Abstract

There is a strong political focus on moving cargo transportation from trucks to ships to reduce environmental emissions and road congestion. We study how the introduction of a future generation of autonomous ships can be utilized in maritime transportation systems to become more cost-efficient, and as such contribute in the shift from land to sea. Specifically, we consider a case study for a Norwegian shipping company and solve a combined liner shipping network design and fleet size and mix problem to analyze the economic impact of introducing autonomous ships. The computational study carried out on a problem with 13 ports shows that a cost reduction up to 13% could be obtained compared to a similar network with conventional ships.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The maritime shipping industry is experiencing a development towards the utilization of autonomous ships that will have a different design than conventional ships. With no crew on-board, it will not be necessary to have a deckhouse nor accommodation. The resulting saved space and weight can be used to carry more cargoes. In addition to the operational cost reduction, autonomous ships offer ecological advantages as they reduce fuel consumption and carbon dioxide emission. However, international regulations per today lead to challenges in introducing fully autonomous ships because traditionally the captain has the responsibility to ensure the safety of the ship at sea. Conversely, it is expected that Norwegian regulations will be adapted quickly to allow the utilization of autonomous ships nationally. For instance, Norway can be seen as a leading country within autonomous ship technology. Two Norwegian companies, Kongsberg Maritime and Yara, developed one of the world’s first commercial autonomous ship, Yara Birkeland. This motivates the development of a shipping network based on mother and daughter ships that utilize advantages of hub and feeder networks, where conventional mother ships sail in international waters, while autonomous daughter ships sail in national waters and tranship the cargoes with the mother ships.

This concept of conventional mother and autonomous daughter ships is in this paper applied on a case study for a Norwegian shipping company that transports containers between Europe and several ports along the Norwegian coast. The aim is to determine an optimal liner shipping network design (LSND) and the optimal fleet of vessels to be deployed in terms of number and size, as well as the route to be sailed for each vessel so that ports demand and weekly services are satisfied. To study the economic impact of introducing autonomous ships, we first solve this problem with only conventional ships and compare this to the solution where daughter ships are autonomous.

Several research studies have been conducted for developing different versions of LSND problems, see for example [1,2,3]. More recently, Brouer et al. [4] develop a base integer programming model and benchmark suite for the LSND problem. This model is extended by Karsten et al. [5] to include transit time. Karsten et al. [6] base their article on the contribution of [5] and propose the first algorithm that explicitly handles transshipment time limits for all demands. Wang and Meng [7] consider an LSND with transit time restrictions, but the model does not consider transshipment costs. Holm et al. [8] study a LSND problem for a novel concept for short sea shipping where transshipment of daughter and mother ships is performed at suitable locations at sea.

In the following, we describe the LSND problem for the Norwegian case study considered in this paper in more detail, followed by a description of the proposed solution methodology, the computational study and conclusions.

2 Problem Description

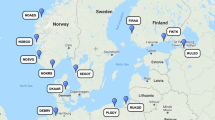

The problem is considered from a shipping company’s point of view, operating a fleet of mother and daughter ships in a transportation system. The mother ships sail on a main route between ports in Europe and the Norwegian coastline. The daughter ships are autonomous and sail along the Norwegian coastline, serving smaller ports. The objective is to study the economic impact of introducing autonomous ships in the liner shipping network.

Ports are classified into main and small ports according to their size and location. Main ports are large ports and placed along the Norwegian coastline and can be served by mother ships and daughter ships. Small ports are not capable of docking a mother ship, and hence, can only be served by daughter ships. The small ports act as feeder ports, and the main ports can act as hubs. Furthermore, the continental port is the departure port of the mother ships and is located on the European continent.

The mother ships sail between the European continent and selected main ports, referred to as main routes. It is assumed that there is only one mother route. To maintain a weekly service frequency, several mother ships can be deployed on the main route. Also, mother ships sail on southbound journeys, i.e. they start by serving the northernmost Norwegian port, then serve other main ports located further south. The daughter ships sail between ports located along the Norwegian coastline and the routes are referred to as daughter routes. One daughter ship can be deployed on a daughter route, and hence, the duration of a daughter route cannot exceed 1 week. It is possible that a main port is not visited by a main route. In such a case, a daughter route must serve this port.

The fleet size and mix are to be determined in the problem. The fleet of daughter ships is heterogeneous, meaning the ships can differ in capacity and corresponding cost components. The fleet of mother ships is homogeneous, and their size is determined a priori so that all cargoes of the system can be transported. The aim is to create a network of main and daughter routes such that the total costs of operating the container transportation system are minimized.

3 Solution Methodology

To solve the underlying problem, a solution methodology is proposed based on two steps. A label setting algorithm is developed to generate candidate routes. These are taken as input in a mathematical model to find the best combination of routes while minimizing costs.

1st Step: Route Generation

A label setting algorithm is used to generate all feasible and non-dominated mother and daughter routes.

The main routes are deployed by mother ships and start and end at the main continental port. A stage of mother route generation corresponds to a partial route that starts with the continental port and visits main Norwegian ports. This partial route is extended to visit another Norwegian port not previously visited or to return to the continental port. However, since main Norwegian ports are visited during the southbound journeys, the extension is only allowed to visit a port located further south. Furthermore, there is no time restriction on the main routes, meaning that a partial route can be extended to any main port located further south. To guarantee a weekly service, the number of mother ships that are deployed on a main route is proportional to the number of weeks the completion of the route takes.

A daughter route differs from a mother route and can include both main ports and small ports. The starting and ending port of a daughter route is called transshipment port. A partial daughter route can be extended to any main or small port. The extension is limited by the route time, which must be completed within 1 week. Also, the number of containers on board a daughter ship cannot exceed its capacity. In a case where two partial routes have the same visited ports but in a different order, the partial route with a lower number of containers on board and fuel cost dominates. By doing so, a set of feasible and non-dominated daughter routes is generated.

2nd Step: Path-flow Based Formulation

Due to the space limitation of this manuscript, only a verbal description of the mathematical model is given. The input is a set of mother and daughter routes with their corresponding weekly operational costs. The binary decision variables decide on the mother and daughter routes to take up in the solution. The objective function of the 0-1 integer programming model minimizes the total costs of using a fleet of mother and daughter ships of the network. One set of constraints enforce that each main port must be visited by either a daughter or a main route. Another set of constraints ensure that each small port is served by a daughter route. A further constraint is used to select only one main route. A final set of constraints establishes the transshipment relation between main and daughter routes.

4 Computational Results

The test data consists of served ports by the liner shipping company in Norway. In total, there are 13 ports located at the Norwegian coastline and one main continental port located in Maasvlakte, Rotterdam. The cargo demand to and from Rotterdam for each port is provided by the company. This constitutes the normal demand scenario from which two additional scenarios are derived. The second (high) scenario reflects a 40% increase in demand. The third (very high) scenario represents an increase of 100% of demand.

The capacity of the mother ships is an input of the model and can be determined a priori by taking the maximum of the total number of containers going either from or to Rotterdam. For this case study, the capacity equals to 1000 TEU (twenty-foot equivalent unit) is considered for normal and high demand scenarios. A mother ship with this capacity requires an average fuel consumption of 0.61 tonnes/h when sailing at 12 knots, and its weekly charter cost is estimated to 53,000 USD. Conversely, the very high demand scenario requires a mother ship with a higher capacity, 1350 TEU. Such a mother ship requires 0.69 tonnes/h for fuel consumption and has a charter cost of 54,000 USD.

Three different ship types are selected for daughter ships with capacities of 86 TEU, 158 TEU, and 190 TEU, and referred to as small S, medium M and large L daughter ships, respectively. Autonomous ships have no deckhouse nor accommodation, making these ships lighter with reduced air resistance. This has an immediate impact on the fuel consumption, which is lower than conventional ships. In addition, the time charter costs for autonomous ships exclude the crew cost as we assume full autonomy and estimate an increase of around 5% in construction costs (see [9]). In our experiment, we used the estimation provided by naval architects at SINTEF Ocean for autonomous and conventional ships with a sailing speed set to 8 knots. The different cost parameters for autonomous and conventional daughter ships are given in Table 1.

The route generation procedure has been implemented using MATLAB version R2018a, 64-bit. The mathematical model has been implemented with the commercial optimization software Xpress-IVE version 1.24.24 64-bit, with Xpress Model Version 4.8.3 and Xpress Optimizer Version 33.01.02.

Table 2 presents the results of solving the LSND problem with conventional and autonomous daughter ships. The total operating costs, with the corresponding cost components, are listed, together with the daughter fleet composition, the number of routes generated, and the solutions times. For the fleet composition, small daughter ships are denoted by S, medium by M and large by L. The mother ships deployed for normal and high scenarios are with 1000-TEU capacity and denoted by I, whereas very high scenario requires a larger vessel with 1350-TEU capacity denoted by II. The route generation time is the sum of the route generation time for both main and daughter ships.

As can be seen from Table 2, the number of daughter routes decreases as the demand increases, which is due to the ship capacity restriction of the generated routes. On the other hand, the normal demand scenario shows that the fleet of autonomous daughter ships is larger with smaller ships than the corresponding conventional daughter fleets. This effect is caused by the decrease in cost components for the autonomous ships, and in particular the time charter costs, which motivates the use of autonomous daughter ships in short sea shipping. Indeed, the reduction of the total operational costs is 9.7% for normal demand and reaches up to 12.9% for very high demand scenario.

5 Conclusion

This paper studies the introduction of autonomous ships to a liner shipping network design problem on a Norwegian case study. The liner shipping network consists of a single mother route that sails from a European port to main ports at Norway and daughter routes that do transshipment at main ports to serve small ports (and also main ports not visited by the main route). The problem is solved for a liner shipping company using a path-flow mathematical model. The results show that a reduction between 9 and 13% in operating costs can be obtained by utilizing autonomous daughter ships.

References

Agarwal, R., Ergun, H.: Ship scheduling and network design for cargo routing in liner shipping. Transp. Sci. 42, 175–196 (2008). https://doi.org/10.1287/trsc.1070.0205

Álvarez, J.F.: Joint routing and deployment of a fleet of container vessels. Marit. Econ. Logist. 11, 186–208 (2009). https://doi.org/10.1057/mel.2009.5

Reinhardt, L.B., Pisinger, D.: A branch and cut algorithm for the container shipping network design problem. Flex. Serv. Manuf. J. 24, 349–374 (2011). https://doi.org/10.1007/s10696-011-9105-4

Brouer, B.D., Alvarez, J.F., Plum, C.E.M., Pisinger, D., Sigurd, M.M.: A base integer programming model and benchmark suite for liner-shipping network design. Transp. Sci. 48, 281–312 (2013). https://doi.org/10.1287/trsc.2013.0471

Karsten, C.V., Brouer, B.D., Desaulniers, G., Pisinger, D.: Time constrained liner shipping network design. Transp. Res. E Logist. Transp. Rev. 105, 152–162 (2017). https://doi.org/10.1016/j.tre.2016.03.010

Vad Karsten, C., Brouer, B.D., Pisinger, D.: Competitive liner shipping network design. Comput. Oper. Res. 87, 125–136 (2017). https://doi.org/10.1016/j.cor.2017.05.018

Wang, S., Meng, Q.: Liner shipping network design with deadlines. Comput. Oper. Res. 41, 140–149 (2014). https://doi.org/10.1016/j.cor.2013.08.014

Holm, M.B., Medbøen, C.A.B., Fagerholt, K., Schütz, P.: Shortsea liner network design with transhipments at sea: a case study from Western Norway. Flex. Serv. Manuf. J. (2018). https://doi.org/10.1007/s10696-018-9317-y

Kretschmann, L., Burmeister, H.-C., Jahn, C.: Analyzing the economic benefit of unmanned autonomous ships: an exploratory cost-comparison between an autonomous and a conventional bulk carrier. Res. Transp. Bus. Manag. 25, 76–86 (2017). https://doi.org/10.1016/j.rtbm.2017.06.002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Msakni, M.K., Akbar, A., Aasen, A.K.A., Fagerholt, K., Meisel, F., Lindstad, E. (2020). Can Autonomous Ships Help Short-Sea Shipping Become More Cost-Efficient?. In: Neufeld, J.S., Buscher, U., Lasch, R., Möst, D., Schönberger, J. (eds) Operations Research Proceedings 2019. Operations Research Proceedings. Springer, Cham. https://doi.org/10.1007/978-3-030-48439-2_47

Download citation

DOI: https://doi.org/10.1007/978-3-030-48439-2_47

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-48438-5

Online ISBN: 978-3-030-48439-2

eBook Packages: Business and ManagementBusiness and Management (R0)