerical model can be used to quantify the extrudability of 3DCP material using either ram-type or rotating screw-type extruders.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

3D concrete printing (3DCP) is a novel additive manufacturing technique, where a 3D model can be fed into the system and printed layer wise using robots. Due to the free form construction used in the 3DCP method, geometrically complex shapes can be achieved without using high-cost formworks as in conventional construction methods. Because of the elimination of formwork usage in the 3DCP construction technique, cost and wastage can be reduced. Also, as a result of the usage of automation methods such as robot arms for construction, manual labor usage can be reduced. This may result in reducing human errors, construction hazard and will speed up the construction work [1].

The extrusion-based 3DCP, in which the material should be pumped and extruded through a nozzle in a layer-wise manner, is the commonly used and most efficient technique in construction. The material extrusion and deposition should be continuous without any blockages or segregation. The commonly used term, “extrudability” can be defined as how effectively the material can be extruded fulfilling the above-mentioned criteria. However, extrudability depends on the nozzle size, type of extrusion methods such as ram-type and screw-type, the extrusion speed, and most importantly the rheology of the material. Therefore, extrudability can be effectively defined with respect to the system used for the extrusion, but, for a given system, the material rheology highly affects the extrudability criteria. For example, the material with higher yield stress (i.e. minimum shear stress at the onset of material flow) and higher viscosity (i.e. resistance to flow) have a low tendency to extrude [2]. Also, the ability to form a lubricating layer (a layer consists of finer particles and liquid) between the extruder wall and the flowing material plug may improve the extrudability by minimization of wall friction [3].

Further, the extruded and deposited layers should have enough green-strength to support the vertical stresses induced from the top layers without any failure in addition to its own weight [4, 5]. To fulfill this, the material should achieve higher yield stress after deposition, which is opposite to the requirement for the extrusion process. This is very difficult to achieve and requires a fundamental understanding of the rheology of the material. Therefore, this paper aims to characterize the rheological parameters important for extrusion using a ram extrusion method. Also, a numerical simulation tool was developed using the discrete element method to simulate the ram extrusion and the screw-type extrusion. The developed model can be used in future research to improve the extrudability of 3D printing concrete by improving material rheology as well as the extruder type used.

2 Material Characterization Using Ram Extrusion

The rheology and controlling the rheology play a major role in 3DCP. Therefore, proper rheological characterization should be done using suitable methods. The rheometers widely used to characterize the rheology of normal and self-compacting concrete. However 3D printable concrete has higher stiffness, yield stress, and higher viscosity, hence, rheometers have limitations when implementing high stiff concrete with larger aggregates [16]. Alfani et al. [6] proposed techniques to measure rheology for extrudable cement-based material. The ram extrusion is one of those techniques, where the material is filled inside an extruder barrel and then extruded through a die or an orifice using a ram. The material is extruded at different velocities to obtain maximum steady-state extrusion pressure. The flow curve is developed using the analytical model proposed in Benbow et al. [7] by correlating the extrusion pressure and mean shear velocities. The rheological parameters of extrudable material can then be estimated from the flow curve. The proposed model by in Benbow et al. [7] is based on a uni-axial form of the Herschel-Bulkley model, however, Basterfield et al. [8] and Zhou et al. [9] later developed a specific model to use in an orifice extrusion and given in Eq. (1).

Where \( P \), \( D_{0} \), \( D \), \( V \) are extrusion pressure, barrel diameter, orifice diameter, and material flow velocity at the orifice respectively. \( \sigma_{0} \), \( k \) and \( n \) are the uniaxial yield stress, flow consistency and flow index parameters (rheological parameters) which define the uniaxial form of Herschel-Bulkley model. \( A \) is a constant which defines by the flow index and the maximum convergent angle (\( \theta_{max} \)) as in Eq. (2).

In the current study, rheological characterization was carried out using the orifice extrusion test and the analytical model shown in Eq. (1).

3 Discrete Element Method (DEM)

Discrete Element Method (DEM) was successfully used in the past to simulate the flow behavior of concrete [10]. The time-stepping algorithm, in which the velocities and accelerations of the particles due to contact forces are considered constant for a small time step. The forces are calculated for the next time step using the displacement of the particles in contact. Further details and theory on DEM simulation technique can be found elsewhere [10, 11].

The DEM model used in this study is a two-phase hardcore-softshell model, where the hardcore (aggregate) is covered with a softshell (cement paste). This type of model is used to simulate the liquid bridge force between two particle contacts or particle wall contacts. Also, the two-phase model reduces the number of particles used in the simulation, hence, it decreases the computational time.

In the current study, Itasca Particle Flow Code (PFC) [12] 2D and 3D versions were used for the simulations. The user-defined particle-particle and wall-particle interactions were implemented in normal particle contact direction and in shear direction separately. The user-defined commands were written in C++ and compiled as a dynamic link library (dll) file to run directly in the software. The Eq. (3), Eq. (4) and Eq. (5) show the force-displacement relationship of particle-particle contacts in normal (particles in compression), normal (particles in tension) and in shear directions respectively. A similar type of force-displacement relationship and DEM model was used by previous researchers to model the SCC and normal concrete flow behavior [11, 13].

Where, \( F_{n,c} \), \( F_{n,t} \), \( F_{s,t} \) are the normal contact force in compression, normal contact force in tension and shear forces respectively for the considered time step (\( t \)). \( F_{n,t - 1} \) and \( F_{s,t - 1} \) are the normal tensile force and shear force calculated in the previous time step. \( d_{n} \) is the characteristic normal distance of the two particles, where the positive value means overlapping of particles and negative value denotes the separation of particles (particle distance more than zero). Therefore tensile forces considered to be negative in the expressions. \( d_{p} \) is the paste thickness for the two-phase particle. In the previous equations, \( k_{n1} , \,k_{n2} , \,k_{n3 } ,\,k_{n4} \) and \( k_{s} \) are the contact stiffness values in the considered direction. \( F_{max,t} \) and \( F_{max,c} \) are the maximum characteristic tensile force and the maximum characteristic compressive force of the particles.

4 Experimental Work

4.1 Materials and Mix

In this study, a printable concrete mix which includes General Purpose (GP) cement, silica fume and graded aggregate (supplied by SIBELCO Australia Ltd.) were used. The silica fume of 110 g was used for 1 kg of cement weight. The graded aggregate can be divided into two categories as coarse aggregate (with 1.18 maximum particle diameter) and fine aggregate (with 600 \( \upmu \)m of maximum particle diameter). The coarse graded aggregate used is 560 g per 1 kg of cement. 1.11 kg of fine aggregate was used per 1 kg of cement weight. The water to cement ratio used is 0.23 as a weight ratio. Superplasticizer amount of 0.7 mL per 100 g of binder (cement and silica fume) and retarder amount of 0.4 mL per 100 g per binder also were used in the mix.

The same mixing protocol is followed throughout the experimental procedure. Initially, the dry mix consists of cement, silica fume and aggregate were mixed in a 5 L Hobart mixer around 3 min at low speed (speed 1). Afterward, water was added gradually and mixing was done around 1 min at low speed. Finally, the superplasticizer and retarder were gradually added (while mixing) and the high shear mixing (speed 2) was done around 5 min.

4.2 Rheology Characterization

Rheology characterization of the mix was carried out using a custom made ram extruder. The material was extruded through an orifice using displacement rates varying from 0.1 mm.s−1 to 4 mm.s−1. The barrel diameter (\( D_{0} \)) used in the extruder is 200 mm and the orifice diameter (\( D \)) used is 40 mm. The barrel height is around 450 mm and can accommodate a large amount of material. Therefore, the test setup gives the advantage of conducting several trials of extrusion with only using a single fill of the material inside the extruder.

Initially, the material was filled up to around 400 mm level and compaction of the material was done using a steel rod to remove the entrapped air. Using the piston (ram) attached to a 50 kN MTS testing system, the material can be extruded through the orifice using different displacement rates. It should be noted, that the test was initiated with the highest displacement rate to the lowest displacement rate to avoid the liquid phase migration reported in previous literature [14, 15] at lower displacement rates. Test for a considered displacement rate can be stopped when a steady piston force (steady-state) achieved in the force vs. time or force vs. displacement curves. Afterward, the test can be continued for a different displacement rate.

Three trials were conducted for each ram displacement rate and the average steady extrusion force was calculated. The extrusion force was converted to extrusion pressure considering the piston cross-sectional area. The piston driving velocity was converted to material flow velocity (\( V \)), considering the mass conservation. The extrusion pressure vs. mean shear rate plot was shown in Fig. 1. With the least square error method, the analytical model given in Eq. (1), was fitted to experimental data to achieve the rheological parameters given in Fig. 1.

4.3 Screw Type Extrusion and Power Consumption Measurement

A screw-type extruder (used in a gantry print system at Swinburne University of Technology) was used to quantify the extrudability of the material. Burbidge et al. [17] and Botten et al. [18] explain the method to estimate the extrusion pressure gradient in a hopper (i.e., along the material flow direction) for single-screw extrusion from the rheological parameters characterized in ram extrusion.

In the current study, the measurement of power consumption was done for different screw rotational speeds to find the relationship between the rheological parameters characterized in ram extrusion and the relative power (\( \delta P) \) measurements. A power measurement source can be installed between the power supply and the printer to monitor the power consumption. Initially, power consumption measurements were done at different speeds (from 0.5 rev.s−1 to 2.5 rev.s−1) of screw rotations without any material inside the hopper. Afterward, the power consumption measurements were done for different speeds with the material inside the hopper. The material inside the hopper kept at a constant level and the print head kept stationary without any movement. The power consumption difference with and without material was recorded as the relative power consumption. Additionally, the discharge rates (\( Q \)) of the material also were recorded for different screw rotational speeds.

The relative power consumption and discharge rate of the material for different screw rotational speeds are shown in Fig. 2. The relative power consumption increases with rotational speed showing a power-law relationship. The discharge rate increases linearly with the increasing rotational speed.

5 Numerical Simulation

5.1 Orifice Extrusion

The orifice extrusion experimental results were used to calibrate the numerical model. DEM 2D simulations were used to reduce the computational time. Mono size particles were selected similar to the maximum particle size (particle diameter) used in the experimental (i.e., 2 mm approximately). The initial characteristic distances were selected using the analytical models developed by Mikami et al. [19].

In the current simulation, particles were generated inside the extruder barrel (without any overlapping) until the system reaches approximately a target porosity of 0.1. This is similar to the experimental porosity value calculated at the beginning of the extrusion test. Afterward, gravity is activated to achieve equilibrium. At the particular stage, orifice was covered with a wall to prevent the particles from falling from the bottom. Afterward, the piston was moved similar to the constant velocities used in the experimental procedure and the piston force was recorded.

The experimental ram force at the lowest piston driving velocity was matched to the numerical piston driving force at the particular velocity to calibrate the characteristic forces \( F_{max,t} \) and \( F_{max,c} \). Afterward, the simulations were conducted for other piston velocities and the force vs. velocity values were plotted for experimental and numerical simulations. In order to match both gradients, the \( k_{visc} \) the value was adjusted. Table 1 provides the calibrated DEM model parameters.

The comparison of the numerical steady-state extrusion force and the experimental extrusion force values for different piston driving velocities are shown in Fig. 3.

From Fig. 3, it can be seen that the numerical ram forces and experimental ram forces are similar after the calibration process. The maximum difference between experimental and numerical ram force is around 15%.

5.2 Screw Type Extrusion Simulation

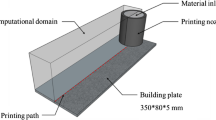

Using the calibrated model from the orifice extrusion, the screw-type extrusion was simulated with different rotational speeds. The particle size was increased by two times for the 3D simulations to reduce the computational time. A proportional parameter was incorporated to increase the calibrated forces and the stiffness values as mentioned in [11]. Figure 4 shows the modeled screw extruder geometry similar to the one used in the experimental work.

In the simulations, the downward push force applied by the extruder was recorded to compare with the experimental \( \delta P/Q \) value (which can be correlated with extrusion pressure in a screw-type extrusion). Figure 5 (a) shows the variation of vertical screw force with time for different rotational speeds (flow direction is negative z-direction). In this preliminary study, the average extrusion force exerted by the screw (in the negative z-direction) at steady-state is considered and shown in dotted straight lines in Fig. 5 (a). With the available computational capacity (3.4 GHz clock speed and 16 GB RAM), for small rotational speeds such as 1 and 1.5 rev.s−1, the initiation of extrusion of the material was considered.

Figure 5 (b) shows the comparison of the experimental \( \delta P/Q \) value and the numerical extrusion pressure value (extrusion force/cross-sectional area of the nozzle). As seen in Fig. 5 (b), both the experimental and numerical pressure values show a similar trend (increasing pressure with increasing rotational speed), however, the numerical pressure values are higher than the experimental pressure values (\( \delta P/Q \)). The possible reasons may be the higher particle sizes used and the mono-sized particles used in the simulations. The forces from the agitating blade also should have a contribution to the power-consumption in experimental results. Therefore, in future research, the particular component also should be considered. Finally, it can be concluded, that there should be a direct link between the rheological parameters obtained from orifice extrusion test and the extrudability of cementitious material in a screw-type extruder.

6 Conclusions

Preliminary studies were done to characterize the extrudability of 3DCP in the current work. DEM was used as the numerical simulation method for the purpose. The following conclusions can be made from the study.

-

Relative power consumption increases with the increasing rotational speed giving a power-law relationship between the two parameters (in a screw-type extruder). Relative power measurements can be used as an effective method to characterize the extrudability of different mixes.

-

The material discharge rate increases linearly with the rotational speed in a screw-type extruder.

-

Ram extrusion can be effectively used to characterize the rheological parameters of 3DCP material. Also, it can be used to calibrate the DEM numerical model.

-

The DEM two-phase model can be used effectively to simulate the ram extrusion forces. The developed model can be used in other flow simulations such as screw-type extrusion as well. Therefore, the developed tool is useful in quantifying extrudability and also to design screw-type extruders for 3DCP applications.

References

Wolfs, R., Salet, T., Hendriks, B.: 3D printing of sustainable concrete structures. In: Proceedings of IASS Annual Symposia, vol. 2, pp. 1–8. International Association for Shell and Spatial Structures (IASS) (2015)

Roussel, N.: Rheological requirements for printable concretes. Cem. Concr. Res. 112, 76–85 (2018)

Choi, M., Roussel, N., Kim, Y., Kim, J.: Lubrication layer properties during concrete pumping. Cem. Concr. Res. 45, 69–78 (2013)

Jayathilakage, R.I., Rajeev, P., Sanjayan, J.: Predication of strength-based failure in extrusion-based 3D concrete printing. In: Rheology and Processing of Construction Materials, pp. 391–399. Springer (2019)

Jayathilakage, R., Rajeev, P., Sanjayan, J.: Yield stress criteria to assess the buildability of 3D concrete printing. Constr. Build. Mater. 240, 117989 (2020)

Alfani, R., Guerrini, G.: Rheological test methods for the characterization of extrudable cement-based materials—A review. Mater. Struct. 38(2), 239–247 (2005)

Benbow, J., Bridgwater, J.: Paste Flow and Extrusion Oxford Series on Advanced Manufacturing. Clarendon Press, Oxford (1993)

Basterfield, R., Lawrence, C., Adams, M.: On the interpretation of orifice extrusion data for viscoplastic materials. Chem. Eng. Sci. 60(10), 2599–2607 (2005)

Zhou, X., Li, Z., Fan, M., Chen, H.: Rheology of semi-solid fresh cement pastes and mortars in orifice extrusion. Cem. Concr. Compos. 37, 304–311 (2013)

Mechtcherine, V., Gram, A., Krenzer, K., Schwabe, J.-H., Shyshko, S., Roussel, N.: Simulation of fresh concrete flow using Discrete Element Method (DEM): theory and applications. Mater. Struct. 47(4), 615–630 (2014)

Shyshko, S.: Numerical simulation of the rheological behavior of fresh concrete (2013)

Itasca Consulting Group I: PFC—Particle Flow Code (2D), Ver. 6.0. Itasca, Minneapolis (2014)

Krenzer, K., Mechtcherine, V., Palzer, U.: Simulating mixing processes of fresh concrete using the discrete element method (DEM) under consideration of water addition and changes in moisture distribution. Cem. Concr. Res. 115, 274–282 (2019)

Perrot, A., Lanos, C., Melinge, Y., Estellé, P.: Mortar physical properties evolution in extrusion flow. Rheol. Acta 46(8), 1065–1073 (2007)

Toutou, Z., Roussel, N., Lanos, C.: The squeezing test: a tool to identify firm cement-based material’s rheological behaviour and evaluate their extrusion ability. Cem. Concr. Res. 35(10), 1891–1899 (2005)

Jayathilakage, R., Sanjayan, J., Rajeev, P.: Direct shear test for the assessment of rheological parameters of concrete for 3D printing applications. Mater. Struct. 52 (2019)

Burbidge, A., Bridgwater, J.: The single screw extrusion of pastes. Chem. Eng. Sci. 50(16), 2531–2543 (1995)

Botten, A., Burbidge, A., Blackburn, S.: A model to predict the pressure development in single screw extrusion. J. Mater. Process. Technol. 135(2–3), 284–290 (2003)

Mikami, T., Kamiya, H., Horio, M.: Numerical simulation of cohesive powder behavior in a fluidized bed. Chem. Eng. Sci. 53(10), 1927–1940 (1998)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 RILEM

About this paper

Cite this paper

Jayathilakage, R., Sanjayan, J., Rajeev, P. (2020). Characterizing Extrudability for 3D Concrete Printing Using Discrete Element Simulations. In: Bos, F., Lucas, S., Wolfs, R., Salet, T. (eds) Second RILEM International Conference on Concrete and Digital Fabrication. DC 2020. RILEM Bookseries, vol 28. Springer, Cham. https://doi.org/10.1007/978-3-030-49916-7_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-49916-7_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-49915-0

Online ISBN: 978-3-030-49916-7

eBook Packages: EngineeringEngineering (R0)