Abstract

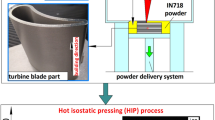

The laser additive manufacturing technology is studied that applies lasers to fabricate the complexly shaped parts by successive selective melting of the metal powder in a layer by layer process. The turbine blade test parts were manufactured by the selective laser melting (SLM) process using an Inconel 718 powder. A multidirectional scanning strategy was used during SLM. The paper is focused on the study of the surface features and material characteristics of the SLM-printed parts. The surface texture supplemented by roughness profile parameters is analyzed. The microstructure, material compositions, material phases, porosity, and hardness in the near-surface layers are also addressed. Microstructural studies were performed by the X-ray diffraction analysis, optical microscopy, and scanning electron microscopy. Results indicated that partially melted powder particles, balling, and signs of the laser tracks are formed on the side surfaces of SLM-built turbine blades. The columnar dendritic microstructure mainly consists of a base γ-phase matrix and \( \gamma^{||} \)-phase precipitates. The SLM-built turbine blade parts show the accumulation of porosity close to the surface.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kumar, S., et al.: A comparison of additive manufacturing technologies. Int. J. Innov. Res. Sci. Eng. Technol. 3, 147–152 (2016)

Sames, W.J., et al.: The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 61, 315–360 (2016)

Zhang, Y., et al.: Additive manufacturing of metallic materials: a review. J. Mater. Eng. Perform. 27, 1–13 (2018)

Yakout, M., et al.: On the characterization of stainless steel 316L parts produced by selective laser melting. Int. J. Adv. Manuf. Technol. 95, 1953–1974 (2018)

Koutiri, I.: Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process. Technol. 255, 536–546 (2018)

Caiazzo, F., et al.: Laser powder-bed fusion of Inconel 718 to manufacture turbine blades. Int. J. Adv. Manuf. Technol. 93, 4023–4031 (2017)

Akca, E., et al.: A review on superalloys and IN718 nickel-based superalloy. Period. Eng. Nat. Sci. 3, 15–27 (2015)

Lesyk, D.A., et al.: Post-processing of the Inconel 718 alloy parts fabricated by selective laser melting: Effects of mechanical surface treatments on surface topography, porosity, hardness and residual stress. Surf. Coat. Technol. 381, 125136 (2020)

Ealy, B., et al.: Characterization of LAM-fabricated porous superalloys for turbine components. J. Eng. Gas Turbines Power 6, 58080 (2016)

Mostafa, A., et al.: Structure, texture and phases in 3D printed IN718 alloy subjected to homogenization and HIP treatments. Metals 7, 196–219 (2017)

Ali, H., et al.: Effect of scanning strategies on residual stress and mechanical properties of selective laser melted Ti6Al4V. Mater. Sci. Eng., A 712, 175–187 (2018)

Liu, S., et al.: Additive manufacturing of Ti6Al4V alloy: a review. Mater. Des. 164, 107552 (2019)

Nasab, M.H., et al.: On morphological surface features of the parts printed by selective laser melting (SLM). Adv. Manuf. J. 24, 373–377 (2018)

Sabzi, H.E., et al.: Defect prevention in selective laser melting components: compositional and process effects. Mater. 12, 3791 (2019)

Idell, Y., et al.: Unexpected δ-phase formation in additive-manufactured Ni-based superalloy. J. Miner. Met. Mater. Soc. 68, 950–959 (2016)

Wang, X., et al.: Review on powder-bed laser additive manufacturing of Inconel 718 parts. Proc. ImechE Part B. 23, 1890–1903 (2017)

Lesyk, D.A., et al.: Surface finishing of complexly shaped parts fabricated by selective laser melting. In: Tonkonogyi, V. et al. (eds.) Advanced Manufacturing Processes. InterPartner-2019. LNME, pp. 186–195. Springer, Cham (2020)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Lesyk, D., Martinez, S., Dzhemelinkyi, V., Lamikiz, A. (2020). Additive Manufacturing of the Superalloy Turbine Blades by Selective Laser Melting: Surface Quality, Microstructure and Porosity. In: Karabegović, I. (eds) New Technologies, Development and Application III. NT 2020. Lecture Notes in Networks and Systems, vol 128. Springer, Cham. https://doi.org/10.1007/978-3-030-46817-0_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-46817-0_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-46816-3

Online ISBN: 978-3-030-46817-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)