Abstract

The peculiar atomic structure of γ′ precipitates [Ni3(Al/Ti)-L12] in Ni-based superalloys produces high-energy faults when dislocations glide them, giving their significant strength at high temperatures. The mechanisms behind the strength failure of these alloys above 800 °C are still controversial. Recent advances in atomic resolution microscopy have allowed to study these mechanisms with unprecedented detail. In our study, we have characterised a SX superalloy from RT to 1000 °C. Multiscale microscopy (TEM and SEM) are combined with physical modelling to fully understand the correlation between the strength drop and the changes in the γ′ shearing mechanism. Our results show that, far from previous beliefs, the initial failing of alloy strength is not a consequence of dislocation climbing. Instead, local chemical changes around the γ′ shearing dislocations boost their gliding, thus producing the sudden drop of strength. This new understanding can be used to beat the current temperature limits of these alloys.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Resistance to high-temperature plasticity is a significant advantage of the nickel-based superalloys, particularly when in single-crystal form. This important characteristic comes from a careful arrangement of shear resistant $\gamma$’ precipitates. The high-energy faults formed when dislocations glide through these precipitates are known to provide this unique strength at high temperatures. This important mechanism becomes ineffective when the shearing dislocations have enough mobility to overcome the γ′ precipitates at high temperature [1, 2]. Historically, this was the consensus reason for the sudden drop of strength observed above 700 °C in these alloys. But is this the case?

In the recent years, advances in atomic resolution chemical microscopy (atom probe and TEM-EDX) have allowed the study of the population of mechanisms in this temperature regime with unprecedented detail [3,4,5,6,7,8]. These studies have shown the presence of other complex diffusion mechanisms different from the traditional dislocation climbing [3, 6]: traditional dislocation shearing is aided by segregation processes leading to changes in the plastic strength above 700 °C.

However, there is a key-point missing: these studies are constrained to single-condition spots, thus not providing a complete picture of the mechanism. What is clearly needed to extract a convincing theory is a systematic study between the temperature, appearance of segregation micromechanisms, and loss of strength. This is a critical step to design improved grades of superalloys. In this presentation, we will present an atomic study of the evolution of the microsegregation processes as a function of the temperature and we will associate the changes in the segregation levels with the loss of strength in the alloy. The study is structured as follows: first, a commercial SX superalloy is mechanically tested at seven different temperature conditions (from RT to 900 °C). Second, critical samples before, at, and after the yield drop are selected for advanced TEM-EDX analysis. Third, the microsegregation levels associated with the dislocation shearing are quantified; mapping the change of mechanism from unsegregated a thermal shearing to segregation assisted shearing. Finally, this observed behaviour is modeled in a multiscale chemo-mechanical framework combining density functional theory (DFT), diffusion theory and continuum mechanics (CM). Finally, the strength of the material as a function of the temperature is recovered by the model and explained from the different levels of segregation as the testing temperature increases.

Methods

The single-crystal superalloy MD2 of composition Ni-11.2Al-9.3Co-5.3Cr-2.6 W-2Ta-1.65Ti-1.33Mo-0.2Si-0.03Hf (at.%) is used in this study. Electron-backscattered diffraction (EBSD) was used to measure the deviation from the ideal nominal orientation <001> with less than 5° error.

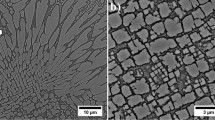

Compression experiments under a constant strain rate of \( \dot{\varepsilon } = 10^{ - 5} \,{\text{s}}^{ - 1} \) were performed at different temperatures covering the strength drop regime of the alloy. An overview of the tested specimen’s geometries is presented in Fig. 1. Cylinders of 5 mm diameter and 5 mm height were employed for the compression tests in an Instron servo-electric machine. Digital image correlation was used to track the material deformation for all tests.

Results

The mechanical behaviour for the different testing conditions is presented in Fig. 2. It can be observed a reduction of the hardening levels as the temperature increases and a sudden drop of properties after 750 °C.

The strength of the alloy is presented in Fig. 3. The strength drop region is identified between 750 and 850 °C Specific samples between 650 and 850 °C were selected for atomic resolution TEM-EDX chemical analysis of their deformation structures. The conditions are: 650 °C before the yield drop, 700 °C just as the yield drop, and 800 and 850 °C after the yield drop.

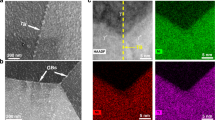

The dominant deformation mechanism under this temperature regime was found to be fault shearing combined with some level of segregation [3]. A typical segregated deformation structure (APB) of this alloy within a γ′ precipitate is shown in Fig. 4 left. The effect of the observed segregation on the stacking fault energy is critical for the strength of the alloy [9, 10]. For this reason, DFT simulations were computed using VASP code [11] for the dominant faults observed in this alloy (APB, CESF, CISF, and Microtwin). The fault energies were computed at segregation levels of 0, 25, 50, 75, and 100 at.% of Co and Cr at the fault plane. As an example, the computed fault energies for an APB are shown in Fig. 4 right. Segregation produces a lowering of the high APB energy down to levels typical of the γ stacking faults [12].

Discussion

In order to understand, the connection between the fault chemistry and the strength of the alloy, the results obtained by DFT were coupled with a chemo-mechanical FEM code developed in-house. The model solves the coupled diffusion field of segregates (Co and Cr for this alloy MD2) with the stress required for the faults to propagate in the γ′. These elements are the ones observed as prominent segregates in this alloy [3, 13]. The driving force arising from the reduction of the stacking fault energy was included in the diffusion formulation.

An exemplary validation case of the segregation at a mature twin in a γ′ precipitate is presented in Fig. 5. The computed results captured the enrichment of the twin boundaries and the recovery of the γ′ composition within the twin core as observed in the experiment (left). The levels of segregation at the twin boundaries in the simulation are slightly higher, which can be explained by the qualitative aspect of the EDX measurements or misalignment of the fault.

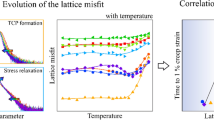

This model has been then used to connect and rationalise the chemical changes of the faults observed as function of the temperature with the drop of the strength in the alloy MD2. The computed cases in Fig. 6 show the evolution of the SESF to microtwin formation process. Two critical cases are simulated: deformation at 750 °C just before the yield drop and deformation at 850 °C after the yield drop. The results show clearly higher segregation levels at 850 °C producing the observed drop of stress in the simulation (from 1409 at 750 °C to 1035 at 850 °C). The segregation fields are correlated with EDX experiments at the same testing conditions showing good agreement. These results support the role of the segregation of stacking faults as precursor of the strength drop above 700 °C in this SX superalloys.

Simulations of SESF formation (step 1) and maturing into microtwins (steps 2–3) in MD2-γ′ precipitate at two different temperatures: 750 and 850 °C. The computed required model stress for constant deformation rate is indicated and compared with the experimentally observed. The results connect the drop of the strength in the alloy with the chemical changes at the faults enhanced at higher temperatures

The Cr and Co enrichment of the different faults observed experimentally and in the model with respect to the surrounding γ′ precipitate composition requires long-range diffusion from the bulk. The diffusion flux was shown to be driven by the transformation of the high-energy faults created by the shearing of the dislocations to low energy ones. This is achieved by stabilizing locally a γ-like structure at the fault and thus removing the wrong-neighbours penalty. This process is illustrated schematically in Fig. 7 for the different faults observed. For the case of the lower energy faults (SISF–SESF), the segregation of solute species is believed to decrease the energy of these faults according to the published work in the literature [14, 15].

Atomic structures of the different faults observed in this paper (APB, CISF, and CESF-Microtwin). Red lines represent high-energy wrong neighbour bonding in the unsegregated faults (top) which might be suppressed or at least lowered their energy by the segregation of Ni-like atoms such as Cr and Co (bottom)

Conclusions

As a summary, this paper use combined TEM-EDX to analyse the evolution of the critical segregation events in a SX Ni-based superalloy, quantifying the drop of strength as a function of the temperature and composition of the faults. The following conclusions are extracted:

-

These segregation changes at the faults have been linked with the observed strength drop in the alloy by means of combined DFT and chemo-mechanical modelling of the alloy system.

-

The experimental and modelling results show that the increase level of segregation stabilise a γ-like structure locally at the fault, thus, lowering the staking fault energy.

-

This reduction of stacking fault energy has been shown to promote plasticity in the γ′ thus reducing the required strength for dislocation shearing.

References

Epishin A, Link T (2004) Mechanisms of high-temperature creep of nickel-based superalloys under low applied stresses. Phil Mag 84(19):1979–2000

Zhu Z, Basoalto H, Warnken N, Reed RC (2012) A model for the creep deformation behaviour of nickel-based single crystal superalloys. Acta Mater 60(12):4888–4900

Barba D, Smith TM, Miao J, Mills MJ, Reed RC (2018) Segregation-assisted plasticity in Ni-based superalloys. Metall Mater Trans A 49(9):4173–4185

Smith TM, Unocic RR, Deutchman H, Mills MJ (2016) Creep deformation mechanism mapping in nickel base disk superalloys. Mater High Temp 33(4–5):372–383

Kontis P, Li Z, Collins DM, CormierJ, Raabe D, Gault B (2018) The effect of chromium and cobalt segregation at dislocations on nickel-based superalloys. Scr Mater 145:76–80

Smith TM, Esser BD, Good B, Hooshmand MS, Viswanathan GB, Rae CMF, Ghazisaeidi M, McComb DW, Mills MJ (2018) Segregation and phase transformations along super lattice intrinsic stacking faults in Ni-based superalloys. Metall Mater Trans A 49(9):4186–4198

Freund LP, Messe OMDM, Barnard JS, Goken M, Neumeier S, Rae CMF (2017) Segregation assisted microtwinning during creep of a polycrystalline l12 hardened Co-base superalloy. Acta Mater 123:295–304

Eggeler YM, Müller J, Titus MS, Suzuki A, Pollock TM, Spiecker E (2016) Planar defect formation in the γ′ phase during high temperature creep in single crystal CoNi-base superalloys. Acta Mater 113:335–349

Rao Y, Smith TM, Mills MJ, Ghazisaeidi M (2018) Segregation of alloying elements to planar faults in γ′-Ni3Al. Acta Mater 148:173–184

NC Eurich and Paul David Bristowe (2015) Segregation of alloying elements to intrinsic and extrinsic stacking faults in γ′-Ni3Al via first principles calculations. Scr Mater 102:87–90

Kresse G, Furthmuller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54(16):11169

Vorontsov VA, Voskoboinikov RE, Rae CMF (2012) Shearing of γ′ precipitates in Ni-base superalloys: a phase field study incorporating the effective-surface. Phil Mag 92(5):608–634

Barba D, Pedrazzini S, Vilalta-Clemente A, Wilkinson AJ, Moody MP, Bagot PAJ, Jerusalem A, Reed RC (2017) On the composition of microtwins in a single crystal nickel-based superalloy. Scr Mater 127:37–40

Breidi A, Allen J, Mottura A (2018) First-principles modeling of super lattice intrinsic stacking fault energies in Ni3Al based alloys. Acta Mater 145:97–108

Titus MS, Mottura A, Viswanathan GB, Suzuki A, Mills MJ, Pollock TM (2015) High resolution energy dispersive spectroscopy mapping of planar defects in L12-containing Co-base superalloys. Acta Mater 89:423–437

Acknowledgements

This project has been fully funded by US Air Force Project FA9550-18-1-7000.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Barba, D., Egan, A., Kench, S., Smith, T.M., Mills, M.J., Reed, R.C. (2020). On the Temperature Limits of Ni-Based Superalloys. In: TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36296-6_73

Download citation

DOI: https://doi.org/10.1007/978-3-030-36296-6_73

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36295-9

Online ISBN: 978-3-030-36296-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)